Wastewater treatment is essential for protecting public health and our environment, but what happens to the waste that’s removed? This process generates a significant amount of bio sludge, a material that requires careful management. For years, disposal has been a costly and complex problem for many treatment plants. However, innovative technology is changing the narrative. Instead of viewing bio sludge as a liability, advanced treatment processes can transform it into a valuable asset, creating sustainable solutions for a circular economy.

Table of contents

- Key Highlights

- Understanding Bio Sludge and Biosolids

- How Bio Sludge Is Produced

- Types of Bio Sludge in India

- Conventional Bio Sludge Treatment Methods

- Limitations of Traditional Bio Sludge Disposal

- Advanced Solution – Paddle Dryer for Bio Sludge

- Transforming Bio Sludge into Value Using Paddle Dryers

- Safe Use and Quality Control in Bio Sludge Products

- Conclusion

- Frequently Asked Questions

Key Highlights

- Bio sludge is a major byproduct of the wastewater treatment process, posing significant disposal challenges.

- Traditional disposal methods like landfilling and land application carry environmental risks and regulatory hurdles.

- Advanced solutions, such as the AS Engineers Paddle Dryer, offer an efficient way to treat and reduce bio sludge volume.

- The drying process converts bio sludge into valuable resources like Class A biosolids for fertilizer or fuel for energy generation.

- Paddle dryers provide a safe, energy-efficient, and cost-effective solution for modern sewage sludge management.

- Proper treatment ensures the final product meets strict quality standards, protecting public health and the environment.

Understanding Bio Sludge and Biosolids

In the world of wastewater treatment, you will often hear the terms “bio sludge” and “biosolids.” While they are related, they are not the same. Understanding the distinction is key to appreciating the journey from raw waste to a reusable resource. Bio sludge is the initial, untreated organic matter separated from sewage.

Biosolids, on the other hand, are the end product. After sewage sludge undergoes a thorough treatment process to reduce pathogens and stabilize organic matter, it becomes biosolids. This treated material can be safely recycled and used for beneficial purposes, such as improving soil quality. The following sections will explore these concepts in more detail.

Defining Bio Sludge in Wastewater Treatment

Bio sludge is the semi-solid and liquid residue produced during the municipal wastewater treatment process. It is essentially an accumulation of microorganisms, organic matter, and inorganic compounds that are removed from sewage. When wastewater enters a treatment plant, various processes separate these solids from the water.

This raw sludge is a complex mixture. It consists of the biomass generated by the biological breakdown of waste materials. Think of it as the heart of the pollutant removal system, as it captures contaminants that would otherwise harm the environment. However, in its raw form, it is voluminous, has a high water content, and contains pathogens.

Because of these characteristics, raw bio sludge cannot be directly disposed of or reused. It requires further treatment to reduce its volume, stabilize its organic components, and eliminate health risks. Proper management is not just about disposal; it’s about transforming a problematic byproduct into something safe and beneficial.

Key Differences Between Bio Sludge and Biosolids

The primary distinction between bio sludge and biosolids lies in the level of treatment. Bio sludge is the raw, untreated organic material collected during wastewater treatment. Biosolids are what bio sludge becomes after undergoing rigorous treatment processes to meet specific quality and safety standards.

This transformation is critical for reuse. The treatment process, which can include digestion, dewatering, and drying, is designed to significantly reduce pathogens and stabilize the organic materials. This ensures the final product is safe for handling and application. In the United States, the term “biosolids” was specifically introduced to differentiate the treated, reusable product from untreated sewage sludge.

Here are the key differences:

- Treatment: Bio sludge is raw, while biosolids have been treated to reduce pathogens and stabilize organic matter.

- Safety: Biosolids meet strict regulatory standards, making them safe for land application.

- Usefulness: Biosolids are a valuable resource used as fertilizer or soil conditioner, whereas raw sludge is a waste product requiring disposal.

- Regulatory Status: The term “biosolids” often implies that the material has met legal requirements for beneficial reuse, such as those set by the Environmental Protection Agency (EPA).

Composition and Characteristics of Bio Sludge

The composition of bio sludge can vary widely depending on the source of the wastewater and the treatment processes used. However, it generally contains a rich mix of organic and inorganic materials. The high concentration of organic matter and nutrients makes it potentially valuable but also challenging to handle.

These sludge characteristics are important to understand for effective treatment. Key components include organic compounds, nitrogen, and phosphorus, which are essential plant nutrients. However, sludge can also contain undesirable substances.

Here are some common components found in bio sludge:

- Organic Matter: Includes proteins, sugars, and other biodegradable materials. Volatile solids are a measure of this organic content.

- Nutrients: Rich in nitrogen and phosphorus, making it a potential fertilizer.

- Pathogens: Contains disease-causing microorganisms that must be eliminated.

- Contaminants: May contain heavy metals, toxic chemicals, and pharmaceuticals, depending on the wastewater source.

How Bio Sludge Is Produced

Bio sludge is a natural byproduct generated within every sewage treatment plant. The wastewater treatment process is designed to separate solids from water, and these collected solids form the sludge. This happens in multiple stages, primarily during primary and secondary treatment.

Initially, heavier solids settle out of the wastewater in a phase called primary treatment, creating primary sludge. The liquid then moves to secondary treatment, where biological processes generate even more sludge. Understanding these stages is the first step toward effective sludge management. Let’s look closer at the specific processes that create bio sludge.

