Managing industrial wastewater is more critical than ever. As industries grow, so does the challenge of treating effluent to prevent water pollution. An effluent treatment plant (ETP) is essential for environmental protection, but the game is changing. Instead of just treating large volumes of wastewater, leading industries are now embracing volume reduction. This proactive approach to wastewater treatment not only meets regulatory demands but also opens doors to greater efficiency, cost savings, and sustainability. Are you ready to explore this shift?

Table of contents

- Key Highlights

- Understanding Volume Reduction in Industrial Effluent Treatment Plants (ETPs)

- Overview of Industrial Effluent Treatment Processes

- Major Trends Shaping Industrial Wastewater Management in India

- Benefits of Adopting Volume Reduction Strategies

- Technologies Driving Volume Reduction in ETPs

- Selecting the Right Volume Reduction Technology for Your Industry

- Regulatory Guidelines Supporting Volume Reduction in India

- Volume Reduction and Pollution Control Compliance

- Challenges in Adopting Volume Reduction for Industrial ETPs

- Cost Implications and Savings from Volume Reduction

- Applicability Across Industrial Sectors

- Conclusion

- Frequently Asked Questions

Key Highlights

Here are the key takeaways on the latest trends in industrial wastewater management:

- Volume reduction is becoming a central strategy for managing industrial wastewater and improving effluent treatment plant (ETP) efficiency.

- The focus is shifting from simple compliance to creating circular water systems that prioritize water reuse and resource recovery.

- Modern treatment technologies like membrane filtration and advanced evaporators are making volume reduction more achievable.

- Stricter regulatory compliance standards in India are driving industries to adopt more advanced wastewater treatment methods.

- Adopting volume reduction not only lowers environmental impact but also offers significant cost savings on operational expenses.

Understanding Volume Reduction in Industrial Effluent Treatment Plants (ETPs)

So, what exactly is volume reduction in the context of an industrial treatment plant? Simply put, it’s a strategy focused on minimizing the total amount of industrial wastewater that needs to be treated and discharged. Instead of just processing every drop of effluent, this approach looks for ways to reduce the initial water volume at the source.

By generating less wastewater, your treatment processes become more manageable and efficient. A smaller volume means your ETP can operate more effectively, using less energy and fewer chemicals. This not only streamlines your effluent treatment but also paves the way for significant operational improvements. Let’s look closer at what volume reduction means and why it’s gaining so much traction.

Definition and Significance of Volume Reduction

Volume reduction is the process of minimizing the quantity of wastewater that flows into an effluent treatment plant. This strategy goes beyond traditional treatment by focusing on reducing water use and recycling it within your processes. The goal is to shrink the final discharge volume, making treatment easier and more cost-effective.

The significance of this approach is massive. By reducing the amount of effluent, your facility can more easily meet stringent discharge standards. A smaller volume of wastewater is simpler to treat to a high quality, ensuring you remain compliant with environmental regulations. It’s a proactive step toward minimizing your overall water footprint.

Furthermore, volume reduction is a cornerstone of water reuse initiatives. When you treat a smaller, more concentrated stream of wastewater, you can recover higher-quality water that can be reintroduced into your production cycles. This reduces your dependence on fresh water sources and lessens your facility’s environmental impact, turning a waste product into a valuable resource.

Factors Driving the Adoption of Volume Reduction in 2025

The push toward volume reduction in 2025 isn’t happening by chance. Several powerful factors are encouraging industries to rethink their approach to waste management and embrace more sustainable practices. These drivers reflect a broader shift in how we view water as a resource.

One of the biggest motivators is the increasing need for water conservation. With fresh water sources becoming scarcer, industries are under pressure to reduce their consumption. Volume reduction directly supports this by enabling water reuse and creating more circular systems. It’s a key component of any serious sustainable development strategy.

Additionally, evolving regulatory landscapes are playing a huge role. Governments are setting tougher rules for effluent discharge, forcing companies to find more effective treatment solutions. Key drivers include:

- Stricter Regulatory Compliance: New, more stringent discharge limits for pollutants are making it harder for traditional systems to keep up.

- Corporate ESG Goals: Companies are adopting water footprint accounting to strengthen investor confidence and meet environmental, social, and governance (ESG) targets.

KeyTerms and Terminology Used in ETP Volume Reduction

As you explore volume reduction for your effluent treatment plant, you’ll come across some specific terms and technologies. Understanding this terminology is the first step toward choosing the right treatment processes for your needs.

These terms describe advanced methods designed to remove contaminants and recover water, helping you reduce the final volume of discharged effluent. Many of these technologies are essential for treating complex waste streams containing organic pollutants and dissolved solids.

Here are a few key terms you should know:

- Membrane Filtration: A physical separation process using membranes like Reverse Osmosis (RO) or Ultrafiltration (UF) to remove fine particles and dissolved substances.

