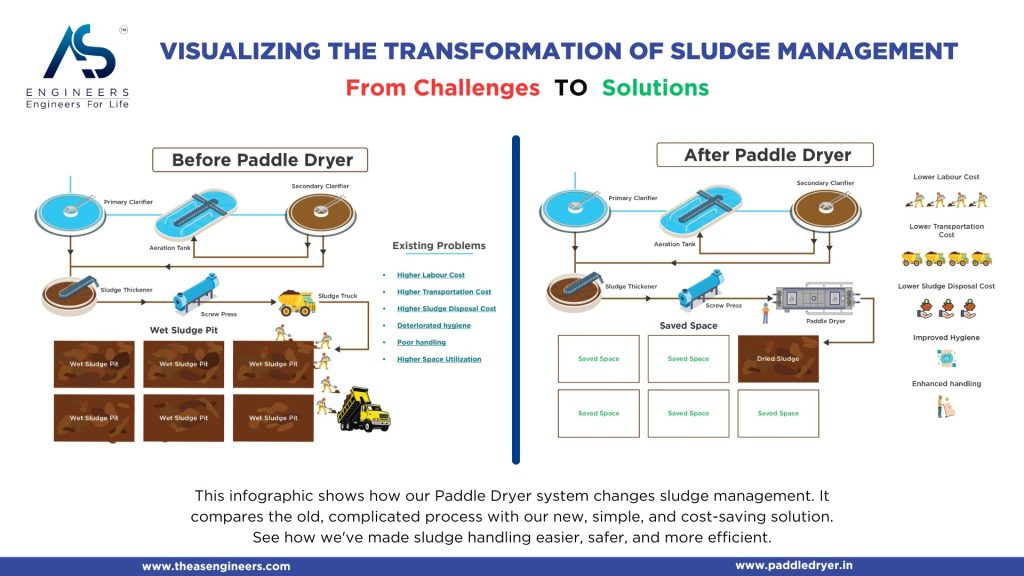

Have you ever wondered how facilities deal with the mountains of wet sludge that come from wastewater treatment processes or industrial operations? Sludge dryers are the answer. They turn water-laden, semi-solid waste into a manageable material that you can store, transport, and reuse more easily. By focusing on sludge dryers early in your waste management plan, you set yourself up for cost savings, regulatory compliance, and a more sustainable future.

In this guide, you will discover the ins and outs of sludge dryers (paddle dryer) systems—how they work, their various types, and the best practices for getting the most out of them. Whether you manage a municipal wastewater plant or you work in a heavy industry setting, this article will show you how to optimize your sludge drying technology for maximum efficiency. Let’s dive in!

Understanding Sludge Dryers and Their Role in Industry

Sludge is the byproduct of many treatment processes, ranging from sewage treatment plants to chemical manufacturing operations. Because sludge often contains high moisture content, it poses several challenges:

- High volume: Wet sludge occupies more space in landfills or storage facilities.

- Additional transport costs: Water adds weight, which increases shipping costs.

- Regulatory constraints: Many regions enforce strict disposal requirements that demand thorough moisture reduction.

Sludge dryers solve these problems by reducing moisture content. They involve heat transfer methods that evaporate water within the sludge, leaving behind a solid material that is easier to handle, cheaper to transport, and safer to dispose of or reuse. Through this transformation, industries can meet environmental regulations more easily, lower their energy consumption in the broader disposal chain, and potentially repurpose the dried byproduct.

