Effective sludge management is a critical challenge for industries and municipal wastewater treatment plants. As disposal costs rise, finding an efficient and sustainable solution is more important than ever. Solar drying presents a powerful alternative, using the sun’s natural energy to reduce sludge volume and moisture content. This guide explores the fundamentals of solar sludge drying, from its working principles to its many advantages. As a leading sludge dryer manufacturer, AS Engineers provides advanced solutions for ETP, STP, and CETP sludge treatment.

Table of contents

- Key Highlights

- Fundamentals of Solar Sludge Drying

- Types of Sludge Suitable for Solar Drying

- Core Components and Structure of a Solar Sludge Dryer

- The Solar Sludge Drying Process Step-by-Step

- Key Factors Influencing Efficiency in Solar Sludge Dryers

- Advantages of Solar Sludge Drying for Indian Industries

- Industries and Applications of Solar Sludge Dryer Technology

- Design and Installation Guidelines for Solar Sludge Dryers

- Common Operational Challenges and Mitigation Strategies

- Future Innovations and Technology Trends

- Frequently Asked Questions (FAQ)

- Conclusion

Key Highlights

- Solar sludge drying uses free solar energy for an eco-friendly drying process, significantly reducing energy costs.

- The technology effectively reduces sludge volume, which lowers transportation and disposal costs.

- Modern solar dryers are enclosed greenhouse structures with automated systems for efficient sludge management.

- The drying process helps in pathogen reduction, making the final dried sludge safer to handle.

- This method supports sustainability in wastewater treatment by minimizing greenhouse gas emissions.

- It is suitable for various sludge types from ETP, STP, and CETP operations.

Fundamentals of Solar Sludge Drying

Solar sludge drying is a technology that leverages the sun as a free and abundant heat source to remove water from wastewater sludge. This method is an energy-efficient alternative to conventional thermal drying, which relies on fossil fuels or other energy-intensive sources. By harnessing solar radiation, the drying process becomes more sustainable and cost-effective.

The core idea is to use a controlled environment, like a greenhouse, to amplify the sun’s heating power. This accelerates water evaporation, transforming wet, heavy sludge into a dry, lightweight material that is easier and cheaper to manage. Below, we’ll examine the specific principles, evolution, and key differences of this technology.

