Are you looking for an effective way to manage industrial waste? An industrial sludge dryer could be the perfect solution for your business. These powerful machines streamline the sludge drying process, reducing waste volume and making disposal more manageable and cost-effective. However, navigating the market to find the right sludge dryer at the right price can be challenging. This guide is here to help. We will walk you through everything you need to know about industrial sludge dryer prices in India, helping you make a smart investment.

Key Highlights

Here is a quick rundown of what you will find in this guide to industrial sludge dryer machine prices:

- The price of sludge dryers in India varies widely, from as low as ₹7,02,000 to over ₹4 crore.

- Key factors influencing the price include capacity, technology type, construction materials, and automation levels.

- Leading manufacturers and suppliers include Acmefil Engineering Systems, Technomart India, and Whirler Centrifugals.

- The drying process and sludge type (textile, pharmaceutical, municipal) also impact the machine’s final cost.

- You can find affordable options for SMEs, including compact and solar-powered sludge drying systems.

- Always provide detailed specifications to suppliers to get an accurate price quotation.

Overview of Industrial Sludge Dryer Machines in India

The Indian market for industrial sludge dryer machines is diverse, with a wide array of options available to suit different industrial needs. From small-scale solar dryers to massive rotary systems for municipal waste, there is a solution for almost any application. These machines play a crucial role in modern wastewater treatment and waste management, helping companies comply with environmental regulations and reduce operational costs.

Choosing the right sludge dryer involves understanding what they do, where they are used, and the benefits they offer. In the following sections, we will explore the purpose of these machines, their common applications in Indian industries, and the key advantages of integrating a sludge drying process into your operations.

Definition and Purpose of Sludge Dryer Machines

So, what exactly is a sludge dryer machine? In simple terms, it is specialized industrial equipment designed to remove water and moisture from wet sludge. Sludge, the semi-solid residue from wastewater treatment processes, is often heavy and difficult to handle due to its high water content. The primary purpose of sludge dryers is to significantly reduce the moisture content in this waste.

The drying process transforms the wet, bulky sludge into a lighter, drier material, often in the form of powder or small granules. This reduction in volume and weight is the core function of the machine. By turning wet sludge into dry solids, it becomes much easier and cheaper to transport, store, and dispose of.

Ultimately, these machines help streamline your waste management system. The resulting dry material can sometimes be repurposed, for instance, as a fuel source or agricultural compost, turning a waste product into a valuable resource. The entire sludge drying operation is designed for efficiency and cost reduction.

Common Applications Across Indian Industries

Industrial sludge dryers are incredibly versatile and find use across a multitude of sectors in India. Any industry that operates a wastewater treatment plant can benefit from an efficient sludge drying system. The ability to dramatically reduce sludge volume makes these machines an invaluable asset for cost-effective and environmentally responsible waste management.

You will find sludge dryers being used in various demanding environments where managing waste is a top priority. Their application helps businesses handle everything from chemical byproducts to organic waste efficiently.

Some of the most common applications include:

- Pharmaceutical and Chemical Industries

- Wastewater Treatment Plants (ETP, STP)

- Textile and Dyeing Units

- Food and Beverage Processing

- Organic Waste Composting

Key Benefits of Using Sludge Dryers

Integrating an industrial sludge dryer into your operations brings a host of significant benefits. The most immediate advantage is the drastic reduction in waste volume and weight. By removing a high percentage of moisture content, you lower your transportation and disposal costs, which are often calculated by weight.

Another key benefit is the improved handling and storage of waste. Dry sludge is less odorous, more stable, and easier to manage than its wet counterpart. The reduced drying time compared to traditional air-drying methods means your waste management process becomes faster and more efficient.

Furthermore, using sludge dryers can create new value streams. The key benefits include:

- Reduced Disposal Costs: Lowering the amount of sludge to be transported saves money.

- Environmental Compliance: Helps meet regulations for waste disposal.

- Resource Recovery: Dried sludge can sometimes be used as fuel or fertilizer, turning waste into a resource.

Market Price Range of Industrial Sludge Dryer Machines

When you start looking for an industrial sludge dryer, one of the first things you will notice is the incredibly wide price range. In India, you can find machines priced from as low as ₹7,02,000 for a small solar unit to well over ₹4,00,00,000 for a large-scale municipal sludge dryer. This vast difference in price can seem confusing at first.

This variation is due to a combination of factors, including the machine’s capacity, the technology it uses, and the materials it’s made from. To help you understand what to expect, the following sections break down the average pricing trends, different price segments, and the cost differences between new and used machines.

Average Pricing Trends in India

The average price for an industrial sludge dryer in India isn’t a single number but a broad spectrum. Pricing trends show that the cost is directly linked to the machine’s complexity and capacity. For small-scale needs, you can find budget-friendly options that get the job done without a massive investment.

For example, a 100 kg solar sludge dryer from Radha Energy Cell is listed at approximately ₹7,02,000, making it an accessible entry point. A more standard industrial model, like a low-energy dryer from Whirler Centrifugals, might start around ₹10,95,000. These prices reflect smaller capacities, typically around 10-100 kg/hr.

As you move up in scale, the prices increase significantly. Mid-range paddle dryers or thermal dryers for pharmaceutical use can be found in the ₹7,00,000 to ₹15,00,000 range. For very large capacities, such as those needed for municipal sewage treatment, prices can soar to ₹40,00,000 or even higher, reflecting the robust engineering required.

Typical Price Segments (Budget, Mid-Range, Premium)

To make sense of the market, it helps to think about sludge dryers in three typical price segments: budget, mid-range, and premium. Each segment caters to different operational scales and financial capabilities, ensuring there’s a machine for nearly every need.

