Welcome to the world of cleaner water! If you’re involved in wastewater treatment, you know how important it is to remove solids effectively. Fine screening is a fundamental process that sets the stage for all subsequent treatment. Whether you’re considering a rotary drum screen or a static screen, understanding how they work is your first step toward achieving clarity and efficiency in your operations. This guide will walk you through everything you need to know about these essential tools.

Table of contents

- Key Highlights

- Understanding Fine Screens in Wastewater Treatment

- Rotary Drum Fine Screens – Design and Working Principle

- Comparing Rotary Drum Fine Screens with Static Fine Screens

- Advantages of Using Fine Screen Rotating Drum Systems

- Types of Rotary Drum Screens and Their Mechanisms (Internally vs. Externally Fed)

- Selection Criteria for Drum Fine Screens in India

- Maintenance Best Practices and Long-Term Reliability of Drum Fine Screens

- Environmental Impact and Sustainability of Rotary Drum Screens

- Conclusion

- Frequently Asked Questions

Key Highlights

- Fine screening is a crucial first step in both municipal and industrial wastewater treatment.

- Rotary drum screens offer a self-cleaning, efficient solution for solid liquid separation.

- These systems protect downstream equipment by effectively removing suspended solids.

- Proper selection of screen type is vital for optimizing your treatment process.

- Regular maintenance ensures the long-term reliability and performance of your fine screens.

- Rotary drum screens are a durable and cost-effective choice for modern wastewater management

Understanding Fine Screens in Wastewater Treatment

Fine screening is a key part of the preliminary treatment stage in wastewater treatment plants. Its main job is to remove solid waste, such as suspended solids and organic material, from the water before it moves on to more sensitive processes. By catching these materials on a screen surface, you prevent clogs and damage to downstream equipment.

This initial separation is vital for the overall health and efficiency of the entire system. Without effective fine screening, the performance of subsequent treatment stages can be severely compromised. Let’s explore the different types of screens and how they achieve this important task.

The Role and Importance of Fine Screen Rotating Drum Systems

A rotary drum fine screen is a mechanical, self-cleaning device that acts as a powerful solid liquid separator in wastewater treatment. Imagine a large, rotating cylinder or drum. As wastewater flows through it, solids are captured on the screen surface while the cleaner water passes through. This continuous rotation is the secret to its efficiency.

The rotational motion serves two purposes. First, it constantly exposes a fresh screen surface to the incoming wastewater, ensuring a consistent filtration rate. Second, it lifts the captured solid waste out of the water, where it can be easily removed by a cleaning system, often involving brushes or spray nozzles.

This design makes drum screens incredibly effective at protecting the rest of the wastewater treatment system. By removing debris early on, you ensure that pumps, pipes, and biological reactors can operate without the risk of blockages or damage, leading to a smoother and more reliable process.

What Are Static Fine Screens and How Do They Function?

Unlike their rotating counterparts, static fine screens have no moving parts. They rely on gravity and the flow of the wastewater itself to perform the separation. These screens are typically set at an angle, and as water flows over them, solid particles are caught on the screen surface while the liquid passes through the screen openings.

The captured suspended solids slide down the screen surface due to gravity, accumulating at a collection point for removal. Because they lack a mechanical drive system, static screens are simpler in design and often have lower initial and operational costs. They are a straightforward solution for solid-liquid separation.

However, their performance can be more dependent on the characteristics of the wastewater and the flow rates. They may require more frequent manual cleaning to prevent clogging, especially in applications with high solids loading. The choice between a static and a rotary screen often comes down to the specific needs of your facility.

Rotary Drum Fine Screens – Design and Working Principle

Rotary drum fine screens are engineered for performance and durability. Their design typically features a cylindrical screen drum, often made with wedge wire or a perforated plate, housed within a frame. The robust stainless steel construction ensures resistance to the corrosive environment of wastewater. The rotational motion is key to their operation.

As wastewater enters the screen basket, the drum slowly rotates. This movement allows water to pass through the screen openings while trapping solids inside or outside the drum, depending on the feed type. This continuous, gentle motion prevents solids from plastering onto the screen surface, ensuring efficient and uninterrupted filtration. We will now look at the key components and how they work together.

Key Components of the Drum Fine Screen

The effectiveness of a drum fine screen comes from the synergy of its core components. Each part is designed to contribute to its overall performance, from filtration to self-cleaning. The heart of the unit is the cylindrical screen itself, which does the heavy lifting of separation.