Definition and Working Principle of Solar Sludge Dryer

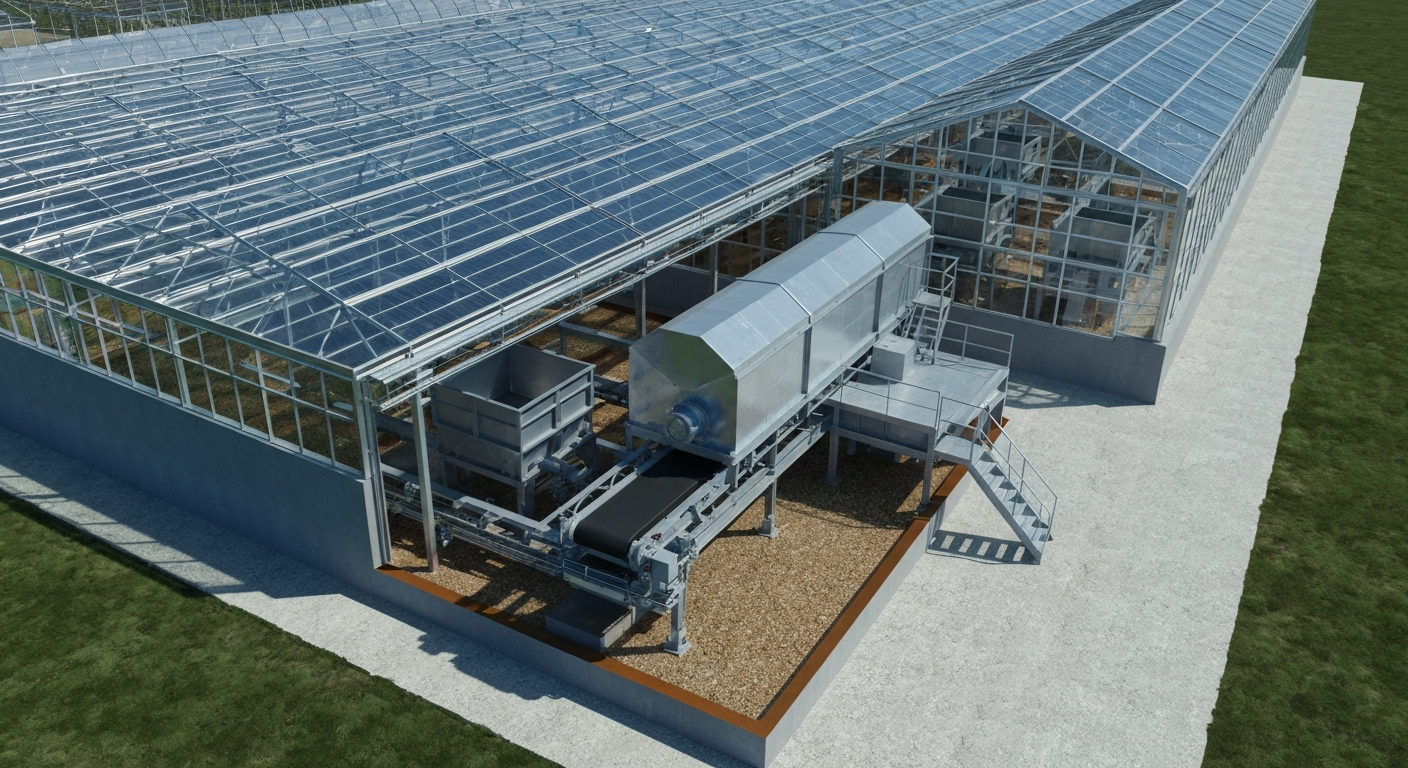

So, what is solar sludge drying and how does it work? A solar sludge dryer is a system designed to use solar radiation to evaporate the water content from dewatered sludge. The process takes place inside a large, enclosed structure, typically a greenhouse with a transparent roof, which traps the sun’s energy and heats the air and the sludge inside.

The working principle is straightforward. Short-wave solar radiation passes through the transparent covering and is absorbed by the dark surface of the sludge, heating it directly. This temperature increase causes water molecules in the sludge to evaporate into the air above it. This phenomenon is known as the greenhouse effect.

An automated ventilation system helps control the climate inside the dryer. It circulates the air to prevent a stagnant layer of moisture from forming over the sludge surface. When the air becomes saturated with moisture, it is exchanged with drier ambient air, ensuring the drying process continues efficiently until the desired dryness is achieved.

Evolution of Solar Sludge Drying Technology

The concept of using the sun for sludge management is not new. For decades, wastewater management facilities have used open sludge drying beds. These early methods involved spreading sludge in open-air beds and letting the sun and wind do the work. However, this approach was slow, weather-dependent, unhygienic, and often produced strong odors.

To improve drying performance, these beds were sometimes covered with glass or plastic sheets to protect them from rain. Operators would also manually turn the sludge to expose wetter layers to the air. While an improvement, this process remained cumbersome and could not consistently achieve high levels of dryness, especially during monsoon seasons.

Modern solar drying plants represent a significant leap forward. Today’s systems, like the HUBER SRT system, are fully enclosed greenhouses with automated machinery for turning, mixing, and aerating the sludge. This continuous movement prevents odor, ensures uniform drying, and allows for year-round operation, transforming a basic concept into a highly efficient and reliable technology.