Understanding these categories can help you narrow down your search. The segment you choose will depend on your required throughput, the type of sludge you’re processing, and your long-term operational goals.

- Budget (Under ₹5,00,000): This segment includes small-capacity machines, manual dryers, and solar dryers. They are perfect for small enterprises or businesses with minimal sludge output. Examples include solar dryers around ₹72,000 and basic paddle dryers starting at ₹3,75,000.

- Mid-Range (₹5,00,000 – ₹25,00,000): Here you’ll find automatic, medium-capacity industrial sludge dryers. These are often made of mild steel or standard stainless steel and are suitable for many chemical, pharmaceutical, and wastewater treatment plants.

- Premium (Over ₹25,00,000): This category features high-capacity, fully automated systems made from premium materials like high-grade stainless steel. These include large rotary drum dryers and customized systems designed for heavy-duty municipal or large industrial use, with prices reaching several crores.

Pricing Differences for New vs. Pre-owned Machines

When considering your budget, you might wonder about the price variation between new and pre-owned sludge dryer machines. A brand-new machine is the most common choice, offering the latest technology, a full manufacturer’s warranty, and comprehensive after-sales support. The higher price reflects this peace of mind and reliability.

On the other hand, a pre-owned sludge dryer machine can be a significantly more affordable option, making it an attractive choice for businesses with tight capital budgets. However, this lower initial cost comes with potential trade-offs. A used machine may not include a warranty, could have a shorter operational lifespan, and might require more frequent maintenance.

If you are considering a pre-owned unit, it is crucial to conduct a thorough inspection and, if possible, get a maintenance history. While the upfront savings are appealing, you must weigh them against the potential for higher long-term repair costs and the absence of supplier support. Choosing between new vs. pre-owned depends on your risk tolerance and budget.

Factors Influencing the Cost of Sludge Dryer Machines

The price tag on a sludge dryer machine isn’t arbitrary. Several critical factors come together to determine the final cost. Understanding these cost factors will empower you to evaluate quotes more effectively and choose a machine that provides the best value for your specific requirements. The initial investment is directly tied to the machine’s capabilities and construction.

From the sheer size and processing power to the type of technology used, each element plays a role. In the sections that follow, we’ll examine the five most significant factors that influence pricing: capacity, construction materials, technology, automation, and brand reputation.

Capacity and Throughput Impact on Price

One of the most significant factors driving the price of an industrial sludge dryer is its capacity and throughput. Capacity refers to the amount of wet sludge the machine can process in a given period, typically measured in kilograms per hour (kg/hr) or tons per day (TPD). As you might expect, a machine designed to handle more sludge costs more.

For instance, a compact dryer with a capacity of 10-50 kg/hr is suitable for small operations and will have a much lower price point, often under ₹5,00,000. In contrast, a high-throughput machine with a capacity of 500 kg/hr or more, designed for a large industrial plant, will carry a substantially higher price, often exceeding ₹12,00,000.

When requesting a quote, specifying your required throughput is essential. This allows suppliers to recommend a correctly sized machine, ensuring you don’t overpay for capacity you don’t need or under-invest in a machine that can’t keep up with your sludge output. The price scales almost directly with the drying process volume.

Construction Materials and Durability

The materials used to build a sludge dryer machine play a crucial role in its durability, lifespan, and, consequently, its price. The choice of construction materials is often dictated by the type of sludge being processed. Common materials include mild steel (MS), carbon steel, and various grades of stainless steel (SS).

A machine made from mild steel is generally the most budget-friendly option. However, it may be susceptible to corrosion if used to process acidic or highly chemical sludge. This makes it better suited for less aggressive materials.

On the other hand, a sludge dryer constructed from stainless steel costs more but offers superior corrosion resistance and durability. For industries like pharmaceuticals and chemicals, where sludge can be highly corrosive, stainless steel is often a necessity. While the initial investment is higher, the extended lifespan and lower maintenance needs can result in a better long-term return on investment.

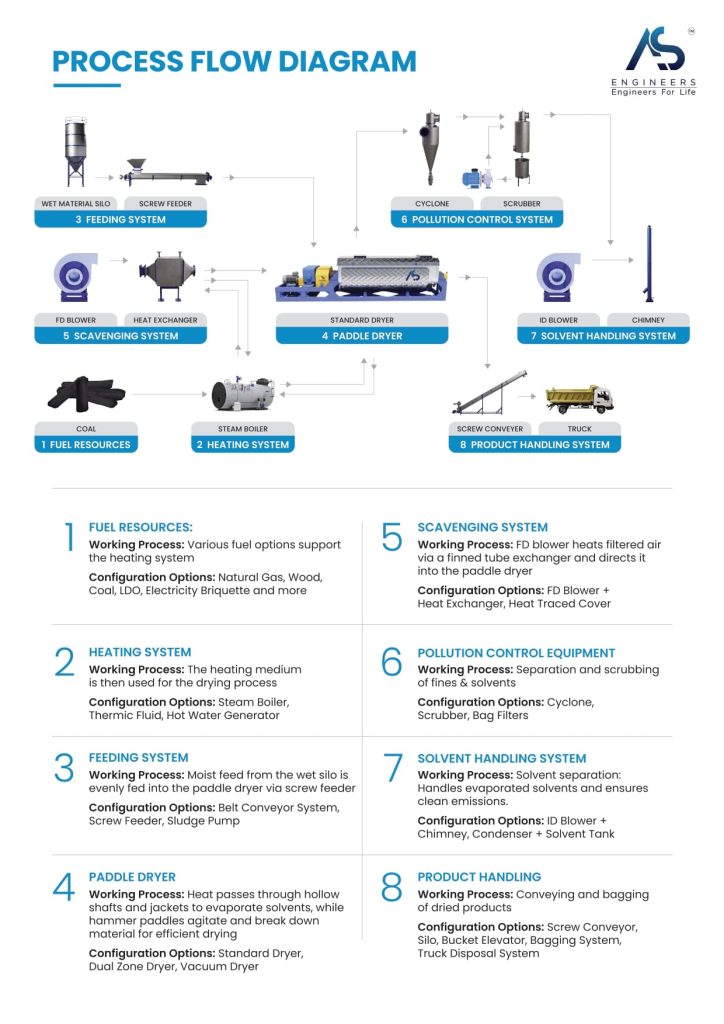

Technology Type: Thermal, Paddle, Rotary, Solar

The drying technology is another major factor that determines the cost of a sludge dryer. Different technologies offer varying levels of efficiency, energy consumption, and suitability for different types of sludge. Each technology type comes with a different price tag, reflecting its complexity and operational benefits.

