Every day, wastewater treatment facilities across the globe generate over 45 million tons of industrial and municipal sludge—a complex byproduct that presents both significant environmental challenges and surprising opportunities. Whether you’re a facility manager grappling with rising disposal costs, an environmental consultant seeking compliance solutions, or a municipal official planning infrastructure upgrades, understanding sludge management fundamentals can save your organization thousands of dollars while protecting public health.

This comprehensive guide reveals proven strategies for handling industrial and municipal sludge efficiently, cost-effectively, and in full regulatory compliance. You’ll discover treatment technologies that reduce disposal volumes by up to 90%, innovative recycling methods that transform waste into valuable resources, and regulatory insights that prevent costly violations.

Table of contents

- Understanding Industrial and Municipal Sludge: Types and Characteristics

- Treatment Technologies for Sludge Management

- Disposal Methods and Environmental Considerations

- Regulatory Framework and Compliance Requirements

- Cost Management and Economic Optimization

- Emerging Technologies and Future Trends

- Frequently Asked Questions About Industrial and Municipal Sludge

- Conclusion: Building Sustainable Sludge Management Programs

Understanding Industrial and Municipal Sludge: Types and Characteristics

Industrial and municipal sludge represents the semi-solid residue remaining after wastewater treatment processes. This material consists of organic matter, microorganisms, chemicals, and various contaminants removed from wastewater streams during treatment operations.

Municipal Sludge Composition and Sources

Municipal sludge originates from domestic wastewater treatment plants serving residential communities, commercial establishments, and small businesses. The composition typically includes:

Primary sludge forms during initial settling processes, containing approximately 95-97% water content along with organic solids, food particles, and human waste materials. This fraction represents the heaviest pollutant load removed during preliminary treatment stages.

Secondary sludge develops through biological treatment processes where microorganisms consume organic pollutants. Also called activated sludge, this material contains dead bacteria, protozoa, and other microorganisms that performed the biological treatment function.

Tertiary sludge results from advanced treatment processes designed to remove specific contaminants like phosphorus, nitrogen compounds, or trace chemicals requiring specialized removal techniques.

Industrial Sludge Characteristics and Challenges

Industrial sludge presents more complex management challenges due to diverse contamination sources and varying chemical compositions. Manufacturing facilities, chemical plants, food processing operations, and pharmaceutical companies generate sludge containing:

Heavy metals including lead, mercury, cadmium, and chromium create long-term environmental concerns requiring specialized treatment and disposal protocols. These contaminants persist in the environment and bioaccumulate through food chains.

Chemical compounds from manufacturing processes introduce synthetic materials, solvents, and reactive substances that may require neutralization before safe disposal. Some industrial sludges contain volatile organic compounds (VOCs) that pose air quality risks during handling.

Biological contaminants from food processing and pharmaceutical operations may harbor pathogens requiring thermal treatment or chemical disinfection before disposal or beneficial reuse applications.

Treatment Technologies for Sludge Management

Effective sludge treatment reduces volume, stabilizes organic matter, and eliminates pathogens while preparing material for final disposal or beneficial reuse. Modern treatment facilities employ multiple technologies in integrated treatment trains.

Physical Treatment Methods

Thickening processes concentrate sludge solids by removing free water through gravity settling, dissolved air flotation, or mechanical thickening systems. These processes typically increase solids content from 1-3% to 4-8%, significantly reducing subsequent processing volumes and costs.

Gravity thickeners work effectively for municipal primary sludge, achieving 8-12% solids concentrations through simple settling mechanisms. Dissolved air flotation systems excel with biological sludges that resist gravity settling due to fine particle sizes and low specific gravity.

Dewatering technologies further reduce moisture content using mechanical systems like belt filter presses, centrifuges, or screw presses. Modern dewatering equipment achieves 18-25% solids content, transforming liquid sludge into semi-solid cake suitable for transportation and disposal.

Biological Treatment Approaches

Anaerobic digestion stabilizes organic matter while producing renewable biogas containing 60-70% methane. This process reduces volatile solids by 40-60% while generating energy that offsets treatment facility power consumption.

Mesophilic digestion operates at 95-100°F and achieves stable operation with 15-30 day retention times. Thermophilic digestion at 130-140°F accelerates organic matter breakdown and enhances pathogen destruction but requires careful process control.

Aerobic digestion provides an alternative biological treatment approach using oxygen to decompose organic matter. While requiring continuous aeration energy, aerobic systems offer simpler operation and better process stability for smaller facilities.