Key Differences Between Solar and Conventional Sludge Drying

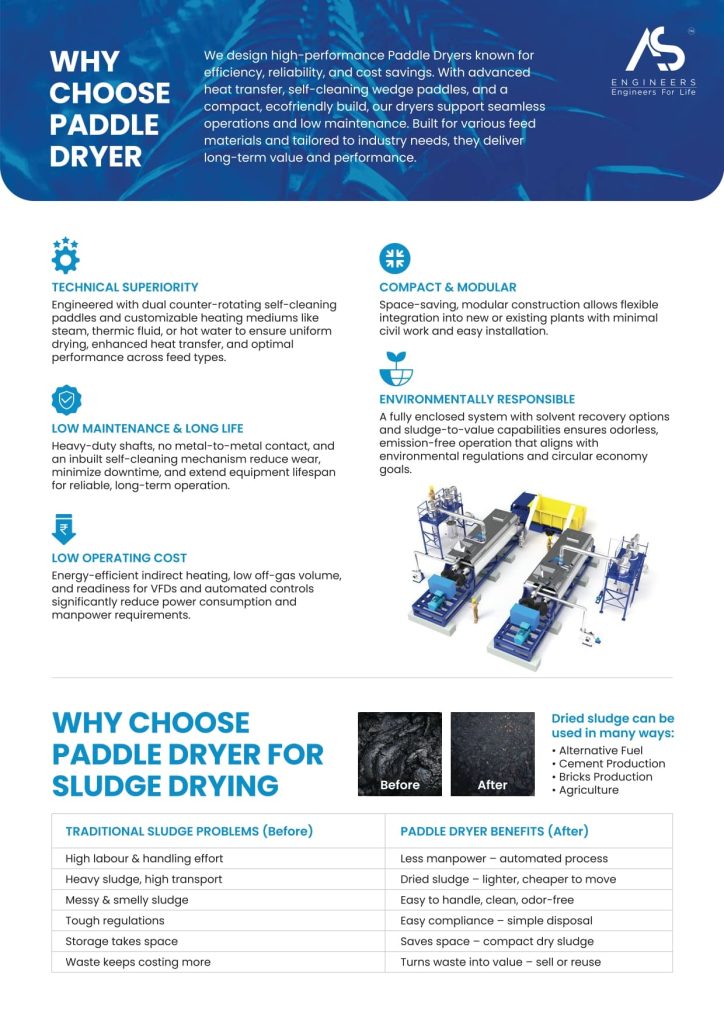

The primary difference between solar and conventional sludge drying lies in the energy source. Solar drying harnesses free, renewable solar energy, while conventional thermal drying methods, such as a Paddle Dryer, rely on fossil fuels, natural gas, or electricity, which are costly and have a larger carbon footprint. This makes solar drying an inherently more sustainable and economical choice.

One of the main benefits of using solar sludge dryers is the drastically lower energy consumption. A conventional thermal dryer might use over 800 kWh to remove one ton of water, whereas a solar dryer requires only 20-30 kWh of electrical power for its mechanical components like fans and sludge turners. This massive reduction in energy use leads to significant operational cost savings.

Furthermore, solar drying operates at lower temperatures over a longer period, which can be beneficial for pathogen reduction. Conventional thermal drying is faster but requires complex equipment and higher capital investment for energy recovery systems to remain efficient.

| Feature | Solar Sludge Drying | Conventional Thermal Drying |

|---|---|---|

| Energy Source | Primary: Solar energy. Secondary: Minimal electricity. | Fossil fuels, natural gas, or electricity. |

| Energy Consumption | Very low (20-50 kWh per ton of water removed). | Very high (over 800 kWh per ton of water removed). |

| Operating Costs | Low, due to free energy source. | High, due to fuel and electricity costs. |

| Environmental Impact | Minimal greenhouse gas emissions. | Significant carbon footprint. |

| Footprint | Requires a larger land area. | More compact footprint. |

| Drying Time | Slower, can take several days. | Faster, completed in hours. |

Types of Sludge Suitable for Solar Drying

Solar sludge drying is a versatile technology capable of treating various types of wastewater sludge. The key requirement is that the sludge can be mechanically dewatered to a certain consistency before it enters the dryer. This pre-treatment step is crucial for optimizing the efficiency of the solar drying process.

Whether the sludge comes from industrial processes or municipal sewage treatment, solar dryers can handle it. The characteristics of the sludge, such as its organic content and initial water content, will influence the drying time and final product, but the fundamental process remains effective. The following sections will detail the specific sludge types treated.

ETP, STP, and CETP Sludge Characteristics

Various types of sludge from different treatment plants can be effectively managed using solar sludge drying systems. Sludge from Effluent Treatment Plants (ETP), Sewage Treatment Plants (STP), and Common Effluent Treatment Plants (CETP) are all suitable candidates for this technology. While their compositions may differ, the goal of reducing water content remains the same.

