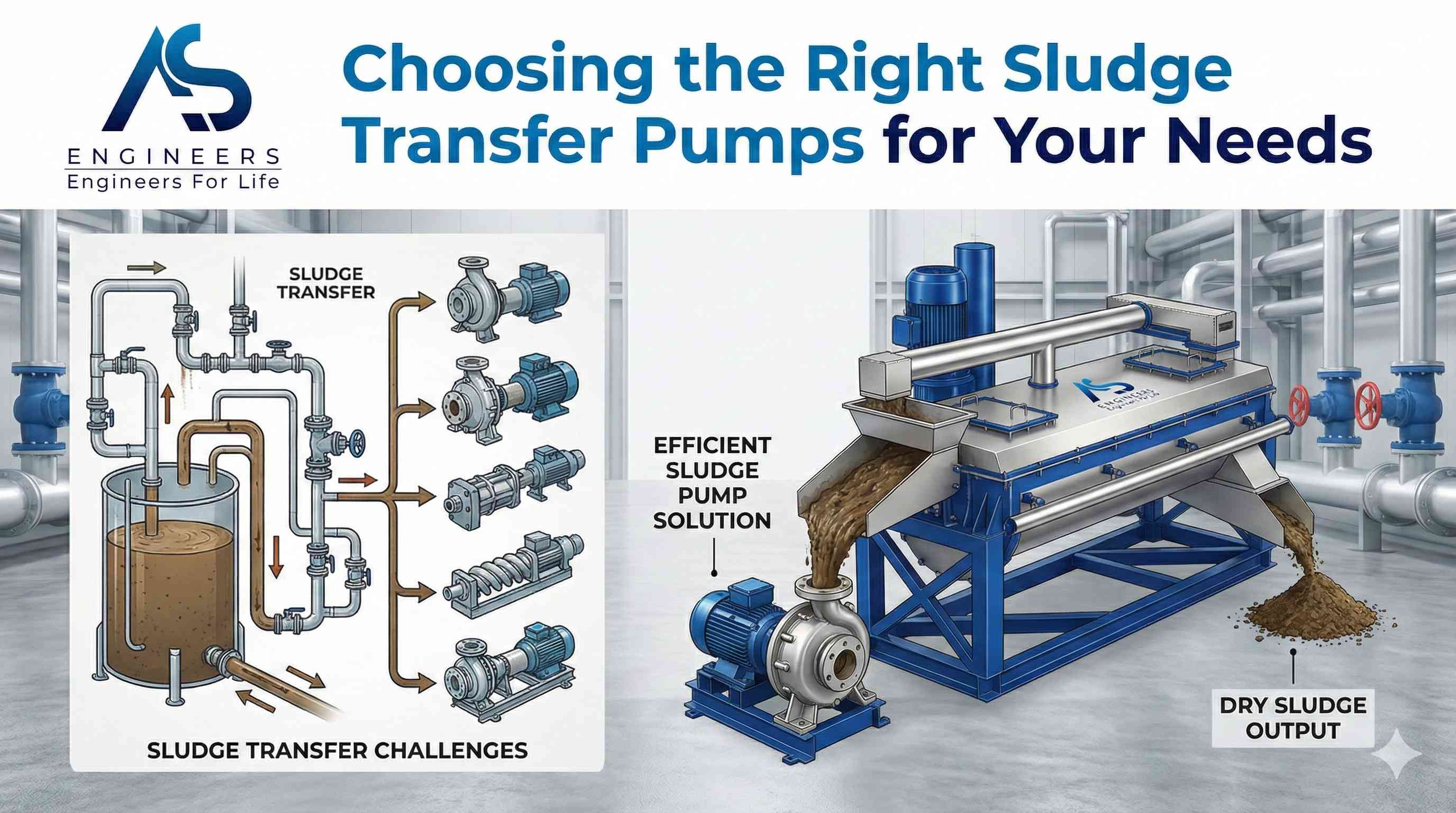

Welcome to our comprehensive guide on sludge transfer pumps! If you work in wastewater treatment or any industry that handles thick, heavy fluids, you know how challenging it can be to move sludge effectively. A sludge pump is a specialized piece of equipment designed for this exact task. In this guide, we’ll explore the different types of sludge pumps, their working principles, and how to select the perfect one for your needs. Let’s get started on finding the right solution for your operations.