- Zero Liquid Discharge (ZLD): A goal-oriented process where all wastewater is purified and recycled, leaving zero liquid waste for discharge.

- Multiple Effect Evaporator (MEE): A system that efficiently evaporates water from effluent in multiple stages, concentrating the waste and recovering clean water.

- Agitated Thin Film Dryer (ATFD): A technology used to dry wet solids or slurries into a powder, significantly reducing the final waste volume.

Overview of Industrial Effluent Treatment Processes

Industrial effluent treatment processes play a vital role in managing wastewater generated by various sectors. These processes encompass multiple stages such as primary treatment, secondary treatment, and advanced treatment to remove pollutants effectively. Biological treatment methods, like the activated sludge process, use microorganisms to break down organic matter, while chemical coagulation helps in removing suspended solids and heavy metals. Ensuring regulatory compliance not only meets discharge standards but also protects public health and aquatic life. By optimizing these processes, industries contribute to sustainable development and minimize their environmental impact.

Conventional ETP Stages Explained

Traditional effluent treatment is typically broken down into three main stages. Each one plays a distinct role in removing pollutants and cleaning the water before it leaves your facility. Understanding these stages helps you see where modern improvements can be made.

The first stage is primary treatment, which is a physical process. Here, large solids and grit are removed using screens and sedimentation tanks. This initial step prepares the wastewater for more advanced treatment by taking out the biggest particles.

Next comes secondary treatment, a biological phase that targets dissolved organic matter. This stage often involves:

- Activated Sludge Process: Microorganisms are used to break down organic pollutants in the presence of oxygen.

- Chemical Coagulation: Chemicals are added to help fine particles clump together, making them easier to remove. Finally, tertiary treatment provides a final polish to the water, removing any remaining contaminants through filtration and disinfection to meet discharge standards.

Comparison Between Traditional and Modern ETP Approaches

The evolution of ETPs has seen a significant shift from traditional processes to advanced treatment methods. While traditional approaches focus on basic compliance, modern systems prioritize efficiency, water recovery, and sustainability. This change is driven by stricter regulations and the growing need for water conservation.

Modern approaches integrate advanced technologies like membrane filtration and Membrane Bioreactors (MBRs). These systems deliver much higher quality effluent, making it suitable for reuse within the facility. This not only reduces fresh water consumption but can also lower long-term operational costs, despite a potentially higher initial investment.

Let’s compare the two approaches:

| Feature | Traditional Processes | Modern Advanced Treatment |

|---|---|---|

| Goal | Meet basic discharge standards | Maximize water recovery and enable reuse |

| Technology | Sedimentation, Activated Sludge Process | Membrane Filtration (RO, UF), MBR, MEE |

| Water Recovery | Low to moderate | High, often enabling Zero Liquid Discharge |

| Footprint | Large, requires significant space | Compact and often modular |

| Operational Costs | Lower initial cost, higher long-term costs | Higher initial cost, lower long-term costs |

Role of Volume Reduction in Standard Treatment Workflows

Integrating volume reduction into a standard effluent treatment plant workflow fundamentally changes the game. Instead of just treating whatever comes down the pipe, you are actively minimizing the load on the entire system. This makes every subsequent step more efficient and less resource-intensive.

When you reduce the volume of wastewater, the size of the required treatment equipment can be smaller. This means lower capital costs for tanks, pumps, and filters. Operationally, you’ll see benefits like reduced energy consumption for aeration and pumping, as well as lower chemical usage for treatment methods like coagulation.

Ultimately, this approach helps your facility move closer to zero liquid discharge. By concentrating the waste stream, you can more effectively apply advanced treatment methods to recover clean water and valuable resources. Some processes, like anaerobic digestion of concentrated organic waste, can even support energy recovery by producing biogas, turning a liability into an asset.

Major Trends Shaping Industrial Wastewater Management in India

In India, the landscape of industrial wastewater treatment is rapidly evolving. Driven by stricter environmental regulations and a growing awareness of water scarcity, industries are moving beyond basic compliance. The focus is now on sustainability, efficiency, and resourcefulness.

Key trends include a strong push for water reuse, the adoption of digital technologies for real-time monitoring, and adherence to updated norms from the Central and State Pollution Control Boards. These shifts are transforming how Indian industries manage their wastewater. Let’s explore these trends in more detail.

Increasing Focus on Water Conservation and Reuse

One of the most significant trends in India today is the intense focus on water conservation and reuse. With increasing pressure on freshwater supplies, industries are recognizing that wastewater is not a waste product but a valuable resource. This mindset is driving a shift toward creating circular water systems.

Many facilities are now treating process water on-site so it can be safely reintroduced into their production streams. This near-closed loop approach dramatically reduces the consumption of fresh water and shrinks the facility’s overall water footprint. Breweries, food processors, and power plants are leading the way by recycling their treated water.