ETP sludge originates from industrial wastewater and can contain a mix of chemicals, metals, and organic matter specific to the industry. STP sludge, on the other hand, is from municipal wastewater and is primarily organic. CETP sludge is a combination of treated effluents from multiple industrial units. Regardless of the source, the dewatered sludge is a semi-solid material with high moisture content.

For optimal solar drying, the sludge should be mechanically dewatered to a solid content of around 20% or more. This “puncture-resistant” state allows the sludge turning equipment to mix and aerate it effectively. The drying process itself is not dependent on whether the sludge is stabilized or digested, making it a flexible solution for various pre-treatment methods.

Industrial and Municipal Sludge Treated with Solar Sludge Dryers

Both industrial sludge and municipal sewage sludge are commonly treated using solar sludge dryers. For industries, managing sludge from their ETPs is a significant operational cost. By using a solar dryer, they can dramatically reduce the sludge volume, which in turn cuts down on the high costs associated with transporting and disposing of this waste at certified landfill sites.

Municipalities face a similar challenge with the large quantities of sewage sludge produced by STPs. Solar drying provides an economical and environmentally friendly way to manage this public waste stream. The process significantly reduces the mass of the sludge, making handling and final disposal more manageable and less expensive.

Inside the drying chamber, the process is the same for both types. The sludge is spread out and regularly turned to facilitate evaporation. The final dried product, a granulate with a high solids content, is easy to store and transport. This makes solar drying a practical solution for any facility generating large volumes of wet sludge.

Core Components and Structure of a Solar Sludge Dryer

A modern solar sludge dryer is much more than just a covered bed. It is an engineered system with several key components working together to maximize drying efficiency. The main element is the greenhouse structure, or drying hall, which is designed to trap solar heat and protect the sludge from the elements.

Inside this structure, a sophisticated system manages the sludge and controls the environment. This includes mechanisms for spreading and turning the sludge, as well as a ventilation system to manage air flow and humidity. Let’s look closer at how these components are designed and how they function.

Solar Greenhouse Design and Material Selection

A typical solar sludge dryer is designed as a large greenhouse structure. Its key components include a transparent roof and walls, a concrete floor, a sludge turning mechanism, and a ventilation system. The design prioritizes maximizing the capture of solar energy while protecting the process from external weather conditions like rain.

The material selection is critical for a durable and efficient greenhouse structure. The building envelope, or covering, must be made of a transparent material that allows short-wave solar radiation to pass through but traps the resulting heat. Options include specialized polythene films or glass, chosen for their durability and light transmission properties. The frame itself is often made of sturdy, corrosion-resistant materials like stainless steel to withstand the humid internal environment.

Proper design also includes features that optimize drying performance. For instance, the orientation of the greenhouse can be planned to maximize sun exposure throughout the day. The floor is typically a solid concrete slab that supports the sludge and the turning machinery, ensuring a stable and reliable base for the entire operation.

Conveyance, Mixing, and Turning Mechanisms

The heart of an active solar drying system is the automated sludge turner. This machine is crucial for achieving optimal drying. It travels the length of the drying hall, performing several functions: distributing fresh sludge, mixing the existing sludge bed, and conveying the drying material toward the discharge end.

The purpose of continuous mixing is to break up the drying sludge surface and bring wetter particles from below to the top. This regular aeration creates a loose, wave-like sludge bed with a massive evaporation surface. It also keeps the sludge in an aerobic state, which is vital for preventing the development of bad odors.

This unique turning and transporting method ensures that every part of the sludge is evenly exposed to the warm, dry air. By constantly restacking and aerating the material, the sludge turner prevents the formation of a dry crust that would otherwise slow down the drying process. This ensures consistent and efficient moisture removal from the entire sludge volume.

The Solar Sludge Drying Process Step-by-Step

The solar sludge drying process is a systematic journey that transforms wet, heavy sludge into a dry, manageable product. This journey begins long before the sludge enters the solar dryer and involves several carefully controlled stages to ensure maximum efficiency and a high-quality final output.

From initial pre-treatment to the final removal of dried granules, each step plays a vital role. The process combines mechanical dewatering with the natural power of the sun in a controlled environment. Let’s break down the key stages involved in the drying of sewage sludge using solar technology.

