Introduction: What Happens When Wastewater Goes Untreated?

Imagine this: You’re walking near a river in a semi-urban area. The water smells foul, a thin layer of foam floats on the surface, and plastic waste drifts downstream. Now imagine that same river was once used for drinking water, irrigation, and even fishing. What happened?

According to the United Nations, over 80% of the world’s wastewater flows back into the environment untreated, contaminating ecosystems and public health systems alike. That’s not just an environmental problem—it’s a human crisis.

Enter the wastewater treatment plant.

Whether you’re a plant operator, environmental engineer, policymaker, or concerned citizen, understanding how a wastewater treatment plant works—and why it’s essential—is the first step toward sustainable water management. From purifying sewage to recycling industrial effluent, wastewater treatment plants silently protect public health, conserve freshwater, and support economic resilience.

In this guide, we’ll take you behind the scenes of these complex but vital systems—exploring the science, technologies, types, and real-world impact of wastewater treatment plants.

By the end, you’ll walk away with:

- A clear understanding of the wastewater treatment process

- Real-world case studies and expert tips

- FAQs optimized for Google’s featured snippets

- Actionable advice on planning or upgrading a treatment facility

Let’s dive deep into the world of water recovery.

What is a Wastewater Treatment Plant & Why Does It Matter?

A wastewater treatment plant (WWTP) is an engineered facility designed to clean used water—also known as sewage or effluent—before releasing it back into the environment or reusing it for non-potable applications like industrial processes, landscaping, or even groundwater recharge.

The goal? Remove contaminants—physical, chemical, and biological—so that water is safe for discharge or reuse.

Quick Definition:

A wastewater treatment plant is a system that removes pollutants from water generated by homes, industries, and commercial activities, making it safe to return to nature or reuse.

Why It Matters More Than Ever

Let’s be blunt: Earth isn’t making more water. The water we have keeps getting reused, which means the cleaning part of the cycle is mission-critical. Especially when we’re facing:

- Climate change and growing water scarcity

- Rapid urbanization and industrialization

- Groundwater depletion

- Rising demand for water reuse

Without WWTPs, untreated water loaded with pathogens, heavy metals, microplastics, and chemicals would devastate aquatic life and public health. And that’s not hypothetical—it’s already happening in regions where infrastructure is lacking.

Who Uses Wastewater Treatment Plants?

WWTPs aren’t just for cities—they serve a wide range of users:

- Municipalities: Treating sewage from homes, offices, and businesses.

- Industrial Zones: Managing effluent from textile, chemical, food, and pharmaceutical plants.

- Residential Societies: Local STPs (Sewage Treatment Plants) are common in modern housing complexes.

- Hospitals, Hotels & Educational Campuses: Specialized ETPs (Effluent Treatment Plants) for high-volume use.

- Agriculture: Reusing treated water for irrigation.

Regulatory Frameworks Around the World

Wastewater treatment is a highly regulated field. Depending on where you are, several authorities govern water discharge and treatment norms:

- India: CPCB & State Pollution Control Boards enforce discharge limits under the Water (Prevention and Control of Pollution) Act, 1974.

- USA: EPA (Environmental Protection Agency) oversees treatment standards under the Clean Water Act.

- Europe: The EU Water Framework Directive dictates integrated water policy compliance.

- Global: The WHO, UN-Water, and UNESCO offer guidelines and frameworks for sustainable treatment systems.

Failure to comply can result in legal penalties, plant shutdowns, or worse—irreversible environmental damage.

Breaking the Myth: Wastewater Isn’t Just “Dirty Water”

One common misconception is that wastewater is just “toilet water.” In reality, wastewater includes:

- Greywater from showers, sinks, and laundry

- Blackwater from toilets

- Industrial effluent rich in chemicals, oils, dyes, or pharma residues

- Stormwater runoff from roads and construction sites

Each of these streams has unique contaminants, which means one-size-fits-all treatment doesn’t work. That’s why plants are designed with specific processes to target specific pollutants.

How a WWTP Fits Into the Circular Economy

Modern wastewater treatment isn’t just about discharge—it’s about resource recovery. Plants are evolving into Water Resource Recovery Facilities (WRRFs) that:

- Produce biogas through sludge digestion

- Recover nutrients like phosphorus and nitrogen

- Recycle treated water for industrial cooling, flushing, or irrigation

This aligns perfectly with the UN SDG 6 (Clean Water & Sanitation) and SDG 12 (Responsible Consumption & Production).

Key Components of a Typical Wastewater Treatment Plant

Here’s what most plants include (detailed process coming next):

- Inlet chamber & screening unit

- Grit removal system

- Primary clarifier

- Aeration tank

- Secondary clarifier

- Tertiary treatment unit (RO, UV, etc.)

- Sludge thickener and dryer (e.g., paddle dryers)

- Final treated water tank

We’ll explore these in-depth in the next section.

Wastewater Treatment Process Explained Step-by-Step

Most people think of wastewater treatment as a single tank with bubbling water. But in reality, it’s a carefully engineered, multi-stage process that transforms dirty, contaminated water into clear, reusable effluent.

Each stage targets a specific type of contaminant—solid, organic, chemical, or microbial—and requires distinct equipment and conditions to function effectively.

Let’s break down the full wastewater treatment process into its four major phases:

1. Preliminary Treatment: Mechanical Cleaning Begins

Goal: Remove large, non-biodegradable materials like plastics, sticks, leaves, rags, and stones that can clog downstream equipment.