Key components work together to ensure reliable operation:

- Cylindrical Screen/Screen Basket: This is the filtration medium, often constructed from a perforated plate or wedge wire screen made of durable stainless steel. Its openings determine the size of particles captured.

- Drive System: A motor and gearbox provide the slow, steady rotational motion essential for continuous screening and solids transport.

- Spray Nozzles and Cleaning System: As the drum rotates, spray nozzles wash the captured solids off the screen and into a collection trough, ensuring the screen remains clear and efficient.

These parts are typically housed in a tank or frame, also made from corrosion-resistant materials like stainless steel. This robust construction guarantees a long service life even in the harsh conditions of wastewater treatment.

How the Drum Mechanism Enhances Filtration Efficiency

The rotational motion of drum screens is what truly sets them apart in terms of filtration efficiency. Unlike static screens that can get clogged, the continuous movement ensures that the entire screen surface is utilized effectively. This prevents blinding and maintains a consistent flow of water through the screen.

As the drum rotates, it gently tumbles the captured solid particles. This action allows more water to drain from the solids before they are discharged, resulting in a drier waste product and better solid-liquid separation. The collected solids are then lifted out of the water flow to a discharge point.

Furthermore, the integrated self-cleaning system, typically using spray nozzles or brushes, activates as the clean part of the screen rotates into position. This action removes the collected solids automatically, resetting the screen surface for the next cycle. This automated process ensures high filtration efficiency with minimal manual intervention.

Comparing Rotary Drum Fine Screens with Static Fine Screens

When choosing a fine screening solution, it’s important to understand the fundamental differences between rotary drum and static fine screens. The most obvious distinction is movement—rotary screens are dynamic, while static screens are passive. This core difference influences everything from operational efficiency and maintenance needs to energy consumption.

Each screen type has its place in wastewater treatment, and the best choice depends on your specific application and priorities. Below, we’ll examine their operational differences in more detail and help you decide which screen is the right fit for your needs.

Operational Differences Explained

The primary operational difference lies in how each screen manages solids and stays clean. Rotary screens use mechanical rotation and an automated cleaning system, providing continuous, unattended operation. This makes them highly efficient and reliable, especially for flows with high or variable solids content.

Static screens, on the other hand, rely on gravity and the angle of the screen surface. They have no moving parts, which means lower energy use and mechanical maintenance. However, they may require more frequent manual checks and cleaning to prevent clogging, which can affect their overall efficiency if not properly managed. The material choice, often stainless steel over carbon steel, also impacts durability for both types.

Here is a simple comparison:

| Feature | Rotary Drum Screen | Static Fine Screen |

|---|---|---|

| Mechanism | Dynamic, rotating drum | Passive, fixed screen |

| Cleaning | Automated (sprays/brushes) | Primarily gravity-assisted, may require manual cleaning |

| Energy Consumption | Higher due to motor | Very low to none |

| Efficiency | High and consistent | Can vary with flow and solids load |

| Maintenance | Regular checks on mechanical parts | Minimal mechanical maintenance, focus on clog prevention |

Which Screen Type Is Right for Your Wastewater Application?

Deciding between a rotary drum screen and a static fine screen depends entirely on your specific wastewater application. What works for a small municipal plant may not be suitable for a large industrial facility.

A rotary drum screen is often the preferred choice for applications with high flow rates or significant amounts of solids, such as in larger municipal wastewater plants or industrial wastewater from food processing and textile industries. Their self-cleaning ability ensures continuous operation with minimal oversight, which is crucial for protecting sensitive downstream equipment.

Conversely, static fine screens can be an excellent, cost-effective solution for smaller applications with lower or more predictable solids loading. Their simplicity and low energy use make them attractive for smaller facilities or pre-screening in less demanding industrial settings. The key is to evaluate your flow, solids characteristics, and operational capacity before making a choice.

Advantages of Using Fine Screen Rotating Drum Systems

The benefits of integrating a rotary drum system into your wastewater treatment process are significant. These machines are workhorses, delivering exceptional solid liquid separation with remarkable efficiency. Their automated, self-cleaning design minimizes the need for manual intervention, reducing labor costs and operational headaches.

Beyond the immediate performance, rotary drum screens offer long-term value through their durability and relatively low energy consumption compared to other mechanical systems. Let’s look closer at how they improve water quality and provide a cost-effective solution for industrial settings.

Solid-Liquid Separation and Improved Wastewater Quality

The primary function of a rotary drum screen is to serve as an excellent solid liquid separator. By effectively capturing suspended solids and other fine particles at the beginning of the treatment process, these screens drastically reduce the load on all subsequent stages. This initial cleanup is fundamental to successful wastewater management.

