Welcome! The Dahej and Bharuch region in Gujarat is a bustling industrial hub. While this drives economic growth, it also puts immense pressure on water resources. Zero liquid discharge (ZLD) has emerged as a crucial approach to wastewater treatment, aiming to recycle every drop of water. However, implementing ZLD systems here is not without its challenges. This blog will explore the top hurdles faced by ZLD plants in this unique industrial corridor and discuss effective solutions to overcome them.

Table of contents

- Key Highlights

- Overview of Zero Liquid Discharge (ZLD) Plants in Dahej and Bharuch

- Core Technical Challenges for ZLD Plants in the Dahej/Bharuch Region

- Compliance with Environmental Regulations and Standards

- Operational and Financial Hurdles Faced by ZLD Operators

- Sludge Disposal Challenges and Solutions in ZLD Plants

- Technological Innovations and Best Practices in ZLD for the Region

- Conclusion

- Frequently Asked Questions

Key Highlights

Here are the key takeaways from our discussion on ZLD plants in the Dahej/Bharuch region:

- Implementing zero liquid discharge (ZLD) systems presents unique technical and financial challenges for industries in this region.

- Strict environmental regulations from bodies like the Gujarat Pollution Control Board drive the need for effective wastewater treatment.

- High energy consumption and operational costs are significant hurdles for ZLD plant operators.

