Managing the massive volumes of sludge from wastewater treatment is a growing challenge for industries and municipalities. Traditional disposal methods are costly and environmentally taxing. But what if you could turn this challenge into an opportunity? Enhancing sludge drying processes with waste heat recovery offers a powerful solution.

This technology captures and reuses heat that would otherwise be lost, dramatically reducing energy consumption and operational costs. It’s a smart strategy for making your sludge management more efficient, sustainable, and economical.

Key Highlights

- Waste heat recovery significantly boosts the energy efficiency of sludge drying plants by reusing thermal energy.

- Paddle dryers are highly effective for sludge drying, offering superior heat transfer and control.

- Implementing a heat recovery system can drastically reduce operational costs and shorten investment payback periods.

- Modern wastewater treatment facilities can capture waste heat from sources like exhaust air and other industrial processes.

- Sewage sludge drying with heat recovery transforms a waste product into valuable resources like fuel or construction materials.

- This approach helps facilities meet environmental regulations and achieve sustainability goals.

Types of Sludge Drying Systems

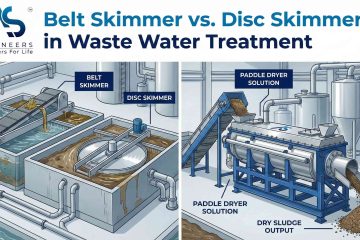

When it comes to thermal drying, not all systems are created equal. Different technologies are available, each suited for specific types of sludge and operational goals. For instance, belt dryers spread sludge on a moving belt while hot air passes through it, making them ideal for large volumes of municipal sludge. Rotary drum dryers tumble the material in a heated, rotating cylinder, ensuring continuous and effective mixing.

Other specialized systems include fluidized bed dryers, which suspend sludge particles in hot air for rapid drying, and spray dryers, which atomize sludge into fine droplets. However, one of the most efficient and versatile options is the paddle dryer. This system uses hollow, heated paddles for indirect heat transfer, providing precise control over the drying process and handling even difficult or hazardous dewatered sludge with ease. Understanding these options is the first step toward choosing the right solution for your needs.

Overview of Waste Heat Recovery in Sludge Drying Plants

Imagine capturing the heat generated during the sludge drying process and using it to power the system itself. That’s the core idea behind waste heat recovery. In a typical sludge drying plant, a significant amount of heat energy is lost through exhaust gases. A waste heat recovery system intercepts this energy and redirects it to preheat the air or sludge entering the dryer.

This simple yet effective loop reduces the need for external fuel sources like natural gas, directly cutting down on energy costs and improving overall plant efficiency. It’s a key strategy for transforming a high-energy process into a more sustainable and cost-effective operation. The following sections will explore how this technology works and why it is so important.

Defining Waste Heat Recovery for Sludge Management

At its heart, waste heat recovery is a form of energy recycling. In sludge management, it involves capturing thermal energy from one part of the process and reusing it in another. For example, the hot, moist air exhausted from a dryer is a prime source of waste heat. Instead of venting this energy into the atmosphere, a specialized piece of equipment called a heat exchanger is used.

This heat exchanger transfers the thermal energy from the hot exhaust air to the cool, fresh ambient air that is being drawn into the dryer. This preheats the incoming air, so the primary heating system doesn’t have to work as hard.

By integrating a heat exchanger, a sludge drying plant can significantly improve its energy efficiency. This reduction in the demand for new energy directly translates to lower fuel consumption and operational savings, making the entire sludge treatment process more sustainable and economical. It is a fundamental step toward optimizing energy recovery in your facility.

Importance of Waste Heat Utilization in Modern Treatment Facilities

In today’s world, the pressure is on for wastewater treatment facilities to be both environmentally responsible and economically viable. This is where waste heat utilization becomes critically important. Sludge drying is traditionally an energy-intensive process, contributing significantly to a plant’s overall energy consumption. By harnessing waste heat, you can slash these energy demands, leading to substantial cost savings on fuel.

Beyond the economic advantages, adopting waste heat recovery aligns with modern sustainability goals. It reduces a facility’s carbon footprint by burning less fossil fuel and promotes the principles of a circular economy through efficient resource recovery. The key benefits include lower operational costs, improved energy efficiency, and a smaller environmental impact.

As regulations become stricter and energy prices continue to rise, integrating waste heat recovery is no longer just an option—it’s a necessity for forward-thinking treatment facilities aiming for long-term operational excellence and environmental stewardship.