Table of contents

- Key Highlights

- Working Principle of Sludge/Slurry Pumps

- Understanding Sludge Transfer Pumps and Their Importance in Waste Management

- Common Applications of Sludge Transfer Pumps in India

- Difference Between Sludge and Slurry Pumps

- Types of Sludge Transfer Pumps Available

- Paddle Dryer: The Best Sludge Management System for ETPs

- Beginner’s Guide: How to Select the Right Sludge Transfer Pump

- Essential Features to Look for in a Sludge Transfer Pump

- Maintenance Tips for Long-Lasting Sludge Transfer Pumps

- Frequently Asked Questions

- Conclusion

Key Highlights

- Sludge pumps are essential for moving thick, viscous materials in wastewater treatment and various industries.

- The two main types of sludge pumps are centrifugal and positive displacement pumps, each suited for different applications.

- Choosing the right sludge pump depends on factors like sludge viscosity, solid content, flow rate, and the specific application.

- Regular maintenance, including inspection and cleaning, is crucial for the reliable operation and long service life of your pump.

- For sludge management in ETPs, a paddle dryer offers a highly efficient way to dry sludge after it’s transferred by a sludge pump.

Working Principle of Sludge/Slurry Pumps

Understanding how a slurry pump operates is key to appreciating its power. The most common type, a centrifugal pump, uses a simple yet effective mechanism. Slurry enters the pump at the center of a rotating impeller. This impeller spins rapidly, creating a strong centrifugal force that throws the mixture of liquid and solid particles outward. As the slurry moves to the edge of the impeller, its speed is converted into pressure energy within the pump’s casing, forcing it out of the discharge pipe.

This pumping action, driven by converting electrical energy into kinetic energy, is what makes these pumps so effective at handling hazardous or dense liquids. A positive displacement pump, another common type, works differently by trapping a fixed amount of slurry and forcing it through the system. This method provides a steady, controlled flow, which is ideal for very thick and viscous materials. Both mechanisms are designed to make pumping challenging liquids an easy and low-maintenance task.

Understanding Sludge Transfer Pumps and Their Importance in Waste Management

Sludge transfer pumps are the workhorses of waste management. These robust pumps are engineered to move viscous, sludgy materials that are common byproducts in wastewater treatment plants and various industries. Without them, managing and processing waste would be incredibly difficult and inefficient.

Their ability to handle high solids content prevents the clogs and breakdowns that would plague standard pumps. This ensures that operations run smoothly, from moving raw sewage to transferring dewatered sludge for disposal. Now, let’s explore what these pumps are and how they differ from similar equipment.

What is a Sludge Transfer Pump and How Does It Work?

So, what exactly is a sludge transfer pump? It is a heavy-duty pump specifically designed to transport thick, semi-solid materials with a high solids content. Unlike pumps made for water or other thin liquids, a sludge pump is built to handle abrasive and viscous substances found in industrial and municipal wastewater treatment.

The type of pump you need depends on the material you’re moving. For instance, centrifugal pumps use a rotating impeller to create flow, which is effective for less viscous sludge. For thicker substances with very high solids content, a positive displacement pump is often the better choice. It moves material by trapping a set volume and forcing it through the discharge outlet.

This specialized design is crucial because traditional pumps would quickly wear out or clog when faced with the heavy, abrasive nature of sludge. By choosing the right type of pump, you ensure reliable and efficient operation in even the most demanding environments.