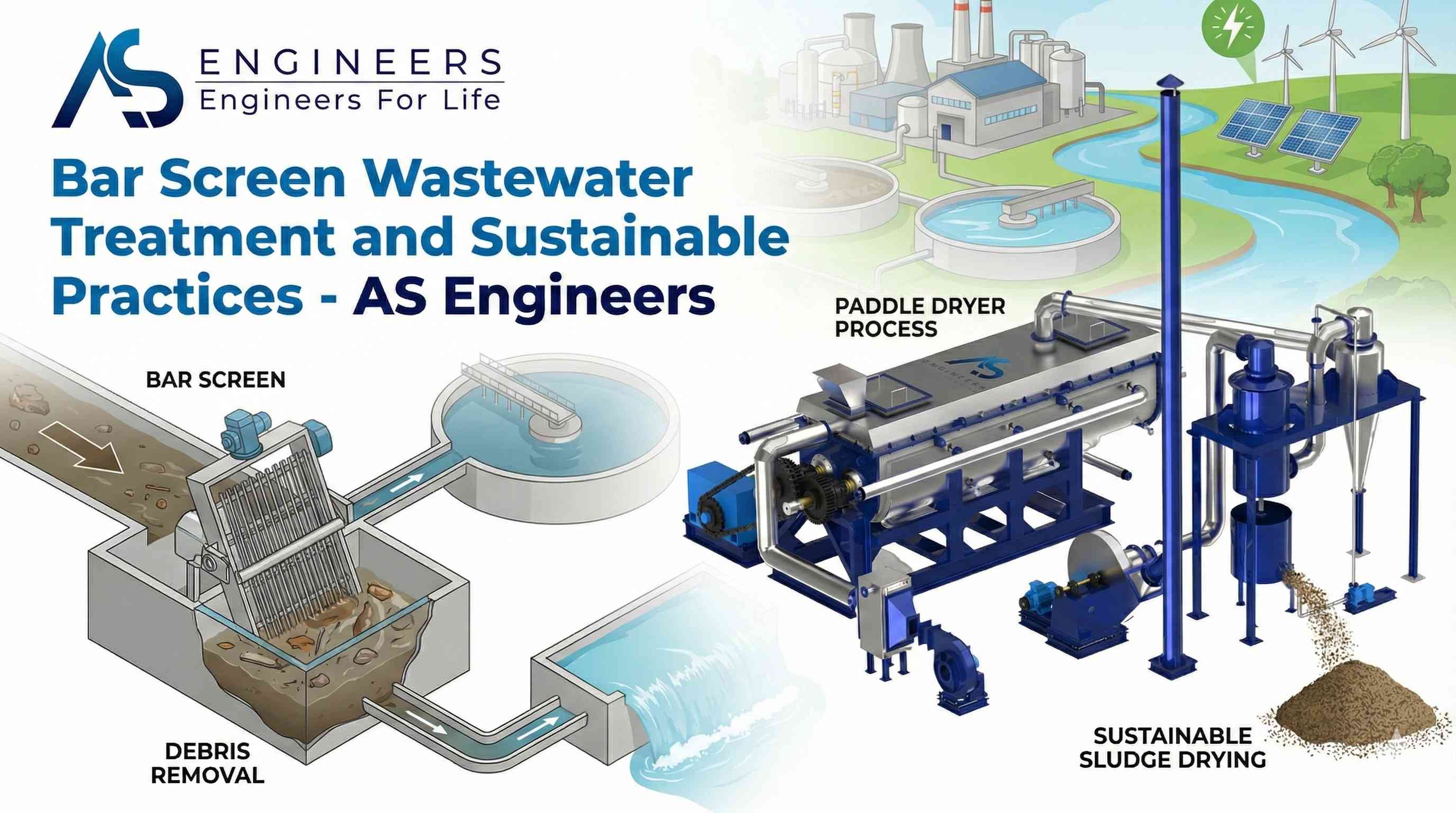

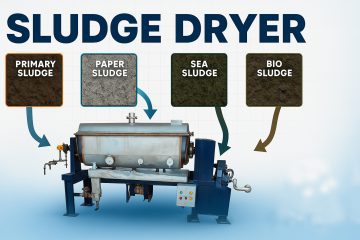

- Sludge disposal is a major concern, but innovative solutions like paddle dryers offer an efficient way to manage solid waste.

- Properly managing water quality and high-salinity streams is crucial for successful ZLD implementation.

Overview of Zero Liquid Discharge (ZLD) Plants in Dahej and Bharuch

A zero liquid discharge plant is a wastewater management system designed to eliminate any liquid waste from your industrial processes. The primary goal is to treat and recycle all industrial wastewater, leaving only solid residues behind. This approach significantly reduces the environmental impact of your operations.

In areas like Dahej and Bharuch, where industrial activity is dense, a ZLD plant plays a vital role in conserving water. By promoting water reuse, these facilities help your business comply with environmental laws and ensure a sustainable water supply for future operations.

Unique Industrial Landscape and Its Influence on ZLD Implementation

The Dahej and Bharuch region is home to a high concentration of industrial units, particularly from the chemical industry, textile plants, and pharmaceutical companies. This dense clustering of factories creates a complex wastewater profile. Each industry generates effluent with unique characteristics, including varying levels of salinity, contaminants, and chemical compounds. How does this local industrial activity impact ZLD plants? It means a one-size-fits-all approach to ZLD implementation simply won’t work.

Your facility’s wastewater might contain high levels of dissolved solids, while a neighboring plant might struggle with toxic organic compounds. This diversity requires ZLD systems to be highly customized. The design must account for the specific water chemistry and contaminants produced by your industrial processes to ensure effective treatment and regulatory compliance.

Ultimately, the unique industrial landscape directly influences the technology, cost, and operational strategy for any ZLD implementation. Your system must be robust enough to handle fluctuating wastewater loads and compositions, making the engineering and design phases incredibly important for long-term success.

Regional Water Quality Considerations for ZLD Systems

The water quality in the Dahej and Bharuch region presents specific challenges for ZLD systems. The raw water sources may already have high levels of dissolved solids and hardness, which can complicate the treatment process even before industrial contaminants are introduced. Are there any region-specific water quality challenges for ZLD implementation here? Absolutely.

The primary issue is the high total dissolved solids (TDS) and salinity found in both the source water and the industrial effluent. This unique water chemistry makes processes like reverse osmosis more difficult, as membranes can quickly become clogged or scaled. This leads to reduced efficiency, higher energy use, and increased maintenance costs for your ZLD system.

To ensure the final treated water meets the required purity standards for reuse, your ZLD system must include extensive pretreatment and robust concentration technologies. Properly addressing these regional water quality issues is essential for protecting your equipment and achieving sustainable water management.

Core Technical Challenges for ZLD Plants in the Dahej/Bharuch Region

Operating a zero liquid discharge system in a demanding industrial environment like Dahej and Bharuch comes with significant technical hurdles. The complex nature of the wastewater, coupled with the need for high efficiency, puts immense strain on the entire ZLD process. These challenges directly impact operational costs and overall performance.

The primary technical difficulties revolve around managing highly saline and complex waste streams and ensuring effective pretreatment. Furthermore, the high energy consumption required for thermal processes remains a persistent issue for many operators. Let’s look at these challenges more closely.

High-Salinity Wastewater Management and Complex Streams

Industries in Dahej and Bharuch, especially chemical and textile plants, often produce high-salinity wastewater. Managing these complex streams is one of the biggest challenges in wastewater treatment. High salt concentrations can hinder the effectiveness of conventional biological treatments and damage sensitive equipment. How do ZLD plants in this region manage these streams? They rely on advanced multi-stage treatment processes.

