Managing industrial sludge is a challenge for many businesses. Effective sludge drying is essential for reducing waste volume, minimizing disposal costs, and ensuring environmental compliance. If you’re looking for a solution, continuous sludge dryers offer an efficient and uninterrupted process. A high-quality dryer machine not only simplifies sludge management but also improves your operational workflow. Gujarat has emerged as a key region for manufacturing these systems, providing a range of options to suit your needs.

Table of contents

- Key Highlights

- Leading Continuous Sludge Dryer Manufacturers in Gujarat

- Types of Continuous Sludge Dryers Offered in Gujarat

- Essential Features of Gujarat Continuous Sludge Dryers

- Drying Capacity and Performance Comparisons

- Price Range and Cost Factors Among Gujarat Manufacturers

- Industry Applications of Continuous Sludge Dryers

- Feedback and Reviews from Indian Clients

- Conclusion

- Frequently Asked Questions

Key Highlights

- Gujarat is a central hub for leading dryer manufacturers offering advanced sludge dryers for various industries.

- You can find different types of continuous sludge dryer models, including paddle and rotary systems.

- Manufacturers in Gujarat provide customization options to meet specific sludge drying requirements.

- Key features to consider include energy efficiency, drying capacity, and material of construction for reliable performance.

- These sludge dryers play a crucial role in effective wastewater treatment and sludge management.

- Finding the right supplier ensures quality, timely delivery, and excellent after-sales support.

Leading Continuous Sludge Dryer Manufacturers in Gujarat

When searching for reliable sludge dryer manufacturers, Gujarat stands out with its robust industrial ecosystem. The state is home to numerous companies specializing in high-quality sludge drying systems designed for durability and performance. These manufacturers cater to a diverse clientele, offering equipment built from a wide range of materials to handle different types of industrial sludge.

Choosing the right partner from the many sludge dryer manufacturers in Gujarat is key to getting a system that fits your specific needs. These suppliers offer both standard and customized solutions, ensuring you find the perfect match for your operational requirements.

Below, we’ll look at some of the top suppliers and their credentials.

Overview of Top Gujarat-Based Suppliers

Gujarat hosts several reputable dryer manufacturers known for producing reliable equipment. Companies like Laxmi En-fab Private Limited, Indusmatrix India Private Limited, and Shiva Technofab are prominent names in the Vadodara region, offering various types of sludge dryer machine models. These suppliers are often featured on B2B platforms where you can check supplier ratings and product details.

Many of these companies, including promotional partners like Malhari Projects Pvt Ltd (MIPL), focus on providing solutions that align with industry needs. They offer a range of dryers, from paddle dryers to ETP sludge dryers, ensuring you have multiple options to compare. This competitive market helps you find equipment that balances cost, quality, and features.

Here is a quick look at some of the suppliers you might encounter:

| Supplier Name | Location | Key Offering |

|---|---|---|

| Laxmi En-fab Pvt. Ltd. | Vadodara, Gujarat | Industrial Sludge Dryer |

| Indusmatrix India Pvt. Ltd. | Vadodara, Gujarat | Sludge Dryer / Paddle Dryer |

| Shiva Technofab | Vadodara, Gujarat | ETP Sludge Dryers |

| AS Engineers | Ahmedabad, Gujarat | ETP Sludge Dryer |

Credentials and Industry Presence of Key Manufacturers

The top manufacturers in Gujarat distinguish themselves through their strong credentials and commitment to quality. They adhere to predefined industry standards, ensuring that every machine delivers safe and reliable operation. This focus on product quality means you can expect durable equipment that performs consistently, even in demanding industrial environments.

Another important aspect is their ability to meet your unique needs. Leading suppliers offer customization to tailor the equipment to your specific type of sludge and operational scale. They understand that a one-size-fits-all approach doesn’t work for sludge management. You can discuss your requirements directly with them to get a machine that is a perfect fit.

Furthermore, these manufacturers are known for their professionalism, which includes factors like a reasonable delivery time. Many provide clear timelines, with some advertising a delivery time of around 30 to 60 days, helping you plan your project schedule effectively. This reliability in service and product quality builds trust and ensures a smooth procurement process.

Types of Continuous Sludge Dryers Offered in Gujarat

Gujarat-based manufacturers offer a variety of continuous sludge dryers to meet diverse industrial needs. The type of dryer you choose will depend on your specific sludge drying requirements, including the sludge composition, desired moisture content, and processing volume. These suppliers provide machines made from a wide range of materials to ensure compatibility and longevity.