Key Differences Between Sludge Transfer Pumps and Slurry Transfer Systems

While the terms are sometimes used interchangeably, there are key differences between sludge and slurry. Sludge is a thick, semi-solid material, often with a very high concentration of solids, like dewatered waste from a treatment plant. A slurry, on the other hand, is a mixture of solid particles suspended in a liquid, which is generally more fluid than sludge.

This distinction affects the equipment used. Sludge pumps are built to handle the thick, often non-flowing consistency of sludge. They typically use mechanisms like positive displacement to move the material. Slurry transfer systems, including centrifugal slurry pumps, are designed for more fluid mixtures where particles are suspended.

These systems are common in mining for transporting minerals mixed with water. The pumps must handle abrasive materials, but the primary challenge is moving a liquid mixture, not a dense, semi-solid mass. The choice between a sludge pump and a slurry pump depends entirely on the consistency of the material you need to move.

Common Applications of Sludge Transfer Pumps in India

In India, sludge transfer pumps play a vital role across numerous sectors. Their most prominent application is in municipal wastewater management, particularly in sewage treatment plants where they handle raw and treated sludge containing various solid particles. These pumps are essential for keeping our cities clean and our water resources safe.

Beyond municipal use, they are also critical in a wide range of industrial processes. From food processing to mining, these pumps are relied upon to move challenging materials efficiently. Let’s look at some of these key applications in more detail.

Use in Sewage Treatment Plants and Effluent Treatment Plants (ETP)

Sewage treatment plants (STPs) and effluent treatment plants (ETPs) are primary users of sludge transfer pumps. In these facilities, pumps are needed at almost every stage of the treatment process. They move raw sewage, which often contains fibrous materials and foreign objects, into the primary treatment tanks.

After initial settling, sludge pumps transfer the collected primary sludge for further processing. For these applications, positive displacement pumps are often ideal because they can handle thick, viscous sludge without clogging. Progressive cavity pumps are a popular choice in STPs and ETPs for their ability to provide a steady, low-pulsation flow.

Key tasks for sludge pumps in these plants include:

- Transferring primary and secondary sludge to digesters.

- Moving dewatered sludge for final disposal.

- Recirculating sludge within the treatment process.

Other Industrial and Municipal Uses

Beyond wastewater treatment, sludge pumps are indispensable in many other industrial and municipal settings. Their robust design makes them suitable for handling some of the toughest materials generated during industrial processes. For example, in the food processing industry, these pumps move thick waste products like fruit pulps and batters.

The mining industry also relies heavily on these pumps. They are used to transport abrasive slurries containing minerals and rock fragments from excavation sites to processing facilities. This requires pumps built with highly durable materials to withstand constant wear.

Other significant applications include:

- Power Generation: Moving fly ash slurry from thermal power plants.

- Construction: Pumping drilling mud and removing slurry from construction sites.

- Chemical Processing: Handling corrosive chemical sludges and viscous fluids.

Difference Between Sludge and Slurry Pumps

The main difference between a sludge pump and a slurry pump lies in the material they are designed to handle. A sludge pump is engineered for thick, viscous, and often non-settling materials with a high concentration of solid particles. Think of the thick waste from a sewage treatment plant. Pump performance here is about moving a dense mass effectively.

A slurry pump, conversely, is designed to move a liquid mixture containing suspended solids that might be abrasive. These solids can be fine or coarse but are transported within a liquid medium. The focus is on withstanding abrasion and maintaining flow velocity to prevent solids from settling in the pipeline. While a slurry pump can handle some sludge, a dedicated sludge pump is almost always superior for highly viscous applications.

Types of Sludge Transfer Pumps Available

When it comes to selecting a sludge pump, you have several options. The main types of sludge pumps fall into two broad categories: centrifugal and positive displacement. Each is designed with specific characteristics to handle different kinds of sludge, from thin and watery to thick and abrasive.

Popular positive displacement options include progressive cavity pumps and diaphragm sludge pumps, which are known for their ability to handle highly viscous materials. Understanding the different types available will help you make an informed decision for your specific needs. Let’s examine some of these pump types more closely.