The Role of Paddle Dryer Technology in Sludge Drying

Among the various thermal drying technologies, the paddle dryer stands out for its exceptional efficiency and versatility in sludge drying applications. This system uses a unique mechanism of indirect heat transfer, which provides precise temperature control and uniform drying. The design features hollow paddles mounted on shafts that mix and move the sludge while transferring heat.

This method is particularly effective for waste heat recovery, as the enclosed system minimizes heat loss and maximizes thermal efficiency. As you’ll see, the specific working principle and advantages of paddle dryers make them a leading choice for facilities looking to optimize their drying process.

Working Principle of Paddle Dryers

The effectiveness of a paddle dryer lies in its clever design for indirect heat transfer. The dryer consists of a trough containing rotating shafts fitted with hollow, wedge-shaped paddles. A heating medium, such as thermal oil, steam, or hot water, circulates through these hollow paddles and the jacket of the trough. This setup ensures that heat is transferred to the sludge through contact with these heated surfaces, not by direct contact with hot air.

As the shafts rotate, the paddles continuously mix and move the sludge forward. This constant agitation breaks up clumps and exposes new surfaces to the heat, resulting in highly uniform and efficient drying. The process is gentle yet thorough, preventing material degradation while effectively evaporating water content.

Because the heating medium is in a closed loop, the paddle dryer offers excellent control over the drying process temperature. This makes it a reliable and energy-efficient solution for various sludge treatment applications, capable of producing a consistently dry final product.

Advantages of Paddle Dryers in Waste Heat Recovery Applications

Paddle dryers are uniquely suited for waste heat recovery applications, offering several key advantages that boost energy efficiency and reduce costs. Their enclosed, indirect heating design is central to these benefits, making them a smart investment for any sludge drying operation. The main advantages include superior thermal performance and operational flexibility.

The indirect heat transfer method allows for precise temperature control, which prevents overheating and degradation of organic compounds in the sludge. This is crucial for creating high-quality byproducts. Furthermore, the enclosed system minimizes heat loss to the environment, maximizing the energy recovery potential.

Key benefits of using paddle dryers with waste heat recovery include:

- High Energy Efficiency: The closed-loop system retains more thermal energy, reducing the overall demand for external fuel.

- Uniform Drying: Continuous mixing ensures a consistent final product with low moisture content, which is easier to handle and transport.

- Versatility: Paddle dryers can effectively process various types of sludge, including sticky, oily, or hazardous materials.

Common Waste Heat Sources in Industrial Sludge Drying

A major advantage of implementing a heat recovery system is the ability to tap into various sources of waste heat that are often readily available in an industrial setting. This “free” energy can significantly offset the fuel costs associated with the sludge drying process. The heat source can be internal to the drying plant or come from an entirely different industrial process nearby.

Understanding where this waste heat comes from is the first step in designing an efficient recovery system. The following sections will look at common sources found within municipal plants and how heat from broader industrial applications can be harnessed.

Sources within Municipal Wastewater Plants

Within a municipal wastewater treatment plant, you don’t have to look far to find valuable sources of waste heat. One of the most common and accessible sources is the exhaust air from the sludge dryer itself. After passing through the sludge, this air is hot and saturated with water vapor, carrying a significant amount of thermal energy.

Instead of being released into the atmosphere, this post-process air can be routed through a heat exchanger. In this system, the heat is transferred to the cooler ambient air that is being supplied to the dryer, effectively pre-heating it. This simple loop significantly reduces the amount of new energy needed to bring the drying air up to the required temperature.

Other potential sources in a sewage treatment facility could include flue gases from CHP (Combined Heat and Power) units or even the heat generated during anaerobic digestion. By identifying and utilizing these internal heat sources, a plant can create a more self-sustaining and efficient heat recovery operation.

Harnessing Industrial Process Waste Heat

Beyond the confines of a wastewater plant, a vast amount of waste heat is generated by various industrial processes. This presents a significant opportunity for sludge drying operations, especially if your facility is located near other industrial sites like power plants, cement kilns, or manufacturing facilities. The flue gas from these processes is a prime source of high-temperature heat energy.

This waste heat can be captured and transferred to the sludge dryer using a heat exchanger. For example, hot exhaust from a factory’s furnace can be used to heat thermal oil, which is then circulated through a paddle dryer. This creates a symbiotic relationship where one industry’s waste becomes another’s energy source.