Whether you need a system for partial drying before incineration or complete drying for disposal, you can find a suitable solution. The two most common technologies available are paddle dryer systems and rotary dryer technologies, each with its own set of advantages.

Let’s explore these two popular types of sludge dryers in more detail.

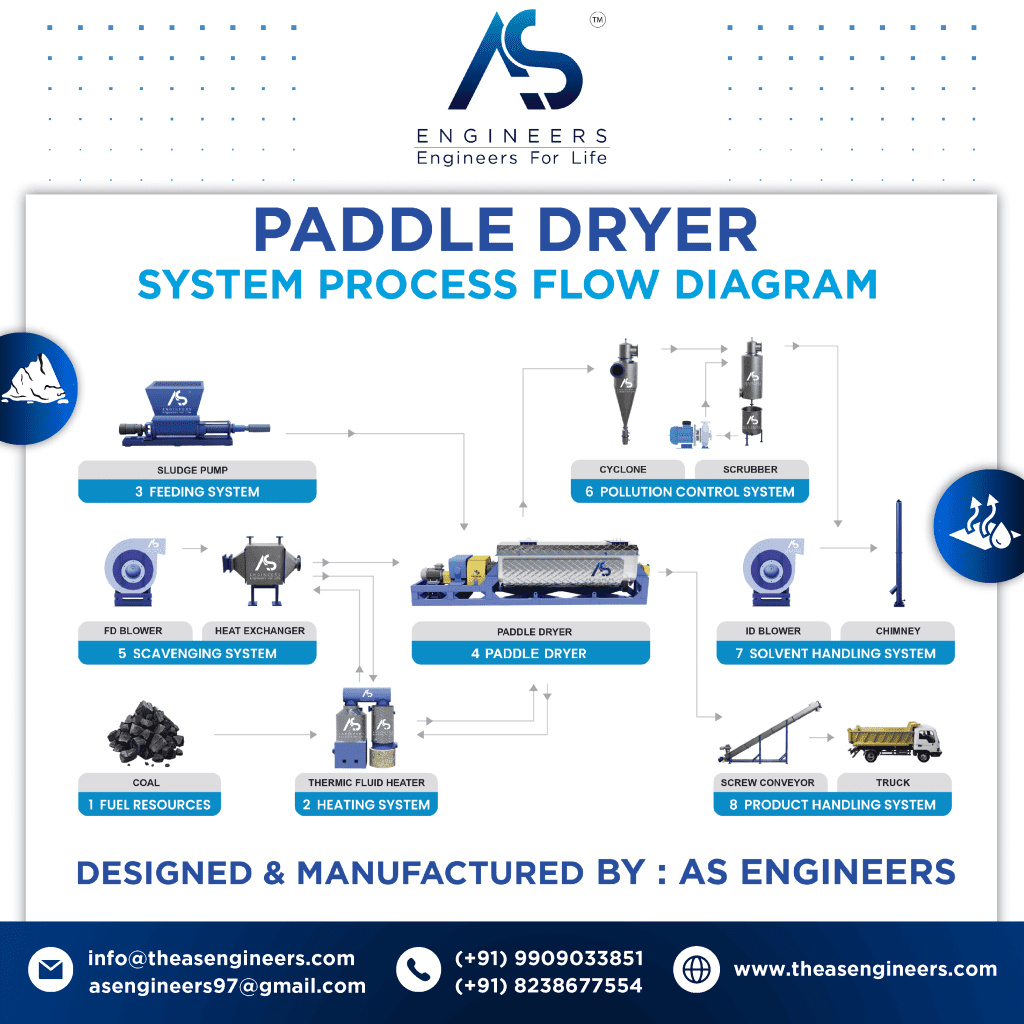

Paddle Dryer Systems

A paddle dryer is an excellent choice for efficient and controlled sludge drying. This system uses rotating heated paddle shafts inside a trough to process the sludge. The design focuses on maximizing heat transfer through indirect heating, which allows for precise temperature control and uniform product quality. This method is highly effective for moisture removal from wet materials.

These systems are often built using robust materials like stainless steel to handle corrosive sludge and ensure a long service life. The specially shaped paddles are designed to agitate and mix the sludge without transporting it too quickly, allowing for a longer retention time. This feature is particularly beneficial for achieving low final moisture levels and even pasteurizing the sludge.

Key features of paddle dryer systems often include:

- Designed for continuous operation and maximum heat transfer.

- Once-through drying technology that avoids back-mixing.