Improving the quality of wastewater early on provides several key benefits:

- Protection of Downstream Equipment: Removing solids prevents clogging and damage to pumps, membrane systems, and biological reactors.

- Enhanced Treatment Efficiency: With fewer solids to process, downstream systems can operate more effectively and efficiently, leading to a higher quality final effluent.

Ultimately, better solid-liquid separation means a more stable and reliable treatment process. Rotary drum screens ensure that large debris and fine particles are removed consistently, which is the first and most critical step toward achieving your water quality goals.

Cost-Efficiency and Durability in Indian Industrial Settings

For industrial applications in India, cost-efficiency and durability are paramount. Rotary drum screens deliver on both fronts, making them a smart long-term investment. Their robust construction, typically using high-grade stainless steel, ensures they can withstand the harsh conditions of industrial wastewater for years with minimal maintenance.

This durability translates directly into cost savings. A well-built drum screen requires fewer repairs and replacements, reducing downtime and associated expenses. Furthermore, their efficient operation leads to savings in other areas:

- Reduced Disposal Costs: By dewatering solids more effectively during separation, rotary screens reduce the overall volume and water content of the waste, lowering disposal fees.

- Lower Operational Costs: Automated operation minimizes labor requirements, and the low energy consumption keeps utility bills in check.

These factors combine to offer a low total cost of ownership, making rotary drum screens an economically sound choice for a wide range of industrial applications, from food processing to chemical manufacturing.

Types of Rotary Drum Screens and Their Mechanisms (Internally vs. Externally Fed)

Rotary drum screens come in two primary feed types: internally fed and externally fed. The choice between them depends on the specific mechanism required for your wastewater and the type of solids you need to remove. In an internally fed drum screen, wastewater is introduced into the center of the rotating screen drum. The water flows out through the wedge wire screen, leaving the solids trapped on the internal surface. These solids are then carried by the rotation to the top, where they are discharged. This design is often better for finer screening applications.

Externally fed drum screens work the opposite way. Wastewater flows over the top of the rotating drum, and solids are captured on the exterior surface. As the drum rotates, the solids are lifted out of the water and scraped or washed off. This mechanism is highly efficient for handling higher flow rates and larger solids, making it a common choice for preliminary treatment in both municipal and industrial wastewater treatment settings.

Selection Criteria for Drum Fine Screens in India

Choosing the right drum fine screen in the Indian market requires careful consideration of several key factors. You can’t simply pick a model off a shelf; the screen must be matched to your facility’s unique needs. Important selection criteria include the expected flow rates, the nature of the solids in your wastewater, and the required screen size or opening. A durable stainless steel construction is almost always recommended to handle corrosive elements and ensure a long service life.

Beyond the technical specifications, you should also evaluate the manufacturer’s reputation and the support available within the Indian market. A good supplier will help you with proper sizing and offer reliable after-sales service. By balancing technical needs with practical considerations, you can select a drum fine screen that provides optimal performance and long-term value for your investment.

Project Sizing and Specification Considerations

Proper project sizing is the most critical step in selecting a drum fine screen. An undersized screen will be overwhelmed, leading to poor performance and potential overflows, while an oversized one is an unnecessary capital expense. The sizing process must begin with a thorough analysis of your wastewater.

You need to consider two main factors:

- Flow Rates: You must know your average and peak flow rates. The screen must be able to handle the maximum expected volume without compromising efficiency.

- Solids Loading: The type and amount of solids are just as important. Wastewater from a food industry application will have different characteristics than municipal wastewater, influencing the required screen size and opening.

Consulting with an expert to match these specifications to the right equipment is essential. Correct sizing ensures that your drum screen integrates seamlessly into your overall treatment process and functions effectively for years to come.

Evaluating Manufacturers and Price Points in India

Once you have your technical specifications, the next step is to evaluate manufacturers and their price points in the Indian market. While price is always a factor, it shouldn’t be the only one. The long-term value of a rotary drum screen comes from its quality, reliability, and the support provided by the manufacturer.

When comparing your options, look for:

- Proven Reputation: Choose manufacturers known for quality equipment and positive customer feedback within the wastewater industry.

- Support and Warranty: A good warranty and accessible after-sales service are crucial for ensuring your equipment runs smoothly and any issues are resolved quickly.

Finding the best price for drum screens involves more than just the initial purchase cost. Consider the total cost of ownership, including maintenance, durability, and operational efficiency. Investing in a higher-quality rotary drum screen from a reputable manufacturer often proves more economical in the long run.