Self-Priming Sludge Transfer Pumps

Are you looking for a pump that can start working without being manually filled with liquid first? A self-priming sludge pump is your answer. These pumps are designed to lift liquid from a level below the pump itself, making them incredibly convenient for many applications. They can create a vacuum to draw sludge into the pump body and begin the pumping process automatically.

Most self-priming pumps are a type of centrifugal pump. They are typically installed above the liquid level, which makes them much easier to access for maintenance and inspection. This is a significant advantage over submersible pumps, which must be removed from the liquid for service.

Their ability to prime themselves ensures reliable operation, especially in situations where the pump may run dry intermittently. This feature is particularly useful in sump applications or for dewatering tasks where the liquid level can fluctuate.

Progressive Cavity and Diaphragm Pumps

For handling very thick and viscous sludge, progressive cavity and diaphragm pumps are excellent choices. Both are types of positive displacement pumps, meaning they move a fixed volume of fluid with each cycle, providing a consistent, low-pulsation flow.

Progressive cavity pumps use a helical rotor that turns inside a stator. This action creates sealed cavities that move the sludge gently from the suction end to the discharge end. They are perfect for shear-sensitive materials and can handle sludge with a high solids content. These are often the best choice for sewage treatment plants.

Diaphragm sludge pumps use a flexible membrane that moves back and forth. This motion creates suction to draw sludge in and then pressure to push it out. Because the diaphragm is the only moving part in contact with the fluid, these pumps are durable and can handle abrasive and corrosive materials with ease.