Harnessing this external heat offers several benefits:

- It provides a stable and consistent heat source, which is ideal for continuous drying operations.

- It significantly lowers the sludge drying plant’s reliance on purchased fuels like natural gas.

- It contributes to regional industrial sustainability by creating an energy-sharing ecosystem.

Methods for Recovering Waste Heat in Sludge Drying Processes

Once you’ve identified a source of waste heat, the next step is to choose a method to capture it and integrate it into your drying process. The two primary approaches are direct and indirect heat exchange. The choice between them depends on factors like the type of dryer, the characteristics of the waste heat source, and the desired end-product quality.

Both methods rely on a heat exchanger to transfer thermal energy, but they differ in how the heat is applied to the sludge. Let’s explore these two fundamental techniques for efficient heat recovery.

Direct Heat Exchange Systems

In a direct heat exchange system, the heating medium comes into direct contact with the sludge. The most common example of this is using hot air to dry the material. In a waste heat recovery context, this involves using the captured heat to warm up a stream of air, which is then blown directly over or through the sludge, carrying away moisture.

For instance, the waste heat from an industrial flue gas could be used to heat ambient air via a heat exchanger. This pre-warmed hot air is then channeled into a belt dryer, where it passes through the thin layer of sludge, causing water evaporation. This method is straightforward and effective for dryers that rely on convection.

However, direct heat systems can have drawbacks. The direct contact means that any pollutants in the hot air stream could potentially contaminate the sludge. This approach also offers less precise temperature control compared to indirect methods, which may not be suitable for heat-sensitive materials.

Indirect Heat Integration Techniques

Indirect heat integration offers a more controlled and efficient way to use recovered waste heat. In this method, the heating medium never touches the sludge directly. Instead, thermal energy is transferred through a conductive surface, such as the walls of a trough or the surface of hollow paddles in a paddle dryer. A carrier fluid, like thermal oil or steam, is used to move the heat.

This technique, also known as thermal integration, allows for precise temperature management and prevents any cross-contamination between the heat source and the sludge. It is particularly well-suited for paddle dryers, where thermal oil heated by a waste heat source can be circulated through the hollow paddles and jacket.

Key advantages of indirect heat integration include:

- Better Process Control: Maintains a consistent temperature, protecting the sludge from degradation.

- Higher Efficiency: Closed-loop systems minimize heat loss, maximizing the use of recovered energy.

- Purity of End-Product: Prevents contaminants from the heat source from mixing with the sludge.

Technical Approaches to Maximizing Energy Efficiency

Simply installing a heat recovery system is not enough; you need to ensure it operates at peak performance to maximize energy efficiency. This involves a combination of smart design choices and ongoing operational strategies. From the initial layout to daily monitoring, every detail plays a role in how much thermal energy you can successfully recover and reuse.

Two key technical approaches are crucial for getting the most out of your sludge drying process: optimizing the thermal integration of the system and implementing robust monitoring and control strategies. Let’s look at how these approaches work.

Optimizing Thermal Integration

Optimizing thermal integration is all about designing the system for maximum heat transfer. This starts with correctly sizing the equipment, especially the heat exchanger. An undersized heat exchanger won’t capture enough waste heat, while an oversized one can lead to unnecessary capital costs and diminishing returns. The goal is to find the sweet spot that delivers the best financial and energy performance.

Achieving an optimal energy balance requires careful analysis of the heat source and the dryer’s requirements. This includes considering factors like the temperature and flow rate of the waste heat stream and the ambient air conditions, which can vary throughout the year.

Strategies for optimizing thermal integration include:

- Conducting a thorough energy audit to identify all potential heat sources and sinks.

- Using simulation software to model different heat exchanger sizes and configurations.

- Ensuring all hot surfaces and pipes are properly insulated to minimize heat loss.

Monitoring and Control Strategies for Efficient Performance

Once your heat recovery system is installed, maintaining its efficiency requires continuous oversight. Modern monitoring and control strategies use advanced automation to ensure the sludge drying process runs optimally at all times. This involves placing sensors throughout the system to track key parameters like temperature, moisture content, and air flow rates in real-time.

This data is fed into a central process control unit, which can automatically adjust operating conditions. For example, if the moisture content of the incoming sludge changes, the system can increase or decrease the heat input to maintain a consistent final product. This prevents energy waste from over-drying and ensures the system adapts to changing conditions.

