Understanding Sewage Sludge Treatment: A Complete Guide

Have you ever wondered what happens to all the waste flushed down the drain every day? According to recent estimates, municipal waste water treatment plants worldwide produce millions of tons of sewage sludge annually. In some areas, this sludge is simply discarded, creating health hazards and environmental strains. But here’s a surprising fact: with the right sewage sludge treatment strategies, you can transform what many consider ‘waste’ into valuable resources like renewable energy and nutrient-rich fertilizer.

This guide explores innovative sludge water treatment methods, regulatory frameworks, and real-life success stories to show how even the most burdensome wastewater treatment systems can become a key player in our sustainability goals. Whether you manage a large municipal plant, run an industrial facility, or just want to stay informed, read on to discover how proper sewage sludge management can protect public health, conserve the environment, and create new business opportunities.

Table of contents

1. Understanding Sewage Sludge: Definition and Composition

When wastewater flows into a treatment plant—carrying domestic, industrial, and sometimes storm-related flows—it undergoes various processes like screening, sedimentation, and biological treatment. The resulting solid byproduct, known as sewage sludge, contains organic matter, microorganisms, and nutrients that participate in the digestion process, and sometimes trace levels of heavy metals or other contaminants.

Where Does Sewage Sludge Come From?

- Primary Treatment: Settling tanks capture solids such as grit and debris, creating a sludge with higher organic content and lower moisture than raw wastewater, leading to the need for tertiary treatment.

- Secondary Treatment: Biological processes (commonly activated sludge systems) produce secondary sludge, often rich in microbial biomass, which may also require tertiary treatment for enhanced purification.

- Combined Sources: In certain treatment configurations, primary and secondary sludges are blended, forming a mixed sludge.

Main Components

- Organic Matter: The decomposable carbon fraction, often a significant energy source if captured correctly, includes various organic compounds.

- Pathogens: Bacteria, viruses, and parasites can persist in raw sludge, necessitating disinfection or stabilization.

- Nutrients: Nitrogen and phosphorus, which can benefit agriculture if properly managed.

- Inorganic Solids: Sand, silt, and sometimes metals.

The composition varies by region and industrial inputs. Cities with heavy industry may yield sludge containing metals or toxic substances, influencing treatment choices. Understanding your specific sludge profile is crucial for designing an effective sludge water treatment process.

2. Why Sewage Sludge Treatment Matters

Before exploring advanced methods, let’s clarify why sewage sludge treatment and the wastewater treatment process hold such significance.

- Public Health: Untreated sludge can harbor pathogens, leading to diseases if mishandled. Proper treatment helps eliminate or reduce disease-causing organisms.

- Environmental Protection: Sludge can pollute water bodies and soil when dumped. Treatment minimizes contamination and promotes ecosystem health, complying with the regulations set by the U.S. Environmental Protection Agency.

- Regulatory Compliance: Many regions have stringent rules on sludge disposal. Meeting these standards is vital to avoid fines or legal complications.

- Resource Recovery: Treated sludge can provide renewable energy through biogas or act as a valuable soil conditioner. This not only offsets disposal costs but can also generate revenue or reduce reliance on nonrenewable resources.

Moreover, adopting robust sludge management strategies signals corporate and municipal responsibility. Stakeholders—from government agencies to local communities—now pay closer attention to environmental performance and sustainability indicators.

3. Core Processes in Sewage Sludge Treatment

“Treatment” is not a single event but a series of steps aimed at reducing water content, neutralizing pathogens, and stabilizing organic matter. Understanding these stages is essential when devising an efficient strategy.

3.1 Thickening

Thickening increases sludge dry solids content by separating water. Methods range from simple gravity thickeners—where solids settle—to mechanical approaches like dissolved air flotation (DAF) or centrifuges. Thickening yields a denser sludge, reducing storage volume and transportation costs for subsequent steps.

- Gravity Thickening: Relies on sedimentation, commonly used for primary sludge.

- DAF Thickening: Injects pressurized air to float solids, suited for secondary sludge with lighter flocs.

- Centrifugal Thickening: Uses high-speed rotation to separate solids from water.

3.2 Stabilization

Stabilization reduces odors, pathogens, and the potential for putrefaction by promoting controlled microbial action.