This move toward water reuse is a core pillar of sustainable development. By implementing resource recovery strategies, companies not only conserve a precious resource but also enhance their operational resilience. It’s a smart business decision that aligns perfectly with environmental stewardship, helping to ensure long-term water security for everyone.

Impact of Digitalization and Automation on ETPs

Digitalization and automation are revolutionizing how ETPs are managed. The integration of smart technologies is moving wastewater treatment from a reactive, compliance-driven task to a proactive, data-driven operation. This shift brings unprecedented levels of efficiency and control.

Artificial intelligence (AI), Internet of Things (IoT) sensors, and digital twins are transforming the way treatment technologies are monitored and optimized. Real-time monitoring allows operators to track key parameters like pH, BOD, and flow rate continuously. This data enables precise adjustments to treatment processes, ensuring consistent performance and reducing operational costs.

The benefits of digitalization are clear:

- Optimized Performance: Real-time analytics help optimize aeration, chemical dosing, and filtration cycles, which reduces energy and chemical consumption.

- Predictive Maintenance: Automation can predict equipment failures before they happen, enhancing reliability and minimizing downtime.

- Improved Transparency: Continuous monitoring provides accurate data for regulatory reporting and helps identify areas for improvement.

Government Incentives and Regulatory Evolution

The regulatory framework governing wastewater treatment in India is becoming increasingly stringent, pushing industries toward more sustainable practices. The Central Pollution Control Board (CPCB) and State Pollution Control Boards (SPCBs) are at the forefront of this evolution, setting new environmental norms and compliance standards.

These regulatory guidelines are designed to protect India’s water resources by demanding higher quality treated effluent. New discharge limits for contaminants and expanded monitoring requirements are raising the bar for treatment performance. What was once a matter of simple compliance is now a critical aspect of corporate responsibility and environmental leadership.

To encourage adoption of advanced technologies, there may be government incentives available for industries that proactively upgrade their systems. By investing in solutions that support water reuse and volume reduction, you not only ensure you meet the latest regulatory guidelines but may also benefit from financial support, making the transition smoother and more affordable.

Benefits of Adopting Volume Reduction Strategies

Adopting volume reduction strategies in your treatment plant offers a wide range of compelling benefits. It’s a move that pays dividends both for your bottom line and the environment. By minimizing the amount of wastewater you need to treat, you unlock new levels of efficiency and sustainability.

The advantages go far beyond just meeting regulations. You can expect enhanced water recovery, lower operational costs, and a significantly reduced environmental impact. Let’s dig into how these benefits can transform your wastewater management approach.

Enhanced Water Recovery and Reuse

A primary benefit of volume reduction is the dramatic improvement in water recovery. When you treat a smaller, more concentrated stream of effluent, advanced technologies can work more effectively to purify the water to a very high standard. This makes large-scale water reuse a practical reality.

The treated water produced from these systems is often clean enough to be used in non-potable applications like cooling towers, boiler feed, or even directly back into certain industrial processes. This creates a closed-loop system that significantly reduces your facility’s reliance on scarce and expensive freshwater resources.

Ultimately, this focus on high-efficiency water recovery is a critical step toward achieving Zero Liquid Discharge (ZLD). By recycling and reusing as much water as possible, you minimize your discharge and take a major leap forward in water conservation. It’s a win for your operations and a win for the environment.

Improved Plant Efficiency and Performance

Reducing the volume of wastewater has a direct and positive impact on your treatment plant’s overall efficiency and performance. With less water to handle, your existing equipment is no longer overloaded, allowing all treatment processes to function at their optimal level. This leads to more consistent and reliable results.

This enhanced plant efficiency translates directly into lower operational costs. A smaller volume of water requires less energy for pumping and aeration, which are often the biggest energy consumers in an ETP. You will also use fewer chemicals for pH neutralization and coagulation, further reducing your daily expenses.

Moreover, a more efficient plant is easier to manage. Operators can maintain better control over the treatment processes, leading to fewer upsets and compliance issues. In some cases, treating a more concentrated organic waste stream can even open up opportunities for energy recovery through biogas production, adding another layer of financial benefit.

Environmental and Sustainability Advantages

Beyond the operational and financial gains, volume reduction offers powerful environmental and sustainability advantages. By fundamentally changing how you manage wastewater, you can significantly lessen your facility’s environmental impact and strengthen your commitment to sustainable development.

This approach is a cornerstone of effective pollution control. By treating a smaller volume more thoroughly, you ensure the final treated effluent is of a much higher quality, protecting local water bodies from contamination. It’s a proactive measure that goes beyond mere compliance to active environmental stewardship.