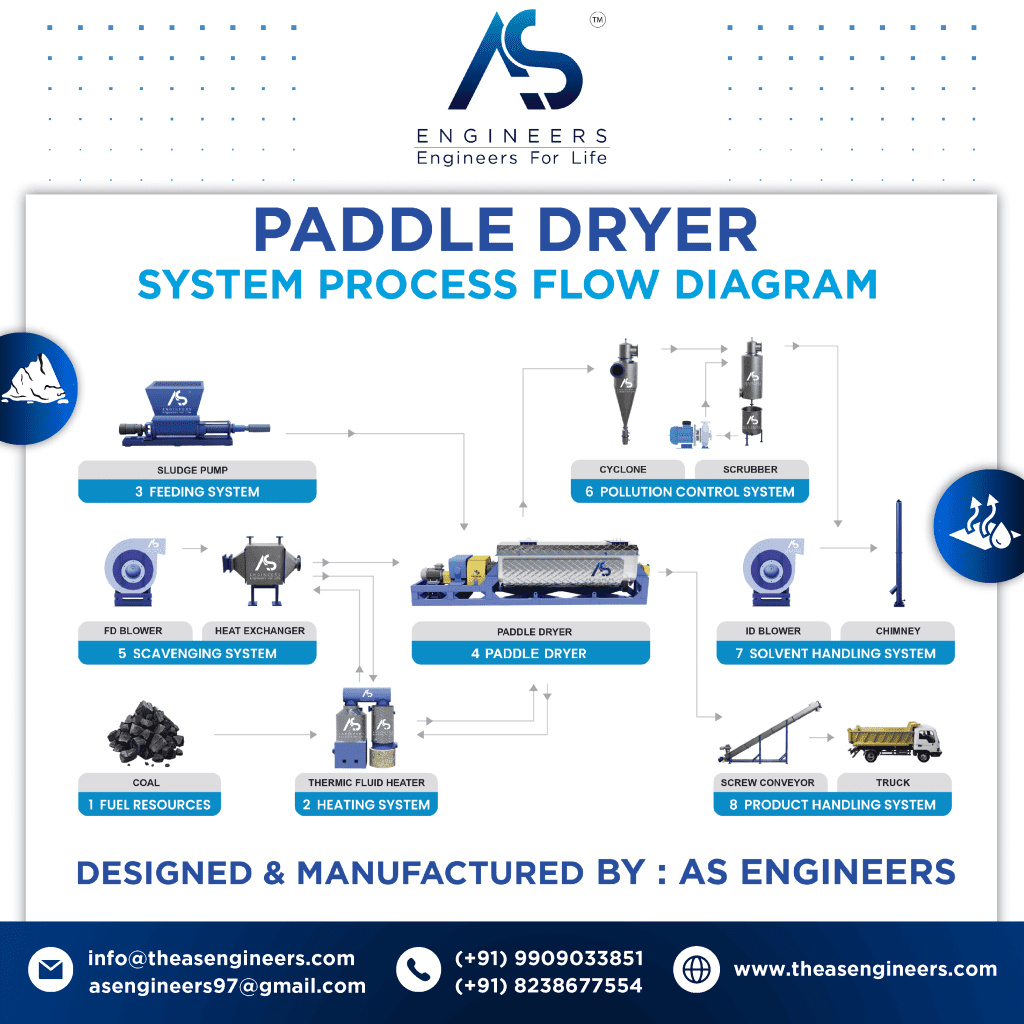

Paddle Dryer: The Best Sludge Management System for ETPs

After your sludge pump has transferred the wet sludge, what’s the next step? For many effluent treatment plants (ETPs), drying the sludge is crucial for reducing its volume and disposal costs. A paddle dryer stands out as the best sludge management system for this phase. This technology offers a highly efficient and controlled way to dewater sludge.

By integrating a paddle dryer into your ETP, you can transform wet, heavy sludge into a dry, manageable material. This makes it the best way to handle sludge management after the initial transfer, creating a more sustainable and cost-effective process.

How Paddle Dryers Work for Sludge Drying

So, how does a paddle dryer achieve such high efficiency in sludge drying? The system works through indirect heat transfer. Wet sludge, fed into the dryer by a sludge pump, comes into contact with heated, rotating, wedge-shaped paddles. The paddles and the jacketed vessel walls are heated, usually by steam or hot oil.

This design maximizes the heat transfer area, allowing moisture to evaporate from the sludge quickly and uniformly. The rotating paddles continuously agitate the sludge, exposing new surfaces to the heat and preventing material from sticking. This is far more effective than trying to dry sludge with methods like compressed air.

The evaporated water is then removed from the system, leaving behind a dry, powdered, or granular final product. This continuous, automated process ensures consistent results and high efficiency, making it an ideal solution for industrial-scale sludge drying.

Advantages of Using Paddle Dryers in Sludge Management

Integrating a paddle dryer into your sludge management system offers numerous benefits. The primary advantage is a significant reduction in sludge volume and weight, which dramatically lowers transportation and disposal costs. This high efficiency makes it a smart investment for any facility generating large amounts of sludge.

Another key benefit is the closed-system design, which minimizes odors and dust emissions, creating a safer and cleaner working environment. The gentle agitation also ensures the final dried product is uniform, which can sometimes be repurposed or sold, turning a waste product into a revenue stream.

The main advantages include:

- High Thermal Efficiency: Lowers energy consumption compared to other drying methods.

- Compact Footprint: Requires less space than many other dryer types.

- Long Service Life: Robust construction ensures optimal performance and durability.

- Process Control: Allows for precise control over the final moisture content.

Beginner’s Guide: How to Select the Right Sludge Transfer Pump

Choosing the right pump for your specific application can feel overwhelming, especially with so many options available. The key is to systematically evaluate your needs and match them with the right equipment. An incorrect choice can lead to poor pump performance, frequent breakdowns, and increased operational costs.

This guide will walk you through the essential steps to select the right sludge pump. We’ll cover everything from assessing your sludge characteristics to comparing manufacturers, ensuring you make a confident and informed decision. Let’s break down what you need to know.