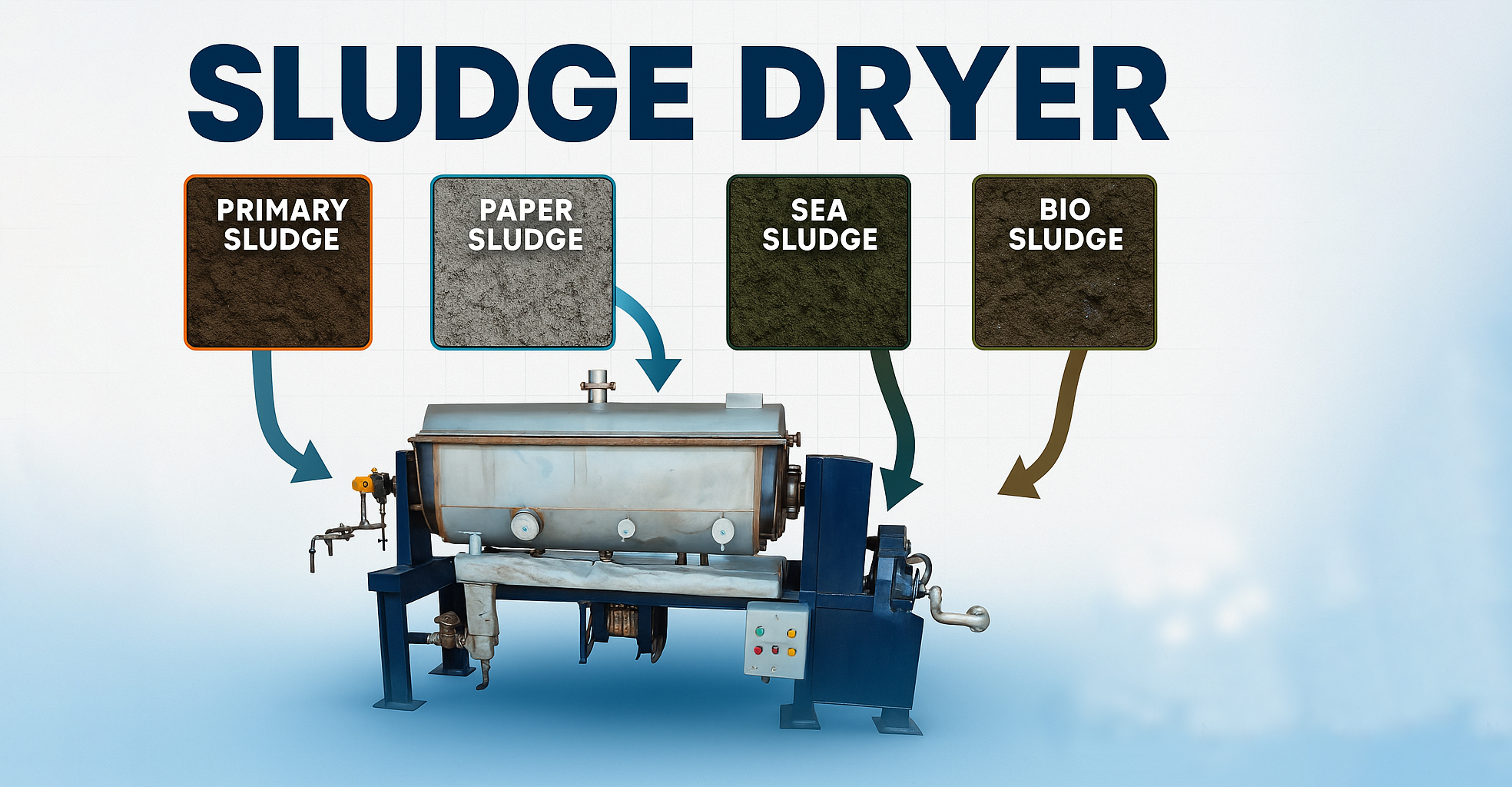

Types of Sludge Dryers

Understanding different sludge dryer types is crucial. Each one suits specific sludge characteristics, plant footprints, and budget constraints. Although you’ll find numerous drying methods on the market, the following four types dominate in various industries.

1. Paddle Dryer

The paddle dryer—often called the backbone of sludge drying technology—relies on rotating paddles that stir and agitate sludge continuously. The paddles reside inside a horizontal cylindrical shell, which might use steam, thermal oil, or hot water to heat the paddles’ surfaces. Here’s why paddle dryers are so popular:

- Consistent Heat Transfer: The paddles keep the sludge in close contact with hot surfaces, which ensures uniform drying.

- Compact Footprint: Paddle dryers typically require less space than other types because they achieve high throughput in a smaller area.

- Versatile Energy Sources: You can heat a paddle dryer with steam, hot water, or thermal oil, giving you flexibility based on your existing resources.

- Low Odor Emissions: The closed design and controlled environment reduce odors and emissions.