Pre-Treatment and Sludge Loading

The first step in the solar drying process is pre-treatment, specifically mechanical dewatering. Before being loaded into the solar dryer, the wet sludge, which is mostly water, undergoes sludge dewatering using equipment like centrifuges or filter presses. This process removes a significant amount of free water, increasing the solid content from just a few percent to around 20% or more.

This pre-treatment step is essential for efficiency. Loading sludge with a higher initial solids content means less water needs to be evaporated in the dryer, which reduces the required drying area and time. For example, drying sludge with 20% solids requires about five times less drying area than sludge with only 5% solids to achieve the same final dryness.

Once dewatered, the sludge is fed into the drying hall. It is then spread evenly across the sludge bed by the automated turning and conveying system. It is best to load the sludge directly from the dewatering equipment to prevent it from being stored for long periods, which can lead to anaerobic conditions and bad odors.

Solar Energy Absorption, Moisture Removal, and Final Output

Once the sludge is spread inside the greenhouse, the main drying process begins. The dark surface of the sludge absorbs the solar energy that penetrates the transparent roof. This heat increases the temperature of the sludge, causing the water within it to turn into vapor. This water evaporation is the core mechanism of moisture removal.

To keep the process going, a ventilation system manages the air inside. Fans circulate the air, preventing a humid layer from settling over the sludge. As the indoor air becomes saturated with moisture, vents open to release it, drawing in drier outside air. This constant air exchange ensures that the environment remains ideal for continuous evaporation.

Over time, this process systematically reduces the water content of the sludge. The sludge slowly transforms from a wet cake into a dry, granular material with a high percentage of dry solids (often 90% or more). This final output is significantly lighter and smaller in volume, making it easy to handle, store, and transport for final disposal or reuse.

Key Factors Influencing Efficiency in Solar Sludge Dryers

The efficiency of a solar sludge dryer is not constant; it depends on several key factors. Since the primary energy source is the sun, climate conditions play the most significant role in determining the drying performance. The amount of available solar radiation directly impacts how quickly moisture can be removed.

However, external weather is not the only variable. The properties of the sludge itself and the way the plant is operated also have a major influence on the overall effectiveness of the system. Understanding these factors is crucial for designing and running a solar dryer at its peak potential.

Climate Conditions and Site Selection

Climate conditions are the most critical factor affecting the efficiency of solar sludge drying. The amount and intensity of solar radiation available at a site directly determine the energy input for the drying process. Regions with high solar irradiance and clear skies will naturally have a much higher water evaporation capacity than cooler, cloudier areas.

The ambient temperature and humidity also play a role. The greenhouse effect works best when there is a significant temperature difference between the inside and outside. The system’s ability to exchange humid indoor air for drier outdoor air is also essential. Drying is faster on sunny, dry days and slower during rainy or overcast periods.

Because of this strong dependence on weather conditions, proper site selection is vital. A successful solar drying plant must be located in an area that receives adequate sunlight year-round. While the system can operate in winter and at night, its performance is significantly enhanced by direct sunshine, which accelerates the entire process.

Sludge Properties and Operational Protocols

Beyond climate, the sludge properties themselves have a major impact on drying efficiency. The initial moisture content of the sludge after mechanical dewatering is a key parameter. Sludge that enters the dryer with a higher solids content (e.g., 20-25%) will dry much faster and require less space than sludge with a low solids content (e.g., 5%).

The physical and chemical composition of the sludge also matters. Factors like particle size, organic content, and whether the sludge is stabilized or digested can influence how it behaves during drying. For instance, some sludges may form granules more easily, which aids in aeration and moisture removal.

Finally, operational protocols are crucial for maximizing volume reduction while minimizing energy consumption. The frequency of turning, the depth of the sludge bed, and the control logic for the ventilation system must be optimized. A well-managed operation ensures the system runs efficiently, prevents odors, and produces a consistently dry final product.

Advantages of Solar Sludge Drying for Indian Industries

For industries across India, managing sludge is a growing financial and environmental concern. The cost of sludge disposal has risen dramatically, making volume reduction a top priority. Solar sludge drying offers a powerful solution that directly addresses these challenges through significant cost savings and improved sustainability.