Key Units Involved:

- Bar Screen: Filters out large debris

- Grit Chamber: Settles sand and gravel

- Oil & Grease Trap: Separates floatable fats and oils

Why it matters: Without this stage, the entire plant could face mechanical failures and overloading. It’s the unsung hero of smooth operations.

Pro Tip from the Field:

During a site visit in Pune, I saw a plant losing over ₹1.5 lakhs/month in pump damage simply because they skipped proper bar screening. Don’t underestimate this “simple” step.

2. Primary Treatment: Settle the Suspended Solids

Goal: Allow gravity to separate out heavy particles (sludge) and floatables (scum) from the water.

What Happens Here:

- Water enters a primary clarifier (or sedimentation tank).

- Suspended solids settle at the bottom.

- Floating materials rise and are skimmed off.

Efficiency: Removes around 50–60% of suspended solids and 30–40% of BOD (Biochemical Oxygen Demand).

3. Secondary Treatment: Biological Breakdown Begins

This is the heart of the treatment plant—where biological magic happens. Microorganisms are used to digest and convert dissolved organic matter into harmless byproducts like CO₂ and water.

Two Most Common Methods:

a. Activated Sludge Process (ASP)

- Air is bubbled into an aeration tank.

- Microbes consume organic pollutants.

- Mixed liquor flows into secondary clarifiers where biomass settles.

b. Trickling Filters or Bio Towers

- Wastewater trickles over a bed of stones or plastic media.

- Microbes form a biofilm and digest organics.

Real-World Stat:

A well-designed secondary treatment can remove up to 90% of BOD and suspended solids—that’s almost drinking-water clarity before chemical polishing.

4. Tertiary Treatment: Advanced Polishing

Goal: Target specific pollutants not removed in earlier stages—nutrients (N, P), microbes, trace chemicals, and heavy metals.

Tertiary Methods Include:

- Filtration (Sand, Dual Media, Activated Carbon)

- Disinfection (UV, Chlorination, Ozonation)

- Reverse Osmosis (RO) for ultrapure reuse water

When is it required?

- When treated water is reused (cooling towers, gardens, toilets)

- For discharge into sensitive ecosystems (lakes, estuaries)