The choice of technology should align with your operational needs, budget, and the specific characteristics of your sludge. Understanding these differences is key to selecting the right machine.

- Solar Dryers: These are often the most affordable option, using sunlight in a greenhouse-like structure to evaporate water. They have very low operating costs but require a large footprint and are dependent on weather conditions.

- Paddle Sludge Dryers: These use heated, wedge-shaped paddles to mix and heat the sludge. They are efficient and compact, making them a popular mid-range choice for various industries.

- Rotary Drum Dryers: These large, cylindrical dryers tumble the sludge through a heated drum. They are ideal for high-capacity applications, such as municipal waste, and typically fall into the premium price segment.

- Thermal/Heat Pump Dryers: This technology uses a closed-loop system to dehumidify air and dry the sludge at lower temperatures. They are known for being energy-efficient and are available at various price points.

Automation and Control Features

The level of automation and the sophistication of the control features significantly influence the price of a sludge dryer machine. Machines can range from fully manual to semi-automatic to fully automated systems that require minimal human intervention. As automation increases, so does the cost.

A basic, manually operated dryer requires an operator to load the sludge, monitor the drying process, and unload the finished product. These are the most affordable but are also labor-intensive and may produce less consistent results. A semi-automatic machine might automate some parts of the process, offering a balance between cost and convenience.

Fully automated dryers, equipped with Programmable Logic Controllers (PLCs), sensors, and user-friendly interfaces, represent the top tier. These systems can automatically adjust temperature and drying time, ensuring optimal efficiency and consistent output. While they have the highest initial cost, the savings in labor and improved performance of the drying process often justify the investment for larger operations.

Brand Reputation and After-Sales Support

The reputation of the manufacturer and the quality of their after-sales support also play into the overall cost of a sludge dryer. Established manufacturers with decades of experience, like Acmefil Engineering Systems or Whirler Centrifugals, often command higher prices for their machines. This premium is for their proven track record of reliability, quality engineering, and customer trust.

A higher price often includes better after-sales support, which is a critical consideration. This can include installation assistance, operator training, readily available spare parts, and responsive maintenance services. Choosing a supplier with a strong support network can save you from costly downtime in the future.

While a machine from a lesser-known brand might be cheaper initially, it could come with risks related to performance and support. Investing in a reputable brand often means you are buying not just a machine, but also a partnership with a reliable supplier who will support you throughout the equipment’s lifecycle.

Leading Manufacturers and Suppliers in India

Choosing the right sludge dryer also means choosing the right partner. The Indian market is home to numerous experienced manufacturers and suppliers, each offering a range of products to fit different needs and budgets. A reliable supplier will not only provide a quality machine but also offer guidance and support to ensure you get the best solution.

From specialists in affordable solar dryers to providers of high-capacity industrial systems, the options are plentiful. To help you navigate the landscape, the following sections highlight some of the leading sludge dryer manufacturers in India, giving you a starting point for your research.

Acmefil Engineering Systems Private Limited

With over two decades of experience, Acmefil Engineering Systems Private Limited is a highly respected name in the industry. Based in Ahmedabad, this manufacturer is known for producing robust and high-quality sludge dryers. They are a TrustSeal Verified supplier on IndiaMART and a Trusted Seller on Tradeindia, indicating a strong reputation for reliability.

Acmefil offers sludge dryer machines designed for demanding industrial applications. For example, their stainless steel sludge dryer, priced around ₹20,00,000, can handle capacities ranging from 100 to 1500 kg/hr. This makes it suitable for medium to large-scale operations in various industries.

Their focus on durable construction materials like stainless steel ensures a long operational life, even when processing challenging waste materials. For businesses looking for a dependable, high-performance machine from an experienced supplier, Acmefil is a strong contender.

Technomart India

Technomart India, located in Kheda, Gujarat, has been a key player in the industrial machinery space for over 16 years. As a GST Verified Exporter on IndiaMART, they have a proven track record of supplying equipment to a broad customer base. They are known for providing powerful and efficient sludge drying solutions.

An example of their offerings is an automatic sludge dryer machine priced at approximately ₹12,00,000. This particular model boasts an impressive treatment capacity of 40 tons per day (TPD) and is constructed from mild steel, making it a cost-effective choice for large-scale industrial use, particularly in the chemical industry.

By offering high-capacity, automatic machines, Technomart India caters to businesses that need to process large volumes of sludge efficiently. Their experience as manufacturers ensures that you receive a machine engineered for performance and reliability in demanding industrial settings.

Whirler Centrifugals Private Limited

Based in Ahmedabad, Whirler Centrifugals Private Limited has nearly 20 years of experience in the field. This supplier is notable for offering a diverse range of sludge dryers that cater to different budgets and needs. Their product lineup demonstrates a clear understanding of varied market requirements, from entry-level to more advanced systems.