Maintenance Best Practices and Long-Term Reliability of Drum Fine Screens

To ensure the long-term reliability of your drum fine screens, a proactive approach to maintenance is essential. While these machines are designed for durability, especially those with stainless steel construction, regular maintenance will guarantee they deliver optimal performance throughout their lifespan. A simple, consistent maintenance schedule can prevent most common issues and extend the life of your equipment significantly.

Routine tasks include inspecting the screen surface for damage or wear, checking that spray nozzles are clear and functioning correctly, and ensuring the drive system is operating smoothly. Lubricating moving parts and keeping the area around the screen clean will also contribute to its longevity. By following these best practices, you can avoid unexpected downtime and costly repairs, ensuring your wastewater treatment process remains efficient and uninterrupted.

Environmental Impact and Sustainability of Rotary Drum Screens

Rotary drum screens play a significant role in promoting sustainability in wastewater treatment. Their efficient design helps facilities reduce their environmental footprint in several ways. By effectively removing solids like organic material at the start of the process, they lessen the burden on subsequent, more energy-intensive treatment stages. This leads to lower overall energy consumption for the plant.

Furthermore, the low maintenance and durable nature of these screens contribute to their eco-friendly profile. Requiring fewer replacement parts and less servicing reduces waste over the equipment’s lifespan. The effective separation of solids also facilitates better waste management, allowing for easier handling, disposal, or even recycling of the captured materials. This makes rotary drum screens a key component in a modern, sustainable wastewater treatment strategy.

Conclusion

In conclusion, fine screens, whether rotary drum or static, play a crucial role in enhancing wastewater treatment processes. They not only improve solid-liquid separation and environmental sustainability but also offer cost-effective and durable solutions for industries in India. By understanding the different types, their mechanisms, and maintenance best practices, you can make informed decisions that align with your specific needs. Investing in high-quality fine screens can ensure long-term reliability and efficiency in your operations. If you have any questions or would like to discuss your requirements further, get in touch with us today.

Frequently Asked Questions

What is the expected lifespan of a rotary drum fine screen in continuous use?

With proper maintenance, a high-quality rotary drum fine screen made from stainless steel can have a long lifespan, often lasting 10 to 15 years or more in continuous operation. The durability of drum screens is one of their key advantages, though lifespan can be affected by the corrosiveness of the wastewater.

What regular maintenance is necessary for drum fine screens?

Regular maintenance for drum fine screens includes routine inspections for wear, cleaning the screen surface, and ensuring the spray nozzles are not clogged. It is also important to check and lubricate moving parts like the drive system to ensure optimal performance and prevent unexpected breakdowns.

Who are the leading manufacturers of drum fine screens in India?

Several reputable manufacturers supply rotary drum screens to the Indian market. When choosing, it’s best to look for established companies with a strong track record, positive customer reviews, and a solid warranty. Evaluating their after-sales support is as crucial as comparing the initial price of their drum screens.

What are fine screens, and how do they differ from traditional filtration methods?

Fine screens are used in preliminary wastewater treatment to physically block and remove suspended solids based on size. Unlike some filtration methods that might use media beds or membranes to trap much smaller particles, fine screens use a perforated or wedge wire screen surface to capture larger debris and solids.

What industries or applications benefit the most from using rotary drum and static fine screens?

Rotary drum screens are highly beneficial for municipal wastewater and sewage treatment plants, as well as industrial wastewater treatment in sectors like food processing and textiles where solids loads are high. Static screens are often suitable for smaller facilities or applications with lower, more consistent flow rates.

How does the choice between rotary drum and static fine screens impact the efficiency of a filtration system?

The choice significantly impacts filtration efficiency. Rotary drum screens offer high, consistent efficiency due to their self-cleaning, dynamic nature, making them ideal for variable loads. Static fine screens are simpler but their efficiency can decline if solid particles cause clogging, requiring more monitoring in a wastewater treatment system.

What maintenance practices are recommended to ensure optimal performance of fine screens?

To ensure optimal performance, regular maintenance is key. For drum fine screens, this includes periodic inspection of the screen, cleaning of spray nozzles to prevent clogging, and lubrication of mechanical components. A consistent schedule of preventive maintenance is the best practice for long-term reliability.

