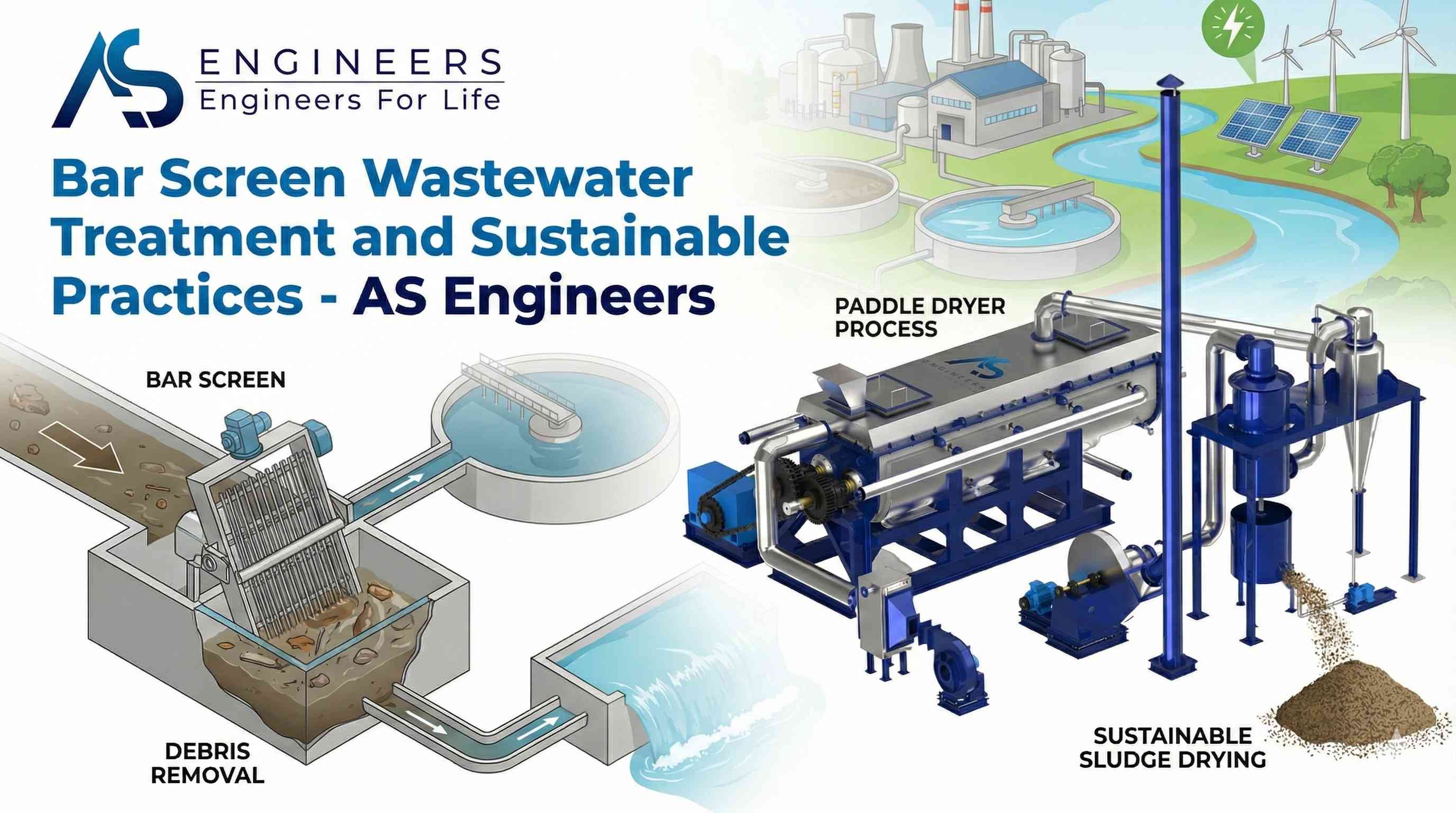

Welcome to the essential world of wastewater treatment. Every day, industrial and municipal facilities produce vast amounts of wastewater that must be cleaned before it can be safely returned to the environment. This process is complex, involving multiple stages to remove pollutants and solids. The very first step in any modern wastewater treatment plant is screening, a critical phase that sets the foundation for all subsequent treatments. Let’s explore how this initial stage works and its importance for the entire system.