- Available in various capacities, from 50 kg/hr to 1500 kg/hr.

Rotary Dryer Technologies

Rotary dryer technologies are another popular option for continuous sludge drying. A rotary drum dryer consists of a large, rotating drum that is slightly inclined. Wet sludge is fed into the higher end, and as the drum rotates, the sludge tumbles and moves toward the lower end. Hot air is passed through the drum, directly contacting the sludge to evaporate moisture.

This tumbling action ensures that the sludge is constantly mixed and exposed to the hot air, leading to efficient and uniform drying. The design is robust and suitable for handling large volumes of material, making it a workhorse in many industrial applications. These dryers are built for continuous use in demanding environments.

Key features of rotary dryer technologies often include:

- High capacity for processing large volumes of material.

- Tumbling action ensures even drying and prevents clumping.

- Precise temperature control for optimal sludge drying.

Essential Features of Gujarat Continuous Sludge Dryers

When selecting an industrial sludge dryer machine in Gujarat, it’s important to look for features that ensure reliable performance and efficiency. A good dryer should effectively reduce the moisture content of your sludge while being durable enough for continuous operation. Customization is also a key aspect, as the right machine should be tailored to your unique needs and sludge characteristics.

Beyond performance, consider the dryer’s environmental impact. Modern machines are designed to minimize emissions and energy consumption, helping you meet sustainability goals. By focusing on these essential features, you can invest in a solution that is both effective and responsible.

Let’s look at some specific features like energy efficiency and customization options.

Energy Efficiency and Sustainability Innovations

Energy efficiency is a top priority for any industrial operation, as it directly impacts your operational costs. Many Gujarat-based manufacturers offer sludge dryers designed to minimize energy consumption. Models like the “EcoSludge Dryer” are specifically engineered with a focus on sustainability. These systems optimize heat transfer and may include energy recovery mechanisms to provide a cost-effective solution for sludge management.

By choosing a sustainable model, you not only save money but also reduce your facility’s environmental impact. These dryers are designed to achieve high drying performance while lowering operational expenses. This makes them an excellent investment for environmentally conscious businesses looking for long-term value.

Features that contribute to energy efficiency include:

- Optimized heat transfer for faster drying with less energy.

- Enclosed designs to prevent heat loss and control odors.

- Use of various heating media, including thermic fluid and solar thermal systems.

Customization for Specific Sludge Types

Every industry produces sludge with different characteristics. Whether it comes from pharmaceutical, chemical, or food processing plants, its composition can vary greatly. Recognizing this, leading Gujarat manufacturers offer customization to meet your unique needs. They can design a sludge dryer that is perfectly suited to your specific sludge drying requirements.

This customization process involves several factors. The manufacturer will consider the nature of the product to be dried, the initial and desired final moisture content, and your required throughput. This ensures the dryer you receive is optimized for performance and efficiency with your specific sludge type.

From small batch systems to large-scale continuous dryers, you can get a customized solution. Manufacturers work with you to understand your process requirements, offering different materials of construction and heating media to build a machine that serves your operations in various industries effectively.

Drying Capacity and Performance Comparisons

The drying capacity of sludge dryers is a critical factor that varies significantly among manufacturers in Gujarat. Capacity, often measured in kilograms per hour (kg/hr), can range from small-scale models around 50 kg/hr to large industrial units capable of processing over 1500 kg/hr. This wide range ensures that businesses of all sizes can find a machine that matches their production volume.

Achieving optimal performance depends on aligning the dryer’s capacity with your operational needs. Factors such as the drying process technology, the heat source used, and the initial moisture content of the sludge all influence the overall throughput and efficiency.

Understanding how technology and other factors impact these rates is crucial for making an informed decision.

How Technology Impacts Production Rates

The technology used in a sludge dryer directly affects its production rate and drying capacity. Advanced sludge drying systems, such as paddle dryers, are designed for maximum heat transfer. By using indirect heating through hollow paddles, these machines can maintain a consistent temperature, which results in faster and more uniform drying. This efficiency allows them to process more material in less time.

Similarly, the design of a rotary dryer influences its throughput. The combination of a large rotating drum and controlled hot airflow ensures that a high volume of sludge with significant moisture content can be dried evenly. The ability to control temperature and airflow allows you to optimize the drying process for different sludge types, maximizing production rates.

Key technological impacts on production include:

- Efficient Heat Transfer: Better heat transfer reduces drying time and increases capacity.

- Uniform Drying: Technologies that promote even mixing prevent wet spots and ensure consistent output.