By integrating these smart controls, you can expect significant operational improvements. An automated heat recovery system leads to greater energy efficiency, consistent product quality, and reduced need for manual intervention, freeing up your staff for other important tasks.

Process Flow of a Typical Waste Heat Recovery Sludge Dryer

To better understand how these systems work in practice, it helps to visualize the entire process flow. From the moment wet sludge enters the facility to the moment dried granules are discharged, a series of interconnected steps ensures both effective drying and efficient heat recovery. This sequence involves several key pieces of equipment working in harmony.

The typical process flow can be broken down into the main equipment and layout, followed by a step-by-step look at the drying and heat recovery sequence. Let’s trace the journey of sludge and heat through the system.

Main Equipment and Layout Considerations

A well-designed sludge drying plant with waste heat recovery features several critical pieces of equipment arranged for optimal flow and efficiency. The layout is designed to minimize transfer distances and heat loss while ensuring safe and easy access for maintenance. The core components work together to dewater, dry, and cool the sludge while recycling thermal energy.

The central piece of equipment is the dryer itself, such as a paddle dryer. This is supported by feeding systems for wet sludge and conveying systems for the dried product. The heart of the energy savings is the heat recovery unit, which includes the heat exchanger, fans, and ductwork to manage airflows. Finally, an emission control system treats exhaust gases before release.

Here is a look at the main equipment in a typical layout:

| Equipment Component | Function |

|---|---|

| Sludge Feed System | Transports dewatered sludge into the dryer. |

| Dryer (e.g., Paddle Dryer) | Uses indirect heat to evaporate water from the sludge. |

| Heat Exchanger | Transfers heat from hot exhaust air to cool inlet air. |

| Conveying System | Moves the dried, powdered sludge to a storage silo. |

| Emission Control | Treats exhaust air to remove odors and particulates. |

Step-by-Step Drying and Heat Recovery Sequence

The journey from wet sludge to a dry, valuable byproduct follows a clear and efficient sequence. Understanding this step-by-step process highlights how drying and heat recovery are seamlessly integrated to maximize performance and minimize energy use. The sequence ensures every bit of thermal energy is used effectively.

First, dewatered sludge is fed into the dryer. Inside, it is heated, and water begins to evaporate. This process creates hot, humid exhaust air, which is the primary source for heat recovery. This hot air is then directed away from the dryer and into the heat recovery unit.

The key steps in the sequence are:

- Drying: Wet sludge enters the dryer, where indirect heat transfer evaporates the water content.

- Exhaust & Heat Capture: The resulting hot, moist exhaust air is sent to a heat exchanger.

- Heat Transfer: In the heat exchanger, thermal energy is transferred from the hot exhaust air to the cool, incoming ambient air, pre-heating it before it enters the dryer.

- Final Product: The now dry sludge is discharged from the dryer and conveyed to storage.

Comparing Thermal Sludge Drying and Other Drying Methods

Thermal sludge drying, especially when enhanced with waste heat recovery, offers a distinct set of advantages compared to other sludge treatment methods like mechanical dewatering or composting. While each method has its place, thermal drying excels in achieving a high level of moisture removal and creating a stable, reusable end-product.

The key differences lie in energy consumption and the quality of the final sludge. The following sections will compare how thermal drying stacks up against alternatives in these critical areas, helping you make an informed decision for your facility.

Differences in Energy Consumption

When evaluating sludge drying methods, energy consumption is a major factor. Traditional thermal drying can be energy-intensive, but integrating waste heat recovery dramatically changes the equation. This makes it highly competitive with other common sludge treatment techniques.

Mechanical dewatering, for example, uses far less energy but only reduces moisture to a limited extent, leaving you with a heavy, wet sludge cake. Composting requires moderate energy but is a slow process and may not be suitable for all types of sludge. Incineration achieves complete volume elimination but has extremely high energy demands.

Here is how thermal drying with heat recovery compares:

- Mechanical Dewatering: Low energy use, but low moisture removal.

- Thermal Drying (with WHR): Moderate energy use, but very high moisture removal.

- Composting: Moderate energy use, moderate moisture removal.

- Incineration: Very high energy use, complete moisture removal.

By recovering thermal energy, the net energy consumption for sludge drying is significantly reduced, offering a balanced solution.