What You’ll Need to Get Started (Equipment, Capacity, Resources)

Before you can choose a pump, you need to gather some basic information about your project. The first step is to understand the resources you are working with. What is the nature of the sludge? What volume do you need to move, and how quickly? Answering these questions is fundamental to finding the right equipment.

You’ll need to determine the required capacity and flow rate. Capacity refers to the volume of sludge the pump can move in a given time, while flow rate is the speed at which it moves. These factors are critical for sizing your pump correctly for your wastewater treatment or industrial process.

Finally, consider the physical setup. Here are a few key things to define:

- The distance and height the sludge needs to be pumped.

- The diameter of the existing or planned pipework.

- The power source available (electric or hydraulic).

Step-by-Step Guide to Choosing a Sludge Transfer Pump

Ready to find the perfect pump? Following a structured approach will simplify the selection process and help you avoid common mistakes. This step-by-step guide is designed to lead you from initial assessment to final decision, ensuring your choice delivers optimal pump performance for your specific application.

Each step will focus on a critical aspect of the selection process. We will start by analyzing your sludge, then move on to evaluating different pump technologies, and finally consider practical aspects like cost and maintenance. This methodical process will ensure a long service life for your equipment.

Here is the simple, four-step process we will follow:

- Assess your sludge characteristics and volume.

- Evaluate pump types and performance features.

- Compare manufacturers and costs.

- Review installation, operation, and maintenance needs.

Step 1: Assess Your Sludge Characteristics and Volume

The first and most important step is to know your sludge. The type of sludge you are handling will heavily influence your pump choice. Is it thin and watery, or thick and viscous? Does it contain large solid particles, or is it more of a uniform paste?

You need to determine the sludge’s key properties: viscosity, abrasiveness, and solids content. A sludge with a high solid content or abrasive particles like sand will require a much more robust pump than a low-solids biosludge. The chemical composition is also important, as corrosive materials will require pumps made from resistant materials like stainless steel.

Finally, calculate the volume of sludge you need to move and the required flow rate. This will determine the size and power of the pump. Having accurate data on these characteristics is essential before you can move on to comparing different pump types.

Step 2: Evaluate Pump Types and Performance Features

Once you understand your sludge, you can start evaluating different types of pumps. As we’ve discussed, the two main categories are centrifugal and positive displacement pumps. Each offers distinct pump performance features suited for different conditions.

A centrifugal pump is generally a good fit for lower-viscosity sludges with smaller solids. They are energy-efficient and can achieve high flow rates. However, for thick, abrasive, or high-solids sludge, a positive displacement pump is almost always the better choice. These pumps provide a consistent flow regardless of pressure and can handle highly viscous materials without issue.

When evaluating pump types, consider these features:

- Solids Handling Capability: The maximum size of solid particles the pump can pass.

- Flow Rate and Pressure: Ensure the pump can meet your operational requirements.

- Material of Construction: Choose materials that can withstand abrasion and corrosion from your sludge.

Step 3: Compare Leading Manufacturers and Cost Considerations in India

With a clear idea of the pump type you need, it’s time to look at manufacturers and costs. In India, several reputable companies produce high-quality sludge pumps. For example, NETZSCH is a leading manufacturer known for reliable progressive cavity pumps designed for various industrial markets. Researching manufacturers with years of experience and a strong presence in the market is always a good idea.

Cost is always a factor. While it might be tempting to choose the cheapest option, you must consider the total cost of ownership. This includes the initial purchase price, operational costs (energy consumption), and maintenance expenses over the pump’s service life. A cheaper pump made from cast iron might not last as long as a more expensive one with a stainless steel pump body if you’re handling corrosive materials.