- In industries like pharma or food with stricter effluent norms

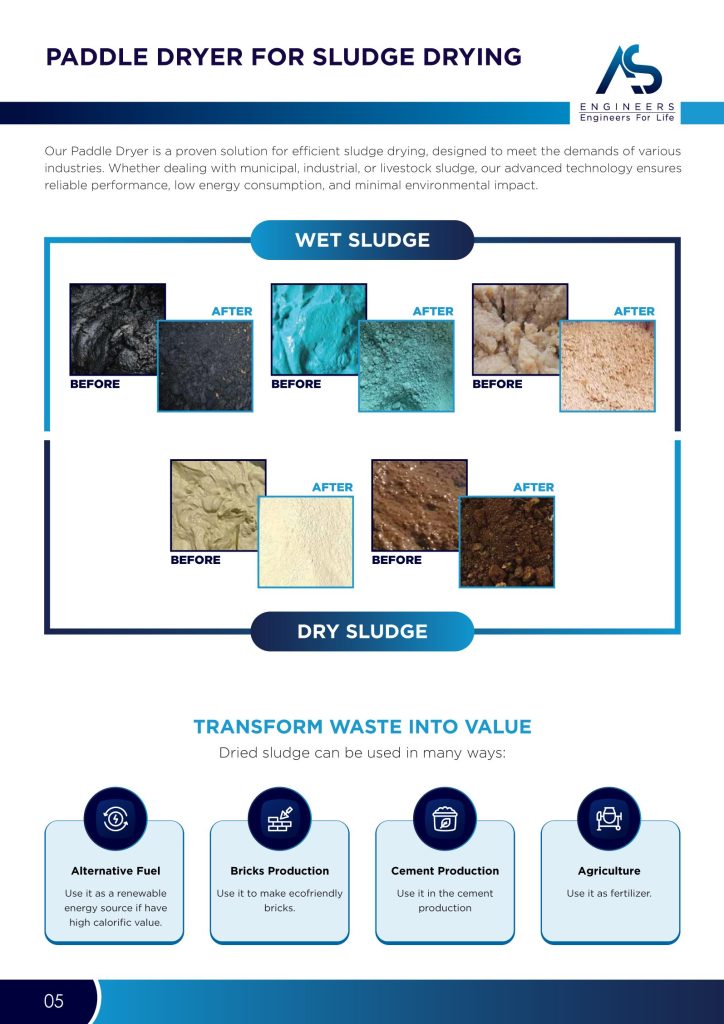

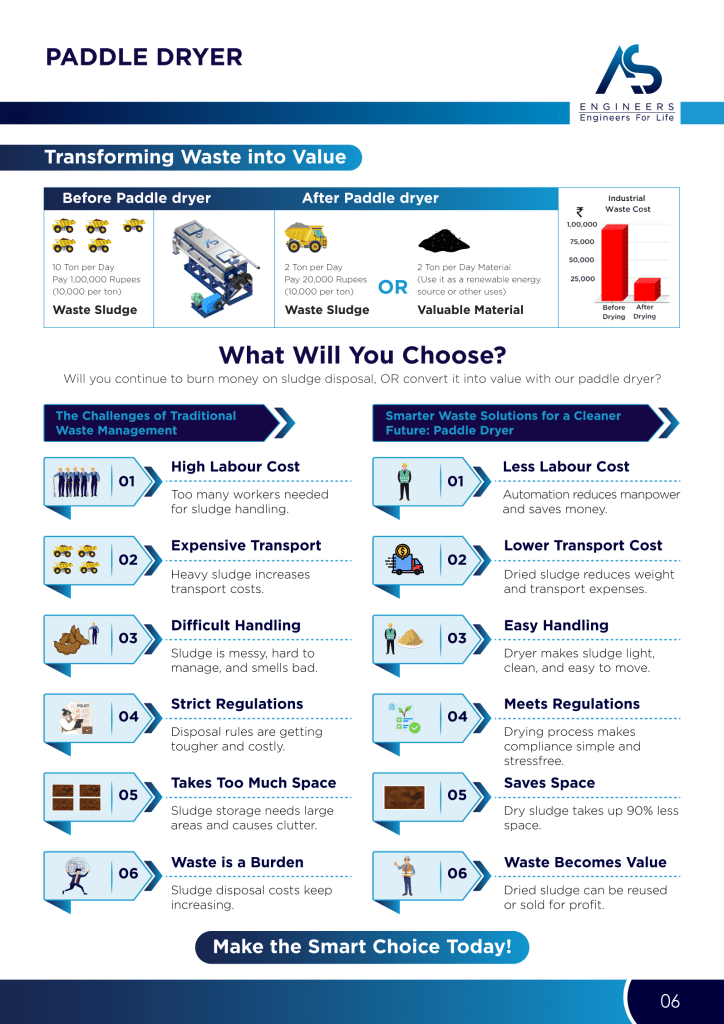

5. Sludge Treatment & Disposal: The Final Frontier

The solids removed at every step—especially primary and secondary sludge—can’t just be dumped.

Sludge Handling Includes:

- Thickening: Reduces water content

- Digestion: Anaerobic or aerobic stabilization to reduce pathogens

- Dewatering: Mechanical methods like filter press or centrifuge

- Drying: Paddle dryers (energy-efficient, compact) are a great choice here

Bonus: Reuse as Fertilizer or Fuel

In some plants, dried sludge is reused as biomass fuel, drastically cutting energy costs and landfill load.

Summary: Treatment Process at a Glance

| Stage | Target Pollutants | Key Technologies |

|---|---|---|

| Preliminary | Trash, grit, oil | Screens, grit chambers |

| Primary | Suspended solids | Clarifiers, skimmers |

| Secondary | Organics, BOD, COD | ASP, trickling filters |

| Tertiary | Nutrients, microbes | UV, RO, filters |

| Sludge Treatment | Biosolids, pathogens | Digestion, drying, reuse |

Deep Dive: Role of Automation and SCADA

Modern WWTPs increasingly rely on:

- SCADA systems (Supervisory Control and Data Acquisition)

- Online sensors for pH, turbidity, DO (Dissolved Oxygen)

- AI-enabled controls for real-time chemical dosing and aeration optimization

Why it matters: Smart monitoring reduces energy consumption by up to 30% and ensures compliance.

Common Errors During Treatment Implementation

- Undersized tanks or wrong process selection (especially in ETPs)

- Skipping sludge treatment leading to hazardous waste pile-up

- Poor maintenance of blowers and diffusers

- Lack of redundancy for critical units

- Improper chemical dosing

Pro Tip: Customize for Waste Type

Different wastewater = different treatment strategy.

| Industry | Common Pollutants | Special Consideration |

|---|---|---|

| Textile | Dyes, surfactants, TDS | Color removal |

| Pharma | Antibiotics, solvents | Tertiary treatment must |

| Food Processing | Fats, grease, BOD | High organic loading |

| Municipal | Organics, pathogens | Must meet discharge norms |

Bonus Tip: Space-Saving Designs

If space is limited, consider:

- MBBR (Moving Bed Biofilm Reactor)

- SBR (Sequencing Batch Reactor)

- MBR (Membrane Bioreactor)

These offer compact footprints and high performance.

Types of Wastewater Treatment Plants: Which One Do You Need?

Not all wastewater treatment plants are created equal.

Depending on the source of the wastewater, its contaminants, required output quality, and available space, different types of plants are designed to handle specific challenges.

Here’s a breakdown of the major types of wastewater treatment plants (WWTPs) used around the world—along with examples, advantages, and use cases.

1. Municipal Wastewater Treatment Plants (STPs)

Used By: Cities, towns, and residential clusters

Treats: Domestic sewage (greywater + blackwater)

Municipal sewage treatment plants—also called STPs (Sewage Treatment Plants)—are the most common type globally. They handle everything that flows out of homes, schools, offices, and public spaces, including:

- Kitchen and toilet waste

- Bathing water

- Laundry discharge

- Minor commercial discharge

🧪 Standard Processes Include:

- Bar screening

- Grit removal

- Primary clarification

- Biological treatment (usually ASP or SBR)

- Disinfection (UV/chlorine)

Real-World Example:

The Okhla STP in Delhi, India, treats over 564 MLD (million liters/day) of sewage and is being upgraded to a tertiary-level facility capable of supplying treated water for agriculture and industry.