By using the sun’s free energy, this technology drastically cuts down on energy consumption compared to conventional methods. This leads to lower operating expenses and a smaller carbon footprint, aligning with both economic goals and environmental regulations. Let’s explore these benefits in more detail.

Cost Savings and Reduced Energy Consumption

One of the most compelling advantages of solar sludge drying is the potential for massive cost savings. Since the sun is the primary energy source, the energy consumption required for the drying process is incredibly low. Compared to thermal dryers that consume over 800 kWh per ton of evaporated water, a solar dryer uses only 20-50 kWh for its electrical components.

This drastic reduction in energy use translates directly to low operating costs. With disposal costs in some parts of India reaching as high as ₹16 per kg, reducing the weight of sludge is crucial. By removing up to 80% of the water weight, solar dryers significantly cut down on the final disposal costs that industries have to pay.

The overall financial benefits are clear:

- Reduced Disposal Costs: Paying to dispose of dry solids instead of water drastically lowers landfill fees.

- Lower Energy Bills: Minimal electricity usage compared to the high energy demand of thermal drying methods.

- Increased Profitability: The combination of lower operational and disposal expenses improves a company’s bottom line.

Environmental, Regulatory, and Sustainability Benefits

The environmental impacts of solar sludge drying are overwhelmingly positive, making it a key technology for environmental sustainability. By relying on renewable solar energy instead of fossil fuels, this method produces minimal greenhouse gas emissions. This helps industries meet their sustainability goals and reduce their overall carbon footprint.

Properly managed solar dryers also offer benefits for public health and the local environment. The enclosed system and aerobic process prevent the release of bad odors, which are a common problem with open drying beds. Furthermore, the drying process can significantly reduce pathogens in the sludge, making the final product safer to handle and transport.

Key sustainability benefits include:

- Reduced Carbon Footprint: Using the sun as a free energy source eliminates the emissions associated with fossil fuel consumption.

- Resource Conservation: The dried sludge has a higher calorific value and can potentially be reused as a fuel supplement, promoting a circular economy.

- Improved Local Environment: Enclosed systems control odors and prevent contamination, protecting the area around the facility.

Industries and Applications of Solar Sludge Dryer Technology

Solar sludge dryer technology is a versatile solution applicable across a wide range of sectors that deal with wastewater management. Any facility that produces a significant volume of sludge as a byproduct of its water treatment processes can benefit from this innovative sludge treatment method.

From large-scale municipal wastewater treatment plants to specialized industrial facilities, the goal is the same: to reduce sludge volume in an economical and sustainable way. The technology’s flexibility allows it to be adapted to different operational scales and sludge types, making it a valuable tool for modern wastewater management.

Wastewater Treatment Plants and Industrial Facilities

The most common users of solar sludge drying technology are municipal wastewater treatment plants (WWTPs) and various industrial facilities. Municipal WWTPs, or STPs, process huge volumes of domestic sewage and are therefore major producers of sludge. For them, solar drying is an ideal solution for large-scale sludge management, helping to reduce the massive disposal costs borne by public utilities.

On the industrial side, any sector that operates an Effluent Treatment Plant (ETP) can benefit. This includes industries like textiles, pharmaceuticals, chemicals, food and beverage, and pulp and paper. These industries often produce sludge with specific characteristics, but the solar drying process remains highly effective at volume and weight reduction.

Ultimately, solar drying is a practical choice for any organization looking to make its sludge management more efficient and sustainable. As a leading sludge dryer manufacturer, AS Engineers offers solutions tailored for both municipal and industrial applications, helping clients turn a costly waste problem into a manageable byproduct.

Integration in Existing ETP, STP, and CETP Operations

A major advantage of solar sludge drying technology is its ability to be seamlessly integrated into existing ETP, STP, and CETP operations. It is not a replacement for the primary water treatment process but rather an enhancement of the final sludge management stage. It fits perfectly after the mechanical dewatering step.

The integration is straightforward. The dewatered sludge cake, which would otherwise be sent directly for disposal, is instead diverted to the solar dryer. The dryer is typically constructed on-site, receiving sludge directly from the facility’s centrifuges or filter presses. This creates a continuous, automated workflow from dewatering to drying.