Table of contents

Key Highlights

Here are the key takeaways from our guide on bar screens and sustainable practices:

- Bar screens are the first line of defense in wastewater treatment, removing large solid waste.

- They protect essential downstream equipment from clogging and damage.

- The main types include manual and mechanical bar screens, each suited for different applications.

- Proper bar spacing is crucial for balancing filtration efficiency with water flow.

- Sustainable practices extend to sludge disposal, where paddle dryers offer a superior solution.

- Effective industrial wastewater treatment relies on quality equipment from initial screening to final disposal.

Understanding Bar Screens in Wastewater Treatment

So, what exactly is a bar screen? Think of it as a large, heavy-duty mechanical filter placed at the very beginning of the wastewater treatment process. Its job is to catch large objects and debris before they can enter the main facility. This simple yet effective tool is fundamental to keeping the entire system running smoothly.

These screens are used to protect more sensitive and expensive equipment downstream. By filtering out large items right away, bar screens prevent clogs and mechanical failures in pumps, pipes, and other machinery. This makes them a vital component in any effective wastewater treatment operation.

Purpose and Importance of Bar Screens

The primary purpose of bar screens is to serve as the first line of defense for a wastewater treatment plant. As wastewater enters the facility, it carries a mix of liquids and solids. Bar screens are strategically placed to intercept the large solid waste before it can cause any trouble. This includes everything from sticks and rags to plastics and other debris.

By removing these materials early, bar screens provide essential protection for all downstream equipment. Pumps, valves, and pipelines are susceptible to damage and clogging from large objects. Preventing these issues not only saves on costly repairs and downtime but also ensures the plant operates efficiently without unexpected interruptions.

Ultimately, the importance of bar screens lies in their ability to improve the overall process. When large solids are removed at the start, the subsequent treatment stages can function more effectively. This ensures a smoother, more reliable wastewater treatment process from beginning to end.

Materials and Debris Removed by Bar Screens

You might be surprised by what ends up in our wastewater systems. Bar screens are designed to capture a wide variety of large objects and coarse solids that could wreak havoc on a treatment facility. Their main job is to filter out any significant solid waste that has found its way into the water flow.

The most common types of large debris removed by coarse bar screens include:

- Rags and cloths

- Paper and cardboard

- Plastics and wrappers

- Wood, sticks, and leaves

- Metal objects

While coarse screens handle the bigger items, some systems also use fine screens to capture smaller materials like hair and fibers. By removing this range of debris, bar screens ensure that only water and smaller, more manageable solids move on to the next stage of treatment.

Types of Bar Screens Used in Indian Wastewater Plants

Not all bar screens are created equal. Depending on the size of the wastewater treatment plant and the volume of debris, different types of bar screens are used across various industrial applications in India. The two main categories are manual and mechanical screens, each with its own set of advantages for specific situations.

Choosing the right type is essential for operational efficiency. While some smaller plants might find a manual screen sufficient, larger facilities with high flow rates benefit from automated mechanical systems. Let’s look at the key differences between these options.

Coarse vs. Fine Bar Screens

One of the most important distinctions between bar screens is whether they are “coarse” or “fine.” This classification is based on the spacing between the bars, which determines the level of filtration. A coarse bar screen has wider gaps and is designed to remove large debris, while fine screens have smaller openings to capture smaller particles.

The choice depends on the specific needs of the wastewater treatment plant. Coarse screens are excellent for the initial removal of bulky items, while fine screens provide a more thorough filtering process, often used to catch things like hair and fibers that can pass through wider gaps.