Pros:

- Government-regulated and funded

- Consistent operation models

- Integrated with city infrastructure

Challenges:

- Overloading during rain

- Maintenance lapses in smaller towns

- Inefficient sludge handling in older plants

2. Industrial Wastewater Treatment Plants (ETPs)

Used By: Manufacturing units, chemical plants, pharmaceuticals, textiles, refineries

Treats: Highly contaminated effluent with complex pollutants

Also known as Effluent Treatment Plants (ETPs), these facilities handle:

- Toxic chemicals

- Heavy metals

- Oils and greases

- High-BOD/COD wastewater

- Industry-specific contaminants (e.g., dyes in textiles, antibiotics in pharma)

Specialized Treatment Options:

- Neutralization tanks

- Dissolved Air Flotation (DAF)

- Advanced Oxidation Processes (AOPs)

- Reverse osmosis (RO)

- Heavy metal precipitation

Case Study:

At a dye manufacturing plant in Ahmedabad, the ETP combines chemical coagulation, biological treatment, and RO filtration to meet Gujarat Pollution Control Board (GPCB) norms. The concentrated RO reject is further treated using a paddle dryer for zero liquid discharge (ZLD).

Pros:

- Tailored to specific pollutants

- Advanced automation possible

- Enables water reuse

Challenges:

- High CapEx and OpEx

- Frequent need for skilled operators

- Strict regulatory monitoring

3. Common and Combined Effluent Treatment Plants (CETPs)

Used By: Industrial clusters (SMEs), special economic zones (SEZs), cooperative estates

Treats: Mixed effluents from multiple sources

CETPs are shared wastewater treatment plants used by multiple small-to-medium industries located in close proximity. Instead of building individual ETPs (which can be expensive), companies contribute to a common facility.

Typical Configuration:

- Equalization tank to homogenize input

- Coagulation-flocculation

- Biological treatment

- Sludge management

- Final polishing unit (optional)

Field Insight:

During a field study in Vapi, Gujarat, we found that one CETP processed wastewater from over 300 small chemical and dyeing units. However, untreated or partially treated inputs from non-compliant units caused system overload—underscoring the importance of strict inlet quality checks.

Pros:

- Economical for small businesses

- Shared maintenance and operations

- Government-backed in many industrial zones

Challenges:

- Uneven pollutant loads from various sources

- Poor inlet effluent quality control

- Requires strong governance and enforcement

4. Decentralized Wastewater Treatment Plants (DWWTs)

Used By: Remote townships, resorts, gated societies, eco-villages

Treats: Small-scale sewage and greywater

These are modular, small-footprint systems installed onsite to treat sewage locally—ideal for areas without sewer networks.

Often Uses:

- Anaerobic digesters

- Constructed wetlands

- Root-zone treatment systems

- MBBR-based bio-reactors

Use Case:

A resort in Kerala implemented a constructed wetland system to treat its wastewater. The treated water is used for gardening and flushing, with zero discharge into the surrounding ecosystem.

Pros:

- Sustainable and low energy

- Cost-effective for isolated users

- Encourages water reuse and soil recharge

Challenges:

- Limited capacity (few thousand liters/day)

- Seasonal load fluctuation

- Requires regular inspection

Which Type of WWTP Is Right for You?

Here’s a quick decision guide:

| User Type | Recommended WWTP | Key Focus Areas |

|---|---|---|

| Large City | Municipal STP | Volume handling, pathogen removal |

| Pharma Factory | ETP | Chemical safety, ZLD compliance |

| Small Industrial Cluster | CETP | Shared costs, inlet control |

| Remote Housing | Decentralized/DWWT | Sustainability, low footprint |

| Food Processing Unit | ETP + Sludge Dryer | Grease control, BOD handling |

Integrated Designs: The Future of Wastewater Treatment

Today’s trend is hybrid designs—combining aspects of all the above.

For example:

- A food factory might use a compact ETP for primary & secondary treatment, followed by a paddle dryer to handle sludge, and then integrate with a central CETP for final polishing.

These integrated systems ensure efficiency, cost savings, and regulatory compliance.

Common Mistakes & Misconceptions in Wastewater Treatment

Even with the best intentions, wastewater treatment can go terribly wrong if the basics are misunderstood or ignored. Many businesses, engineers, and even municipal planners fall prey to certain myths that cost them hefty penalties, inefficiency, and public backlash.

Let’s break down the most frequent errors—and how to avoid them with expert insights.

Mistake 1: “Only large industries or municipalities need treatment plants.”

This is perhaps the most dangerous misconception, especially among SMEs, hotels, and residential developers. Every entity generating wastewater—whether it’s a textile mill, a school, or an apartment complex—has a legal and environmental obligation to treat it.

Reality: Even 50–100 homes can create 15,000+ liters of wastewater per day. Untreated discharge pollutes water bodies, reduces groundwater recharge quality, and attracts legal action under water pollution laws.

Mistake 2: “Tertiary treatment is optional.”

Wrong. While primary and secondary stages remove a good chunk of contaminants, they do not guarantee pathogen-free, reusable water. Without tertiary polishing:

- You risk spreading waterborne diseases

- You can’t use treated water for gardening, cooling, or toilet flushing

- You’re non-compliant with CPCB or EPA discharge standards

For industries, skipping tertiary treatment often results in plant shutdowns or huge fines.

Mistake 3: “All wastewater is the same.”