The initial step often involves membrane filtration technologies like reverse osmosis (RO). RO systems use high pressure to push water through a semi-permeable membrane, leaving salts and other contaminants behind. However, as the water becomes more concentrated, the osmotic pressure increases, making standard RO less effective. To address this, ZLD plants use advanced techniques, including:

- High-pressure RO systems designed for brine concentration.

- Thermal evaporators and crystallizers to remove the remaining water.

- Electrodialysis to separate salts using an electric current.

These technologies allow ZLD plants to handle even the most challenging high-salinity wastewater. By separating waste streams and applying targeted treatments, facilities can recover maximum water while isolating contaminants, ensuring the entire system operates efficiently.

Pretreatment and Chemical Conditioning Issues

Effective pretreatment is the foundation of a successful ZLD system, but it presents its own set of challenges. Raw industrial wastewater often contains large particles, oils, suspended solids, and heavy metals that can damage downstream equipment like membranes and evaporators. What are the main technical challenges? One is designing a pretreatment process that can consistently remove these varied contaminants.

Your pretreatment stage must be robust enough to handle fluctuations in wastewater composition. This often involves a multi-step approach, including screening to remove large particles, chemical conditioning to precipitate heavy metals, and clarification to settle suspended solids. Choosing the right chemicals and dosages is crucial, as incorrect conditioning can lead to further problems like scaling.

While a thorough pretreatment system requires a significant initial investment, it is essential for protecting more expensive components of the ZLD plant. Skipping or under-designing this stage can lead to frequent equipment fouling, increased maintenance, and higher long-term operational costs.

Compliance with Environmental Regulations and Standards

Navigating the web of environmental regulations is a major task for industrial units in Gujarat. Regulatory bodies like the Gujarat Pollution Control Board (GPCB), Central Pollution Control Board (CPCB), and the National Green Tribunal (NGT) set strict standards for wastewater discharge. Achieving regulatory compliance is non-negotiable and is a primary driver for adopting ZLD technology.

These standards are in place to protect the region’s water resources from industrial pollution. For your facility, this means your ZLD system must consistently perform at a high level to avoid penalties and contribute to environmental protection. Let’s explore the key mandates and common compliance hurdles.

Key Regulatory Bodies and Mandates in Gujarat

In Gujarat, several regulatory bodies oversee environmental protection and mandate how industries manage their wastewater. Which environmental regulations most affect your ZLD plant? The guidelines set by the Gujarat Pollution Control Board (GPCB) and the Central Pollution Control Board (CPCPB) are the most direct. These agencies enforce rules under the Water (Prevention and Control of Pollution) Act and the Environment (Protection) Act.

These mandates often require specific industries, such as textiles, chemicals, and pharmaceuticals, to achieve zero liquid discharge. This means your facility is legally obligated to eliminate all liquid discharge, making a fully functional ZLD system a necessity, not a choice. The GPCB regularly inspects industrial units to ensure compliance.

Below is a simple breakdown of the key regulatory bodies and their roles:

| Regulatory Body | Key Role and Mandate |

|---|---|

| Gujarat Pollution Control Board (GPCB) | Sets state-specific effluent standards, issues permits, and conducts regular monitoring and enforcement for all industrial units in Gujarat. |

| Central Pollution Control Board (CPCB) | Develops national standards for pollution control, provides technical guidelines for ZLD implementation, and oversees highly polluting industries. |

| National Green Tribunal (NGT) | A specialized judicial body that handles environmental protection cases and can issue directives to enforce regulations and penalize non-compliant industries. |

Common Environmental Compliance Barriers for ZLD Facilities

Even with advanced ZLD systems, achieving consistent regulatory compliance can be challenging. What are the most common compliance issues that industries in Dahej and Bharuch face? A primary barrier is the variability of industrial wastewater. Sudden changes in production can alter the composition of the effluent, making it difficult for the ZLD system to maintain stable performance and consistently produce treated water that meets discharge or reuse standards.

Another significant hurdle is the lack of real-time monitoring and automated controls. Without these, operators may not be able to react quickly enough to process upsets. This can lead to temporary breaches in compliance, which can attract penalties from regulatory bodies. Ensuring your staff is properly trained to manage these systems is also critical for avoiding operational errors that lead to non-compliance.

Finally, managing the solid waste generated by the ZLD process poses another environmental compliance challenge. This waste is often classified as hazardous and must be disposed of according to strict regulations, adding another layer of complexity to your facility’s environmental responsibilities.

Operational and Financial Hurdles Faced by ZLD Operators

Beyond the technical and regulatory challenges, running a ZLD plant comes with significant operational and financial hurdles. The initial investment for a ZLD system can be substantial, often 4-5 times higher than conventional treatment plants. These high costs don’t stop once the plant is built; ongoing operational costs can be a major strain on your budget.

