Industries have to decide between an Effluent Treatment Plant (ETP) and a Common Effluent Treatment Plant (CETP) for wastewater management. Choosing the right wastewater treatment solution is vital for the environment and following rules.

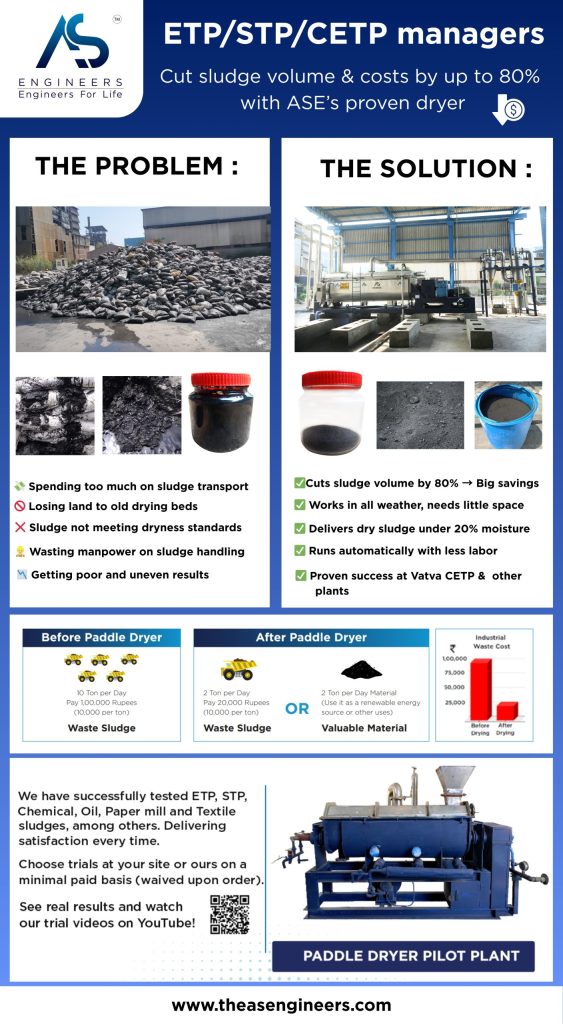

Effective sludge management is key in this process. Our paddle dryer technology efficiently dries different sludges. This helps industries cut sludge disposal costs by up to 80%. It also lessens environmental harm and brings economic gains.

Table of contents

- The Wastewater Treatment Landscape in India

- What is an Effluent Treatment Plant (ETP)?

- What is a Common Effluent Treatment Plant (CETP)?

- ETP vs CETP: A Comprehensive Comparison

- Key Decision Factors When Choosing Between ETP and CETP

- The Sludge Management Challenge in Wastewater Treatment

- Our Paddle Dryer Technology: Revolutionizing Sludge Management

- Implementation Success Stories Across India

- Conclusion: Making the Optimal Choice for Your Wastewater Treatment Needs

- FAQ

Key Takeaways

- Understanding the differences between ETP and CETP is crucial for industries.

- Our paddle dryer technology offers efficient sludge management.

- Effective wastewater treatment solutions can significantly reduce costs.

- Choosing the right treatment plant ensures environmental sustainability.

- Industries can benefit from reduced sludge disposal costs.

The Wastewater Treatment Landscape in India

India’s fast growth in industries has led to more wastewater. This is a big problem for managing industrial waste. The country has many industries like textiles, pharmaceuticals, and chemicals. These industries make different kinds of waste that need special treatment.

Current Challenges in Industrial Effluent Management

Indian industries struggle with managing their waste. They lack good treatment systems, skilled workers, and face high costs. Also, the quality of waste varies, making treatment harder.

Some big problems include:

- Old and small treatment plants

- No standard way to treat waste

- Not enough checks by the government

Regulatory Framework and Compliance Requirements

India has strong rules for handling wastewater. The Central Pollution Control Board (CPCB) sets rules for waste discharge. Industries must follow these rules or face fines and other penalties.

| Regulatory Body | Standards Set | Compliance Requirements |

|---|---|---|

| Central Pollution Control Board (CPCB) | Effluent discharge standards for various industries | Industries must comply with CPCB standards to avoid penalties |

| State Pollution Control Boards (SPCBs) | State-specific regulations and standards | Industries must obtain consent to operate from SPCBs |

Good wastewater treatment is key for India’s environment and health. Knowing the challenges and rules helps industries choose the right treatment options.