Treating pharmaceutical effluent the same way as residential sewage is a recipe for disaster. Every wastewater stream has a unique chemical and biological profile.

| Source | Key Contaminants | Requires Specialized Treatment? |

|---|---|---|

| Residential | Organics, pathogens | Yes – disinfection needed |

| Textile | Dyes, surfactants, high TDS | Yes – chemical oxidation, RO |

| Dairy/Food | Fats, grease, high BOD | Yes – grease trap, aeration |

| Pharma | API residues, solvents | Yes – AOP, ZLD, adsorption |

Mistake 4: “Set it and forget it.”

This approach ruins more plants than poor design ever did.

Even the most advanced WWTPs require:

- Daily performance monitoring (flow, BOD, DO, pH)

- Weekly sludge removal

- Routine equipment maintenance

I once audited an industrial ETP in Gujarat where the MBBR media had not been cleaned in 3 years. The plant was operating at <50% efficiency, and the company didn’t even realize it.

Mistake 5: “The cheapest design is the best.”

Many buyers, especially in small-scale industries or low-budget government projects, go for the lowest upfront bid without understanding life-cycle costs. These savings usually disappear fast due to:

- Frequent breakdowns

- High chemical and energy consumption

- Zero scope for automation

Pro Insight:

“Always evaluate treatment plants by total cost of ownership (TCO), not just CapEx. A ₹30 lakh plant that runs efficiently for 10 years is better than a ₹15 lakh plant that needs revamp in 3.”

Mistake 6: “Sludge? Just dump it somewhere.”

Big no.

Sludge isn’t just smelly waste—it’s often classified as hazardous. Untreated sludge can leach chemicals into landfills, pollute groundwater, and pose serious health risks.

Proper sludge handling involves:

- Thickening → Dewatering → Drying

- Safe disposal or reuse as compost/fuel

✅ Many modern plants use paddle dryers to reduce sludge volume and convert it into energy-rich cake for industrial boilers.

Mistake 7: “Chemical dosing is a guessing game.”

Operators who eyeball chemical dosages—be it alum, lime, or chlorine—often end up:

- Damaging microorganisms in biological systems

- Failing to meet discharge norms

- Wasting money

Use online monitoring sensors and flow-paced dosing systems to keep processes stable.

Quick Recap: Avoid These WWTP Pitfalls

| Mistake | Consequence |

|---|---|

| Ignoring tertiary treatment | Pathogen risk, non-compliance |

| Wrong design for wrong effluent | Ineffective treatment |

| Poor maintenance | Frequent breakdowns, poor output |

| Cheapest solution mindset | High lifetime cost |

| Improper sludge disposal | Legal action, environmental damage |

| Manual chemical dosing | Unpredictable performance |

Up Next: We’ll humanize the topic further with a real-world experience:

“Personal Story: My Visit to a Remote CETP in Gujarat” – what I saw, what went wrong, and what you can learn from it.

in a dusty industrial cluster in Vapi, Gujarat. It wasn’t my first visit to a treatment facility, but what I saw there shifted my perspective completely.

First Impressions: A Plant That Looked Good on Paper

On paper, the CETP was a solid setup. It was designed to treat 5 MLD (million liters per day) of effluent from over 180 micro and small-scale industries, primarily textile dyeing and chemical units. It had:

- An equalization tank

- A primary chemical treatment unit

- Biological aeration tank

- A secondary clarifier

- Sludge dewatering system

Everything looked right. But within 20 minutes of walking into the control room, I knew something was wrong.

The Problem: The Data Didn’t Match Reality

The operator proudly showed me the flow meter and online pH analyzer. But when I asked for:

- Recent lab test results,

- Historical pH logs,

- Daily sludge volume tracking…

There was silence.

Turns out, the pH analyzer had been offline for months, and nobody noticed. Even worse, several of the industries were sending untreated or partially treated wastewater, flooding the CETP with highly acidic or basic effluents.

The biological treatment tank looked like something out of a horror film—no foam, no bubbling, and a nasty smell. The microbes were long dead.

Digging Deeper: Sludge Was the Smoking Gun

We went to inspect the sludge management area. What we found was a 6-month-old mountain of untreated, wet sludge, just dumped on the open ground, slowly leaching into the soil during monsoon rains.

Nobody had bothered to:

- Dewater it properly

- Dry it using the paddle dryer installed months ago (but never wired in)

- Send it for safe disposal

It wasn’t a case of negligence—it was a combination of poor training, lack of accountability, and zero external audits.

The Turning Point: Training + Technology = Results

I sat with the plant management and industry association. We created a simple 30-day action plan:

- Calibrate all sensors and reinstate SCADA monitoring

- Train operators on sampling and chemical dosing

- Enforce mandatory pre-treatment at source

- Commission the idle paddle dryer for sludge volume reduction

Within 3 months, the CETP:

- Reduced power consumption by 12%

- Met GPCB outlet norms consistently

- Processed 3X more sludge into dry cakes ready for industrial fuel use

The Lesson: Compliance Isn’t Enough. Awareness is Everything.

You can spend crores on setting up a WWTP or CETP, but without:

- Proper operator training,

- On-site audits,

- Digital monitoring tools,

- And a culture of responsibility…

…it’s just a box ticking exercise.

Wastewater treatment is not just a process—it’s a continuous commitment.

My Advice to New Plant Owners:

Don’t just rely on what’s on the P&ID or vendor proposal. Visit a real plant. Talk to the operator. Watch the sludge. Smell the aeration tank. Only then will you understand the heartbeat of a treatment facility.