- Anaerobic Digestion: Sludge breaks down in oxygen-free tanks, producing methane-rich biogas.

- Aerobic Digestion: Microorganisms decompose organic matter using oxygen. This process can be energy-intensive but relatively straightforward.

- Lime Stabilization: Adding lime raises the sludge pH, killing pathogens and reducing odors. Quick to deploy but can increase sludge volume.

3.3 Dewatering

Dewatering aims to remove more water, resulting in a cake-like substance. Common technologies include:

- Belt Filter Presses: Sludge passes between porous belts under mechanical pressure.

- Plate and Frame Filter Presses: High-pressure plates squeeze out water to form dry cakes.

- Centrifuges: Similar to thickening but operating at higher speeds to extract more water content.

Effective dewatering reduces transportation costs and eases final disposal or reuse. The choice of dewatering method often depends on sludge type, volume, and financial constraints.

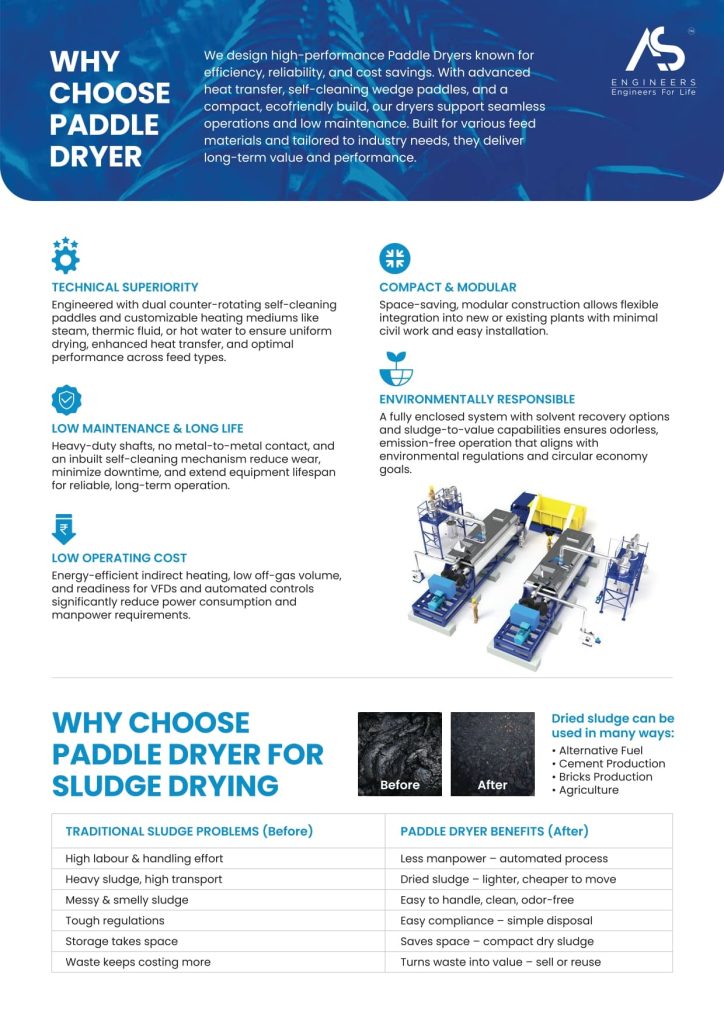

3.4 Thermal Processes

Thermal treatments leverage heat to dry or combust sludge. Some examples:

- Thermal Drying: High temperatures evaporate water, producing a stabilized, powdery product.

- Incineration: Complete combustion of organic solids at extremely high temperatures, reducing sludge mass dramatically.

Thermal processes can be capital-intensive but significantly cut sludge volume, making them attractive where landfill space is scarce.

3.5 Disinfection

Depending on the end use—especially if sludge is destined for agricultural lands—additional pathogen reduction steps may be necessary. Techniques include:

- Heat Treatment: Prolonged exposure to high temperatures kills pathogens.

- Pasteurization: Short-term high-temperature treatment that neutralizes common microorganisms.

- Alkaline Stabilization: Uses high pH to destroy bacteria and viruses.

4. Sludge Water Treatment Technologies

“Sludge water treatment” extends beyond thickening and dewatering. Specialized processes can transform sludge into inert, beneficial, or even profitable products.