What is an Effluent Treatment Plant (ETP)?

Effluent Treatment Plants (ETPs) are key in managing industrial wastewater. They treat industrial effluent and wastewater, making it safer for the environment before it’s released.

Definition and Core Components

An ETP has physical, chemical, and biological treatment steps. It includes primary treatment (like sedimentation), secondary treatment (biological steps), and sometimes tertiary treatment (like filtration and disinfection).

Operational Mechanism and Process Flow

The ETP’s work starts with removing big objects through screening. Then, physical and chemical steps remove contaminants. Next, biological treatments use microorganisms to break down organic matter. After that, the treated water is either discharged or reused.

Industries Best Suited for Individual ETPs

Some industries really benefit from their own ETPs because of their wastewater’s nature and volume.

Pharmaceutical and Chemical Industries

These industries have complex wastewater with many chemicals. An individual ETP can treat it with specific processes for each contaminant.

Textile and Dyeing Units

Textile and dyeing units have a lot of colored wastewater. Their ETP removes dyes and chemicals, making sure the water is safe for the environment.

What is a Common Effluent Treatment Plant (CETP)?

In the world of industrial wastewater, Common Effluent Treatment Plants (CETPs) are a key solution. They treat wastewater from many industries in one place. This makes them a central solution for treatment.

Definition and Infrastructure Components

A CETP is a shared facility for treating wastewater. It serves many industries, usually in industrial areas. It has:

- Systems to collect wastewater from different industries

- Units for physical, chemical, and biological treatment

- Places for handling and disposing of sludge

Collective Treatment Process and Methodology

The treatment in a CETP uses physical, chemical, and biological methods. The steps include:

- Removing big objects and debris first

- Then, removing suspended solids and organic matter

- Lastly, removing the rest of the organic matter and nutrients

Industrial Clusters That Benefit from CETP Implementation

CETPs help many industrial clusters. These include:

Small and Medium Enterprise Zones

SMEs can’t afford their own treatment plants. CETPs are a cheaper option for them.

Industrial Parks and Special Economic Zones

Industrial parks and SEZs have many industries. CETPs are perfect for managing their wastewater.

We’ve set up CETPs for many industrial areas. Our paddle dryer technology helps dry sludge. This makes the treatment process more efficient.

ETP vs CETP: A Comprehensive Comparison

As industries face tough environmental rules, picking between ETP and CETP matters a lot. This part compares these two ways to clean wastewater. We look at their technical and operational differences, costs, and how well they treat water.

Technical and Operational Differences

ETP and CETP differ mainly in design and how they work. An ETP is a single facility for one industry, tailored to its wastewater. A CETP, on the other hand, treats wastewater from many industries with one setup.

ETPs can change how they work based on the industry’s needs. CETPs need a standard way to handle different wastewater types, which can be tough.

Capital and Operational Cost Analysis

ETP and CETP have different costs. ETPs cost more upfront for each industry because they’re built for one. CETPs spread the cost over many industries, making it cheaper for smaller ones.

Running ETPs costs more for each industry. But CETPs save money because they’re bigger and more efficient.

Treatment Efficiency and Performance Parameters

Both ETP and CETP can clean water well if done right. ETPs tend to be more consistent because they handle the same type of wastewater. CETPs are more complex but can also clean water well with the right technology and design.

In short, choosing between ETP and CETP depends on many things like industry size and budget. Knowing the differences helps make a better choice.

Key Decision Factors When Choosing Between ETP and CETP

Choosing between ETP and CETP depends on several key factors. It’s important for industries to understand these to make the right choice. This choice should match their operational needs and environmental goals.

Effluent Characteristics and Treatment Requirements

The type and makeup of an industry’s effluent are crucial. If the effluent is complex or changes a lot, an ETP might be better. On the other hand, CETPs work well for industries with similar effluent.

Scale of Operation and Discharge Volume

The size of an industry and how much effluent it produces matter a lot. Big industries or clusters might save money with CETPs. But, smaller ones or those with less effluent might find ETPs cheaper and easier to manage.

Financial Considerations and Space Availability

Costs and space are big factors in making a choice. CETPs can be cheaper for industries sharing the cost and space. But, ETPs let each industry control its treatment and don’t need to share.

By looking at these factors, industries can make smart choices. These choices help them follow environmental rules and improve their wastewater treatment.