Impact on Sludge Quality and Handling

The choice of drying method has a profound impact on the final sludge quality and how easy it is to handle, transport, and reuse. Methods like mechanical dewatering only remove a portion of the water content, resulting in a wet, heavy cake that is difficult to store and expensive to transport. This partially treated sludge is also prone to odors and pathogen growth.

In contrast, thermal sludge drying produces a superior end-product. By reducing the moisture content to less than 10%, it transforms the sludge into a dry, lightweight, and dust-free granular material. This dried sludge is biologically stable, meaning it is free from pathogens and unpleasant odors, making it much safer and easier to handle.

This high-quality dried sludge is also far more versatile. Its reduced volume and weight slash transportation and disposal costs. More importantly, it can be repurposed as a valuable resource, such as an alternative fuel or a nutrient-rich fertilizer, opening up new revenue streams for your facility.

Key Benefits of Waste Heat Recovery in Sludge Drying Plants

Integrating waste heat recovery into your sludge drying plant is more than just a technical upgrade; it’s a strategic move that delivers substantial and wide-ranging benefits. The advantages go beyond simple energy savings, touching on your facility’s financial health, environmental footprint, and long-term sustainability. It is a powerful tool for modernizing your operations.

The two main categories of benefits are the direct impact on your bottom line through cost reductions and the positive effect on the environment. Let’s explore these key advantages in more detail.

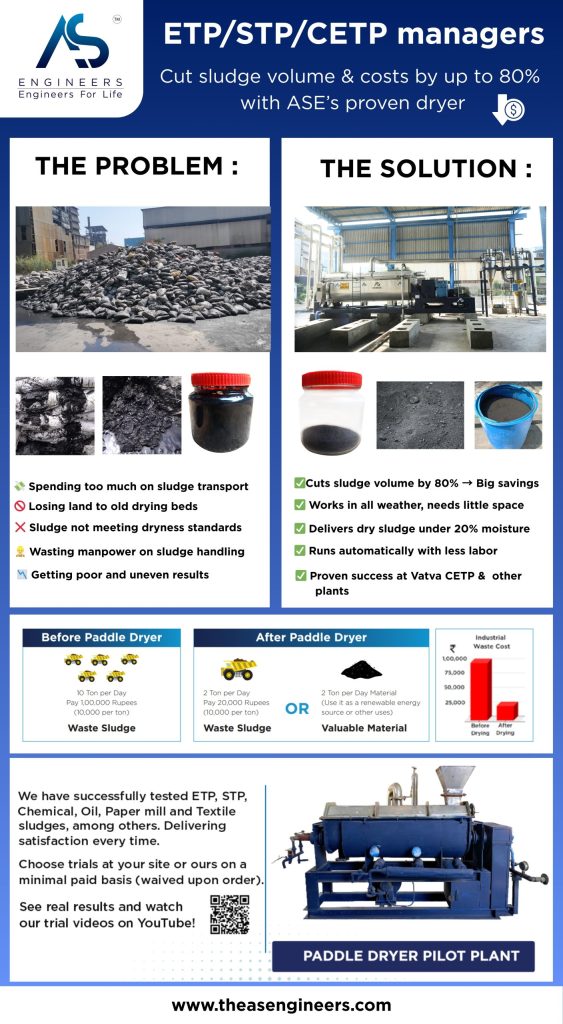

Reduction in Operational Costs and Energy Use

The most immediate and compelling benefit of waste heat recovery is the significant reduction in operational costs. Sludge drying is an energy-intensive process, and fuel can be one of the biggest expenses. By capturing and reusing waste heat, you can dramatically cut down on the amount of natural gas or other fuels your plant needs to purchase, leading to direct and substantial savings on your energy bills.

This improved energy conservation also translates to a faster return on investment. Studies have shown that modernizing a sludge drying plant with an optimized waste heat recovery system can have a payback period of less than four years.

Furthermore, drying the sludge reduces its volume and weight by up to 80-90%. This leads to massive savings on transportation and disposal fees, which are often calculated by weight. By lowering both energy use and disposal expenses, waste heat recovery directly improves your plant’s financial performance.

Environmental Improvements and Sustainability Gains

Beyond the financial savings, waste heat recovery delivers significant environmental improvements. By reducing the consumption of fossil fuels, your sludge drying operation lowers its greenhouse gas emissions, shrinking its overall carbon footprint. This is a crucial step for any organization committed to sustainability and fighting climate change.