Advanced Treatment Technologies

Thermal treatment systems eliminate pathogens and reduce organic content through controlled heating processes. Technologies include pasteurization at 158°F for pathogen destruction, thermal drying for volume reduction, and incineration for complete organic matter destruction.

Chemical stabilization uses lime addition to raise pH above 12, creating hostile conditions for pathogen survival while precipitating heavy metals. Alkaline stabilization provides cost-effective treatment for industrial sludges containing metallic contaminants.

Composting processes transform stabilized sludge into beneficial soil amendment products through controlled aerobic decomposition. Successful composting requires proper carbon-to-nitrogen ratios, adequate aeration, and temperature control to achieve pathogen destruction.

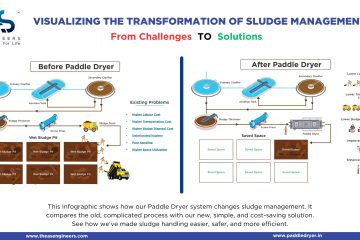

We understand the real-world challenges industries face with sludge management. That’s why we designed our paddle dryer to do more than just dry sludge—it transforms a messy, costly problem into a manageable, efficient process. Our paddle dryer uses indirect heating to gently remove moisture, reducing sludge volume, lowering disposal costs, and helping businesses meet environmental norms with ease. It’s a silent worker behind the scenes, making plants cleaner, safer, and more sustainable. Whether you run an ETP, STP, or industrial unit, our paddle dryer simplifies your sludge drying needs—reliably, efficiently, and with minimal human intervention.

Disposal Methods and Environmental Considerations

Safe sludge disposal requires careful consideration of environmental impacts, regulatory requirements, and long-term sustainability concerns. Modern disposal strategies emphasize resource recovery and environmental protection.

Landfill Disposal Strategies

Landfill disposal remains the most common sludge management approach, accounting for approximately 40% of municipal sludge in the United States. Effective landfill disposal requires:

Proper classification determines acceptable landfill types based on sludge characteristics and contamination levels. Non-hazardous sludges typically qualify for municipal solid waste landfills, while hazardous industrial sludges require secure disposal facilities.

Stabilization requirements ensure sludge meets landfill acceptance criteria for odor control, leachate generation, and gas production. Many landfills require minimum solids content (typically 20-25%) to prevent operational problems.

Transportation considerations include proper containerization, vehicle specifications, and route planning to minimize environmental risks and comply with hazardous materials regulations where applicable.

Beneficial Reuse Applications

Land application transforms treated sludge into valuable fertilizer for agricultural, forestry, and land reclamation projects. Biosolids containing essential nutrients like nitrogen, phosphorus, and organic matter improve soil structure and crop productivity.

Agricultural applications require comprehensive soil testing, crop selection guidelines, and application rate calculations based on nutrient content and regulatory limits. Proper land application prevents groundwater contamination while providing economic benefits to farmers.

Construction material applications incorporate dried sludge into concrete, asphalt, and building materials. These applications provide permanent containment for treated sludge while reducing demand for virgin materials in construction projects.

Regulatory Framework and Compliance Requirements

Industrial and municipal sludge management operates under comprehensive regulatory frameworks designed to protect public health and environmental quality. Understanding applicable regulations prevents costly violations and ensures sustainable operations.

Federal Regulatory Requirements

Clean Water Act provisions establish effluent limitations and pretreatment standards affecting sludge generation and characteristics. Section 405 specifically addresses sludge management requirements for publicly owned treatment works.

Resource Conservation and Recovery Act (RCRA) determines hazardous waste classification criteria and management requirements for industrial sludges. Facilities must conduct hazardous waste determinations and implement appropriate management protocols.

EPA Part 503 Biosolids Rule governs beneficial use of municipal sewage sludge, establishing pathogen reduction requirements, vector attraction reduction standards, and pollutant limits for land application programs.

State and Local Regulations

State environmental agencies typically implement federal programs while adding specific requirements addressing local environmental conditions and public health concerns. Common state requirements include:

Permit programs for sludge treatment facilities, land application operations, and disposal sites require detailed operational plans, monitoring protocols, and reporting procedures.

Transportation regulations specify vehicle requirements, driver qualifications, and route restrictions for sludge hauling operations.

Compliance Monitoring and Reporting

Analytical testing requirements vary based on sludge classification and intended use. Municipal biosolids programs require regular testing for pathogens, metals, and other regulated parameters.

Record keeping obligations include maintaining detailed logs of sludge generation, treatment, and disposal activities with supporting analytical data and regulatory documentation.