The Sludge Management Challenge in Wastewater Treatment

Managing sludge well is key in wastewater treatment. It’s a big challenge for industries. Treating wastewater creates a lot of sludge that needs careful handling and disposal. We’ll look at how sludge is made, how it’s handled, and its effects on the environment and economy.

Sludge Generation Patterns in ETP and CETP Systems

ETPs and CETPs both make sludge, but in different amounts and types. ETPs, for specific industries, make sludge that’s more consistent but can be very polluted. CETPs, with effluent from many industries, have more varied sludge.

The amount of sludge made depends on the industry, treatment, and effluent. Knowing these patterns helps in managing sludge better.

Conventional Sludge Handling Methods and Their Drawbacks

Old ways to handle sludge include thickening, digestion, and landfilling or burning. These methods have big problems. Thickening and digestion use a lot of energy and don’t shrink the sludge much. Landfilling can pollute soil and water, and burning can harm the air if not done right.

Environmental and Economic Impact of Sludge Disposal

Disposing of sludge affects the environment and costs money. Bad disposal can pollute soil and water, harming ecosystems and people. It also costs a lot, making efficient management important.

Using new sludge management tech, like our paddle dryer, helps a lot. It makes sludge smaller and easier to handle. This reduces harm to the environment and saves money.

Our Paddle Dryer Technology: Revolutionizing Sludge Management

Our paddle dryer technology is leading the way in sludge management. It changes how industries deal with wastewater byproducts. It offers a reliable and efficient way to handle sludge disposal.

Advanced Design and Working Principles of Our Paddle Dryers

Our paddle dryers are made with advanced design. They focus on heat transfer efficiency and thermal design. This means they work well and save energy.

Heat Transfer Efficiency and Thermal Design

The heat transfer in our paddle dryers is top-notch. It dries sludge effectively with less energy.

Material Construction and Durability Features

Our paddle dryers are made from high-quality materials. They are built to last, making them durable and long-lasting.

Versatility in Processing Various Sludge Types

Our paddle dryer technology can handle many sludge types. This includes sludges from ETPs and CETPs.

ETP Sludges: Chemical, Biological, and Mixed

Our technology works well with ETP sludges. It can handle chemical, biological, and mixed sludges. This makes it a flexible solution for different industrial needs.

CETP Sludges: Heterogeneous Waste Streams

CETP sludges are also managed by our technology. It ensures they meet environmental regulations.

Achieving 80% Cost Reduction in Sludge Disposal

Using our paddle dryer technology can cut sludge disposal costs by up to 80%. This helps industries save money and be more environmentally friendly.

Our paddle dryer technology is efficient and eco-friendly. It’s perfect for industries looking to improve their sludge management.

Implementation Success Stories Across India

India has made big changes in how it handles industrial wastewater. This is thanks to Effluent Treatment Plants (ETPs) and Common Effluent Treatment Plants (CETPs). These changes are because of the need for better ways to manage wastewater for all kinds of industries.

ETP Case Studies with Measurable Results

Our ETP projects have shown great results in many areas. Here are two examples:

Textile Industry Implementation in Gujarat

In Gujarat, we set up an ETP for a textile factory. It cut wastewater pollution by 90%. This was done with a special treatment that matched the factory’s needs.

Pharmaceutical Sector Application in Maharashtra

In Maharashtra, our ETP for a pharmaceutical company lowered COD and BOD levels a lot. This made sure they followed the rules. It also saved money by cutting down on waste disposal costs.

CETP Implementations with Significant Impact

Our CETP projects have also made a big difference for industrial areas. Here are two examples:

Industrial Cluster Transformation in Tamil Nadu

In Tamil Nadu, a CETP for chemical factories kept 95% of wastewater clean. This greatly improved the area’s environment.

Multi-industry CETP Solution in Uttar Pradesh

In Uttar Pradesh, we set up a CETP for different industries like food and textiles. It greatly reduced wastewater pollution. This shows how CETPs can work well for many industries.

Conclusion: Making the Optimal Choice for Your Wastewater Treatment Needs

Deciding between an Effluent Treatment Plant (ETP) and a Common Effluent Treatment Plant (CETP) is key. It depends on the type of effluent, the size of your operation, and your budget. Knowing the etp vs cetp differences helps find the best fit for your wastewater treatment.