The sustainability benefits are multifaceted and long-lasting. They include:

- Reduced Water Footprint: Conserving fresh water by maximizing reuse.

- Lower Pollution: Minimizing the discharge of pollutants into ecosystems.

- Resource Recovery: Turning waste streams into valuable resources like clean water and energy.

- Lower Carbon Footprint: Reducing energy consumption associated with treatment.

Technologies Driving Volume Reduction in ETPs

Achieving significant volume reduction relies on a suite of advanced treatment technologies. These innovative systems are designed to separate water from contaminants with high efficiency, enabling the recovery of clean water for reuse.

Technologies like membrane filtration, advanced evaporation systems, and enhanced biological treatment methods are at the forefront of this trend. Each offers a unique way to tackle different types of wastewater, making volume reduction a feasible goal for a wide range of industries. Let’s take a closer look at these powerful tools.

Membrane Filtration Technologies (Reverse Osmosis, Ultrafiltration)

Membrane filtration technologies are a cornerstone of modern volume reduction strategies. These systems use semi-permeable membranes to act as a physical barrier, separating pure water from contaminants like dissolved salts, bacteria, and organic molecules. The result is exceptionally high water quality suitable for reuse.

Two of the most common membrane technologies are Reverse Osmosis (RO) and Ultrafiltration (UF). UF is often used as a pre-treatment step to remove larger particles and macromolecules, protecting the more sensitive RO membranes. RO then provides the final polish, removing even the smallest dissolved impurities to produce purified water.

Integrating these technologies into your treatment plant can dramatically increase your water recovery rates. By pushing water through these fine membranes, you can effectively concentrate the waste stream while reclaiming a large portion of the water, a critical step toward minimizing your final discharge volume.

Advanced Evaporation and Concentration Systems

Advanced evaporation and concentration systems are powerful tools for achieving minimal or even zero liquid discharge. These technologies work by heating the effluent to evaporate the water, which is then condensed and collected as clean distillate. The remaining contaminants become a highly concentrated sludge or solid.

Systems like Multiple Effect Evaporators (MEE) are designed for high efficiency. They use the vapor from one stage to heat the next, significantly reducing overall energy consumption compared to single-stage evaporators. This makes the process more economically viable for large-scale applications.

While evaporation can be energy-intensive, it is one of the most effective methods for volume reduction and resource recovery. In addition to recovering clean water, these advanced treatment systems can be used to extract valuable salts or minerals from the effluent, turning a waste disposal problem into a revenue opportunity.

Biological Volume Reduction Methods

Biological treatment methods play a crucial role in volume reduction, particularly by targeting the organic matter in wastewater. These processes use microorganisms to break down organic pollutants, which reduces the overall sludge volume and lowers the Chemical Oxygen Demand (COD) of the effluent.

Modern biological treatment methods are more compact and efficient than traditional systems. Technologies like Membrane Bioreactors (MBRs) combine the conventional activated sludge process with membrane filtration. This results in a much smaller footprint and produces a higher quality effluent that can be directly reused.

Key biological treatment methods that aid volume reduction include:

- Membrane Bioreactor (MBR): Integrates biological degradation with membrane separation for a compact, high-efficiency system.

- Moving Bed Biofilm Reactor (MBBR): Uses biofilm carriers to increase the concentration of microorganisms, allowing for a smaller aeration tank.

- Anaerobic Digestion: Converts high-strength organic waste into biogas, reducing sludge volume while recovering energy.

Selecting the Right Volume Reduction Technology for Your Industry

Choosing the right volume reduction technology is not a one-size-fits-all decision. The optimal solution for your facility depends on a variety of factors, including the specific characteristics of your wastewater, your budget for capital and operational costs, and your long-term goals for environmental protection.

A thorough technology selection process is crucial to ensure you invest in a system that is both effective and sustainable for your industry-specific needs. You need to assess your options carefully to find the perfect fit. Let’s explore the criteria you should consider.

Assessment Criteria for Technology Selection

When evaluating different technologies for volume reduction, a careful assessment is essential to make an informed decision. You need to look beyond the initial price tag and consider the entire lifecycle of the technology to ensure it aligns with your operational and financial goals.

The characteristics of your effluent are the most important starting point. Is it high in organic matter, dissolved solids, or specific chemicals? The right technology must be able to handle your unique waste stream effectively. You should also consider the required quality of the treated water to ensure it meets discharge standards or reuse requirements.

Here are some key assessment criteria to guide your technology selection:

- Capital and Operational Costs: Balance the initial investment against long-term expenses for energy, chemicals, and maintenance.

- Energy Consumption: Evaluate the energy footprint of the technology, as this will be a major operational cost.

- Footprint and Scalability: Consider the physical space required and whether the system can be easily expanded in the future.

- Sludge Management: Assess the volume and type of sludge produced and the associated disposal costs.