The primary financial burdens are linked to high energy consumption and the need for continuous maintenance and skilled labor. These factors can make the long-term financial viability of a ZLD plant a serious concern for many operators. Let’s break down these costs further.

Energy Consumption and Operating Cost Analysis

What operational costs pose the biggest challenge to ZLD plants in this region? Without a doubt, energy consumption is at the top of the list. The thermal processes in a ZLD plant, such as evaporation and crystallization, are extremely energy-intensive. These stages are necessary to remove the last traces of water and create solid waste, but they can consume 10 to 50 times more energy than standard wastewater treatment methods.

This high energy consumption translates directly into high operating costs. In addition to electricity, you have expenses for chemicals like antiscalants and cleaning agents, regular maintenance, and replacing parts like membranes. These combined costs can make running a ZLD plant a significant financial commitment.

However, it’s important to view these costs in context. While the expenses are high, a ZLD plant also offers long-term cost savings. By recycling water, you reduce your reliance on purchasing fresh water, which can be expensive in water-scarce areas. Additionally, avoiding hefty non-compliance fines provides a substantial financial benefit.

Skilled Workforce Requirement and Training Needs

ZLD systems are complex and technologically advanced, meaning they cannot be operated effectively without a skilled workforce. A lack of properly trained personnel is a major operational hurdle. Operators need specialized knowledge to manage the different stages of treatment, troubleshoot issues, and perform routine maintenance to keep the system running efficiently.

Investing in training is crucial for ensuring the long-term success and performance of your ZLD system. A well-trained team can optimize processes, reduce downtime, and ensure compliance with environmental regulations. The evolution of ZLD performance in Dahej and Bharuch is closely tied to the upskilling of the local workforce. Key training areas should include:

- Operating advanced equipment like membrane systems and evaporators.

- Understanding water chemistry and chemical dosing.

- Implementing safety protocols and emergency response plans.

By building a competent team, your facility can move beyond basic operation and toward proactive management and continuous improvement. This commitment to training not only enhances performance but also embeds sustainable practices within your organization’s culture.

Sludge Disposal Challenges and Solutions in ZLD Plants

While ZLD systems are designed to eliminate liquid waste, they create a new challenge: what to do with the solid waste left behind? This sludge, a byproduct of the treatment process, contains all the concentrated contaminants from the wastewater. Proper sludge disposal is critical to prevent a negative environmental impact.

The composition and volume of this sludge make its management a significant operational and financial burden for many ZLD systems. Fortunately, innovative technologies are available to address this issue effectively and sustainably. Let’s look at the types of sludge produced and an efficient solution for its disposal.

Types of Sludge Generated in Dahej/Bharuch ZLD Systems

The sludge generated from ZLD systems in the Dahej/Bharuch industrial belt is not uniform. Its characteristics depend heavily on the type of industry and the specific wastewater treatment processes used. This variability is one of the main technical challenges, as the disposal method must be suitable for the specific type of solid residues produced.

For instance, effluent from the chemical and pharmaceutical industries often results in sludge containing toxic chemicals, heavy metals, and other hazardous materials. This type of sludge requires careful handling and disposal in secured landfills to prevent environmental contamination. On the other hand, sludge from a biological treatment process might have a higher organic content. Common types of sludge include:

- Chemical sludge from precipitation processes.

- Mixed salt crystals from evaporators and crystallizers.

- Organic solids from biological treatment stages.

- Brine concentrates that are solidified.

Properly identifying and categorizing the sludge your ZLD plant produces is the first step toward developing a safe and compliant disposal strategy.

Paddle Dryer Technology: Efficient Sludge Disposal Solution

Managing wet, heavy sludge can be a logistical nightmare and a significant drain on your operational costs. This is where innovative solutions like paddle dryer technology come in. A paddle dryer is an indirect contact dryer that efficiently removes moisture from the sludge, dramatically reducing its volume and weight. What makes this technology so ideal for ZLD applications?

The dryer consists of a set of rotating, wedge-shaped paddles through which a heating medium like steam or hot oil is circulated. As the paddles turn, they agitate the sludge and transfer heat, causing the water to evaporate. This process converts the wet sludge into a dry, granular solid that is much easier and cheaper to handle, transport, and dispose of.

By significantly reducing the sludge volume, a paddle dryer lowers your sludge disposal costs and minimizes the environmental footprint associated with landfilling. It is a highly effective and reliable solution for one of the most persistent challenges in ZLD operations.