In most setups, paddle dryers can handle a wide range of sludge types, including municipal, industrial, and chemical sludge. Because they offer precise heat control, they minimize any risk of overheating or altering sludge properties in undesirable ways.

2. Belt Dryer

Belt dryers move sludge on a conveyor belt through a stream of hot air. The primary heat source can range from burning natural gas to waste heat from other processes. Industries often choose belt dryers when they want:

- Gentle Drying: Belt dryers operate at relatively lower temperatures, which preserves sludge properties and lowers the risk of dust or harmful emissions.

- Scalability: You can expand or shrink the belt length based on your throughput needs.

- Visibility and Control: Belt dryers allow operators to observe the drying process and make real-time adjustments to belt speed or temperature.

However, belt dryers require more space compared to paddle dryers, and they typically involve higher initial costs. You also need to manage airflow, dust collection systems, and regular belt maintenance.

3. Fluidized Bed Dryer

The fluidized bed dryer uses hot air—or another gas—to suspend and “fluidize” sludge particles. Picture a bubbling fluid where hot air moves upward, creating intense contact between the sludge and heat source. Key benefits include:

- Rapid Drying: Constant contact between hot air and sludge leads to faster moisture evaporation.

- Uniform Treatment: Each sludge particle experiences the same drying conditions, which prevents uneven moisture levels.

- Continuous Operation: You can run fluidized bed dryers around the clock.

- Effective Heat Recovery: Many systems recirculate hot air to conserve energy.

Despite its efficiency, a fluidized bed dryer can demand higher capital costs and more advanced operational know-how. You also need to pre-treat or size sludge properly to ensure effective fluidization.

4. Rotary Dryer

A rotary dryer features a large, rotating drum that tumbles sludge while hot gas circulates inside. Common in heavy industries such as mining, it’s a flexible choice for large-scale sludge volumes. Important features of rotary dryers include:

- Versatility: Rotary dryers can accommodate various materials, from sludge to minerals.

- Robust Design: They handle abrasive or coarse sludge without significant wear and tear.

- Easy Scalability: You can install larger drums or operate multiple drums in parallel for higher capacity.

However, rotary dryers can be bulky and consume more space. If your plant sits on limited real estate, you might opt for a more compact design like a paddle dryer.

How Sludge Drying Technology Works

Sludge drying technology revolves around the principle of heat transfer. You introduce heat to the wet sludge through direct or indirect methods, triggering evaporation. The vapor then moves to a condenser or a venting system, leaving a dry, solid product behind. Here’s a simplified breakdown:

- Sludge Input: A feed system loads wet sludge into the dryer.

- Heating: In direct methods, hot air directly contacts the sludge. In indirect methods, a heated surface (like a paddle) transfers thermal energy without direct airflow.

- Moisture Evaporation: Moisture rises as vapor and then exits through an exhaust or collection system.

- Dust and Odor Control: Many setups incorporate cyclones, scrubbers, or bag filters to manage particulates and smells.

- Discharge: Once dried, the sludge exits the system. Operators can then pack it, store it, or repurpose it for agricultural applications or as a fuel supplement.

Energy Consumption and Efficiency Tips

Energy usage remains a crucial factor in sludge drying. High temperatures are necessary, and the process can become expensive if you don’t optimize it. Below are key strategies to lower energy consumption:

- Pre-Dewatering: Reduce moisture before drying by using mechanical dewatering methods such as centrifuges or belt presses. A lower moisture content means less energy for evaporation.

- Heat Recovery Systems: Capture the hot air leaving the dryer and reuse it. Heat exchangers or regenerative thermal oxidizers can reclaim much of the thermal energy.

- Automation and Monitoring: Use sensors to track temperature, moisture levels, and airflow. Automated controls can adjust these variables in real-time to maintain optimal conditions.

- Regular Maintenance: Clean heat transfer surfaces and replace damaged parts to ensure maximum efficiency. A buildup of sludge on paddles or belt surfaces reduces heat transfer.

- Right-Sizing the Equipment: Avoid oversizing or undersizing the dryer. A correctly sized dryer runs closer to its design capacity, which improves efficiency.