The process also aligns with the principles of a circular economy. Instead of treating sludge as a waste product to be landfilled, thermal drying with waste heat recovery transforms it into a valuable resource. The dried, pathogen-free material can be used as a renewable fuel source in cement kilns or as a nutrient-rich soil amendment, promoting resource recovery and reducing landfill dependency.

By adopting this technology, your facility not only complies with increasingly strict environmental regulations but also positions itself as a leader in sustainable waste management. It’s a clear win for both the planet and your public image.

Challenges in Implementing Waste Heat Recovery Systems

While the benefits of waste heat recovery are clear, implementing these systems is not without its challenges. A successful project requires careful planning to overcome potential technical hurdles and ensure the system remains reliable over the long term. Being aware of these challenges from the outset can help you prepare and find the right solutions.

The main difficulties fall into two categories: technical barriers that can arise during design and implementation, and ongoing maintenance and reliability factors. Let’s examine these potential obstacles and how to address them.

Technical Barriers and Solutions

Implementing a waste heat recovery system can present several technical barriers that require smart engineering to solve. One common issue is the variability of the waste heat source. For example, the temperature or flow rate of flue gas from an industrial process might fluctuate, affecting the stability of the drying process. The solution lies in advanced process control systems that can adapt to these changes.

Another challenge is material handling. Sludge can be sticky or abrasive, which can lead to blockages or wear and tear on equipment. This requires careful selection of the dryer type and materials of construction.

Here are some common technical barriers and their solutions:

- Inconsistent Heat Source: Implement buffer systems or automated controls to manage fluctuations in heat supply.

- Corrosive Compounds: Use corrosion-resistant materials for the heat exchanger and ductwork.

- Material Stickiness: Choose a dryer, like a paddle dryer, that is designed to handle difficult materials and prevent buildup.

Maintenance and Reliability Factors

For a waste heat recovery system to deliver consistent savings, it must be reliable. This depends heavily on a robust maintenance program. Without regular upkeep, components like heat exchangers can become fouled or corroded, leading to a drop in heat transfer efficiency and an increase in energy consumption. This can quickly erode the financial benefits of the system.

Establishing a proactive maintenance schedule is crucial. This includes regular inspections of heat exchanger surfaces, cleaning of ducts and fans, and calibration of sensors and controls. The goal is to catch small issues before they become major problems that could lead to costly downtime.

Investing in high-quality, durable equipment from a reputable manufacturer is the first step toward ensuring long-term reliability. A well-designed system, combined with a diligent maintenance routine, will ensure your heat recovery operation performs optimally for years to come, maximizing both energy savings and operational uptime.

Other Value-Added Uses and Byproducts from Sludge (e.g., Construction Materials, Biodiesel, Aggregates)

Thermally dried sludge is much more than just a reduced volume of waste; it’s a raw material with significant potential for reuse. This transformation from a liability into an asset is one of the most exciting aspects of modern sludge management. The dry, stable, and pathogen-free nature of the end-product opens the door to a variety of value-added applications, supporting a true circular economy.

One of the most common uses for dried sludge is as an alternative fuel. Its high calorific value makes it suitable for co-combustion in power plants or cement kilns, replacing a portion of fossil fuels. The inorganic ash can even become part of the final cement product. Additionally, nutrient-rich sludge can be used as a fertilizer or soil conditioner in agriculture. Other innovative uses include manufacturing construction materials like bricks and lightweight aggregates, or even producing biofuels like biodiesel through further processing.

Economic Considerations for Indian Sludge Drying Plants

For sludge drying plants in India, the economic case for implementing waste heat recovery is particularly strong. With rising energy costs and increasing pressure to adopt sustainable practices, this technology offers a clear path to improved profitability and environmental compliance. The financial viability of such a project depends on a careful analysis of investment costs, return on investment (ROI), and available government support.

Understanding these economic factors is essential for making a sound investment decision. Let’s explore the key cost considerations and policy incentives relevant to the Indian context.

Investment Costs and ROI Analysis

The initial investment cost for a waste heat recovery system is a key consideration for any sludge drying plant. This includes the price of the equipment, such as the dryer and heat exchanger, as well as costs for installation, engineering, and commissioning. While this capital expenditure can be significant, it’s important to view it in the context of long-term savings.