4.1 Anaerobic Digestion

Anaerobic digestion, including sludge digestion, ranks among the most prominent technologies for sewage sludge treatment:

- Process Summary: Bacteria break down organic matter in a closed vessel without oxygen, producing biogas (typically methane and carbon dioxide) and a reduced solids fraction (digestate).

- Advantages:Energy recovery via biogas can power plant operations.

- Reduced sludge volume and odor.

- Potential for Class B or Class A biosolids, depending on operating conditions and post-treatment steps.

- Drawbacks:Requires consistent temperature and loading rates.

- High capital cost for digester construction and gas handling systems.

Many municipal wastewater plants rely on anaerobic digestion to cut operational costs and produce renewable energy. With proper gas capture systems, facilities can even sell surplus electricity or biogas.

4.2 Aerobic Digestion

Aerobic digestion uses oxygen-loving microbes to break down sludge in the presence of oxygen:

- Process Summary: Aeration tanks pump oxygen, allowing aerobic bacteria to decompose organic matter.

- Advantages:Simple to operate, no need for gas handling equipment.

- Relatively stable end product if properly managed.

- Drawbacks:Consumes considerable energy for aeration.

- Fewer opportunities for direct energy recovery.

Though not as energy-efficient as anaerobic systems, aerobic digestion can be a good choice for smaller plants or areas lacking the expertise to manage biogas systems.

4.3 Composting

Composting merges sludge with bulking agents like wood chips, sawdust, or yard waste, then fosters microbial decomposition under controlled conditions.

- Windrow Composting: Sludge and bulking agents are piled in rows (windrows) and mechanically turned.

- Aerated Static Pile: Air is forced through a pile using blowers, minimizing the need for turning.

- In-Vessel Systems: Sludge decomposes in enclosed reactors with regulated airflow and temperature.

Composting generates a stable soil amendment rich in organic matter and nutrients. However, it does demand open space and a well-managed process to limit odors.

4.4 Lime Stabilization

Adding lime elevates pH, kills pathogens, and curbs odor. This relatively low-tech method is particularly useful in areas lacking advanced treatment infrastructure. However, the final product can be bulkier and not as versatile for resource recovery as digested or composted sludge.

4.5 Incineration

High-temperature incineration combusts organic solids, leaving a small quantity of ash and flue gas that requires pollution controls. This method significantly reduces the volume of sludge mass and can reclaim energy if the sludge has enough calorific value.

- Benefits: Minimal volume for disposal, potential energy recovery.

- Risks: Air pollution and ash handling must be carefully managed; capital and operating costs can be high.

4.6 Advanced Thermal Methods

Emerging technologies include pyrolysis and gasification. Unlike incineration, they heat sludge in low- or no-oxygen conditions, producing a synthetic gas and biochar. These products can be refined or sold, positioning sludge as a renewable energy feedstock.

Recovery of Volatile Fatty Acids from Sewage Sludge through Anaerobic Fermentation

Anaerobic fermentation is a process that utilizes microorganisms to convert organic pollutants in sewage sludge into valuable byproducts such as volatile fatty acids (VFAs). These VFAs can serve as feedstock for various biotechnological applications, including bioplastics and biofuels. By optimizing the anaerobic digestion process, operators can enhance the recovery of these fatty acids, which are crucial for producing renewable energy, including methane gas, and reducing reliance on fossil fuels. This technique not only improves the economic feasibility of sewage sludge management but also contributes to sustainable waste management practices.

Furthermore, the conversion of organic pollutants into VFAs during anaerobic digestion helps reduce the overall volume of sludge, thereby minimizing disposal costs and environmental impacts. The process also offers a dual benefit: while VFAs are recovered, other harmful components within the sludge can be effectively neutralized. As municipalities and industries seek greener alternatives for waste management, incorporating anaerobic fermentation into sludge treatment strategies presents a promising pathway for maximizing resource recovery from sewage sludge.

5. From Waste to Resource: Beneficial Reuse of Sewage Sludge

One of the most compelling evolutions in sludge water treatment is shifting from disposal to resource recovery. Gone are the days when sludge was viewed purely as a liability.