Industry-Specific Technology Preferences

Different industries generate vastly different types of wastewater, which is why technology preferences are highly industry-specific. A solution that works perfectly for a food processing plant might be completely unsuitable for a pharmaceutical facility.

For example, the food and beverage industry typically produces wastewater with a high organic load (high BOD and COD). For them, biological treatment methods like anaerobic digestion or MBRs are often ideal, as they efficiently break down organic waste and can even generate energy. In contrast, the textile industry deals with high levels of Total Dissolved Solids (TDS), dyes, and chemicals. This requires a combination of chemical treatment, advanced oxidation, and membrane filtration like Reverse Osmosis to remove color and salts.

Similarly, the pharmaceuticals and chemical manufacturing sectors produce complex effluents containing hazardous chemicals and heavy metals. These industries often require multi-stage treatment trains involving advanced oxidation processes, chemical precipitation, and evaporation systems to ensure all toxic compounds are removed and regulations are met.

Case Studies from Indian Industry Sectors

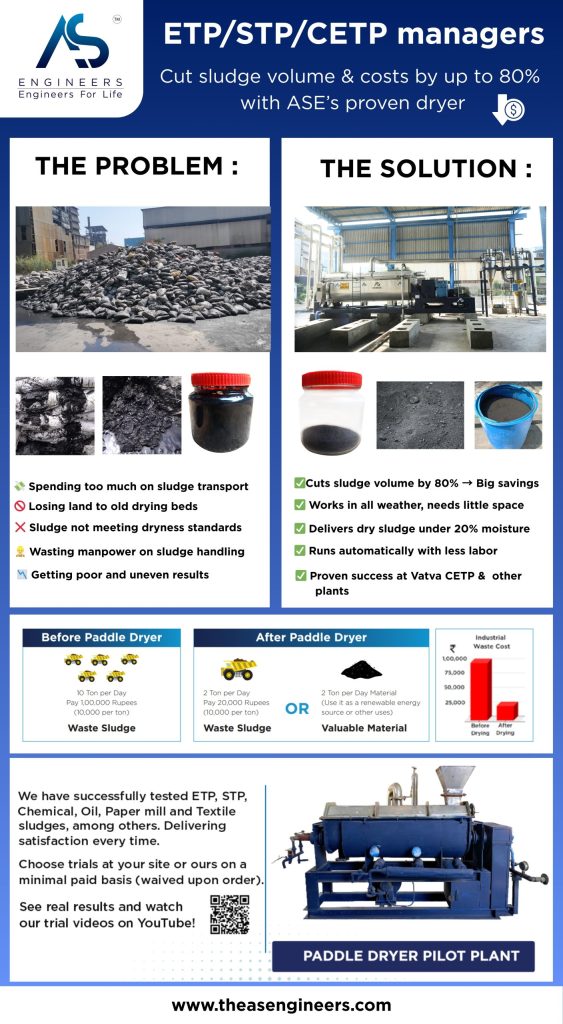

Real-world examples from Indian industries demonstrate the tangible benefits of optimizing an effluent treatment plant for volume reduction. One notable case involves an electrical and manufacturing facility that was struggling with inefficient wastewater management and regulatory non-compliance.

By implementing process optimization, real-time monitoring, and improved sludge management techniques, the company completely transformed its ETP performance. The changes led to a significant reduction in the volume of solid waste generated and ensured the treated effluent consistently met all discharge standards. This greatly reduced the facility’s environmental impact.

The results speak for themselves:

- A 40% reduction in sludge generation.

- Improved compliance with regulatory norms.

- Annual cost savings of approximately ₹12 lakh. This case study proves that investing in better ETP operations is not just an expense but a strategic move that delivers significant financial and environmental returns.

Regulatory Guidelines Supporting Volume Reduction in India

In India, regulatory bodies are playing a pivotal role in pushing industries toward more sustainable wastewater practices, including volume reduction. The regulatory guidelines set by the Central Pollution Control Board (CPCB) and State Pollution Control Boards (SPCBs) are becoming increasingly stringent.

These updated environmental norms indirectly support volume reduction by setting tough discharge standards that are often difficult to meet with conventional treatment methods alone. This encourages industries to adopt advanced technologies that enable water reuse and minimize final discharge. Let’s examine these norms more closely.

CPCB and State Pollution Control Board Norms

The Central Pollution Control Board (CPCB), along with the various State Pollution Control Boards (SPCBs), establishes the legal framework for wastewater discharge in India. These bodies set the quality standards that all treated effluent must meet before it can be released into the environment.

These environmental regulations are not static; they are continuously updated to address growing pollution concerns. Recently, the CPCB has introduced much stricter discharge standards for key parameters, making compliance more challenging for industries using outdated treatment systems. This is a deliberate move to encourage the adoption of better technologies.