Their price offerings are quite competitive. For instance, they list a Low Energy Sludge Dryer for ₹1,95,000, a Paddlecon Sludge Dryer for ₹3,75,000, and a Continuous Sludge Dryer for ₹5,25,000. This variety makes them an excellent choice for businesses looking for options at different price points. On Tradeindia, they also list a Lime Sludge Dryer starting at just ₹50,000.

This wide range allows you to find a machine that fits your specific application and budget. Whether you need a simple, low-cost solution or a more continuous, automated system, Whirler Centrifugals likely has a product to match.

Shiva Global Environmental Private Limited

Shiva Global Environmental Private Limited, with offices in New Delhi, is another established manufacturer with over 12 years of experience. As an IndiaMART Verified Exporter and a Trusted Seller on Tradeindia, they are recognized for their quality and reliability in the environmental equipment sector. They offer robust sludge dryers suitable for heavy industrial use.

Their product listings showcase powerful machines designed for efficiency. For example, they offer an automatic Hydro Treat Sludge Dryer for approximately ₹15,00,000. On another platform, a Carbon Steel Sludge Dryer is listed at ₹20,00,000, indicating their ability to provide machines with different material specifications based on customer needs.

Catering primarily to industrial wastewater treatment, Shiva Global provides solutions that are built to last. Their machines are designed to handle demanding sludge drying tasks, making them a reliable choice for companies prioritizing performance and durability.

Radha Energy Cell

For businesses seeking an eco-friendly and highly affordable sludge drying solution, Radha Energy Cell from Ludhiana is a noteworthy supplier. With 16 years in business, this TrustSeal Verified company specializes in solar-powered technology, offering an innovative alternative to conventional electric or steam-powered dryers.

Their standout product is the 100 kg Solar Sludge Dryer, priced at an exceptionally competitive ₹72,000. This automatic machine runs on a 24V system, making it ideal for organic waste composting and other applications where minimizing operational costs is a top priority. The use of solar power means you save significantly on electricity bills.

Radha Energy Cell provides an excellent option for small to medium-sized enterprises (SMEs) or any organization looking to adopt green technology. Their solar sludge dryer machine proves that effective sludge management doesn’t have to come with a high price tag or a large carbon footprint.

Excellent En-Fab Incorporation

Located in the industrial hub of Ahmedabad, Excellent En-Fab Incorporation has been manufacturing industrial equipment for 12 years. This TrustSeal Verified supplier offers highly capable sludge dryers designed for flexibility and performance. They provide machines that can be tailored to specific industrial requirements.

Their listings show a focus on robust, high-capacity equipment. One of their sludge dryers is priced at ₹30,00,000 and features automatic operation with a choice of construction materials ranging from mild steel (MS) to stainless steel (SS). This flexibility allows customers to choose a material that best suits their sludge type and budget.

On other platforms, they list a sludge dryer for ₹12,00,000, demonstrating their ability to cater to different price points. By offering customizable designs and materials, Excellent En-Fab Incorporation positions itself as a versatile manufacturer for various industrial clients.

Micro Transmission Systems

Micro Transmission Systems, based in Greater Noida’s UPSIDC Surajpur industrial area, is a well-regarded manufacturer with 11 years of experience. They specialize in providing high-quality sludge dryers for a diverse range of industries, including food and beverage, chemical, and stone processing.

Their offerings include a stainless steel automatic sludge dryer listed at ₹20,00,000. This machine is designed for high performance, with a treatment capacity of 100-1500 kg/hr. The use of stainless steel makes it a durable choice for handling potentially corrosive sludge from ETP, STP, and WTP applications.

By catering to multiple industries, Micro Transmission Systems has developed versatile and reliable machines that can meet various operational demands. Their focus on quality materials and high capacity makes them a solid choice for businesses looking for a long-lasting sludge drying solution.

Maxsep System Private Limited

Maxsep System Private Limited, operating from Chennai for the past 10 years, is a TrustSeal Verified supplier known for its customer-centric approach. They provide high-quality sludge dryers and are notable for including installation services with their offerings, which adds significant value for the buyer.

Their listings feature a steam-powered sludge dryer made of stainless steel, priced at approximately ₹15,00,000. This machine is suitable for all industries and can handle a maximum capacity of 1000 kgs. The use of steam as a power source can be a cost-effective option for facilities that already have a steam supply.

The explicit mention of “Installation Service: Yes” in their quotations is a key differentiator. This bundled service simplifies the procurement process for the buyer, ensuring that the machine is set up correctly and ready to operate without the need to hire third-party installers.

Infinite Energy Private Limited

Infinite Energy Private Limited, based in Faridabad, is a prominent manufacturer with 16 years of experience, specializing in high-capacity and premium sludge drying systems. They are the go-to supplier for large-scale industrial and municipal projects that require robust and powerful equipment to handle massive volumes of sludge.

Their price points reflect the scale and sophistication of their machines. For instance, they list a Sewage Sludge Dryer at ₹40,00,000 and a Sludge Rotary Dryer at ₹55,00,000. These prices are indicative of machines with very high throughput, advanced automation, and durable construction designed for continuous, heavy-duty operation.

Infinite Energy also offers specialized solutions, such as their Stainless Steel Poultry/Chicken Litter Dryer priced at ₹30,00,000. For organizations that need to process large quantities of waste reliably, Infinite Energy provides the high-end, engineered solutions required for the job.

Price Offerings by Top Suppliers

As we’ve seen, the price of an industrial sludge dryer can vary significantly from one supplier to another. These price offerings are not just random; they reflect the specific capabilities, materials, and target market of each machine. Understanding this variation is key to finding the best value for your investment.

To help you compare effectively, it’s useful to look at different categories of price quotes. The following sections will explore the typical prices for entry-level models, high-capacity industrial machines, and how factors like special deals and custom specifications can affect the final price you pay.