- Controlled Processing: Adjustable settings for temperature and retention time allow fine-tuning for optimal throughput.

Suitability for Industrial Applications in India

Continuous sludge dryers made in Gujarat are highly suitable for a wide array of industrial applications across India. They are an essential component in wastewater treatment plants (ETPs) and for any facility that generates industrial sludge. The primary goal of these dryers is to significantly reduce the sludge volume and weight, which in turn lowers transportation and disposal costs.

By drying the sludge, you transform it into a more manageable, and sometimes reusable, product. This process is crucial for achieving safe disposal and complying with environmental regulations. For some industries, the dried sludge can even be used as a fuel source, creating additional value.

These dryers serve diverse industries, including pharmaceuticals, chemicals, textiles, and food processing. Their robust construction and ability to be customized make them adaptable to the specific challenges and standards of each sector, providing a reliable solution for sludge management nationwide.

Price Range and Cost Factors Among Gujarat Manufacturers

Yes, there are certainly cost differences between continuous sludge dryer manufacturers in Gujarat. The price range for these machines can be quite broad, with smaller or simpler models starting at lower price points and large, customized systems costing significantly more. For example, you might find prices ranging from ₹3,25,000 to over ₹15,00,000, depending on the specifications.

Several cost factors influence the final price, including the dryer’s capacity, materials, technology, and any requested customizations. It’s also important to consider long-term operational costs, not just the initial purchase price.

Let’s break down the main determinants of equipment costs and some budget considerations for buyers.

Determinants of Equipment Costs

The cost of a sludge dryer machine is determined by several key factors. The material of construction is one of the most significant. A dryer made from stainless steel will be more expensive than one made from mild steel, but it offers superior corrosion resistance and a longer lifespan, especially when dealing with acidic or abrasive sludge.

The type and capacity of the dryer also heavily influence the price. A large-capacity continuous dryer will naturally cost more than a small batch-type unit. The choice of heating medium, such as steam, thermic fluid, or electricity, can also affect both the initial investment and ongoing operational expenses. More complex systems with advanced controls and automation features will also be at the higher end of the price spectrum.

Other factors that contribute to the cost include:

- Customization: Any special modifications to meet unique process requirements.

- Brand Reputation: Well-established brands may command higher prices due to proven quality.

- Delivery Time: Expedited manufacturing and delivery may incur additional charges.

Budget Considerations for Buyers in India

When creating a budget for a sludge dryer in India, it’s crucial to look beyond the initial purchase price. While upfront cost is important, focusing solely on the cheapest option can lead to higher expenses in the long run. You should prioritize product quality and reliable performance to avoid frequent breakdowns and costly maintenance.

Consider the total cost of ownership, which includes operational costs like energy consumption and maintenance. An energy-efficient model may have a higher initial price but can save you a significant amount of money over its lifetime. Investing in a high-quality machine ensures optimal performance and a better return on your investment.

Before making a decision, get quotes from multiple manufacturers and compare them based on specifications, features, and long-term value. Don’t hesitate to ask about warranty, after-sales support, and the availability of spare parts, as these factors are essential for ensuring the reliable performance of your equipment for years to come.

Industry Applications of Continuous Sludge Dryers

Continuous sludge dryers are versatile machines used across various industries to manage waste effectively. Any sector that operates a wastewater treatment plant and generates sludge can benefit from this technology. These dryers are crucial for meeting industry standards for waste disposal and reducing environmental impact.

Key sectors that rely on sludge dryers include chemical processing, pharmaceuticals, textiles, and food processing. Each of these industries produces unique types of sludge, and dryers can be adapted to handle them efficiently.

Let’s examine their specific uses in some of these important sectors.

Use Cases in Chemical and Pharmaceutical Sectors

In the chemical processing and pharmaceutical industries, effective sludge management is a critical part of operations. These sectors often produce sludge that may contain residual chemicals or sensitive compounds, making safe handling and disposal paramount. Sludge dryers play a vital role by significantly reducing the moisture content of this waste.

By drying the sludge, companies can decrease its volume and weight, which drastically cuts down on transportation and disposal costs. The process also stabilizes the sludge, making it less reactive and safer to handle. For some types of sludge, the dried material can be incinerated to recover energy, turning a waste product into a valuable resource.

The enclosed design of modern sludge dryers, such as paddle dryers, helps control odors and emissions, which is particularly important in these highly regulated industries. This ensures that the sludge management process is not only efficient but also compliant with strict environmental standards.