A proper return on investment (ROI) analysis will show just how quickly the project can pay for itself. The primary financial benefits come from drastically reduced fuel bills and lower sludge disposal and transportation costs. Studies on similar projects show that the payback period for a well-designed waste heat recovery system can be surprisingly short, often under four years.

When calculating the ROI, it’s crucial to factor in the price of natural gas or other fuels you are replacing. The higher the energy prices, the faster the payback period will be, making waste heat recovery an economically advantageous choice for many Indian facilities.

Government Incentives and Policies

In India, government policies are increasingly supportive of projects that promote energy efficiency and sustainable waste management. Various incentives may be available at the national and state levels to encourage the adoption of technologies like waste heat recovery. These can play a crucial role in improving the economic feasibility of a sludge drying project.

These incentives can take several forms, such as tax credits, grants, or low-interest loans for green technology investments. Policies focused on renewable energy and resource recovery may also apply, especially if the dried sludge is being used to generate energy.

Potential forms of government support include:

- Subsidies: Direct financial support for purchasing and installing energy recovery equipment.

- Tax Benefits: Accelerated depreciation or tax exemptions for green investments.

- Favorable Regulations: Policies that mandate sustainable sludge management, making technologies like drying more attractive.

Investigating these government policies is a critical step in the financial planning process, as they can significantly lower the net investment cost and improve the overall ROI.

Conclusion

In summary, enhancing waste heat recovery in sludge drying plants is not just an innovative approach; it’s a necessity for achieving efficiency and sustainability. By integrating advanced technologies like paddle dryers with effective waste heat recovery systems, facilities can significantly reduce operational costs while also minimizing their environmental impact. The journey toward maximizing energy efficiency involves navigating challenges and leveraging opportunities for improvement, ultimately leading to better sludge quality and resource utilization. As you consider the implementation of these strategies within your operations, remember that investing in waste heat recovery could pave the way for substantial long-term benefits. To explore how you can optimize your sludge drying processes, feel free to reach out for a consultation!

Frequently Asked Questions

Which types of waste heat sources are most suitable for paddle dryer plants?

The most suitable waste heat sources for paddle dryer plants are stable, medium-to-high temperature streams like flue gas from boilers, furnaces, or CHP units. The hot exhaust air from the sludge drying process itself is also an excellent internal source for heat recovery, creating a highly efficient closed-loop system.

What operational improvements can be expected from integrating waste heat recovery?

Integrating waste heat recovery leads to significant operational improvements, including a sharp reduction in energy consumption and fuel costs. You can also expect more stable and precise process control, resulting in consistent product quality. An optimized energy balance also reduces the overall strain on equipment, potentially lowering maintenance needs.

Are there successful case studies of sludge drying plants using waste heat recovery in India?

Yes, numerous sludge drying plants across various industries in India have successfully implemented waste heat recovery. These case studies demonstrate significant energy savings, reduced operational costs, and rapid ROI. As a leading provider, AS Engineers has helped many clients achieve these results with our advanced paddle dryer and energy recovery solutions.

What are the key benefits of implementing waste heat recovery systems in sludge drying plants?

The key benefits include drastically lower energy costs, a smaller environmental impact due to reduced fuel consumption, and significant savings on sludge transport and disposal. Waste heat recovery also improves overall energy efficiency and helps plants meet sustainability goals by turning waste into a resource.

How does waste heat recovery improve energy efficiency in sludge drying processes?

Waste heat recovery improves energy efficiency by capturing thermal energy from exhaust gases that would otherwise be lost. This captured heat is used, via a heat exchanger, to preheat the incoming air or sludge. This reduces the amount of new fuel needed, achieving greater energy conservation and lowering overall consumption.

What types of technologies are commonly used for waste heat recovery in industrial applications?

Common technologies include heat exchangers (such as plate, shell-and-tube, or air-to-air), which transfer heat between fluid streams. Other systems like heat pumps, thermal integration networks, and Organic Rankine Cycles (ORC) are also used to convert low-grade waste heat from an industrial process into useful thermal or electrical energy.

Are there any regulatory considerations to keep in mind when enhancing waste heat recovery in sludge drying plants?

Yes, regulatory considerations are important. You must ensure that the final treated exhaust air meets local environmental standards for emissions. Additionally, there might be policies or incentives related to energy efficiency and waste management that can impact your project’s design and financial viability, so it’s crucial to stay informed.