Entry-Level Sludge Dryer Machine Price Quotes

If you’re a small or medium-sized enterprise, or if your sludge output is relatively low, you’ll be glad to know there are many affordable, entry-level sludge dryers on the market. These machines provide an accessible starting point for businesses looking to improve their waste management without a huge capital outlay. Most suppliers offer a minimum order quantity (MOQ) of just one unit.

These entry-level models prioritize cost-effectiveness and are often designed for smaller capacities or use energy-efficient technologies. They prove that you don’t need a massive budget to start drying sludge efficiently.

Here are a few examples of entry-level price quotes:

- Solar Sludge Dryer (Radha Energy Cell): Approximately ₹72,000 for a 100 kg capacity machine.

- Manual ETP Sludge Dryer (J. M. Industries): Around ₹90,000 for a 100 kg/hr manual unit.

- Heat Pump Sludge Dryer (Ecotech Solutions): Priced at ₹1,00,000 for a 100 kg to 1000 kg/hr model.

Prices for High-Capacity Industrial Models

For large industrial facilities and municipal wastewater treatment plants, the name of the game is high capacity. These operations generate vast amounts of sludge daily and require machines that can keep up. The prices for these high-capacity industrial models are significantly higher, reflecting their complex engineering, robust construction, and massive throughput.

These premium machines are investments in operational efficiency at a grand scale. A high-capacity sludge dryer machine is built to run continuously, processing thousands of kilograms of sludge per hour. For example, AS Engineers offers a paddle dryer with a capacity of up to 3000 kg/hr, listed at ₹60,00,000.

Similarly, Infinite Energy specializes in this segment, with its Sewage Sludge Dryer priced at ₹40,00,000. At the very top end, a supplier like Ultra Drytech Engineering Projects offers an Industrial & Municipal Sludge Dryer for a staggering ₹4,00,00,000, designed for the largest-scale applications.

Supplier-Specific Deals and Discounts

While online listings provide a good baseline, the quoted price for a sludge dryer is not always final. Many suppliers are open to negotiation, and you may be able to secure a better deal by discussing your needs directly with them. Don’t hesitate to inquire about potential discounts or special offers.

Building a good relationship with a supplier can lead to price variations that work in your favor. It’s always a good practice to explore these possibilities before finalizing your purchase.

Here are a few things to ask about:

- Bulk Order Discounts: If you plan on purchasing multiple machines, either now or in the future, ask if there is a discount for a larger order.

- Package Deals: Some suppliers may offer a reduced price if you bundle the machine with a service contract or an extended warranty.

- Seasonal Promotions: Occasionally, manufacturers may run promotions to clear inventory or boost sales. It’s worth asking if any such offers are available.

Price Variations Due to Custom Specifications

Often, a standard, off-the-shelf sludge dryer machine may not perfectly fit your unique operational needs. In such cases, many manufacturers offer custom-built solutions. However, it’s important to remember that any customization will likely lead to price variations compared to standard models.

Custom specifications allow you to get a machine that is perfectly tailored to your process. For example, you might require a specific grade of stainless steel to handle highly corrosive sludge, or you may need the machine to fit within a constrained physical space. Suppliers like Acmefil Engineering Systems and Indiadrytech explicitly mention that they offer customized designs.

Other common customizations that affect the price include requests for a specific power source (like coal or steam), higher temperature capabilities, or integration with your existing control systems. When you request a custom-built machine, the final price will reflect the additional engineering, materials, and labor required.

Price Differences by Location in India

Did you know that the price of an industrial sludge dryer can also depend on where you are in India? Prices are not always uniform across the country. Major industrial hubs with a high concentration of manufacturers, like Ahmedabad, may have more competitive pricing due to intense local competition.

In contrast, if you are located in a city with fewer local suppliers, the price might be higher to account for shipping and logistics costs. This price variability by location is an important factor to consider in your budget. The following sections offer a glimpse into the market prices in key cities like Ahmedabad and Coimbatore.

Ahmedabad Market Price Overview

Ahmedabad stands out as a major hub for sludge dryer manufacturers in India. The city and its surrounding GIDC industrial estates, such as Vatva and Ambica Nagar, are home to numerous suppliers, including Acmefil, Whirler Centrifugals, and Excellent En-Fab. This high concentration of manufacturers fosters a competitive market environment.

As a result, buyers in Ahmedabad have access to a very wide range of options and price points. The market price for a sludge dryer in this city can be as low as ₹1,00,000 for a heat pump model from Ecotech Solutions or go as high as ₹60,00,000 for a high-capacity paddle dryer from AS Engineers.

This competition means you are more likely to find competitive quotes and have more leverage for negotiation. The easy availability of parts and service in the region is another advantage of sourcing from a major industrial center like Ahmedabad.

Coimbatore Pricing Insights

Coimbatore, another significant industrial city in India, also has a market for industrial sludge dryers. However, the compiled information shows fewer suppliers based directly in the city compared to Ahmedabad. Key suppliers in the area include Super Scientific Suppliers and Enviro Solutions & Service.

The pricing insights from Coimbatore are less direct, as many local suppliers list their products with a “Get Latest Price” tag. This indicates that prices are provided upon request and are likely tailored to the customer’s specific requirements. This approach is common when dealing with specialized or customizable industrial equipment.

The pricing in Coimbatore may also be influenced by the need to ship machines from other manufacturing hubs. This could potentially add to the final cost. To get a clear picture of the pricing, you will need to contact the local suppliers directly with your detailed specifications.

Price Variability Across Major Indian Cities

The price of a sludge dryer machine can fluctuate noticeably depending on the city. This price variability is influenced by local taxes, shipping costs, labor rates, and the density of suppliers in the region. A city with many manufacturers will likely offer more competitive pricing than a location that requires equipment to be shipped from far away.

