Welcome to the essential guide on coarse screening in wastewater treatment. Before water can be purified and safely returned to the environment, it must go through several stages at a treatment plant. The very first step, coarse screening, is one of the most important.

This initial filtering process removes large solid materials from the incoming wastewater, protecting the entire system from damage and clogs. Let’s explore how this simple but vital technology leads the way in efficient wastewater management.

Table of contents

- Key Highlights

- Role of Coarse Screens in Wastewater and Sludge Treatment

- Types of Coarse Screens Used in Municipal and Industrial Settings

- Maintenance and Troubleshooting of Coarse Screens

- Design Considerations and Installation of Coarse Screens

- Performance Evaluation and Optimization of Coarse Screens

- Environmental and Safety Considerations in Coarse Screening

- Paddle Dryers – Advancing Sludge Disposal After Coarse Screening

- Future Trends and Technological Advances in Coarse Screening

- Fine Screening and Microscreening in Wastewater Treatment

- Frequently Asked Questions

- Conclusion

Key Highlights

Here is a quick look at what this article covers:

- Coarse screens are the first line of defense in the wastewater treatment process.

- These screens use a bar rack system to remove large debris and protect equipment.

- Proper maintenance and design are crucial for the efficiency of coarse screens.

- Different types of coarse screens are available for various municipal and industrial applications.

- Paddle dryers offer an advanced solution for sludge disposal after the screening process.

- Effective screening and sludge management contribute to a cleaner environment.

Role of Coarse Screens in Wastewater and Sludge Treatment

At the very beginning of any wastewater treatment process, coarse screens act as the primary gatekeepers. Installed at the intake point of a waste water treatment plant, their main job is to filter out large objects like rags, sticks, plastic containers, and other bulky items from the water stream.

By removing this debris early on, coarse screens prevent it from damaging or blocking pumps, pipes, and other sensitive equipment in the later stages of treatment. This initial step is crucial for both municipal and industrial wastewater treatment, ensuring the entire system runs smoothly and efficiently. We will now examine how these screens work.

How Coarse Screens Function to Remove Large Debris

The function of a coarse screen is straightforward yet highly effective. Most coarse screens consist of a bar rack, which is a series of parallel steel bars placed in the path of the incoming wastewater. As water flows through the gaps between the bars, larger debris is trapped on the upstream side of the screen.

This screening process physically stops coarse solids from continuing into the treatment plant. The captured materials can include a wide variety of items that should not be in the sewer system. Some of the common types of debris removed include:

- Rags and paper

- Plastic bottles and bags

- Branches, leaves, and other organic matter

- Heavy objects that could damage machinery

Once the debris accumulates, it is removed from the bar rack either manually or with an automated mechanical rake. This keeps the screen from clogging and ensures a constant flow of water into the plant for further treatment.

Common Applications of Coarse Screens in Indian Water Facilities

In India, coarse screens play a critical role in a wide range of water treatment facilities. You will find them at the headworks of nearly all municipal sewage treatment plants, where they serve the specific purpose of protecting the downstream treatment processes from large, potentially damaging solids.

Their application extends beyond wastewater.

Key applications include:

- Municipal sewage treatment plants

- Industrial wastewater treatment facilities

- Power plants requiring cooling water

- Desalination and irrigation plants

One of the common challenges is handling the high volume of debris during peak flow periods, which can lead to blockages if not managed properly. This makes the choice of screen type and its maintenance plan very important.

Types of Coarse Screens Used in Municipal and Industrial Settings

There isn’t a one-size-fits-all solution when it comes to coarse screens. Different municipal and industrial settings require different types of screens to handle varying flow rates and debris loads. The most common type is the bar screen, which consists of parallel bars that trap solids.

These bar screens can be broadly categorized based on how they are cleaned. Some are cleaned by hand, while others use automated mechanical systems. Each type has its own advantages and is suited for a specific scale of operation within a treatment plant. The following sections will compare these options.

Hand-Cleaned vs Mechanically-Cleaned Coarse Screens

The choice between a hand-cleaned and a mechanically-cleaned coarse screen often comes down to the size of the facility and its operational needs. Hand-cleaned screens require manual intervention, where an operator uses a rake to physically remove the collected debris from the screen rack. This method is typically suitable for smaller wastewater treatment facilities with lower flow rates.