This setup allows facilities to take immediate control over their sludge volume and disposal costs without disrupting their core water treatment activities. By adding a solar dryer, a plant can upgrade its entire waste management system, making it more cost-effective, compliant with environmental regulations, and sustainable for the long term.

Design and Installation Guidelines for Solar Sludge Dryers

Proper design and installation are fundamental to the success of a solar sludge dryer. Simply building a greenhouse is not enough; the system must be engineered to match the specific needs of the facility and the local climate. This involves careful planning around sizing, capacity, and operational features.

The goal is to create a durable and efficient drying chamber that maximizes solar gain while minimizing operational effort. From determining the right footprint to incorporating automation, every decision impacts the long-term performance and return on investment. The following guidelines cover key considerations for a successful installation.

Sizing and Capacity Planning for Indian Conditions

Sizing and capacity planning are the first critical steps in designing a solar dryer, especially for Indian conditions. The size of the drying hall must be calculated based on the daily or annual volume of sludge the facility produces. It also depends on the initial moisture content of the sludge and the target dryness of the final product.

The diverse climate across India is a major factor. A facility in a sunny, arid region may require a smaller footprint than one in a region with a longer monsoon season, as the evaporation rate will be higher. The design must account for these seasonal variations to ensure the system can handle the sludge load year-round and consistently produce dry sludge.

Proper capacity planning ensures the system is neither oversized, leading to unnecessary capital costs, nor undersized, creating a bottleneck in the sludge management process. A detailed analysis of sludge volume, local solar irradiance data, and desired output is necessary to engineer a system that is both effective and economical.

Automation, Monitoring, and Maintenance Considerations

Modern solar sludge dryers are highly automated systems designed for minimal manual intervention. Automation is key to ensuring consistent drying performance and low operating costs. The sludge turner operates continuously on a pre-programmed schedule, and the ventilation system automatically adjusts based on real-time data.

Effective monitoring is achieved through sensors that measure temperature and humidity inside and outside the dryer. This data is fed to a central control unit, which optimizes the operation of fans and vents to maintain the ideal drying climate. This smart control system ensures maximum water removal while conserving energy.

While largely automated, routine maintenance is still essential for long-term reliability. Key considerations include:

- Mechanical Checks: Regular inspection of the sludge turner, motors, and chains.

- Structural Integrity: Checking the greenhouse film or panels for any damage.

- Sensor Calibration: Ensuring temperature and humidity sensors are providing accurate readings.

Common Operational Challenges and Mitigation Strategies

While solar sludge drying is a highly effective technology, it is not without its operational challenges. The performance of the drying process can be influenced by factors that are sometimes outside of an operator’s control, such as the weather. However, with proper design and management, these challenges can be effectively mitigated.

Key concerns include fluctuations in performance due to seasons, potential for odor, and ensuring the final product quality. By understanding these potential issues ahead of time, facilities can implement strategies to maintain a smooth and efficient operation year-round.

Seasonal Performance Fluctuations

One of the main limitations or challenges associated with solar sludge drying is seasonal variation in performance. Because the sun is the primary energy source, the drying process is naturally faster and more efficient during long, sunny summer days. In contrast, performance will be slower during winter or extended monsoon periods when solar radiation is weaker and less frequent.

This dependency on weather conditions means the system’s throughput can fluctuate. Facilities must plan for this by designing the dryer with enough capacity to handle sludge accumulation during less favorable periods. The residence time of the sludge in the dryer will be longer in winter than in summer to achieve the same level of dryness.

To mitigate these fluctuations, some plants incorporate a supplementary heat source. This could be waste heat from another industrial process, flue gases, or even a heat pump. This hybrid approach ensures a more consistent drying rate throughout the year, combining the low cost of solar energy with a reliable backup for periods of low sunlight.

Odor Control, Pathogen Management, and Product Quality

Odor control is a common concern in any sludge treatment process. However, modern solar dryers are designed to minimize odors effectively. The continuous turning and mixing of the sludge by the automated turner aerates it, keeping it in an aerobic state. Anaerobic conditions, which are the primary cause of bad odors, are thus prevented.

Pathogen management is another important aspect. The prolonged exposure to heat inside the greenhouse, combined with the drying process, significantly reduces the levels of pathogens in the sludge. In many cases, the final dried product can meet strict regulatory standards for pathogen content, such as the EPA Class A requirements, making it much safer to handle.