To illustrate this, let’s look at the range of prices found across some of India’s major industrial cities. The table below shows representative price ranges based on available listings, highlighting how costs can differ from one metropolitan area to another.

| City | Representative Low Price | Representative High Price |

|---|---|---|

| Ahmedabad | ₹72,000 (Solar) | ₹60,00,000 (High-Capacity Paddle) |

| Pune | ₹2,00,000 (Industrial) | ₹15,00,000 (Low-Temp Automatic) |

| New Delhi | ₹15,00,000 (Hydro Treat) | ₹20,00,000 (Carbon Steel) |

| Hyderabad | ₹7,20,000 (Wastewater) | ₹7,50,000 (ETP Dryer) |

| Faridabad | ₹30,00,000 (Poultry Litter) | ₹55,00,000 (Rotary Dryer) |

| Chennai | ₹15,00,000 (Steam Powered) | ₹25,00,000 (Industrial ETP) |

Industry-Specific Price Analysis

The industry you operate in has a direct impact on the type of sludge dryer you need and, therefore, its price. Sludge from a textile mill is very different from sludge from a pharmaceutical plant, and each requires a machine with specific features. This industry-specific demand leads to variations in machine design and cost.

An industrial sludge dryer is not a one-size-fits-all solution. The materials, safety features, and technology must be matched to the application. In the following sections, we will analyze the pricing considerations for sludge dryers used in the textile, pharmaceutical, and municipal sectors.

Sludge Dryers for Textile Industry

The textile industry generates a significant amount of sludge, often laden with dyes, chemicals, and fibers. This type of sludge can be corrosive and requires a dryer that can withstand harsh conditions. Consequently, a sludge dryer for the textile industry often needs to be constructed from durable materials like stainless steel to prevent corrosion and ensure a long service life.

This requirement for specialized materials naturally influences the price, making these machines more expensive than a standard mild steel model. The drying process must also be efficient to keep up with the high volume of wastewater produced in textile manufacturing, potentially requiring a machine with a shorter drying time and higher throughput.

While specific “textile sludge dryer” prices are not always listed separately, you can expect the cost to be in the mid to high range, similar to those designed for the chemical industry. The investment ensures that the machine can reliably handle the unique challenges of textile waste.

Machines for Pharmaceutical & Chemical Plants

When it comes to pharmaceutical and chemical plants, the requirements for sludge dryers are among the most stringent. These industries handle materials that can be hazardous, volatile, or require sterile processing conditions. As a result, the machines used must meet very high standards of safety and material purity.

Sludge dryers for these sectors are almost always constructed from high-grade stainless steel (like SS304 or SS316) to prevent contamination and resist chemical corrosion. Features like indirect heating, vacuum drying, or explosion-proof components might also be necessary, adding to the complexity and cost. The goal is to reduce the moisture content without compromising safety or product integrity.

These specialized requirements mean that a sludge dryer for a pharmaceutical or chemical plant will be priced at a premium. For example, suppliers like Vikrama Innovative Technologies offer dryers for the pharmaceutical industry starting around ₹7,20,000, while high-capacity paddle dryers can exceed ₹20,00,000.

Environmental and Municipal Sludge Dryer Pricing

Environmental and municipal sludge management deals with waste from sewage treatment plants (STPs) and water treatment plants (WTPs). The primary challenge here is the sheer volume of sludge produced. A medium-sized city can generate tons of sludge every day, requiring dryers with massive capacity and continuous operation capabilities.

For these applications, large-scale systems like rotary drum dryers or belt dryers are common. These machines are engineered for heavy-duty performance and reliability. The pricing for municipal sludge dryers reflects this scale, often running into crores of rupees. For instance, Infinite Energy offers a sewage sludge dryer for ₹40,00,000, while Ultra Drytech lists a municipal model for ₹4,00,00,000.

Alternatively, some municipalities opt for large solar drying facilities. While the initial setup cost can be substantial, the long-term operational savings on energy can be immense. The drying process for environmental sludge focuses on volume reduction to minimize landfill costs.

Sludge Dryer Machine Platforms: Price Comparison

In today’s digital age, online B2B platforms are invaluable tools for sourcing industrial equipment. Websites like IndiaMART and Alibaba allow you to browse a vast catalog of sludge dryer machines from numerous suppliers in one place, making price comparison easier than ever. These platforms offer transparency and a direct line of communication with manufacturers.

By using these resources, you can quickly get a sense of the market rates and identify potential suppliers that fit your budget. The following sections provide a closer look at the pricing information you can typically find on IndiaMART and Alibaba.

IndiaMART Price Listings

IndiaMART is one of India’s largest online B2B marketplaces and a fantastic resource for anyone looking to buy an industrial sludge dryer. The platform features hundreds of listings from manufacturers and suppliers across the country, providing a comprehensive overview of the market. You can easily filter searches by city, supplier verification status, and price.

The price listings on IndiaMART clearly demonstrate the wide spectrum of costs. You can find everything from highly affordable models to premium industrial systems, giving you the ability to compare options that fit your specific needs.

Here are some examples of the price range you’ll find:

- Low End: A 100kg Solar Sludge Dryer from Radha Energy Cell for ₹72,000.

- Mid-Range: A Sludge Dryer Machine from Technomart India for ₹12,00,000.

- High End: A 3000kg/hr Paddle Dryer from AS Engineers for ₹60,00,000.

Alibaba Pricing Insights

Alibaba is a global B2B platform that connects buyers with manufacturers from around the world, particularly from China. When searching for a sludge dryer machine on Alibaba, you will find a wide variety of options, often at very competitive prices. However, there are a few key differences to keep in mind compared to domestic platforms.