For example, the new norms require significantly lower levels of pollutants in the treated effluent, including:

- Biochemical Oxygen Demand (BOD): ≤ 10 mg/L

- Chemical Oxygen Demand (COD): ≤ 50 mg/L

- Total Suspended Solids (TSS): ≤ 10 mg/L Meeting these tough standards often necessitates advanced treatment and volume reduction strategies.

New Compliance Standards for ETP Discharge

The latest compliance standards for ETP discharge represent a major step up in pollution control. These new rules are designed to ensure that the treated effluent released by industries has a minimal impact on the environment. For many facilities, achieving these standards will require a significant upgrade in their treatment capabilities.

The focus is on reducing not just organic pollutants but also nutrients and microbial contamination. This holistic approach to water quality is essential for protecting India’s rivers, lakes, and groundwater from further degradation. Regulatory compliance is no longer just about avoiding fines; it’s about active environmental preservation.

Key new discharge standards that industries must now meet include:

- Total Nitrogen: ≤ 5 mg/L

- Ammonical Nitrogen: ≤ 5 mg/L

- Fecal Coliform: ≤ 100 MPN/100 mL These stringent quality standards make a strong case for implementing volume reduction, as it is easier to achieve such high purity levels when treating a smaller, more manageable volume of water.

Monitoring and Reporting Requirements

To ensure adherence to the new environmental norms, regulatory bodies have also strengthened monitoring and reporting requirements. Industries are now expected to provide transparent, real-time data on the performance of their ETPs. This holds facilities accountable and ensures that discharge standards are met consistently.

Many regulatory guidelines now mandate the installation of Continuous Effluent Monitoring Systems (CEMS). These systems use inline sensors to automatically track key parameters like pH, TSS, BOD, and COD. The data is often transmitted directly to the pollution control board, leaving no room for discrepancies.

This emphasis on continuous monitoring and reporting makes it crucial for industries to maintain optimal ETP performance at all times. Volume reduction strategies can help in this regard by creating a more stable and efficient treatment process. A well-controlled system is much more likely to stay within the prescribed discharge standards, making reporting a smooth and stress-free process.

Volume Reduction and Pollution Control Compliance

There is a direct and powerful link between volume reduction and achieving pollution control compliance. When you reduce the amount of effluent discharge, you simplify the path to meeting even the strictest regulatory compliance standards. It’s a strategic approach to environmental protection.

By treating a smaller, more concentrated waste stream, your ETP can operate more effectively to remove pollutants. This ensures the final discharge is cleaner and consistently meets all legal requirements. Let’s explore how this strategy strengthens your compliance framework.

Linking Volume Reduction with Legal Compliance

Achieving legal compliance is a top priority for any industrial operation, and volume reduction is a powerful ally in this effort. The core principle is simple: it is far easier and more cost-effective to treat a smaller volume of wastewater to a very high standard than it is to treat a massive volume to a mediocre one.

When you implement volume reduction, you are effectively concentrating the pollutants into a more manageable stream. This allows your advanced treatment systems to target and remove contaminants more efficiently, ensuring that the final effluent consistently meets the stringent discharge standards set by the pollution control board.

This proactive approach significantly lowers the risk of non-compliance and the associated penalties, such as heavy fines or even plant shutdowns. By linking volume reduction directly to your strategy for meeting environmental regulations, you transform compliance from a reactive burden into a manageable and predictable part of your operations.

Strategies to Meet Discharge Parameters Using Volume Reduction

Successfully using volume reduction to meet discharge standards involves a multi-pronged approach. It starts with optimizing processes at the source to minimize water usage and continues through to the final treatment methods. This holistic strategy ensures that the final treated effluent is clean and compliant.

Continuous monitoring is key to this process. By tracking the performance of your treatment methods in real time, you can make immediate adjustments to ensure that parameters like BOD, COD, and TDS remain within the legal limits. A data-driven approach removes guesswork and enhances reliability.

Here are some effective strategies to consider:

- Source Reduction: Modify production processes to use less water from the start.

- Process Optimization: Segregate different wastewater streams to treat them more effectively.

- Advanced Treatment: Use technologies like reverse osmosis or evaporation to remove the toughest contaminants from the concentrated stream.

- Water Reuse: Recycle treated water for non-potable uses, reducing the final discharge volume to a minimum.

Reporting and Documentation Practices

Meticulous reporting and documentation are essential for proving regulatory compliance. In an era of strict oversight, simply meeting discharge standards is not enough; you must be able to prove it with clear and accurate records.

Your documentation should include detailed logs of your ETP’s daily operations, results from water quality tests, and records of all maintenance activities. If you are using continuous monitoring systems, the data logs from these devices are a critical part of your compliance record. This information provides a transparent account of your efforts to manage effluent discharge responsibly.