Adoption Across Textile and ETP Plants

The textile industry is known for its high water consumption and, consequently, its generation of large volumes of sludge from wastewater treatment. Effluent Treatment Plants (ETPs) in textile mills produce a slurry-like sludge that needs to be dewatered and dried. Continuous sludge drying systems are widely adopted in these facilities to manage this waste stream efficiently.

After initial dewatering using equipment like a filter press or screw press, the sludge is fed into a dryer. Technologies like paddle dryers or even a flash dryer can be used to quickly reduce the remaining moisture. This process converts the wet, bulky sludge into a dry, manageable solid, which is much easier and cheaper to transport and dispose of.

By integrating sludge drying into their ETP operations, textile plants can achieve better waste management, adhere to environmental regulations, and reduce their operational footprint. This adoption is a key step towards more sustainable practices within the textile industry.

Feedback and Reviews from Indian Clients

Before investing in a sludge dryer, it’s wise to research feedback and reviews from other Indian clients. Customer experiences can provide valuable insights into a manufacturer’s product quality, reliability, and level of service. Checking supplier ratings helps you gauge a company’s reputation in the market.

This due diligence can help you avoid potential issues and choose a supplier known for reliable performance and customer satisfaction. The right feedback can confirm if a manufacturer lives up to its promises.

So, where can you find these reviews, and what should you look for?

Common Customer Experiences and Satisfaction

Positive customer experiences often highlight a few key areas that lead to high satisfaction. First and foremost is product quality. Clients are most satisfied when the sludge dryer performs as advertised, delivering consistent drying results and operating without frequent breakdowns. Reliability is crucial, as downtime can disrupt plant operations.

Another significant factor is customer support. Satisfied customers often mention responsive and helpful support from the manufacturer, from the initial inquiry to installation and after-sales service. Quick delivery times and transparent communication throughout the procurement process also contribute greatly to a positive experience.

Common themes in positive feedback include:

- Durability and Robust Construction: The machine withstands demanding industrial environments.

- Excellent Performance: The dryer effectively reduces moisture and meets capacity requirements.

- Responsive After-Sales Service: The manufacturer provides timely support for maintenance and troubleshooting.

Where to Find Trusted Supplier Ratings

Finding trusted supplier ratings and reviews is easier than ever, thanks to various online platforms. B2B marketplaces like Aajjo.com are excellent trusted sources for gathering feedback on industrial equipment suppliers in India. These platforms often feature dedicated sections for supplier reviews, allowing you to see what other buyers have to say about their products and services.

On these sites, you can find detailed listings for sludge dryers from various Gujarat-based manufacturers. The listings often include product specifications, images, and sometimes even direct feedback or ratings from previous customers. This allows you to compare different suppliers side-by-side and make a more informed choice.

Beyond B2B platforms, you can also look for case studies or testimonials on the manufacturers’ own websites. While these are curated, they can still provide useful insights into the company’s projects and client base. Contacting the manufacturer directly to ask for client references in your industry is another effective way to get honest feedback.

Conclusion

In summary, selecting the right continuous sludge dryer manufacturer in Gujarat can significantly impact your industrial operations. With a variety of options available, understanding the key features, types, and customer feedback is essential for making an informed decision. From energy efficiency to tailored solutions for specific sludge types, the leading suppliers in Gujarat offer innovative technologies that cater to diverse industry needs. By prioritizing these factors, you can ensure optimal performance and sustainability in your processes. If you’re ready to take the next step, feel free to reach out for further assistance or a consultation on finding the best solution for your requirements!

Frequently Asked Questions

What factors should I prioritize when selecting a continuous sludge dryer in Gujarat?

When selecting sludge dryers, prioritize the type of dryer that suits your sludge, its capacity for moisture removal, and overall product quality. Also, consider the efficiency of the drying process and the machine’s energy consumption to ensure it meets your operational needs and budget for the long term.

Do Gujarat manufacturers provide after-sales support and maintenance?

Yes, reputable dryer manufacturers in Gujarat typically provide comprehensive after-sales support to ensure reliable performance. Positive customer experiences and high supplier ratings often reflect good service, including maintenance support, timely assistance, and spare parts availability. Always confirm the scope of after-sales service before purchasing.

Are there energy-efficient models available for Indian industries?

Absolutely. Many manufacturers offer energy-efficient sludge dryers designed to lower operational costs and reduce environmental impact. These sustainable models use optimized heat transfer and may include energy recovery systems, making them a smart, cost-effective choice for Indian industries focused on long-term efficiency and eco-friendly operations.