Wastewater Treatment Plant vs Septic Tank — Which One Is Better?

Whether you’re building a residential township, managing a hotel property, or planning an industrial estate, one decision you’ll likely face is:

“Should I go for a wastewater treatment plant (WWTP) or just install septic tanks?”

At first glance, septic tanks might seem like a low-cost, low-hassle solution. But dig a little deeper, and you’ll see why WWTPs are increasingly the smarter and more sustainable choice—especially in areas where space is limited, water reuse is important, or regulations are tight.

Let’s compare them head-to-head.

Comparison Table: Wastewater Treatment Plant vs Septic Tank

| Feature | Wastewater Treatment Plant (WWTP) | Septic Tank |

|---|---|---|

| Type of Treatment | Mechanical, biological, and chemical stages | Basic sedimentation only |

| Pathogen Removal | High (especially with tertiary treatment) | Low |

| Water Reuse Possibility | Yes (gardening, flushing, industrial use) | No (requires further treatment) |

| Footprint Required | Moderate to high (can be compact with MBBR/SBR) | Low to moderate |

| Odour Control | High (well-managed systems) | Low control, prone to odour |

| Sludge Handling | Dewatered and dried with equipment | Manual removal (every 1–2 years) |

| Compliance with Norms | CPCB/EPA compliant | Non-compliant for most urban use cases |

| Initial Cost (CapEx) | High | Low |

| Operating Cost (OpEx) | Moderate (can be optimized) | Minimal, but includes desludging fees |

| Maintenance | Requires trained staff | Periodic emptying |

| Ideal For | Urban housing, industries, institutions | Rural homes, off-grid houses |

How Do Septic Tanks Work?

Septic tanks are essentially large underground containers where:

- Wastewater enters and settles into layers (solids sink, scum floats)

- The middle liquid layer exits to a leach field (soil absorption area)

- Solids accumulate over time and must be pumped out

But here’s the problem:

- No real biological or chemical treatment

- No removal of pathogens, nitrates, or harmful surfactants

- Major source of groundwater contamination when not properly maintained

In fact, septic tank overflows are one of the leading causes of pathogen infiltration in rural drinking water supplies (WHO).

Why WWTPs Are the Future (Even for Small Communities)

Modern compact wastewater treatment plants—especially those using:

- SBR (Sequencing Batch Reactors)

- MBBR (Moving Bed Biofilm Reactor)

- MBR (Membrane Bioreactor)

…are ideal for:

- Gated societies

- Resorts & eco-villages

- Institutions & hostels

- Hospitals

They:

- Use minimal land

- Offer reusable water output

- Are fully enclosed (no smell, no mess)

- Can integrate automation (SCADA, remote alerts)

Environmental Consideration: The Impact Over Time

Let’s look at the environmental impact over 10 years:

| Parameter | WWTP | Septic Tank |

|---|---|---|

| Water pollution | Controlled (meets standards) | High risk if not desludged regularly |

| Water reuse | Up to 85% possible | None |

| Soil health | Safe when reused | Often degraded from leachate |

| Carbon footprint | Higher initially, lower long-term | Lower initially, higher over time |

Cost Analysis: Cheaper Isn’t Always Better

While septic tanks may cost ₹30,000–₹60,000 to install per unit, WWTPs for small communities may cost:

- ₹8–15 lakh for a 20 KLD system

- ₹30–50 lakh for a 100 KLD system

But consider:

- Reduced municipal sewage charges

- Treated water reuse = water savings

- Sludge reuse for fuel or compost

- Lower legal liability and better resale value of property

True Cost = CapEx + OpEx + Compliance + Risk Mitigation

Quick Verdict

| Use Case | Recommended Solution |

|---|---|

| Rural farmhouse | Septic Tank |

| Off-grid cabin with low water use | Septic Tank |

| Housing society (50+ homes) | Compact WWTP (MBBR or SBR) |

| Industrial complex | WWTP with ETP + ZLD integration |

| Hospital or school campus | Decentralized WWTP |

| Areas with water reuse goals | WWTP with tertiary polishing |

Personal Take:

I’ve seen developers try to “cut corners” by installing septic tanks in luxury projects—only to face odour complaints, mosquito infestations, and hefty retrofitting costs within 2 years. Investing in a WWTP is like buying insurance—for your environment, your brand, and your long-term peace of mind.

Case Study: Chennai’s Tertiary Treatment Success for Recycled Water

Water scarcity isn’t a distant concern—it’s a daily crisis in many parts of India. And no city embodies this more than Chennai, the capital of Tamil Nadu, where repeated droughts and overdrawn groundwater supplies have put millions at risk.

But in recent years, Chennai has become a national example of wastewater reuse done right, thanks to its forward-thinking approach to tertiary treatment and water recycling.

Here’s how the city turned a major problem into a model solution.

The Background: Chennai’s Water Crisis

In 2019, Chennai made global headlines when its reservoirs went bone dry. Tankers lined the streets. Hotels shut down. Office buildings closed early due to toilet shortages.

The root cause?

- 50% of its population depended on groundwater

- Water demand exceeded 1,200 million liters per day (MLD)

- Nearly 80% of wastewater was not being reused

City officials realized: we don’t have a water shortage—we have a water reuse problem.