Best Practices for Effective Sludge Drying

Drying sludge isn’t only about heat; it’s also about handling, safety, and compliance. Here are proven best practices:

- Understand Your Sludge Characteristics: Analyze the sludge’s chemical composition, moisture content, and potential for toxic emissions. Choose a dryer type that aligns with these characteristics.

- Invest in Proper Training: Dryer operators need practical experience and training. They must know how to troubleshoot temperature fluctuations, adjust flow rates, and maintain the equipment daily.

- Maintain Cleanliness: Residual sludge can coat internal surfaces and paddles, reducing heat transfer. Implement a strict cleaning schedule to avoid buildup.

- Plan for Odor Control: Use sealed systems, activated carbon filters, or thermal oxidizers to manage odors. Nearby communities may complain if you ignore smell management.

- Check Local Regulations: Many regions enforce rules on sludge disposal, air emissions, and workplace safety. Stay informed and apply for the right permits.

- Adopt a Lifecycle Approach: Evaluate the long-term operational costs (maintenance, energy, workforce training) rather than just focusing on the initial equipment purchase. This perspective saves you time and money in the long run.

Common Misconceptions About Sludge Dryers

Misconception 1: Sludge Dryers Always Require Huge Budgets

While some industrial dryers have hefty price tags, you can find cost-effective paddle dryers or belt dryers that match smaller-scale operations. Financing options and government incentives may also offset initial costs.

Misconception 2: Dryer Output is Always Waste

Dried sludge often finds a second life in agriculture as a soil amendment or in certain industrial processes as a low-grade fuel. With the right treatments and certifications, dried sludge can become a valuable resource.

Misconception 3: Sludge Dryers Use Excessive Energy

Yes, sludge drying can consume significant energy, but modern systems optimize heat exchange and recirculation. Pre-dewatering and energy recovery technology slash costs and environmental impact.

Misconception 4: All Sludge is the Same

Sludge varies in composition, particle size, and moisture levels. A dryer designed for municipal sewage sludge might not suit chemical sludge with toxic compounds. You must choose equipment based on actual sludge properties.

Frequently Asked Questions (FAQs)

1. Can I use the same sludge dryer for different types of sludge?

Yes, but you need to verify compatibility. Paddle dryers can handle many sludge varieties, but certain chemical or biological properties may require specialized materials or temperature controls. Consult the dryer’s manufacturer for guidance on multi-type usage.

2. How do I handle odors during the sludge drying process?

Odor control measures include sealing the dryer, using activated carbon filters, or directing exhaust gases to thermal oxidizers. Some plants also install air scrubbing systems to capture foul-smelling compounds before they escape.

3. What should I do with the dried sludge?

Many facilities send dried sludge to landfills because it meets lower-volume disposal requirements. Others use it in agriculture as a soil conditioner, provided it meets environmental standards. In some cases, industries burn it as a supplementary fuel source.

4. How long does it take to dry sludge in a paddle dryer?

Drying time depends on sludge moisture content, dryer capacity, and operating temperatures. In general, a paddle dryer can process high-moisture sludge in a few hours. More advanced setups with higher temperatures or smaller volumes can shorten that timeline.

5. Is sludge drying technology environmentally friendly?

Sludge drying technology can be eco-friendly if you implement energy recovery, odor control, and strict emission guidelines. By reducing transportation needs and converting sludge into a reusable resource, you minimize your environmental footprint.

Conclusion: Your Next Steps in Sludge Drying

Sludge dryers stand as a crucial component in modern waste and byproduct management. From paddle dryer systems that offer compact yet powerful drying to belt dryers that cater to large-scale operations, you have a range of choices. Each dryer type brings unique advantages—whether it’s efficient heat transfer, simplified handling, or gentle drying temperatures.

After you weigh the pros and cons, consider your energy sources, sludge characteristics, and compliance requirements. Always invest in robust training, strong maintenance protocols, and thorough pilot testing. That approach ensures your sludge drying technology runs at peak performance and delivers a tangible return on investment.

What do you think about transforming sludge from a sticky waste product into a reusable resource? Share your thoughts or experiences with sludge dryers below! If you’re ready to dive deeper, explore our other resources on sustainable waste management and discover how strategic choices in sludge drying can lead to lower costs, fewer emissions, and a greener future.