Here’s a simple breakdown of their differences:

| Feature | Coarse Bar Screen | Fine Bar Screen |

|---|---|---|

| Purpose | Removes large objects like rags, wood, and plastics. | Removes smaller debris like hair, fibers, and fine solids. |

| Bar Spacing | Wider (typically 6 mm and above). | Narrower (less than 6 mm). |

| Application | Primary screening in most wastewater plants. | Secondary screening or in applications with fine debris. |

Mechanical Bar Screens and Their Operation

For larger facilities with high flow rates, mechanical bar screens are the go-to solution. Unlike their manual counterparts, these systems automate the cleaning process, eliminating the need for constant manual intervention. This automation ensures that the screen remains clear and that water can flow without obstruction.

How do they work? A mechanical bar screen often uses a multi-rake screen mechanism. As debris accumulates on the bars, a series of rakes moves upwards, scraping the solids off the screen. The collected waste is then typically deposited onto a conveyor system, which transports it to a collection bin for disposal.

This continuous, automated operation makes mechanical screens highly efficient. They can handle large volumes of wastewater and debris with minimal labor, reducing operational costs and improving the overall productivity of the treatment process. This makes them ideal for both large municipal and industrial plants.

Working Mechanism of Bar Screens

The working mechanism of bar screen wastewater treatment is straightforward but highly effective. At its core, a bar screen acts as a physical barrier or mechanical filter. It consists of a series of inclined vertical bars placed directly in the path of the incoming water flow.

As wastewater passes through, the gaps between the bars allow water and smaller particles to continue into the plant. However, larger solid materials are blocked by the bars and accumulate on the screen’s surface. From there, the debris is removed, either by hand or by an automated system, to keep the screen from clogging.

Bar Spacing and Its Impact on Efficiency

The design of a bar screen, particularly the bar spacing, has a direct impact on its performance. The distance between each vertical bar determines what gets caught and what passes through. Closer spacing results in high separation efficiency, as it can capture smaller pieces of debris.

However, there’s a trade-off to consider. Tightly spaced bars can become clogged more quickly, which increases head loss the pressure difference before and after the screen. This can slow down the flow rate and require more frequent cleaning. If the spacing is too wide, larger debris might slip through, defeating the screen’s purpose.

Finding the right balance is key. The ideal bar spacing depends on the characteristics of the wastewater, the expected volume of solids, and the plant’s overall design. The goal is to maximize debris removal without creating a bottleneck in the system.

Bar Screen Chambers: Structure and Function

A bar screen isn’t just placed randomly in the water; it’s housed within a specially designed structure known as a bar screen chamber. This chamber is essentially a channel that directs the entire flow of wastewater through the screen, ensuring that no water bypasses the filtration process.

The design of this chamber is critical and is tailored to the specific needs of the facility. Engineers consider factors like the channel’s width and depth, the expected water level, and the overall site conditions. The structure must be robust enough to handle the constant flow and pressure of the wastewater.

In essence, the bar screen chamber provides the framework that allows the screen to do its job effectively. It ensures that all incoming water is properly screened, setting the stage for the rest of the treatment process to function as intended.

Sustainable Sludge Drying Solutions by AS Engineers

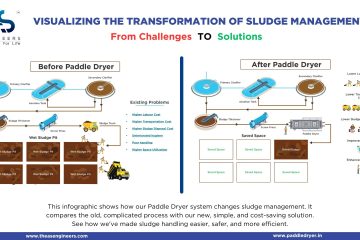

After solids are removed, what happens to the accumulated waste, or sludge? Sustainable sludge disposal is a growing concern for any wastewater treatment plant. Simply sending it to a landfill is becoming less viable and more expensive. A more forward-thinking approach is to process the sludge on-site, reducing its volume and creating a more manageable end product. This is where sustainable sludge drying comes into play.

For effective sludge management, the paddle dryer is the best technology available. It offers a highly efficient and environmentally friendly method for drying sludge. As a leading manufacturer of this advanced equipment, AS Engineers provides robust paddle dryers designed for demanding industrial wastewater treatment applications, helping you close the loop on your waste management cycle.

The Paddle Dryer Advantage for Sludge Disposal

Choosing the right method for sludge disposal is crucial, and the paddle dryer offers significant advantages over traditional techniques. This technology uses a unique mechanism to dry sludge efficiently, making it a cornerstone of modern sustainable practices in waste management. It significantly reduces the volume of waste, which in turn lowers disposal and transportation costs.