The paddle dryer offers significant cost savings by reducing sludge volume and moisture content, which cuts down transportation and disposal expenses. Its low energy consumption, thanks to indirect heating and efficient heat transfer, minimizes operational costs. With low maintenance needs, continuous operation, and the ability to recover heat, it ensures long-term savings. Additionally, the dried sludge can be reused as fuel, further adding to the economic benefits and sustainability of your operations.

Cost Management and Economic Optimization

Sludge management represents a significant operational expense for wastewater treatment facilities, typically accounting for 25-50% of total plant operating costs. Strategic cost management approaches can substantially reduce these expenses.

Treatment Cost Optimization

Volume reduction strategies provide the highest return on investment by reducing downstream processing, transportation, and disposal costs. Every 10% reduction in sludge volume can decrease total management costs by 15-20%.

Improved thickening and dewatering operations offer immediate cost savings through reduced hauling frequencies and disposal tonnage. Equipment upgrades and process optimization typically pay for themselves within 2-3 years through operational savings.

Energy recovery systems transform sludge treatment from a cost center into a revenue generator. Anaerobic digestion systems producing biogas can offset 20-40% of treatment plant energy consumption while reducing sludge disposal volumes.

Alternative Management Strategies

Regional cooperation programs allow multiple facilities to share treatment infrastructure and achieve economies of scale. Centralized treatment facilities serving multiple communities can reduce per-unit costs by 30-50% compared to individual facility operations.

Public-private partnerships provide access to advanced treatment technologies and specialized expertise without large capital investments. These arrangements can transfer operational risks while guaranteeing cost-effective service delivery.

Emerging Technologies and Future Trends

Innovation in sludge management continues advancing through new technologies addressing volume reduction, resource recovery, and environmental protection. These emerging approaches promise significant improvements in treatment efficiency and cost-effectiveness.

Advanced Treatment Innovations

Thermal hydrolysis pretreatment enhances anaerobic digestion performance by breaking down complex organic compounds and increasing biogas production. This technology can increase digester capacity by 30-50% while improving dewatering characteristics.

Membrane bioreactor technology integrates biological treatment with membrane filtration, producing high-quality effluent while generating concentrated sludge requiring minimal further treatment.

Resource Recovery Opportunities

Nutrient recovery systems extract valuable phosphorus and nitrogen compounds from sludge streams for fertilizer production. These technologies address nutrient pollution concerns while creating revenue streams from waste materials.

Biochar production converts dried sludge into stable carbon compounds useful for soil amendment and carbon sequestration applications. Pyrolysis processes destroy organic contaminants while creating valuable end products.

Frequently Asked Questions About Industrial and Municipal Sludge

- What is the difference between sludge and biosolids?

Biosolids are treated sewage sludge that meets EPA Part 503 requirements for beneficial use, while sludge refers to untreated or partially treated waste materials requiring further processing or disposal. - How long does sludge treatment typically take?

Treatment times vary from several hours for physical processes to 15-30 days for biological treatment methods like anaerobic digestion, depending on desired stabilization levels. - Can industrial sludge be mixed with municipal sludge for treatment?

Industrial sludge can be co-treated with municipal sludge if compatible and properly characterized, but requires careful evaluation of chemical compatibility and regulatory approval. - What are the main environmental risks of improper sludge management?

Improper management can cause groundwater contamination, surface water pollution, air quality problems, and soil contamination from heavy metals and pathogens. - How much does professional sludge management typically cost?

Costs range from $200-800 per dry ton depending on treatment requirements, disposal methods, and regional factors, with beneficial reuse options often providing the lowest long-term costs.

Conclusion: Building Sustainable Sludge Management Programs

Effective industrial and municipal sludge management requires integrated approaches combining proven treatment technologies, regulatory compliance, and economic optimization strategies. Successful programs recognize sludge as a resource requiring proper management rather than simply a waste requiring disposal.

The key to sustainable sludge management lies in volume reduction, beneficial reuse optimization, and continuous process improvement. Facilities implementing comprehensive management strategies typically achieve 30-50% cost reductions while improving environmental performance and regulatory compliance.

Modern treatment technologies offer unprecedented opportunities for resource recovery and environmental protection. By embracing innovation while maintaining operational excellence, wastewater treatment professionals can transform sludge management from a costly burden into a value-generating component of sustainable water infrastructure.

Ready to optimize your facility’s sludge management program? Start by conducting a comprehensive assessment of your current operations and exploring emerging technologies that align with your operational goals and budget constraints.

What is municipal sludge and how is it different from industrial sludge?