On the other hand, mechanically-cleaned screens automate the debris removal process. These systems use mechanisms like chain-driven rakes or reciprocating arms to provide reliable screen rack cleaning without constant human oversight. This automation significantly boosts operational efficiency, especially in larger plants with high volumes of wastewater.

Mechanically-cleaned screens reduce labor costs and ensure the screening process is continuous and effective, preventing backups even during periods of heavy load.

| Feature | Hand-Cleaned Screens | Mechanically-Cleaned Screens |

|---|---|---|

| Application | Small facilities, low flow rates | Medium to large facilities, high flow rates |

| Cleaning Method | Manual raking | Automated rakes or belts |

| Efficiency | Lower, depends on operator availability | Higher, continuous operation |

| Labor Needs | High manual intervention | Minimal oversight required |

Material Selection and Recommended Bar Spacing for Efficiency

The durability and effectiveness of a coarse screen depend heavily on its construction. Materials must be robust enough to withstand corrosive environments and the abrasive force of debris. Stainless steel is a popular choice for its strength and resistance to rust, ensuring a long service life.

The recommended bar spacing is another critical design factor. For coarse screens, this spacing typically ranges from 6 to 150 mm. The exact spacing for your bar rack is chosen based on the type of debris expected and the level of protection required for downstream equipment.

- Wider spacing (e.g., 100 mm) removes very large objects.

- Narrower spacing (e.g., 20-40 mm) captures smaller coarse solids.

- Proper spacing prevents clogs while ensuring effective removal.

Choosing the right material and bar spacing is essential for achieving high operational safety and efficiency. A well-designed screen minimizes maintenance needs and maximizes the protection of your wastewater treatment system.

Maintenance and Troubleshooting of Coarse Screens

To ensure your coarse screens function correctly, regular maintenance is non-negotiable. This involves routine inspections to check for wear and tear on the bars and mechanical components. Keeping the screen and its clear openings free from stubborn blockages is vital for maintaining a consistent water flow. For a reliable screen rack, operators should lubricate moving parts and confirm that automated cleaning systems are working as they should. A scheduled maintenance plan helps prevent unexpected breakdowns and extends the equipment’s lifespan.

Common issues include blockages caused by large concentrations of debris, especially after storms. Mechanical failures in the cleaning mechanism are another concern. Systems like the Huber coarse screen Trashmax are designed to be robust and handle heavy loads, but even they require periodic checks. Troubleshooting often involves manually removing obstructions, adjusting the cleaning cycle, and inspecting electrical systems to prevent disruptions and ensure the screen operates smoothly.

Design Considerations and Installation of Coarse Screens

When designing and installing a coarse screen, several factors must be considered to ensure it meets its specific purpose. The design should account for the expected flow rate of the wastewater, the type and size of debris in the sewer system, and the physical space available at the treatment plant. The screen’s angle of installation, typically between 70 to 90 degrees, also affects cleaning efficiency and flow dynamics. These considerations guarantee the screening process is optimized for the facility’s unique conditions.

Proper installation is just as important as the design itself. Coarse screens are installed at the headworks of the treatment plant, the very first point of entry for raw wastewater. The installation must allow for easy access for maintenance and cleaning to ensure smooth operation. Correctly anchoring the screen in the channel prevents it from moving under the force of the water and debris, ensuring its long-term stability and functionality.

Performance Evaluation and Optimization of Coarse Screens

Evaluating the performance of your coarse screens is key to maintaining the overall efficiency of your treatment facility. A performance evaluation typically involves measuring the amount of debris removed and monitoring the screen for any signs of clogging or overflow. By tracking metrics like debris capture rate and downtime, you can get a clear picture of how well your screen is working. This data helps identify potential issues before they impact the protection of sensitive equipment downstream.

Based on this evaluation, you can implement optimization strategies to enhance operational efficiency. This might involve adjusting the frequency of the automated cleaning cycle to better handle varying coarse solid loads or upgrading screen components. Regular reviews of the screen’s placement and design can also lead to improvements. Optimizing your coarse screening process not only protects your machinery but also reduces energy consumption and manual labor, contributing to a more cost-effective operation.