5.1 Soil Conditioner and Fertilizer

Stabilized sludge often referred to as biosolids contains nutrients such as nitrogen and phosphorus crucial for crop growth. Spreading biosolids on farmland can improve soil structure, reduce the need for chemical fertilizers, and close nutrient loops. Strict guidelines govern application rates and pathogen levels, ensuring public health and environmental safety.

Advantages:

- Reduces the cost of chemical fertilizers.

- Enhances soil fertility and water retention.

- Cuts landfill usage.

Challenges:

- Public perception and acceptance, especially if nearby communities worry about odors or contaminants.

- Strict regulatory controls on metal content, pathogen limits, and monitoring.

5.2 Biogas Production

In anaerobic digestion, the methane-rich biogas can be harnessed to power combined heat and power (CHP) units, generate electricity, or even be upgraded to natural gas quality. Many wastewater treatment plants worldwide now operate as energy-neutral or net energy producers.

Benefits:

- Offsets or eliminates reliance on external fossil fuels.

- Reduces greenhouse gas emissions by capturing methane that would otherwise vent into the atmosphere.

- Creates a circular economy model for the wastewater sector.

5.3 Building Materials and Other Innovations

Research continues to uncover creative ways to repurpose sludge:

- Bricks and Cement: Dried sludge or ash from incineration can be added to clay bricks or cement mixtures, potentially lowering the carbon footprint of traditional building materials.

- Biochar and Activated Carbon: Certain pyrolysis methods produce char that can filter pollutants or enrich soils.

- Polymer Extraction: Scientists are experimenting with extracting polymers like polyhydroxyalkanoates (PHAs) from sludge, which can be used in biodegradable plastics.

Such technological advancements enhance the economic viability of sludge management, encouraging private investments and policy support.

6. Regulatory Landscape and Safety Considerations

Sewage sludge management is strictly governed by environmental and public health regulations. These laws exist to protect water bodies, soil quality, and local populations from harmful contaminants.

6.1 Standards for Biosolids

Many countries classify treated sludge—often called “biosolids”—based on pathogen reduction and chemical composition. For example, certain standards differentiate between “Class A” biosolids, which can be used without restriction in agriculture, and “Class B” biosolids, subject to additional constraints. Meeting these standards typically involves robust treatment processes and routine testing.

6.2 Environmental Permits and Monitoring

Treatment facilities often require operating permits. Permit conditions usually include:

- Emissions Limits: Covers air pollutants, water discharges, and odor.

- Sampling Protocols: Regular testing of sludge for metals, pathogens, and other contaminants.

- Land Application Rules: Defines application rates, setback distances from water sources, and record-keeping.

Non-compliance can lead to significant fines or forced plant closures, reinforcing the importance of consistent monitoring and reporting.

6.3 Worker Health and Safety

Plant operators and maintenance crews may face hazards like toxic gases, pathogens, and heavy machinery. Effective safety programs include:

- Personal Protective Equipment (PPE): Gloves, masks, goggles, and protective clothing.

- Regular Training: Emergency response drills, equipment handling, and hazard identification.

- Engineering Controls: Adequate ventilation, gas detection systems, and restricted access to high-risk areas.

A well-managed facility prioritizes worker welfare while maintaining operational efficiency.

7. Key Factors in Selecting a Sludge Treatment Method

Every facility faces unique conditions, so there’s no universal solution for sewage sludge treatment. Managers must evaluate several criteria before deciding on a path forward.

7.1 Sludge Characteristics

The relative proportions of primary vs. secondary sludge, chemical additives, and industrial discharges can drastically change your treatment requirements. Highly organic sludges may be ideal for anaerobic digestion, whereas sludge loaded with metals might require advanced treatments or disposal restrictions.

7.2 Scale and Budget

Large municipalities often benefit from economies of scale, making methods like incineration or combined heat and power more feasible. Smaller plants may choose simpler, lower-capital approaches such as aerobic digestion or composting.

- Capital Costs: Construction, land acquisition, equipment.

- Operational Expenses: Energy, labor, maintenance, chemicals.

- Return on Investment: Potential revenue from biogas or fertilizer sales.

7.3 Regulatory Compliance

Local laws on land application, disposal, and air emissions can make or break certain strategies. For instance, incineration is unviable in jurisdictions with very strict air pollution standards unless you invest in costly flue gas treatment systems. Always confirm that your chosen method meets or exceeds local regulations.