Proper documentation also includes records of sludge disposal, chemical consumption, and energy usage. These details create a complete picture of your wastewater management practices. Maintaining organized and comprehensive records not only satisfies regulatory requirements but also helps you analyze your plant’s performance and identify opportunities for further improvement.

Challenges in Adopting Volume Reduction for Industrial ETPs

While the benefits of volume reduction are clear, the transition is not without its challenges. Industries often face a combination of economic barriers, technical hurdles, and operational complexities when shifting to more advanced wastewater treatment systems.

These obstacles can range from high initial investment costs to the need for a more skilled workforce. Understanding these challenges is the first step in creating a realistic and successful implementation plan. Let’s look at some of the common barriers you might encounter.

Economic and Technical Barriers

The most significant hurdles to adopting volume reduction are often economic and technical. The advanced treatment technologies required for these systems typically come with a substantial upfront capital investment. For many companies, this initial cost can be a major deterrent.

Beyond the initial purchase, some advanced systems have higher operational costs. For instance, thermal evaporators can have high energy consumption, which can impact your facility’s overall energy budget. These ongoing expenses must be carefully weighed against the long-term savings from water reuse and reduced disposal fees.

From a technical perspective, there are other barriers to consider:

- High Capital Investment: The cost of technologies like MBRs, RO systems, and evaporators can be significant.

- Increased Energy Consumption: Certain processes, particularly thermal ones, require a lot of energy to operate.

- Maintenance Complexity: Advanced systems often require more specialized maintenance and spare parts.

- Process Stability: Managing highly concentrated waste streams can sometimes be more complex than dealing with dilute effluent.

Operational Issues and Workforce Skill Requirements

Shifting to advanced volume reduction technologies also brings new operational issues. These systems are more sophisticated than traditional treatment plants and demand a higher level of process control and monitoring to function effectively.

This sophistication requires a workforce with new skills. Operators must be trained to manage complex processes, interpret data from real-time sensors, and troubleshoot advanced equipment. A lack of trained personnel can lead to operational issues, reduced efficiency, and even system failures, undermining the benefits of the new technology.

Investing in comprehensive training programs for your ETP staff is therefore just as important as investing in the hardware itself. A skilled and confident team is your best insurance against operational problems. They will be able to optimize the treatment plant’s performance, ensure consistent compliance, and maximize the return on your technology investment.

Addressing Sector-Specific Obstacles

The challenges of implementing volume reduction can vary significantly from one industry to another. These sector-specific obstacles arise from the unique composition of the wastewater each industry produces. A tailored approach is necessary to overcome these industry-specific hurdles.

For example, industries that produce wastewater with highly variable loads or compositions may find it difficult to maintain stable treatment processes. A sudden change in the effluent characteristics can disrupt the balance of a biological system or foul a membrane, requiring careful pre-treatment and process control.

Different sectors face distinct challenges:

- Pharmaceuticals: The presence of complex and often hazardous chemicals can make treatment difficult and require multiple advanced treatment stages.

- Textiles: High concentrations of dyes and salts (TDS) necessitate specialized chemical treatment and membrane processes that can be prone to fouling.

- Tanneries: Wastewater from tanneries contains heavy metals like chromium and sulfides, which require specific removal processes before biological treatment.

Cost Implications and Savings from Volume Reduction

When considering volume reduction, it’s essential to look at the full financial picture. While there is an initial investment required to upgrade your systems, the long-term savings in operational costs and water management costs can be substantial.

This strategic investment can lead to a surprisingly quick payback. By reducing water consumption, lowering disposal fees, and potentially qualifying for financial incentives, you can turn your ETP from a cost center into a source of savings. Let’s break down the cost implications and potential returns.

Investment Payback Periods

Calculating the investment payback period is a crucial step in justifying the capital costs of a new volume reduction system. The payback period is the time it takes for the accumulated savings from the new system to equal the initial investment. A shorter payback period makes the project more financially attractive.

To calculate this, you need to balance the upfront capital costs against the projected annual savings. These savings come from various sources, including reduced water purchase costs, lower effluent disposal fees, and decreased operational costs for energy and chemicals. The more water you can reuse, the faster the payback.

Factors that contribute to a shorter payback period include:

- High Water Costs: If your facility is in an area with expensive fresh water, the savings from reuse will be greater.

- Significant Resource Recovery: If you can recover valuable materials or generate energy (biogas), this creates an additional revenue stream.

- Lower Operational Costs: Reduced energy and chemical consumption directly contributes to faster payback.

Reductions in Water and Effluent Management Costs

One of the most direct financial benefits of volume reduction is the significant cut in water and effluent management costs. By treating and reusing water on-site, you drastically reduce the amount of fresh water you need to purchase from municipal sources or extract from the ground. Over time, this can lead to massive savings.