Choosing the right treatment is crucial. It affects how well wastewater is treated, meets legal standards, and your costs. Our paddle dryer technology helps manage sludge, saving money and protecting the environment.

Understanding ETP and CETP’s roles and benefits helps industries make better choices. We suggest looking at your needs and seeing how our solutions can help with your wastewater goals.

FAQ

What are the main differences between ETP and CETP?

ETP and CETP differ in design, operation, and use. ETP is for single industries, treating their waste. CETP, on the other hand, treats waste from many industries together. We’ll look at their technical details, how they work, and their effectiveness.

How do ETP and CETP handle sludge management?

Both ETP and CETP produce sludge during treatment. Our paddle dryer technology efficiently dries and manages this sludge. This reduces disposal costs by up to 80%. Our technology is designed for various sludge types, making it versatile.

What factors should be considered when choosing between ETP and CETP?

Choosing between ETP and CETP depends on several factors. These include the type of waste, the size of the operation, costs, and available space. Understanding these factors helps make the right choice for wastewater treatment needs.

How do regulatory requirements impact ETP and CETP implementation?

Regulations are key in deciding between ETP and CETP. It’s important to follow environmental laws. Our solutions meet these standards, ensuring compliance and reducing environmental harm.

Can our paddle dryer technology be integrated with existing ETP or CETP systems?

Yes, our paddle dryer technology can be added to existing ETP or CETP systems. This improves sludge management and lowers disposal costs. Our dryers are designed to fit various treatment setups, ensuring smooth integration and top performance.

What are the cost implications of choosing ETP over CETP or vice versa?

The costs of choosing ETP or CETP vary based on several factors. These include initial investment, ongoing costs, and maintenance needs. We analyze these costs to find the most affordable option. Our paddle dryer also helps save on sludge disposal costs.

In choosing AS Engineers, you partner with a reliable and dedicated team helping to make your wastewater treatment process even more efficient and environmentally beneficial. Our innovative technology that not only dramatically reduces the volume of sludge compound but also allows resource reuse will soon provide for a very ecological practice.

When comparing paddle dryers with other dryer types such as belt dryers, several key differences come into focus that can significantly impact operational efficiency and results. Paddle dryers excel in providing more uniform heat distribution, which is essential for achieving optimal drying performance. Unlike belt dryers, which rely on continuous movement across a flat surface, paddle dryers utilize rotating paddles to agitate the material, ensuring that every particle gets adequate exposure to heat. This not only reduces drying time but also minimizes the risk of overheating or burning the sludge.

Furthermore, paddle dryers generally have a smaller footprint and are designed for multi-phase drying, allowing for the effective processing of sludge with variable moisture content. In contrast, belt dryers may require extensive space and can struggle when handling high-moisture materials. While both types of dryers offer unique advantages, paddle dryers stand out for their versatility, efficiency, and effectiveness, making them a preferred choice for industries seeking reliable sludge management solutions.

Contact AS Engineers today to explore how our advanced sludge drying technology can elevate your wastewater treatment process while contributing to a cleaner and greener future. Let’s work together to make a positive impact on our planet.

Sludge Dryer Exporter – Countries We Serve

AS Engineers is a leading sludge dryer manufacturer and exporter in India, committed to delivering cutting-edge drying solutions worldwide. Our extensive reach includes countries across North America, Europe, Asia, and the Middle East, where we provide tailored sludge drying solutions to meet the specific needs of diverse industries. As a trusted sludge dryer manufacturer, we ensure our products comply with international quality standards, making them ideal for various applications in wastewater treatment, energy recovery, and resource optimization.

Countries: USA, North America, Germany, Europe, Australia, Oceania, UAE, Middle East, South Africa, Africa

Our commitment to excellence and customer satisfaction drives us to offer customized solutions that enhance operational efficiency and sustainability. By partnering with AS Engineers, you can access advanced sludge drying technology designed to minimize environmental impact and promote resource recovery in your operations.

Request a quote

If you are looking for efficient sludge dryers tailored to your specific needs, contact us today to request a quote. Our team at AS Engineers is ready to provide you with customized solutions that enhance your sludge management process, reducing your sludge volume in India. Reach out now to explore how our cutting-edge technology can benefit your operations!

Ready to Transform Your Sludge Management?

Reach out to us for custom-made sludge drying solutions tailored to suit your facility’s needs and target objectives of sustainability.

- Phone: +91-990 903 3851

- Email: info@theasengineers.com