Have you ever wondered how industries transform wet, sticky sludge into dry, usable materials in just a few hours? Or how delicate food ingredients are dried without losing their quality? The answer lies in a remarkable piece of equipment: the paddle dryer. This unsung hero of industrial processes is a game-changer for sectors like chemical processing, food production, and wastewater treatment.

In this comprehensive guide, we’re diving deep into the world of paddle dryers. You’ll discover what they are, how they work, their benefits, and why they’re so essential across various industries. We’ll explore different types, real-world applications, maintenance tips, and even future trends. By the end, you’ll have the knowledge to understand paddle dryers inside and out—and maybe even choose the right one for your needs. Let’s get started!

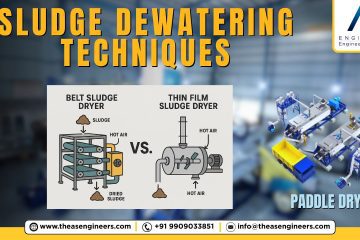

What is a Paddle Dryer?

A paddle dryer is an industrial drying system designed to remove moisture from materials like sludge, pastes, and powders. Picture a large cylindrical vessel with a rotating shaft lined with paddles. Those paddles are the secret sauce—they mix and agitate the material while heat dries it out. The result? A uniform, dry product ready for the next step in the process.

Paddle dryers stand out because of their efficiency and versatility. Whether it’s turning wastewater sludge into a manageable powder or drying heat-sensitive chemicals, these machines get the job done. They’re a staple in industries where moisture control is critical, and their unique design makes them a cut above traditional dryers.

How Does a Paddle Dryer Work?

So, how does this magic happen? Let’s break it down.

At its core, a paddle dryer uses heat and agitation to evaporate moisture. Here’s the step-by-step process:

- Material Loading: Wet material—think sludge or a thick paste—is fed into the dryer’s cylindrical chamber.

- Paddle Action: The rotating shaft, fitted with specially designed paddles, stirs the material. This constant movement ensures every particle gets exposed to heat.

- Heat Transfer: Heat comes into play in one of two ways:

- Direct Heating: Hot gas flows through the chamber, directly contacting the material.

- Indirect Heating: The vessel walls or paddles are heated (often with steam or hot oil), transferring heat to the material without gas contact.

- Moisture Removal: As the material heats up, moisture evaporates. The vapor is then vented out, leaving behind a dry product.

- Discharge: Once drying is complete, the finished product is discharged, ready for use or further processing.

The beauty of this system lies in its precision. The paddles don’t just mix—they scrape the walls to prevent buildup, ensuring consistent drying. It’s like a chef stirring a pot to keep everything cooking evenly, but on an industrial scale.

Types of Paddle Dryers

Not all paddle dryers are created equal. Depending on your needs, you might encounter these variations:

1. Direct vs. Indirect Paddle Dryers

- Direct: Hot air or gas flows through the material. It’s fast and ideal for robust materials that can handle direct heat.

- Indirect: Heat transfers through the vessel walls or paddles. This gentler method suits heat-sensitive materials like pharmaceuticals or food ingredients.

2. Batch vs. Continuous Paddle Dryers

- Batch: Processes one load at a time. Perfect for smaller operations or when precise control is needed.

- Continuous: Material flows in and out nonstop. Great for high-volume production lines.

Each type has its strengths, and the right choice depends on your material and goals. More on that later!

Applications of Paddle Dryers

Paddle dryers are incredibly versatile. Here’s where they shine:

Industries That Rely on Paddle Dryers

- Wastewater Treatment: Drying sludge into a compact, manageable form for disposal or reuse.

- Chemical Processing: Handling sticky or heat-sensitive compounds with care.

- Food Production: Drying ingredients like starches or proteins without degrading quality.

- Pharmaceuticals: Processing powders and pastes under strict conditions.

- Mining: Drying mineral slurries efficiently.

Real-World Examples

- A wastewater plant uses a paddle dryer to reduce sludge volume by 80%, cutting disposal costs.

- A food manufacturer dries potato starch, preserving its texture for instant mashed potatoes.

These examples show why paddle dryers are indispensable—they solve tough drying challenges across the board.

Advantages of Paddle Dryers

Why choose a paddle dryer over other drying systems? Here are the top benefits:

- Efficiency: The paddle design maximizes heat transfer, cutting drying time and energy use.