Prices on Alibaba are typically listed in US dollars and often as a range (e.g., $15,000 – $71,000). This is because the final price depends on the order quantity and specifications. It is also important to note that most prices are quoted as FOB (Free on Board).

FOB pricing means the quoted price does not include:

- International shipping costs

- Import duties and taxes

- Local transportation and installation charges

You must factor these additional costs into your budget to determine the total landed price of the machine.

E-commerce Options for Sludge Dryers in India

While large B2B platforms like IndiaMART are excellent for comparison, they aren’t the only e-commerce option for sourcing a sludge dryer. Many manufacturers now have their own sophisticated websites where you can explore their product range in detail and initiate a purchase inquiry directly.

Suppliers like Malhari Projects Pvt Ltd have websites that function as a digital showroom, complete with product specifications and an easy-to-use “Enquire Now” feature. This direct-to-manufacturer approach can be highly beneficial. You can build a direct relationship with the supplier, get expert advice on the best machine for your needs, and receive a detailed quote tailored to your specifications.

For complex industrial equipment like a sludge dryer machine, the e-commerce experience is less about a simple “add to cart” and more about facilitating a detailed conversation. Using a manufacturer’s website is an effective way to start that conversation and gather the precise information needed to make an informed decision.

Affordable Sludge Dryer Options for Small & Medium Enterprises

If you run a small or medium-sized enterprise (SME), the price tags on large industrial sludge dryers can seem daunting. The good news is that you don’t need to break the bank to implement an effective sludge drying solution. The market offers a variety of affordable options specifically designed to meet the needs and budgets of smaller businesses.

From compact machines with a smaller footprint to energy-efficient models that save on running costs, there are plenty of ways for SMEs to invest wisely. The following sections will explore some of these affordable sludge dryer options.

Compact Sludge Dryers for SMEs

For small and medium enterprises, space and budget are often top concerns. Compact sludge dryers are the perfect solution, offering efficient drying performance in a smaller package and at a more accessible price point. These machines are designed for lower throughput, making them ideal for businesses that don’t generate massive volumes of sludge.

These smaller units allow SMEs to gain the benefits of sludge volume reduction—like lower disposal costs and easier handling—without the hefty investment required for a large industrial system. They are a practical first step into modernizing your waste management process.

Here are some affordable, compact options:

- Small-Capacity Dryers: Models with a capacity of 10-100 kg/hr are widely available and are priced competitively.

- Solar Dryers: A 100 kg capacity solar sludge dryer can be purchased for under ₹1 lakh, offering an excellent return on investment.

- Manual or Semi-Automatic Models: Opting for a machine with less automation can significantly reduce the initial purchase price.

Energy-Efficient Models for Cost Savings

When calculating the total cost of a sludge dryer, it is crucial to look beyond the initial purchase price. The ongoing operational costs, especially energy consumption, can add up significantly over the machine’s lifetime. For SMEs, choosing an energy-efficient model is a smart way to manage long-term expenses and boost profitability.

Solar sludge dryers are a prime example of an energy-efficient solution. By harnessing the power of the sun, they offer a drying process with virtually zero energy costs. While they require more space and are weather-dependent, the long-term savings are undeniable for businesses in sunny climates.

Another excellent option is the heat pump sludge dryer. This technology is known for its low energy consumption because it recycles heat within a closed-loop system. Investing in an energy-efficient model might sometimes mean a slightly higher upfront cost, but the savings on your monthly electricity bills will lead to a lower total cost of ownership.

Financing and Lease Deals

A large capital expenditure can be a major hurdle for many small and medium enterprises, even for more affordable sludge dryer models. To make this technology more accessible, it is worth exploring financing and lease deals. These options allow you to acquire the equipment you need without a massive upfront payment.

While suppliers may not always advertise these options directly, you should always inquire about them. Some manufacturers may have partnerships with financial institutions that offer business loans specifically for machinery purchases. This can help you spread the cost over several years, making it much more manageable for your cash flow.

Leasing is another powerful alternative. By leasing a sludge dryer, you pay a fixed monthly fee for its use, avoiding the need to purchase it outright. At the end of the lease term, you may have the option to buy the equipment, upgrade to a new model, or simply return it.

Installation, Commissioning & Maintenance Costs

The final price you pay for a sludge dryer goes beyond the cost of the machine itself. To get a true picture of your total investment, you must also consider the costs associated with installation, commissioning, and ongoing maintenance. These additional expenses are a critical part of the total cost of ownership.

Are these services included in the supplier’s quotation, or are they extra? Understanding this is key to budgeting accurately and avoiding unexpected bills down the line. The following sections will discuss what to expect regarding these essential services.

Is Installation Included in Supplier Quotations?

Whether installation is included in the price of a sludge dryer machine varies from one supplier to another. It is not a standard inclusion, so you must clarify this point with every supplier you contact. Getting this information in writing within the official quotation is crucial to avoid any misunderstandings.

Some customer-focused suppliers do include installation and commissioning as part of their package. For example, Maxsep System Private Limited explicitly states “Installation Service: Yes” in their product listings. Similarly, AS Engineers notes that their price is “WITH ERECTION AND COMMISIONING.” This bundled approach simplifies the process for the buyer and ensures the machine is set up correctly by experts.

However, other suppliers may treat installation as a separate, chargeable service. If it is not mentioned in the quote, assume it is an additional cost and ask for a detailed price breakdown for the service.

Typical Charges for Maintenance Services

Regular maintenance is essential to keep your sludge dryer machine running efficiently and to prolong its operational life. The cost of these maintenance services can vary depending on several factors, including the complexity of the machine, your location, and the type of service agreement you choose.

Most suppliers offer maintenance services in two ways: on a per-call basis or as part of an Annual Maintenance Contract (AMC). A per-call service is charged each time a technician visits your site for repairs or servicing. This might be suitable for minor issues but can become expensive for frequent or major problems.