Here’s a simple comparison of factors to consider:

| Feature | Low-Cost Option | Premium Option |

|---|---|---|

| Pump Body Material | Cast Iron | Stainless Steel / High-Chrome Alloy |

| Initial Cost | Lower (e.g., ₹1,00,000) | Higher (e.g., ₹3,00,000+) |

| Service Life | Shorter, especially with abrasive materials | Longer, designed for heavy-duty use |

| Maintenance | More frequent repairs may be needed | Less frequent, easier serviceability |

Step 4: Review Installation, Operation, and Maintenance Requirements

The final step is to consider the practicalities of owning and operating the pump. The ease of installation can impact your initial setup costs and timeline. Some pumps, like self-priming models, offer more flexibility in placement, which can simplify the installation process.

Operation and maintenance are critical for ensuring a long service life. How easy is it to service the pump? Are spare parts readily available from the manufacturer? A pump designed for ease of maintenance, with features like replaceable liners or easily accessible seals, can save you significant time and money in the long run.

Before making your final purchase, request the operation and maintenance manual from the manufacturer. Reviewing these documents will give you a clear picture of what will be required to keep your pump running smoothly and efficiently for years to come.

Essential Features to Look for in a Sludge Transfer Pump

When you’re ready to invest in a sludge transfer pump, certain features are non-negotiable for ensuring reliable operation. You’ll want a pump built with durability in mind, featuring a robust pump casing and materials that offer excellent corrosion resistance. This is key to achieving a long service life, especially in harsh industrial environments.

Beyond materials, you should also consider design elements that contribute to consistent performance and simple upkeep. Let’s explore the most important features that separate a good pump from a great one.

Reliability for Continuous Operation

For most industrial applications, a sludge pump needs to run continuously without failure. Downtime can halt production and lead to significant financial losses. Therefore, reliability for continuous operation is perhaps the most critical feature to look for. How do you ensure this?

Look for pumps built with high-quality components, such as top-brand bearings and heavy-duty mechanical seals. Some premium pumps feature oversized bearings and dual seals housed in an oil bath, which provides extra protection and allows for long, uninterrupted running times.

Good pump performance over the long term also depends on a design that can handle fluctuations in pressure and viscosity without faltering. A pump that delivers a steady, low-pulsation flow, like a progressive cavity pump, will contribute to more reliable operation of the entire system.

Ease of Maintenance and Longevity

A pump that is difficult to maintain will inevitably have a shorter life. Ease of maintenance is directly linked to a long service life. Look for pumps designed with serviceability in mind. Features like replaceable wear plates or liners mean you can swap out worn components without replacing the entire pump casing, saving time and money.

The availability of spare parts is another crucial factor. Choose a manufacturer that can provide quick access to replacement parts to minimize downtime during repairs. Simple designs with fewer moving parts, like some centrifugal pumps, can also mean less wear and tear and easier servicing.

Finally, consider the materials. A pump body and impeller made from high-chrome cast iron, stainless steel, or a special alloy will offer superior corrosion resistance and durability against abrasive sludge. This investment in better materials pays off with a much longer operational life.

Maintenance Tips for Long-Lasting Sludge Transfer Pumps

Once you’ve installed your new sludge pump, proper maintenance is the key to maximizing its service life. Neglecting regular care can lead to premature failure, costly repairs, and unexpected downtime. A simple, proactive maintenance schedule will keep your pump running at peak efficiency.

Taking the time for regular checks and cleaning will protect your investment and ensure reliable operation day in and day out. Here are some essential tips for keeping your sludge pump in top condition.

Regular Inspection and Cleaning Procedures

Proactive maintenance starts with regular inspections. A routine visual check can help you spot developing issues before they become major problems. Make it a habit to inspect the pump for any signs of leaks, unusual vibrations, or strange noises during operation.

Cleaning is also a critical part of your maintenance routine. Sludge can build up inside the pump and pipework, reducing efficiency and potentially causing clogs. Periodically flushing the system and cleaning the pump’s impeller and casing will help maintain optimal performance.

Here are some key inspection points:

- Check the mechanical seal oil for any signs of contamination.

- Inspect the pump impeller and wear plates for visual signs of damage or wear.

- Examine the power cable for any damage.