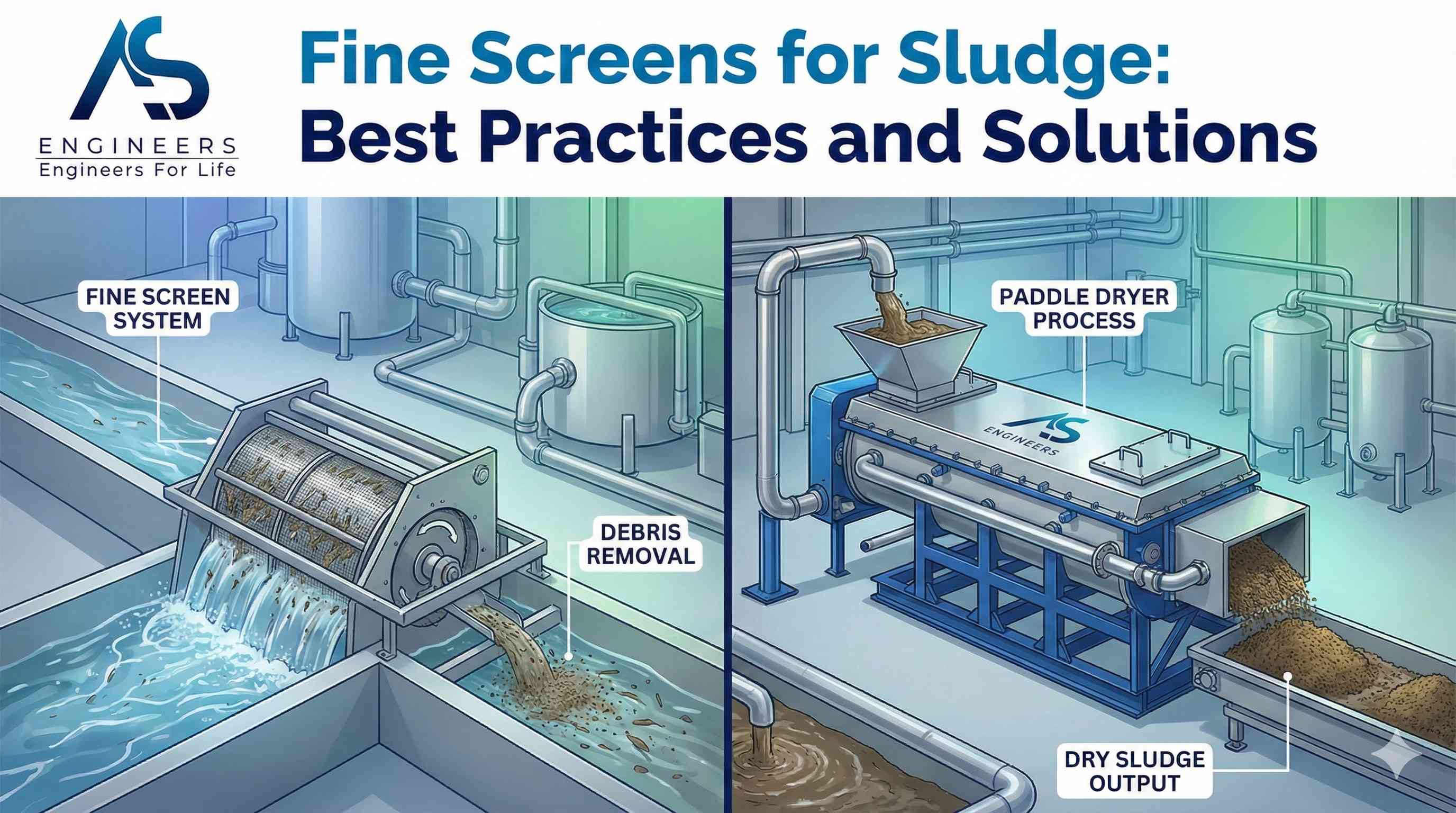

Now that you have effectively separated solid waste from your wastewater using fine screens, you are left with sludge a byproduct that requires proper management. Handling and disposing of this sludge can be costly and challenging due to its high water content. The key to efficient sludge management is dewatering, and the most advanced method for this is drying.

When it comes to sludge drying, the paddle dryer emerges as the best solution. It offers a highly efficient, indirect drying method that significantly reduces sludge volume, minimizes disposal costs, and produces a stable, dry end-product. For those seeking the most reliable and technologically advanced paddle dryers, AS Engineers stands out as the leading manufacturer. With a commitment to quality and innovation, AS Engineers provides robust and efficient paddle dryer systems tailored to meet the specific needs of your facility, turning a waste management problem into a cost-effective solution.