7.4 Public Acceptance

Odor complaints or negative perceptions of biosolids can spark community resistance. Effective stakeholder engagement—including transparent communication, odor control measures, and demonstration projects—can help earn the public’s trust.

Biotechnological Approaches to Sludge Dewatering

Biotechnological approaches to sludge dewatering focus on utilizing microbial processes to enhance the removal of water from sewage sludge. By employing specific strains of bacteria or fungi, facilities can promote the breakdown of organic matter, which naturally reduces the sludge volume and facilitates easier dewatering. These biotechnological solutions are often more sustainable compared to traditional mechanical methods, as they can decrease energy consumption and chemical use.

In addition to improving dewatering efficiency, these biotechnological methods can also enhance the quality of the dewatered sludge, making it more suitable for beneficial reuse applications. For instance, the resulting biosolids can be transformed into high-quality organic fertilizers or soil amendments, providing valuable nutrients for agricultural use. Overall, these innovative approaches not only streamline the sludge treatment process but also contribute to a circular economy by recovering resources from what was once considered waste.

8. Real-World Case Studies

To illustrate these concepts, let’s look at three scenarios where communities and industries leveraged sludge water treatment to benefit both the environment and their bottom line.

8.1 Urban Municipality Success Story

A large city in Europe faced soaring landfill fees and space limitations. Officials opted for an advanced anaerobic digestion system. Co-digestion with food waste from local restaurants increased biogas yields. The city deployed combined heat and power (CHP) units to generate electricity and heat for the sewage treatment plant. Surplus energy was sold to the grid, offsetting operational costs. Result? A nearly self-sustaining facility with a dramatic cut in disposal fees.

8.2 Small Community Approach

A rural township in North America lacked the funds for high-tech systems. They selected a low-cost composting strategy, mixing dewatered sludge with wood chips from a nearby sawmill. Residents volunteered labor for turning windrows, and the compost was given away to local farmers. With minimal capital outlay, the town effectively reused its sludge, enhanced local soil, and educated the community on sustainable waste management.

8.3 Industrial Facility Innovation

A paper mill in Asia generated significant wastewater sludge with fibrous content. Management tested a dual approach: partial dewatering followed by thermal drying. The dried sludge was used as a supplementary fuel in the mill’s steam boiler. By capturing energy from the sludge, the company reduced its reliance on coal, cut greenhouse gas emissions, and earned carbon credits under a regional environmental scheme.

9. Challenges and How to Overcome Them

9.1 Funding Gaps

Challenge: Many treatment methods require substantial capital. Small municipalities or private firms might struggle to secure loans or government grants.

Solution: Explore public-private partnerships, international development funds, or revenue-generating angles—like biogas power sales—to attract investors.

9.2 Technology Limitations

Challenge: Some advanced processes need consistent feedstock quality or specialized expertise.

Solution: Start with a pilot program or phased implementation to fine-tune operational parameters. Where possible, collaborate with universities or research institutions for guidance and innovation.

9.3 Public Outreach and Opposition

Challenge: Nearby residents may object to perceived odors, traffic, or health hazards.

Solution: Offer transparent project details, host facility tours, and highlight benefits like job creation or green energy. Collaborative community planning eases tension and fosters trust.

9.4 Regulatory Hurdles

Challenge: Complex or inconsistent regulations at local, state, and federal levels can stall projects.

Solution: Early engagement with regulatory bodies, thorough permitting processes, and robust compliance strategies. Seek clarifications and adapt designs to meet the highest applicable standards.

By preparing for these challenges from the outset, you ensure smoother implementation and longer-term viability.

Use of Sewage Sludge for the Development of Adsorbents for Waste Water Treatment

Sewage sludge has emerged as a promising material for the production of adsorbents used in wastewater treatment. By converting treated sludge into adsorbent materials, facilities can effectively remove pollutants such as heavy metals and organic pollutants along with organic contaminants from wastewater. The process typically involves pyrolyzing or carbonizing the sludge to enhance its adsorption capacity, resulting in a highly effective filtering agent.