Simultaneously, you lower your effluent management costs. Disposing of wastewater, whether to a common effluent treatment plant or directly into the environment (after treatment), often involves fees based on volume. By minimizing your final discharge, you reduce these fees. This also applies to solid waste management, as more efficient treatment can lead to less sludge production.

These reductions in day-to-day operational costs have a direct impact on your bottom line. The money saved on water purchase and waste management can be reallocated to other core business activities, improving your company’s overall financial health.

Financial Incentives for Early Adopters

To accelerate the adoption of sustainable technologies, governments and environmental agencies sometimes offer financial incentives to early adopters. These programs are designed to help offset the initial investment required for upgrading to advanced volume reduction systems, making the transition more accessible for businesses.

These government incentives can come in various forms, such as grants, tax credits, or low-interest loans. They recognize that investing in green technology benefits not just the company but the entire community by conserving water and reducing pollution. Taking advantage of these programs can significantly improve the financial case for your ETP upgrade.

Exploring available financial incentives should be a key part of your planning process. Look for:

- Subsidies for Green Technology: Direct financial assistance for purchasing and installing eligible equipment.

- Tax Benefits: Credits or deductions for capital investments in pollution control and water conservation technologies.

- Lower Financing Costs: Access to special loan programs with favorable interest rates for sustainable projects.

Applicability Across Industrial Sectors

Volume reduction is a relevant and powerful strategy for nearly every industrial sector, but its application must be highly customized. The design of an effective effluent treatment plant depends entirely on the unique characteristics of the wastewater being produced.

From food processing to pharmaceuticals, every industry faces its own sector-specific obstacles and generates a different profile of pollutants. Therefore, a successful volume reduction strategy requires an industry-specific approach, carefully selecting technologies that can handle the unique challenges of your effluent.

Volume Reduction in Textile, Pharmaceutical, and Food Industries

In the textile, pharmaceutical, and food industries, volume reduction has become essential for efficient wastewater management. By focusing on techniques like membrane filtration and reverse osmosis, these sectors effectively minimize the total volume of wastewater generated. This not only aids in achieving regulatory compliance with environmental norms but also enhances the potential for water reuse. Implementing volume reduction strategies helps reduce operational costs and energy consumption, while simultaneously protecting aquatic life and preserving water quality. Ultimately, these practices contribute to sustainable development and responsible waste management.

Suitability for Small, Medium, and Large-Scale ETPs

Tailored solutions exist for various scales of effluent treatment plants (ETPs), ensuring optimal wastewater management. Small-scale ETPs can effectively implement volume reduction technologies to manage limited effluent discharge while maintaining water quality. Medium-sized facilities benefit from balanced treatment processes that combine biological methods and advanced tech like membrane filtration for enhanced resource recovery. Large-scale operations often adopt zero liquid discharge systems to comply with stringent regulatory standards, significantly curtailing environmental impact. Each scale can achieve sustainable development goals, supporting a safer ecosystem while fulfilling public health obligations.

Conclusion

Recognizing the significance of evolving trends in industrial effluent treatment processes is vital for sustainable practices. Embracing volume reduction not only addresses regulatory compliance but also enhances water conservation efforts. By adopting advanced treatment technologies, industries can significantly minimize harmful discharges and protect both public health and aquatic life. As awareness of environmental impact grows, integrating effective wastewater management practices into daily operations becomes imperative. Ultimately, pursuing these innovative approaches not only aligns with environmental norms but also fosters a commitment to responsible resource recovery for a greener future.

Frequently Asked Questions

Is volume reduction applicable for all types of industrial effluent in India?

Volume reduction is essential for various industries in India, such as textiles, pharmaceuticals, and food processing. However, the applicability may vary based on the specific effluent characteristics and treatment requirements, necessitating tailored approaches for effective implementation across different types of industrial effluents.

Does volume reduction impact day-to-day ETP operations?

Volume reduction significantly enhances day-to-day ETP operations by minimizing waste handling and disposal costs, improving resource efficiency, and ensuring compliance with regulatory standards. This leads to smoother operations, reduced environmental impact, and potential savings for facilities across various industrial sectors.

How does volume reduction help industries lower pollution levels and remain compliant?

Volume reduction minimizes the volume of wastewater generated, which directly reduces pollutant loads. By adopting efficient effluent treatment practices, industries can effectively lower their environmental impact, leading to compliance with regulatory standards and contributing to sustainability efforts.

What are the key trends currently shaping industrial effluent treatment processes (ETP)?

Current trends in industrial effluent treatment processes (ETP) include the adoption of advanced technologies, increased focus on sustainability, and regulatory compliance. These trends emphasize efficiency, cost reduction, and innovative solutions that enhance water reuse and minimize environmental impact across various industries.