Environmental and Safety Considerations in Coarse Screening

Coarse screening is not just about operational efficiency; it also has important environmental and safety implications. The reliable removal of bulky material, plastics, and other inorganic waste prevents these pollutants from entering subsequent treatment stages where they could disrupt biological processes or end up in the environment. Proper disposal of the collected screenings, which can include organic matter, is crucial for environmental safety. Some materials can be sent to a landfill, while others may be suitable for recycling.

Ensuring high operational safety for workers is another priority. Coarse screening areas can be hazardous, so facilities must have safety measures like barriers, warning signs, and proper ventilation. Workers handling the screenings should wear personal protective equipment (PPE). Regular equipment maintenance is also a key safety practice, as it prevents mechanical failures that could pose a risk to personnel and disrupt the entire treatment process.

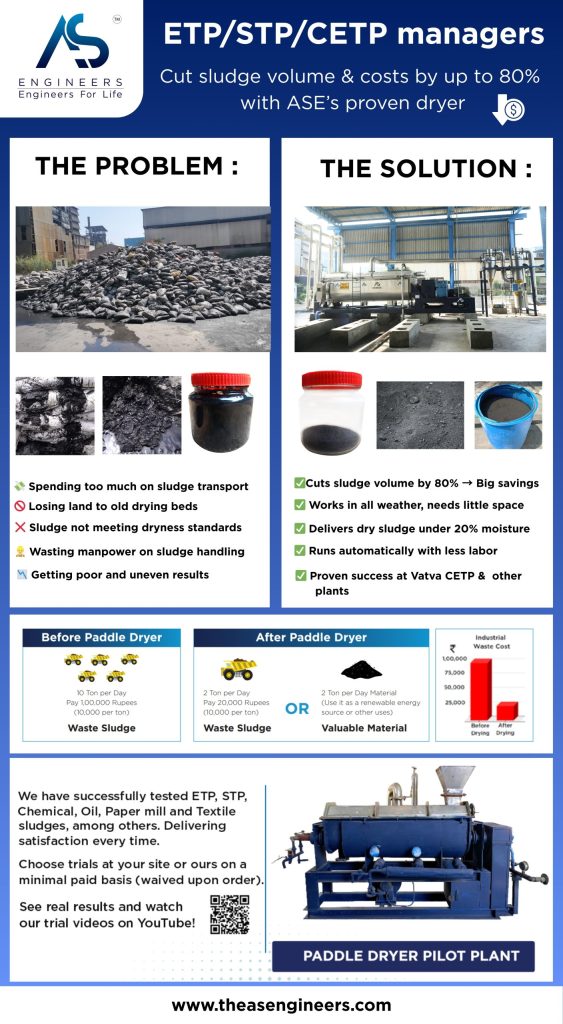

Paddle Dryers – Advancing Sludge Disposal After Coarse Screening

After coarse screening and other treatment steps, what happens to the collected solids, or sludge? Managing this byproduct is a crucial step in the wastewater journey. While coarse screens handle the initial large debris, the later stages of treatment produce a significant amount of sludge that requires proper disposal.

This is where innovative technologies like paddle dryers come into play. Paddle dryers offer an advanced and sustainable solution for sludge disposal. They efficiently dry the wet sludge, dramatically reducing its volume and turning it into a manageable, often valuable, product.

Paddle Dryer Technology: Converting Waste into Value

Paddle dryer technology is revolutionizing sludge disposal. A paddle dryer is an indirect contact dryer that uses heated, intermeshing paddles to agitate and dry wet sludge. As the sludge moves through the machine, the heat evaporates the water, leaving behind a dry, powdered, or granular solid. This process is highly efficient and can reduce sludge volume by up to 90%.

This reduction in volume significantly lowers transportation and disposal costs. More importantly, the dried sludge can often be repurposed, effectively converting waste into a valuable resource. Depending on its composition, the final product has several uses:

- As a biofuel for energy generation.

- As a component in construction materials like cement.

- As a soil conditioner in some agricultural contexts.

This approach transforms the final step of the treatment process from a disposal problem into a value-creation opportunity, making it a highly sought-after solution for many industrial applications.

AS Engineers—India’s Leading Paddle Dryer Manufacturer

When it comes to advanced sludge management solutions, AS Engineers stands out as India’s leading paddle dryer manufacturer. With a commitment to innovation and quality, they provide robust and efficient paddle dryers designed to meet the demanding needs of modern wastewater treatment facilities.