The use of sewage sludge-based adsorbents not only provides an eco-friendly solution for wastewater treatment but also promotes the circular economy by repurposing waste materials. This innovative approach reduces the need for synthetic adsorbents, which can be costly and environmentally harmful. As industries increasingly prioritize sustainability, leveraging sewage sludge for wastewater treatment demonstrates a significant advancement in resource recovery technology.

10. Frequently Asked Questions (FAQ)

Q1: What is the difference between “sewage sludge” and “biosolids”?

Biosolids refer specifically to treated sewage sludge that meets regulatory standards for beneficial reuse, such as land application. “Sewage sludge” is the raw or partially treated material produced by wastewater treatment plants.

Q2: Does sludge water treatment always include anaerobic digestion?

Not necessarily. While anaerobic digestion is popular due to its biogas benefits, other methods like aerobic digestion, composting, or thermal processes can be equally valid depending on local conditions and goals.

Q3: How can smaller facilities handle sludge if they lack specialized equipment?

They can use simpler methods like lime stabilization, composting, or partnerships with larger regional plants. In some cases, mobile dewatering or shared treatment services are an option.

Q4: Is incineration harmful to the environment?

If properly managed with modern air pollution controls, incineration can minimize environmental impacts. However, it can be energy-intensive and may produce ash that requires safe disposal.

Q5: What is the recommended frequency for sludge dewatering?

Frequency varies based on sludge production rates, plant size, and treatment capacity. Some facilities dewater continuously, while others schedule it weekly or monthly. Monitoring sludge levels and moisture content is key.

11. Myth-Busting Section

Myth 1: “Sludge Is Always a Liability”

Reality: With the right sewage sludge treatment method, sludge can transform into a valuable product—be it compost, biogas, or even a renewable fuel source.

Myth 2: “Incineration Is the Only Way to Achieve Volume Reduction”

Reality: Advanced dewatering or thermal drying can significantly cut volume without full incineration. Moreover, approaches like anaerobic digestion break down solids and harness energy rather than just burning it.

Myth 3: “Regulatory Standards Are Too Strict to Make Biosolids Viable”

Reality: While regulations can be rigorous, they ensure public safety and environmental protection. By following best practices and investing in proper treatment, facilities can meet these standards and create high-quality biosolids.

Myth 4: “Sewage Sludge Automatically Means Foul Odors for Nearby Residents”

Reality: Many technologies feature odor-control measures like enclosed digesters, biofilters, or well-managed compost piles. Proactive operational practices can greatly minimize unpleasant smells.

Myth 5: “Small Communities Can’t Afford Advanced Treatment”

Reality: Scalable solutions exist for different budget ranges. Shared infrastructure, decentralized plants, and state or federal grants often make advanced treatments accessible even for smaller locales.

Conclusion

Sewage sludge treatment and industrial wastewater treatment are no longer just about managing waste; it’s about reimagining what we traditionally consider “waste” into a valuable asset. From producing biogas that powers entire facilities to generating safe, nutrient-rich biosolids for agriculture, the potential benefits are vast. By choosing the right combination of treatment methods—be it aerobic digestion, incineration, composting, or advanced thermal processes—you can protect public health, comply with regulations, and even boost revenue. Ready to explore the possibilities? Share your thoughts below, subscribe for more insights, and check out related guides to delve deeper into sustainable sludge solutions.

What are the main steps involved in sewage sludge treatment?

The sewage treatment process typically involves several key steps: thickening, stabilization, dewatering, and final disposal or beneficial reuse. Initially, thickening reduces the volume of sludge by separating excess water. Following this, stabilization processes—such as anaerobic or aerobic digestion—help to neutralize pathogens and organic matter. The next step, dewatering, further removes water, transforming the sludge into a manageable cake form. This process often requires further treatment to ensure quality. Finally, the treated sludge can either be disposed of safely or repurposed as biosolids for agricultural applications. Each step is crucial for ensuring efficient and environmentally responsible sludge management.

Why is sewage sludge treatment important for the environment?

Sewage sludge treatment plays a vital role in environmental protection by minimizing the potential hazards associated with untreated sludge. Without proper treatment, sewage sludge can release harmful pathogens and pollutants into soil and waterways, threatening both public health and human health as well as ecosystem stability. By treating sludge, facilities can effectively reduce these risks and promote the safe reuse of nutrients, thereby supporting sustainable agricultural practices. Ultimately, effective sewage sludge management contributes to cleaner water, healthier soil, and a more balanced ecosystem.