Municipal sludge refers to the semi-solid byproduct generated from the waste water treatment of wastewater in municipal treatment facilities. It consists primarily of organic matter, nutrients, and microorganisms resulting from the treatment process. In contrast, industrial sludge originates from various industrial processes and often contains a wider range of contaminants, including heavy metals and chemicals specific to the manufacturing processes. The key difference lies in the composition and potential contaminants present, which necessitates different treatment and disposal approaches.

How is municipal sludge produced during wastewater treatment?

Municipal sludge is produced as a byproduct during the treatment of wastewater, primarily through two stages: primary and secondary treatment. During primary treatment, solids settle out of the wastewater, forming primary sludge. This sludge contains a high concentration of organic materials and pollutants. Secondary treatment involves biological processes where microorganisms further break down organic matter, resulting in secondary sludge, which predominantly consists of dead microbes and residual organic matter. The combination of these processes generates the municipal sludge that requires further treatment and management.

What are the main methods used to treat municipal sludge?

The main methods used to treat municipal sludge include physical, biological, and chemical processes. Physical treatments often involve thickening and dewatering to reduce volume. Biological treatments, such as anaerobic digestion, are a biological process that stabilizes organic matter while reducing pathogens and producing biogas. Chemical treatments may involve lime stabilization to elevate pH for pathogen control. Each method has its advantages, and facilities often employ a combination of these approaches for optimal sludge management.

What are the typical disposal options for municipal sludge?

Typical disposal options for municipal sludge include landfilling, incineration, and beneficial reuse through land application. Landfilling remains a common approach, where treated sludge is deposited in designated landfills, which can produce methane gas during anaerobic decomposition. Incineration reduces sludge volume while generating energy. Beneficial reuse involves applying treated sludge as a soil amendment or fertilizer in agriculture, providing essential nutrients to crops and improving soil quality. The choice of disposal method depends on local regulations, environmental considerations, and economic factors.

What is the composition of municipal sludge from sewage treatment plants?

The composition of municipal sludge from sewage treatment plants varies widely but generally includes organic matter, nutrients (such as nitrogen, trace elements, and phosphorus), microorganisms, and inorganic substances. Organic matter forms the bulk of the sludge, while nutrients are essential for soil health. The presence of heavy metals and other contaminants depends on the sources of the wastewater being treated, including industrial discharges and domestic waste. Regular analysis of sludge composition is essential for determining appropriate treatment and disposal methods.

Are there health risks associated with handling municipal sludge?

Yes, there are health risks associated with handling municipal sludge, primarily due to the potential presence of pathogens and contaminants. Exposure to untreated or inadequately treated sludge can pose significant health risks to public health, including gastrointestinal illnesses and respiratory issues. To mitigate these risks, proper handling procedures, protective equipment, and adherence to regulatory guidelines are crucial. Treatment processes are designed to reduce pathogen levels, but continuous monitoring is necessary to ensure safety.

What regulations govern the treatment and disposal of municipal sludge?

The treatment and disposal of municipal sludge are governed by a combination of federal, state, and local regulations. In the United States, the EPA’s Part 503 regulations set standards for the beneficial use of sewage sludge, including pathogen reduction and pollutant limits. Additionally, state environmental agencies may impose stricter regulations tailored to local conditions. Compliance with these regulations is essential for wastewater treatment systems and facilities to operate legally and sustainably.

How does the volume of municipal sludge generated vary across different regions?

The volume of municipal sludge generated in regions such as the United Kingdom varies across regions due to factors such as population density, wastewater treatment practices, and the nature of the local wastewater stream. Regions with higher population densities and industrial activities typically produce more sludge. Additionally, advanced treatment technologies may reduce the volume of sludge generated per unit of wastewater treated. Local regulations and environmental policies also influence sludge generation and management practices.

Can municipal sludge be reused or recycled, and if so, how?

Yes, municipal sludge can be reused or recycled, primarily through water treatment processes that transform it into biosolids suitable for land application. After undergoing treatment to reduce pathogens and contaminants, treated sludge can be applied to agricultural lands as a fertilizer, enriching the soil with essential nutrients. Additionally, some facilities convert dried sludge into products like biochar or use it in construction materials, promoting resource recovery and reducing environmental impacts.

What environmental concerns are associated with municipal sludge?

Environmental concerns associated with municipal sludge include the potential for groundwater contamination, soil degradation, and air quality issues during handling and disposal. Contaminants such as heavy metals, pathogens, and organic halides can pose risks to human health and ecosystems if not managed properly. Adhering to regulatory standards and implementing best practices in sludge treatment and disposal are essential for minimizing these environmental impacts.