AS Engineers specializes in creating customized solutions for industrial wastewater treatment, helping clients transform their sludge disposal challenges into profitable opportunities. Their paddle dryers are engineered for high performance, durability, and ease of operation, ensuring you get a reliable system that adds value to your process. Key advantages of choosing AS Engineers include:

- Expertise in custom-designed drying solutions.

- High-quality manufacturing for long-term reliability.

- Focus on energy efficiency and operational cost savings.

- Proven track record in various industrial sectors.

By partnering with AS Engineers, you can implement a state-of-the-art paddle dryer system that completes your wastewater treatment cycle, turning waste into a resource and promoting a circular economy.

Future Trends and Technological Advances in Coarse Screening

The future of coarse screening is becoming smarter and more efficient. Technological advances are leading to the development of self-cleaning screens that automatically remove debris, minimizing downtime and reducing the need for manual labor. These innovations are designed to improve the overall efficiency of the screening process and enhance high operational safety. We are also seeing the integration of IoT sensors that monitor screen conditions in real-time, allowing for predictive maintenance and preventing clogs before they happen.

These smart systems can adjust cleaning cycles based on the actual debris load, optimizing energy use and performance. Another trend is the use of new, more durable materials that extend the lifespan of screens in harsh wastewater environments. These advancements are making the initial screening process more reliable and cost-effective than ever before, setting a better foundation for the entire treatment plant.

Fine Screening and Microscreening in Wastewater Treatment

While coarse screens catch the big stuff, the wastewater treatment process doesn’t stop there. The next steps often involve fine screening and microscreening. A fine screen has much smaller openings, typically less than 6 mm, designed to capture smaller particles like hair, food waste, and other fine solids that passed through the coarse screen. This step provides further protection for sensitive downstream equipment, such as membranes and biological treatment systems.

Microscreening goes even further, using fabric or mesh with microscopic clear openings (as small as 10-35 micrometers) to remove very fine suspended solids. This type of screening is often used as a tertiary treatment step to polish the final effluent before it is discharged. In essence, coarse, fine, and microscreening work together in a sequence, each targeting progressively smaller particles to achieve a high level of water purity.

Frequently Asked Questions

What are coarse screens and how do they function in sludge disposal?

Coarse screens are the first stage in wastewater treatment, using a bar rack to physically block large debris from entering a plant. Their role in sludge disposal is indirect; by protecting downstream equipment during the initial screening process, they ensure the systems that create and handle sludge can operate efficiently without damage.

What advantages do coarse screens offer over traditional sludge disposal methods?

Coarse screens are a pretreatment step, not a sludge disposal method. Their primary advantage is protecting the entire treatment process. By ensuring the reliable removal of bulky material upstream, they prevent equipment damage and clogs, which dramatically improves the overall efficiency of the subsequent sludge handling and disposal stages.

How can the use of coarse screens improve wastewater treatment efficiency?

Coarse screens boost wastewater treatment efficiency by removing large solids at the very beginning of the treatment process. This prevents clogs and damage to pumps, pipes, and other machinery. This protection ensures high operational safety and consistent plant performance, which is critical for both municipal and industrial applications.

Are there specific maintenance requirements for coarse screens used in sludge disposal?

Yes, coarse screens require regular maintenance to perform effectively. This includes reliable screen rack cleaning to remove accumulated debris and prevent blockages, as well as routine inspection of mechanical parts. This maintenance is essential for operational efficiency and ensures the entire wastewater plant, including sludge processing systems, runs smoothly.

Conclusion

In conclusion, coarse screens play a crucial role in the sludge disposal process, ensuring effective removal of large debris and enhancing overall wastewater treatment efficiency. By integrating paddle dryer technology, facilities can convert waste into valuable resources, showcasing an innovative approach to sludge management.

AS Engineers stands out as a leading manufacturer, committed to providing high-quality paddle dryers that aid in this transformation. Embracing these advanced techniques not only improves operational efficiency but also contributes to more sustainable environmental practices. If you’re ready to explore how paddle dryers can revolutionize your sludge disposal methods, don’t hesitate to reach out for a consultation.