Troubleshooting Common Issues

Even with regular maintenance, you may occasionally run into problems. Knowing how to troubleshoot common issues can help you get your system back online quickly. If you notice a drop in pump performance, the first step is to check for blockages. Obstructions in the suction line or pump casing are a frequent cause of reduced flow.

Another common issue is excessive wear on components like the impeller or liners, especially with centrifugal slurry pumps handling abrasive materials. If performance declines steadily, it may be time to inspect and replace these parts. Worn components not only reduce efficiency but also increase power consumption.

Here are a few common problems and their potential causes:

- Reduced Flow: Blockage in the pipeline, worn impeller, or incorrect pipe size.

- Pump Not Starting: Electrical issue or motor failure.

- Excessive Vibration: Misalignment, worn bearings, or an unbalanced impeller.

- Pump Overheating: Pumping liquid that is too hot or running the pump dry.

Frequently Asked Questions

Which sludge transfer pump is ideal for sewage treatment plants?

For sewage treatment plants, positive displacement pumps like progressive cavity pumps are often ideal. They handle thick, viscous sludge effectively and provide a gentle, low-pulsation flow that prevents clogging. For thinner sludge, a heavy-duty centrifugal pump designed for solids handling can also provide reliable operation.

Are self-priming sludge transfer pumps available?

Yes, self-priming options are widely available. These pumps, typically a type of centrifugal pump, can lift sludge from a lower level without manual priming. This feature enhances pump performance and convenience, especially in wastewater applications like sump emptying where liquid levels fluctuate.

What are the main features to consider for continuous operation?

For continuous operation, look for robust construction, such as a cast iron or stainless steel pump body, and high-quality components like dual mechanical seals and oversized bearings. Excellent corrosion resistance and a design that ensures reliable operation with minimal wear are key to achieving a long service life.

Where can I buy sludge transfer pumps online in India?

You can purchase sludge pumps directly from leading manufacturers like NETZSCH or through their authorized distributors. Many industrial suppliers and online B2B marketplaces also list a wide range of pumps for various industries. Always ensure you are buying from a reputable seller to get a quality pump casing and reliable after-sales support.

How do different types of sludge affect the choice of transfer pump?

The type of sludge is critical. Thin, watery sludge can be handled by a centrifugal pump, but thick, viscous sludge with a high concentration of solid particles requires a positive displacement pump. The sludge’s abrasiveness and corrosiveness will also dictate the necessary materials for the pump to ensure optimal pump performance.

What is the importance of pump capacity and flow rate in sludge transfer?

Pump capacity and flow rate are crucial for ensuring efficient sludge transfer. Capacity determines the volume of sludge moved over time, while flow rate dictates the speed. Matching these to your system’s needs prevents bottlenecks, reduces energy waste, and ensures the pump performance is optimized for handling high solids.

What factors should I consider when selecting a sludge transfer pump?

When selecting a sludge pump, consider the sludge characteristics (viscosity, solids content), required flow rate and pressure, and the specific application. Also, evaluate the different types of pumps, their materials of construction, and the total cost of ownership, including maintenance and expected service life, to ensure optimal pump performance.

Can I use a single pump for multiple applications, or do I need specialized pumps for different types of sludge?

While some versatile sludge pumps can handle various applications, it’s often best to use specialized pumps for different types of sludge. A single pump may not provide reliable operation if used for both thin slurry and thick, abrasive sludge. Matching the pump to the specific application ensures efficiency and longevity.

Conclusion

In summary, choosing the right sludge transfer pump is crucial for effective waste management in ETPs. Paddle dryers emerge as the best solution for sludge drying, offering efficiency and reliability in handling sludge. By carefully assessing your specific needs and understanding the various types of pumps available, you can ensure optimal performance while maintaining a smooth operation. Remember, the right equipment not only simplifies the process but also contributes to a more sustainable approach to sludge management. If you have any questions or would like further assistance in selecting the perfect sludge transfer pump for your needs, feel free to reach out!