Maintaining consistent product quality is achieved through the automated control system. By managing the drying process, the system ensures the final product is a uniform, dry granulate with a high solids content. This material is stable, easy to store, and has a higher calorific value, making it potentially suitable for use as a supplementary fuel.

Future Innovations and Technology Trends

The field of solar sludge drying continues to evolve, with ongoing innovations aimed at further improving efficiency and reliability. A key technology trend is the integration of supplementary heating systems to overcome seasonal performance dips. Instead of relying solely on renewable solar energy, hybrid systems are becoming more common. These systems can use waste heat from nearby industrial processes, such as flue gases from power plants, as a secondary energy source. This approach not only boosts drying performance in winter but also contributes to energy recovery.

Other innovations focus on advanced climate control and energy efficiency. The use of a heat pump, for example, can help dehumidify the air inside the greenhouse and recover latent heat from the evaporated water, further reducing the net energy consumption. As technology progresses, we can expect to see smarter automation, more durable materials, and even more sophisticated designs that maximize the use of solar and other renewable energy sources, solidifying solar drying’s role in a sustainable, circular economy.

Frequently Asked Questions (FAQ)

The Paddle Dryer is a popular choice for efficient sludge drying. It utilizes mechanical dewatering and thermal energy to significantly reduce the moisture content of dewatered sludge. This method minimizes transportation costs and enhances resource recovery by yielding dried sludge suitable for beneficial reuse. Often, users have questions regarding the optimal drying process, energy consumption, and how this technology supports environmental sustainability. Understanding these factors can help improve sludge management practices within wastewater treatment plants and ensure effective disposal.

Can all types of industrial sludge be treated with a solar sludge dryer?

Yes, a solar sludge dryer is a versatile solution for sludge management and can treat most types of industrial sludge. The key requirement is that the sludge can be mechanically dewatered to a semi-solid state before the drying process begins, making it suitable for wastewater treatment across many industries.

How much operational cost savings are possible with solar sludge drying?

Significant cost savings are possible with solar drying. By using free solar energy, energy consumption is over 95% lower than conventional thermal methods. This, combined with a dramatic reduction in sludge weight, leads to substantially lower energy bills and disposal costs, improving overall profitability for your facility.

What environmental safeguards are required for reliable solar sludge drying?

For reliable solar drying, the main environmental safeguard is the enclosed greenhouse design. This structure contains the sludge, prevents runoff, and, with proper aeration, controls odors. This approach supports sustainability in wastewater management by minimizing local environmental impact and reducing the carbon footprint associated with sludge disposal.

What types of sludge can be treated using solar sludge drying systems?

Solar sludge drying systems can treat a wide variety of sludge types. This includes wastewater sludge from municipal sewage treatment plants (STPs) as well as industrial sludge from Effluent Treatment Plants (ETPs) and Common Effluent Treatment Plants (CETPs). The primary condition is that the sludge is dewatered first.

How is a typical solar sludge dryer designed and what are its key components?

A typical solar dryer is designed as an enclosed greenhouse. Its key components include a transparent roof to capture solar energy, a concrete floor for the drying chamber, an automated sludge turner for mixing and aeration, and a ventilation system to control humidity and optimize the drying process.

Which industries or facilities most commonly use solar sludge drying technology?

Solar sludge drying is most commonly used by municipal wastewater treatment plants that handle large volumes of sewage sludge and various industrial facilities. Industries such as textiles, pharmaceuticals, and chemicals use it to manage sludge from their wastewater management systems, making their sludge treatment more economical and sustainable.

Conclusion

In conclusion, understanding solar sludge drying is vital for industries looking to optimize their wastewater treatment processes. By utilizing solar energy, facilities can achieve significant cost savings and reduce their environmental impact while effectively treating various types of sludge. The efficient operation of solar sludge dryers hinges on several factors, including site selection, proper design, and ongoing maintenance. As technology continues to evolve, we can anticipate even more innovative solutions that enhance the efficiency and effectiveness of sludge drying. For those ready to explore this sustainable option, don’t hesitate to reach out for a consultation to learn how solar sludge drying can benefit your operations.