The Project: Tertiary Treatment and Water Reuse

The Chennai Metropolitan Water Supply and Sewerage Board (CMWSSB) launched a visionary project:

- Build TTRO (Tertiary Treatment and Reverse Osmosis) Plants

- Use treated sewage to supply water to industries, saving freshwater for homes

Two major TTRO plants were commissioned:

- Koyambedu TTRO – Capacity: 45 MLD

- Kodungaiyur TTRO – Capacity: 45 MLD

These plants used:

- Ultra-filtration membranes

- Reverse osmosis (RO)

- UV disinfection

- Online SCADA systems

Impact: Water Reuse at Scale

| Metric | Value |

|---|---|

| Total treated water reused per day | 90 MLD |

| Freshwater saved for residential use | 30–40% of industrial demand |

| Beneficiary industries | Electronics, Pharma, Automobiles |

| Revenue from industrial water supply | ₹80+ crores annually |

| Reduction in sea discharge | 33% decrease in raw sewage flow |

Industries in SIPCOT and other industrial clusters now pay to receive recycled water, reducing their dependency on groundwater or expensive private tanker supplies.

Technology Snapshot

| Stage | Treatment Used |

|---|---|

| Pre-Treatment | Screening, sedimentation |

| Secondary Treatment | SBR (Sequencing Batch) |

| Tertiary Treatment | UF membranes + RO + UV |

| Monitoring | SCADA, pH & TDS sensors |

Fun Fact: Treated water from Koyambedu TTRO is cleaner than municipal drinking water standards—but it’s used only for industrial and cooling purposes (by regulation).

Key Takeaways for Other Cities & Planners

- Sewage is not waste—it’s a resource

Cities sit on billions of liters of reusable water daily. - Tertiary treatment pays for itself

With industrial reuse, the CapEx gets recovered within 5–7 years. - Public-private partnerships (PPP) work

CMWSSB collaborated with industry clusters and private plant operators. - SCADA-based monitoring = compliance

The plants are monitored in real-time, ensuring zero discharge violations.

What This Means for You

Whether you’re:

- A municipal planner,

- A developer of industrial estates,

- A CSR leader focused on sustainability…

This case study shows that investment in tertiary wastewater treatment can yield economic, environmental, and social ROI.

And you don’t have to be a megacity like Chennai. Even mid-sized cities and private campuses can build modular TTRO systems based on this blueprint.

Expert Quote (from media interviews):

“Treated sewage is now a lifeline for our operations. It’s cheaper, cleaner, and more consistent than groundwater or tankers.”

— Operations Head, Automobile Factory in Chennai SIPCOT

Wastewater Treatment for Beginners: How to Start a Plant

If you’re new to wastewater treatment, the idea of building or operating a plant might feel overwhelming. Equipment costs, compliance headaches, sludge disposal—it’s a lot to take in. But don’t worry. With the right roadmap and expert guidance, setting up a wastewater treatment plant can be straightforward, cost-effective, and even profitable in the long run.

This guide breaks down the key decisions, requirements, and actionable steps to get your WWTP project off the ground—whether you’re in real estate, manufacturing, hospitality, or education.

Step 1: Understand Your Wastewater Type

Before choosing any equipment or consultant, you need to analyze your wastewater source and characteristics.

Key Parameters to Test:

- BOD (Biological Oxygen Demand)

- COD (Chemical Oxygen Demand)

- TSS (Total Suspended Solids)

- TDS (Total Dissolved Solids)

- pH and temperature

- Fats, oils, greases (FOG)

🧪 Tip: Conduct a 7-day composite sample test with a NABL-accredited lab.

Step 2: Choose the Right Type of Treatment System

Match your wastewater profile with the most suitable process. Here’s a quick guide:

| Scenario | Recommended System |

|---|---|

| Small residential society (50–100 homes) | SBR or MBBR with tertiary polishing |

| Small-scale factory with oils & greases | ETP with grease trap + ASP |

| College or hotel with water reuse goals | MBBR + UV + RO |

| Space-constrained urban site | MBR (Membrane Bioreactor) |

| Cluster of small industries | CETP with shared governance |

Step 3: Get Regulatory Approvals

In most countries (including India and the US), setting up a WWTP requires multiple approvals:

For India:

- Consent to Establish (CTE) and Consent to Operate (CTO) from State Pollution Control Board

- Environmental Impact Assessment (EIA) if capacity exceeds threshold

- Water reuse/discharge NOC

- Sludge disposal compliance (often through approved TSDF)

⚠️ Non-compliance can result in plant closure or legal penalties under the Water Act, 1974 and Environment Protection Act, 1986.

Step 4: Select a Trusted Vendor or Consultant

Don’t just go with the cheapest quote. Evaluate based on:

- Proven installations (ask for site visits)

- Service availability (AMC support)

- Technology clarity (customized design, not off-the-shelf)

- SCADA compatibility for automation

- After-sales support

Questions to Ask Vendors:

- Can you show a live plant with similar wastewater?

- What’s your O&M plan?

- Do you offer performance guarantees?

- What’s the sludge handling strategy?