- Gentle Handling: Indirect heating protects delicate materials from damage.

- Versatility: Handles everything from sludge to powders with ease.

- Compact Footprint: Takes up less space than some bulkier dryers.

- Low Maintenance: Self-cleaning paddles reduce buildup and downtime.

Case Study: A chemical plant switched to a paddle dryer and saw a 30% drop in energy costs while improving product consistency. That’s the kind of win that makes you sit up and take notice.

How to Choose the Right Paddle Dryer

Picking the perfect paddle dryer isn’t a one-size-fits-all deal. Here’s what to consider:

Key Factors

- Material Properties: Is it sticky, heat-sensitive, or abrasive? This dictates direct vs. indirect heating.

- Capacity: How much material do you need to process daily? Batch or continuous depends on volume.

- Energy Source: Steam, oil, or gas—choose based on availability and cost.

- Space: Ensure the dryer fits your facility’s layout.

Actionable Tips

- Test a small batch with a supplier to see how your material reacts.

- Look for models with adjustable paddle speeds for flexibility.

- Prioritize energy-efficient designs to save long-term costs.

Choosing wisely means better performance and fewer headaches down the line.

Maintenance and Troubleshooting Tips

A paddle dryer is a workhorse, but it needs care to stay in top shape. Here’s how to keep it running smoothly:

Best Practices

- Regular Cleaning: Clear out residue after each run to prevent buildup.

- Lubrication: Keep the shaft and bearings well-oiled.

- Inspection: Check paddles for wear and tear monthly.

Common Issues and Fixes

- Uneven Drying: Adjust paddle speed or heat settings.

- Clogging: Reduce feed rate or check for blockages.

- Overheating: Ensure proper ventilation and monitor temperature controls.

Pro tip: Keep a maintenance log. It’s a simple way to spot patterns and catch issues early.

Future Trends in Paddle Dryer Technology

What’s next for paddle dryers? The industry is buzzing with innovation:

- Smart Controls: Sensors and automation for real-time adjustments, boosting efficiency.

- Energy Recovery: Systems that recycle heat to cut costs and emissions.

- Eco-Friendly Designs: Focus on sustainability with lower energy use and greener materials.

These advancements could revolutionize drying processes, making paddle dryers even more valuable in the years ahead.

Common Misconceptions About Paddle Dryers

Let’s clear up some myths:

- “They’re Only for Sludge”: Nope—they handle powders, pastes, and more.

- “They’re High-Maintenance”: With proper care, they’re quite durable.

- “They’re Too Expensive”: Initial costs are offset by energy savings and efficiency.

Knowing the truth helps you see their real potential.

FAQs About Paddle Dryers

Here are answers to questions readers often ask:

1. What Materials Can Be Dried in a Paddle Dryer?

Anything from sludge and pastes to powders—think wastewater sludge, food starches, or chemical compounds.

2. How Does a Paddle Dryer Compare to Other Dryers?

It’s more efficient than drum dryers and gentler than spray dryers, striking a balance for diverse needs.

3. What’s the Maintenance Like?

Routine cleaning and inspections keep it humming. It’s less demanding than you might think.

4. Are Paddle Dryers Energy-Intensive?

Not necessarily—modern designs focus on energy efficiency, especially with indirect heating.

5. Can They Handle Heat-Sensitive Materials?

Yes! Indirect paddle dryers excel at drying delicate substances without damage.

Conclusion

Paddle dryers are more than just machines—they’re problem-solvers that bring efficiency, quality, and versatility to industries worldwide. From their clever paddle design to their wide-ranging applications, they tackle drying challenges with finesse. Whether you’re in wastewater treatment, food production, or chemical manufacturing, understanding paddle dryers can transform your operations.

We’ve covered the essentials: how they work, their benefits, and how to choose and maintain one. Hopefully, you’re now equipped to make smart decisions about this powerful technology.

Ready to Revolutionize Your Drying Process?

Don’t settle for outdated drying methods or generic equipment. With AS Engineers, you’re partnering with the best in the business. Our paddle dryers are designed to save you time, cut costs, and elevate your operations.

Take the first step today! Contact AS Engineers for a free consultation and see how our industry-leading paddle dryers can transform your workflow. Visit our or call us at +91 990 903 3851 to get started. Let’s dry smarter, together!