An AMC, on the other hand, involves paying a fixed annual fee for a predetermined number of service visits and preventive maintenance checks. This provides predictable maintenance costs and helps prevent major breakdowns before they happen. You should always ask potential suppliers for their schedule of charges for both types of service contracts.

Service Contracts and Extended Warranties

To protect your investment and ensure peace of mind, it is wise to consider purchasing a service contract or an extended warranty for your sludge dryer machine. These options provide a safety net against unexpected failures and help you manage maintenance costs more effectively over the long term.

A service contract, often called an Annual Maintenance Contract (AMC), typically covers preventive maintenance, regular inspections, and sometimes even labor costs for repairs. This proactive approach helps keep your machine in optimal condition and reduces the risk of costly downtime. It turns unpredictable repair bills into a fixed, budgetable expense.

An extended warranty provides coverage for parts and labor beyond the standard manufacturer’s warranty period. While it adds to the initial cost, it can save you from significant expenses if a major component fails after the standard warranty expires. Both service contracts and extended warranties are valuable additions that contribute to a lower total cost of ownership.

How to Request Accurate Price Quotations

Getting a vague price estimate for a sludge dryer isn’t very helpful. To receive an accurate and detailed price quotation that you can actually use for budgeting and comparison, you need to provide potential suppliers with specific information about your requirements. The more details you give, the better the quote will be.

Online platforms like IndiaMART or direct inquiries to manufacturers are the best places to request these quotes. But what information do you need to provide? The following sections outline the key specifications required for a quote and offer tips on how to compare offers effectively.

Specifications Needed for a Detailed Quote

To get a truly useful price quotation for a sludge dryer machine, you need to arm the supplier with as much detail as possible about your operational needs. A generic inquiry will only get you a generic, and likely inaccurate, price range. Providing clear specifications ensures the supplier can recommend the right machine and price it correctly.

Before you contact a supplier, take the time to gather the following essential information. This will streamline the quotation process and help you receive comparable offers from different manufacturers.

Be sure to include these key details in your request:

- Type of Sludge: Specify if it’s from an ETP, STP, or a specific industry (e.g., chemical, pharmaceutical, textile).

- Required Capacity: Your desired throughput in kg/hr or tons/day.

- Moisture Content: The initial moisture percentage of the wet sludge and the target final moisture percentage of the dry solids.

- Preferred Power Source: Let them know if you prefer electric, steam, coal, or solar power.

- Material of Construction: State if you have a preference for mild steel (MS) or stainless steel (SS).

Steps to Compare Multiple Supplier Offers

Once you have received several price quotations, the next step is to compare them. It’s tempting to just look at the final number, but a smart comparison goes much deeper. To find the best value, you need to evaluate each offer comprehensively, looking beyond the initial price tag.

A thorough comparison will help you understand what you are truly getting for your money and prevent you from choosing a cheaper option that costs more in the long run. Use a checklist approach to evaluate each offer systematically.

Here are key steps to compare multiple offers:

- Compare Core Specifications: Ensure you are comparing machines with similar capacity, technology, and construction materials.

- Check What’s Included: Look for “hidden” costs. Does the price include shipping, installation, and training?

- Evaluate After-Sales Support: Compare the warranty periods, availability of spare parts, and the reputation of each supplier’s service team.

- Consider Energy Consumption: A cheaper machine might use more energy, leading to higher operational costs over time.

Negotiation Tips for Getting the Best Deal

After comparing your offers, you will have a good idea of which sludge dryer machine best fits your needs. Now it’s time to negotiate to ensure you get the best possible deal. Negotiation is a standard part of purchasing industrial equipment, and a well-prepared approach can lead to significant savings.

Remember that the “best deal” isn’t always the lowest price. It’s about achieving the best overall value, which includes the machine itself, services, and support. A good negotiation is a respectful conversation aimed at reaching a mutually beneficial agreement.

Here are a few negotiation tips to help you succeed:

- Get Multiple Quotes: Having offers from several suppliers gives you a clear understanding of the market rate and provides valuable leverage.

- Be Prepared to Walk Away: If a supplier is not willing to meet your reasonable budget or needs, be prepared to consider other options.

- Negotiate on the Package: If the price of the machine is firm, try negotiating for included extras like free installation, an extended warranty, or a discount on a future spare parts order.

Conclusion

In conclusion, understanding the price dynamics of industrial sludge dryer machines is crucial for making informed purchasing decisions. With various factors influencing the cost—from capacity and technology to brand reputation—it’s essential to explore all available options. By comparing prices across regions and suppliers, you can find the best deal tailored to your specific needs. Whether you’re considering new or pre-owned machines, being well-informed will help you secure an investment that enhances operational efficiency and meets your budget. If you have any questions or need assistance navigating this market, don’t hesitate to get in touch!

Frequently Asked Questions

What is the average price of an industrial sludge dryer machine in India?

There is no single average price for an industrial sludge dryer in India due to the vast range of available models. Prices can start from under ₹1 lakh for small, solar-powered units and exceed ₹1 crore for high-capacity, automated systems for municipal use. The final price depends entirely on the machine’s specifications.

Do suppliers include installation in the quoted price?

It’s essential to clarify installation costs with suppliers when discussing industrial sludge dryer machines. Some may include installation in the quoted price, while others might charge separately. Always review the contract details to avoid unexpected expenses and ensure a comprehensive understanding of pricing.

Are there affordable sludge dryers for small businesses in India?

Yes, there are affordable sludge dryers designed specifically for small businesses in India. Various manufacturers offer cost-effective models that cater to budget constraints while ensuring efficiency and reliability. Researching local suppliers can help identify suitable options that fit business needs.