What different methods are used to treat sewage sludge?

Various methods are employed to treat sewage sludge, tailored to meet specific operational needs and regulatory requirements. The first step in this treatment process commonly includes techniques like anaerobic digestion, aerobic digestion, composting, thermal drying, and incineration. Each method has its unique advantages and challenges, influencing factors such as cost, energy efficiency, and environmental impact. The choice of treatment often depends on the facility’s size, budget, and the properties of the sludge being processed, with a growing trend towards methods that enhance resource recovery and sustainability.

What is sewage sludge and how is it produced in wastewater treatment plants?

Sewage sludge is the solid byproduct generated during the treatment of wastewater in treatment plants. It primarily consists of organic matter, microorganisms, nutrients, and occasionally, trace elements and contaminants from domestic and industrial sources. The production of sewage sludge occurs during various treatment phases, including primary treatment—where solids settle out—and secondary treatment—where biological processes further break down organic material. The resulting sludge requires effective management to mitigate environmental risks and promote beneficial reuse.

How is treated sewage sludge typically disposed of or reused?

Treated sewage sludge in the United States can be disposed of or reused through several methods, depending on its quality and local regulations. Common disposal methods include landfilling or incineration. However, many facilities now focus on beneficial reuse, utilizing treated sludge (often referred to as biosolids) as organic fertilizers or soil amendments in agriculture. This approach not only reduces landfill waste but also enriches soil health and promotes sustainable farming practices, closing the nutrient loop within the ecosystem.

What are biosolids and how do they relate to sewage sludge treatment?

Biosolids are treated sewage sludge that meets specific regulatory standards for safety and quality, allowing for beneficial reuse, particularly in agriculture. The treatment process typically involves stabilization methods, such as anaerobic digestion or composting, which reduce pathogens and improve the nutrient profile of the sewage sludge. By transforming sewage sludge into municipal solid waste biosolids, facilities can provide a valuable resource for soil enhancement, while simultaneously addressing waste management challenges.

What advances have been made in sewage sludge treatment technologies recently?

Recent advancements in sewage sludge treatment technologies focus on enhancing efficiency and sustainability. Innovations such as thermal hydrolysis, advanced anaerobic digestion techniques, and carbonization processes are gaining traction, offering improved resource recovery and reduced environmental impact. These technologies not only optimize the conversion of sludge into valuable products like biogas and nutrient-rich fertilizers through thermal hydrolysis but also contribute to lower operational costs and enhanced compliance with stringent environmental regulations.

How does sustainable management apply to sewage sludge treatment and disposal?

Sustainable management in sewage sludge treatment and disposal emphasizes resource recovery, minimizing environmental impacts, and ensuring public safety. By adopting practices that prioritize the beneficial reuse of biosolids, including the disposal of sewage sludge, facilities contribute to a circular economy, reducing reliance on chemical fertilizers while enriching soil health. Furthermore, integrating energy recovery systems, such as anaerobic digestion, promotes energy efficiency and reduces greenhouse gas emissions. Overall, sustainable sludge management aligns waste treatment processes with broader environmental goals, fostering long-term ecological balance.

What types of sewage sludge are there and how are they treated differently?

Sewage sludge can generally be categorized into two main types: primary sludge and secondary sludge. Primary sludge, often derived from septic tanks, is generated from the settling of solids during the initial stages of wastewater treatment, while secondary sludge is generated from biological processes that treat dissolved organic matter. Each type requires different treatment approaches; for instance, primary sludge often undergoes anaerobic digestion for energy recovery, whereas secondary sludge may be treated through aerobic processes or composting, depending on its composition and desired end-use.

What are the key regulations or guidelines for sewage sludge treatment?

Key regulations and guidelines for sewage sludge treatment focus on ensuring safety, environmental sustainability, and public health while minimizing health risks. These may include standards for pathogen reduction, heavy metal content, and application rates for land use. In many regions, biosolids must meet specific classifications (such as Class A or Class B) that dictate their suitability for agricultural application. Adhering to these regulations is crucial for facilities to operate legally and responsibly, safeguarding both the environment and local communities from potential contaminants.