Step 5: Plan for Space, Utilities, and Civil Works

Typical space needed for WWTPs (per KLD capacity):

| Technology | Approx. Space per KLD |

|---|---|

| SBR | 0.4–0.6 sq. m |

| MBBR | 0.2–0.4 sq. m |

| MBR | 0.15–0.25 sq. m |

Also consider:

- Electrical panel room

- Sludge drying beds or dryer area

- Treated water storage

- Chemical dosing room (covered and ventilated)

Step 6: Plan for Automation & Monitoring

Even a 20 KLD plant can benefit from:

- DO (Dissolved Oxygen) meters

- pH & ORP sensors

- Flow meters

- Remote SCADA/PLC monitoring

- Cloud-based alarms for system faults

Automation doesn’t just reduce human error—it also helps you stay compliant with real-time data logs.

Step 7: Think Sludge, Not Just Water

New plant owners often overlook this.

All the contaminants you remove from water end up as sludge. Without proper handling, sludge becomes a legal and operational nightmare.

Basic Sludge Management Setup:

- Sludge thickener (for volume reduction)

- Sludge dewatering unit (filter press or decanter)

- Paddle dryer or solar dryer for drying and safe disposal

- Storage bunker for dried sludge

Dried sludge can be sent to:

- Authorized TSDFs

- Brick kilns (if fuel grade)

- Composting (if biodegradable and non-toxic)

Step 8: Maintenance, Training & AMC

After installation, ensure:

- Monthly operator training

- Standard Operating Procedures (SOPs) displayed onsite

- Annual Maintenance Contract (AMC) with your vendor

- Emergency SOPs for power cuts, high ammonia, pump failures

🧠 Expert Advice: Choose vendors who offer O&M services or connect you with local, trained operators.

Bonus Tips for Beginners

- Include a bypass line during installation—useful for maintenance.

- Allocate budget for chemical dosing tanks and neutralizing agents.

- Document everything—from influent characteristics to maintenance logs.

- Always add an inlet screening unit (bar screen, grease trap, grit chamber).

- Never ignore the odour control unit (OCU), especially for hotels and schools.

Your First WWTP Doesn’t Have to Be Perfect — But It Must Be Purpose-Built

Whether your goal is regulatory compliance, water reuse, green building certification, or cost savings—a wastewater treatment plant is no longer optional.

It’s a long-term investment in your facility, your community, and the planet.

FAQs About Wastewater Treatment Plants

1. What is a wastewater treatment plant used for?

A wastewater treatment plant removes contaminants—like solids, bacteria, chemicals, and nutrients—from used water, making it safe to release into the environment or reuse for non-potable applications such as irrigation, flushing, or industrial processes.

2. What are the 3 main stages of wastewater treatment?

The three main stages are:

- Primary Treatment – Settles solids and removes floatables

- Secondary Treatment – Uses microorganisms to degrade organics

- Tertiary Treatment – Polishes water by removing nutrients, pathogens, and dissolved solids

3. How does a wastewater treatment plant work?

A wastewater treatment plant processes sewage through mechanical screening, sedimentation, biological degradation, and chemical polishing. It separates solids, breaks down organic matter, kills pathogens, and treats water to meet environmental or reuse standards.

4. Can treated wastewater be reused?

Yes. Treated wastewater can be reused for gardening, toilet flushing, industrial cooling, construction, and even groundwater recharge. With tertiary treatment, it can meet stringent quality standards for safe, non-potable reuse.

5. What is the cost of setting up a wastewater treatment plant?

Costs vary by capacity and technology:

- Small (20 KLD): ₹8–15 lakhs

- Medium (100 KLD): ₹30–60 lakhs

- Large (1 MLD+): ₹1–3 crores

Recurring expenses include electricity, chemicals, operator salaries, and AMC.

6. What is the difference between an ETP and STP?

An ETP (Effluent Treatment Plant) treats industrial wastewater with complex chemicals, while an STP (Sewage Treatment Plant) handles domestic sewage from homes and offices. ETPs often use chemical and advanced processes, while STPs rely more on biological treatment.

7. What happens to sludge from wastewater treatment?

Sludge is dewatered, dried, and either composted, incinerated, or used as fuel in boilers or cement kilns. Proper sludge treatment prevents environmental hazards and allows safe disposal or resource recovery.

Conclusion: Wastewater Treatment Isn’t Optional — It’s Essential

In a world facing growing water stress, climate instability, and rising regulatory pressure, treating wastewater is no longer just an environmental checkbox—it’s a strategic necessity.

From municipal sewage to complex industrial effluent, wastewater treatment plants (WWTPs) are the silent engines of public health, sustainability, and resource recovery. Whether you’re a city planner, a plant operator, a factory owner, or a responsible citizen, investing in proper wastewater treatment protects:

- Your business continuity

- Your community’s well-being

- And the future of clean water access

Let’s quickly recap what we’ve learned:

- WWTPs use a multi-stage process (primary → secondary → tertiary → sludge handling) to clean contaminated water.

- There are different types of plants (STPs, ETPs, CETPs, decentralized systems)—each tailored to specific needs.

- Tertiary treatment, automation, and sludge management are not luxury upgrades—they’re modern necessities.

- Real-world success stories, like Chennai’s TTRO plants, show how recycled water can power cities and industries.

- With the right guidance, even beginners can plan and operate a compliant, cost-effective, and sustainable WWTP.

Now It’s Your Turn

Are you planning to set up a treatment plant for your business, society, or facility?

Still unsure whether a septic tank is enough or if a full WWTP is the smarter choice?

We’re here to help.

Drop your questions in the comments or contact our expert team for a no-obligation consultation.

Want to explore energy-efficient sludge drying solutions? Check out our blog on paddle dryers for sludge management.

Water is life—don’t let yours go to waste.