Many industrial plants are turning to the paddle dryer because it is not only effective but also economical. By reducing maintenance costs and improving processing times, it delivers a strong return on investment. The key benefits include:

- High thermal efficiency for faster drying

- Compact design that saves valuable plant space

- Low operational and maintenance costs

- Environmentally friendly with minimal emissions

By adopting this technology, you can transform your sludge disposal from a costly problem into a streamlined, manageable process.

Why Choose AS Engineers as Your Paddle Dryer Manufacturer

When investing in critical equipment like a paddle dryer, you need a partner you can trust. AS Engineers stands out as a premier paddle dryer manufacturer, renowned for engineering solutions that last. Our commitment to quality ensures that every unit we produce features durable construction capable of withstanding the rigors of various industrial applications.

Just as bar screens require routine inspections to ensure they function correctly, so does sludge drying equipment. We design our paddle dryers for reliability and ease of maintenance, minimizing downtime and ensuring your operations run smoothly. Our expertise in the field means we understand the unique challenges of wastewater treatment and provide equipment that meets those needs head-on.

Choosing AS Engineers means opting for unparalleled quality, expert support, and a solution built for long-term performance. Let us provide you with a paddle dryer that enhances your plant’s efficiency and sustainability goals.

Frequently Asked Questions

How do bar screens contribute to sustainable wastewater management practices?

Bar screens promote sustainable wastewater management by removing solid waste at the start of the wastewater treatment process. This protects downstream equipment from damage, reducing the need for repairs and replacement parts. This proactive approach conserves resources and energy, making the entire operation more environmentally friendly.

What are the advantages of using bar screens in wastewater treatment facilities?

Using bar screens in wastewater treatment facilities prevents equipment failure by blocking large debris. This significantly lowers maintenance costs and downtime associated with clogged pumps and pipes. By protecting the entire treatment system, they ensure more reliable and efficient long-term operation.

What is bar screen wastewater treatment and how does it work?

Bar screen wastewater treatment is the first line of defense in a treatment plant. It uses a mechanical filter—a screen made of parallel bars—placed in the flow of wastewater. This screen physically blocks large objects from passing through while allowing water to continue to the next treatment stage.

Can bar screen systems be integrated into existing wastewater treatment plants?

Yes, bar screen systems can be integrated into existing wastewater treatment plants. The integration process considers current site conditions and plant layout to ensure a seamless fit. This makes them a versatile solution for upgrading older facilities across many industrial applications.

What are the benefits of using bar screen technology in wastewater treatment?

Bar screen technology offers several benefits in wastewater treatment, including the effective removal of large debris, which prevents clogs and protects equipment. This leads to improved water flow throughout the plant and high separation efficiency, ensuring a smoother and more reliable treatment process.

What maintenance is required for bar screens in a wastewater treatment facility?

Maintenance for bar screens in a wastewater treatment facility includes routine inspections to check for wear and damage. The bars must be cleaned regularly, either manually or automatically, to remove accumulated debris. This proactive care is essential to prevent equipment failure and maintain efficiency.

Can bar screens be integrated with other wastewater treatment processes?

Absolutely. Bar screens are designed to be part of the primary filtration flow and integrate seamlessly with other wastewater treatment processes. They function as the initial step, preparing the wastewater for downstream equipment by providing a crucial first level of filtration.

How does bar screening contribute to sustainable wastewater management practices?

Bar screening contributes to sustainable wastewater management by removing solid waste upfront. This simple action prevents equipment failure and blockages in the wastewater treatment system, leading to a more energy-efficient process with fewer repairs and less waste, making it environmentally and economically sound.

Conclusion

In summary, bar screens play a critical role in wastewater treatment, ensuring efficient removal of debris while supporting sustainable practices. By integrating these systems into your wastewater management processes, you not only enhance operational efficiency but also contribute to environmental conservation.

AS Engineers stands out as a leading manufacturer of paddle dryers, offering innovative sludge drying solutions that complement bar screen technology. With our expertise and commitment to quality, we provide the best sludge disposal methods for your facility. If you’re interested in learning more about how our solutions can benefit your operations, get in touch with us today!