Why Choose AS Engineers as a Sludge Dryer Manufacturer

When it comes to selecting a technology partner to address sludge disposal, choosing the right manufacturer is key. AS Engineers stands out as a leading manufacturer of paddle dryers, offering robust and efficient solutions tailored for the demanding needs of a ZLD plant. Why should you choose them?

AS Engineers has extensive experience in designing and building sludge dryers that deliver reliable performance and low energy consumption. Their systems are engineered to handle the varied and often challenging types of sludge produced by industries in the Dahej/Bharuch region. They focus on providing equipment that not only solves your sludge problem but also integrates seamlessly into your overall wastewater management strategy.

When you partner with AS Engineers, you benefit from:

- Customized designs that match your specific sludge characteristics and volume.

- Energy-efficient technology that helps reduce your plant’s operating costs.

- Durable construction and expert support to ensure long-term reliability.

Choosing a trusted manufacturer like AS Engineers ensures you get a high-quality paddle dryer that provides a lasting solution to your sludge disposal challenges.

Technological Innovations and Best Practices in ZLD for the Region

The challenges of implementing ZLD systems in Dahej and Bharuch have spurred the development of technological innovations and best practices. As technology advances, ZLD is becoming more efficient, reliable, and cost-effective. These improvements are making it easier for industries to achieve their water recycling goals while meeting strict environmental standards.

From advanced membrane filtration to more efficient drying systems, these innovations are changing the landscape of wastewater management. Adopting these technologies is key to overcoming the core challenges of ZLD and building a sustainable industrial operation.

Adoption of Membrane Filtration and Advanced Drying Systems

To tackle the unique challenges of the Dahej/Bharuch region, industries are increasingly adopting a combination of advanced technologies. Among the most used are cutting-edge membrane filtration systems and advanced drying solutions. These technologies work together to create a highly efficient and effective ZLD process.

Modern membrane filtration, including ultrafiltration (UF) and high-recovery reverse osmosis (RO), serves as the workhorse for water recovery. These systems are designed to handle high TDS levels and are more resistant to fouling, allowing for greater water recovery before the brine needs to be sent to thermal treatment. This reduces the load on the energy-intensive evaporation stage, leading to significant cost savings.

Paired with this is the adoption of advanced drying systems, like paddle dryers, to manage the final solid waste. By efficiently dewatering the sludge, these dryers complete the ZLD loop, turning a difficult disposal problem into a manageable process. This integrated approach is becoming a best practice for sustainable water management, ensuring high-quality treated water for reuse and minimizing final waste.

Conclusion

In conclusion, the challenges faced by Zero Liquid Discharge (ZLD) plants in the Dahej and Bharuch region are multifaceted, ranging from high-salinity wastewater management to stringent environmental compliance. However, with innovative solutions like paddle dryer technology, operators can effectively address sludge disposal issues while maintaining efficiency and sustainability. Partnering with trusted manufacturers like AS Engineers can further streamline this process, ensuring that your ZLD systems operate at their best. By embracing advanced technologies and best practices, we can overcome these hurdles and make significant strides towards a more environmentally responsible industrial future. If you’re looking for tailored solutions for your ZLD plant, feel free to reach out for a consultation!

Frequently Asked Questions

How do ZLD plants handle high-salinity and diverse waste streams in Dahej and Bharuch?

ZLD plants manage high-salinity and complex streams through a multi-stage wastewater treatment process. This typically involves advanced technologies like high-pressure reverse osmosis to concentrate the brine, followed by thermal evaporators and crystallizers. This approach effectively separates pure water from the salts and contaminants in the zld plant.

What makes paddle dryer technology ideal for sludge disposal in ZLD applications?

A paddle dryer is ideal for sludge disposal because it efficiently reduces sludge volume by removing moisture. This lowers transportation and disposal costs, reduces energy consumption compared to other methods, and converts wet sludge into a manageable dry solid. Its effectiveness helps lower the overall operational costs of ZLD systems.

Are there specific government incentives available for ZLD implementation in Dahej/Bharuch?

Yes, government incentives are often available to support ZLD implementation. Schemes like the Integrated Processing Development Scheme (IPDS) provide grants for common effluent treatment plants. The Gujarat Pollution Control Board and other state bodies may also offer subsidies to encourage industries to adopt technologies that ensure regulatory compliance with environmental regulations.

What are Zero Liquid Discharge (ZLD) plants and why are they important in the Dahej/Bharuch region?

Zero Liquid Discharge (ZLD) plants are wastewater management systems that treat and recycle all industrial wastewater, producing only solid waste. They are crucial in the Dahej/Bharuch region to combat water scarcity, ensure environmental protection by preventing water pollution, and promote sustainable water reuse in a dense industrial area.