Biological Processes Generating Bio Sludge

The generation of bio sludge is fundamentally a biological process. It happens during the secondary treatment stage, where microorganisms are used to consume the dissolved organic matter in wastewater. These microorganisms, or biomass, are the core of the treatment.

Two main biological processes are used: aerobic and anaerobic digestion. In aerobic digestion, microorganisms break down waste in the presence of oxygen. This is common in activated sludge systems and results in the creation of secondary sludge. The bacteria consume the organic pollutants, grow, and multiply, forming a mass that can be settled and removed.

Alternatively, anaerobic digestion breaks down organic matter in the absence of oxygen. This process is often used to stabilize sludge after it has been collected. It reduces the volume of sludge and produces biogas, a renewable energy source. Both methods are effective at treating wastewater, but they result in the production of sludge that must be managed at the treatment plant.

Role of Industrial and Domestic Wastewater

The source of the wastewater significantly influences the characteristics and volume of sludge produced. Wastewater treatment plants can receive flows from domestic households, commercial establishments, and industrial facilities, each contributing different types of pollutants.

Domestic wastewater primarily consists of human waste, food scraps, and cleaning products. The resulting sludge is typically rich in organic matter and nutrients. In contrast, industrial waste can introduce a wide range of contaminants, including heavy metals, toxic chemicals, and poorly degradable organic compounds. This variability makes treatment more complex.

The mix of wastewater sources affects sludge in several ways:

- Volume of Sludge: Industrial processes can generate higher volumes of sludge compared to purely domestic sources.

- Sludge Characteristics: The presence of industrial chemicals alters the sludge’s composition, potentially making it hazardous.

- Treatment Requirements: Sludge containing industrial contaminants may require more advanced and costly treatment before it can be safely disposed of or reused.

Stages from Wastewater to Sludge Formation

The journey from raw wastewater to bio sludge occurs in distinct stages within a treatment plant. Each stage is designed to remove different types of solids, progressively cleaning the water and concentrating the waste into sludge.

The first step is primary treatment, where wastewater is held in a large tank, allowing heavy solids to settle to the bottom by gravity. This settled material is known as primary sludge. The remaining liquid then flows into the secondary treatment stage.

In secondary treatment, biological processes are used to remove dissolved organic matter. Microorganisms consume the pollutants, forming clumps of biomass that settle out as secondary sludge. The table below outlines these key stages in the wastewater treatment process that lead to sludge formation.

| Stage | Description | Solids Concentration |

|---|---|---|

| Primary Treatment | Physical separation of settleable solids from raw wastewater in a clarifier. | Low to moderate |

| Secondary Treatment | Biological process where microorganisms consume organic matter, creating activated sludge. | Moderate |

| Sedimentation | The process where the newly formed biological sludge settles at the bottom of a tank for collection. | Increasing |

Types of Bio Sludge in India

In India, as in other parts of the world, sewage treatment plants generate different types of bio sludge based on the treatment stage. The two most common types are primary sludge and secondary sludge. Each has unique sludge characteristics that determine how it must be handled and treated.

Primary sludge consists of the raw solids that settle out during the initial phase of treatment, while secondary sludge is the biomass created during biological processes. Understanding the differences between them is crucial for selecting the right management strategy, whether it’s composting, digestion, or advanced drying.

Primary vs Secondary Bio Sludge

Primary and secondary bio sludge are distinguished by how and when they are produced in the wastewater treatment process. Their compositions and characteristics are quite different, which impacts their treatment and disposal options.

Primary sludge is collected from the primary clarifiers. It consists of settleable solids that are removed from raw sewage through sedimentation. This type of sludge typically contains a high level of organic material and has a higher solids concentration compared to secondary sludge.

On the other hand, secondary sludge is generated during the biological treatment phase. It is primarily made up of the microorganisms that consume the organic pollutants in the wastewater. Here are some key distinctions:

- Origin: Primary sludge comes from physical sedimentation, while secondary sludge is a product of biological treatment.

- Organic Matter: Primary sludge has more raw organic material, while the organic matter in secondary sludge is mostly microbial biomass.

- Volatile Solids: The content of volatile solids can differ, affecting how each sludge type behaves during digestion or composting.

Activated Sludge from Sewage Treatment Plants

Activated sludge is the most common type of secondary sludge produced in modern sewage treatment plants. It is generated through the activated sludge process, which uses a high concentration of microorganisms under aerobic conditions to break down organic compounds in wastewater.

In this process, air is pumped into a large tank containing the wastewater and a culture of bacteria and other microbes. These microorganisms consume the organic pollutants as food, converting them into carbon dioxide, water, and more microorganisms. This growing population of microbes forms flocs, or clumps, that can be easily separated from the treated water.

Once the biological process is complete, the mixture flows into a secondary clarifier, where the activated sludge settles to the bottom. A portion of this sludge is returned to the aeration tank to maintain the microbial population, while the excess is removed for further treatment and disposal. This excess is what we refer to as waste activated sludge.

Industrial Bio Sludge and Its Unique Traits

Industrial bio sludge originates from wastewater generated by manufacturing and processing facilities. Unlike municipal sludge, which is relatively consistent, industrial sludge can have highly variable and unique characteristics depending on the specific industry it comes from.

For example, sludge from a metal plating facility will be high in heavy metals, while sludge from a paper mill may contain different chemicals and fibers. This variability presents significant challenges for treatment and disposal. The sludge volume and composition can fluctuate, requiring flexible and robust management systems.

Key traits of industrial bio sludge include:

- Presence of Contaminants: Often contains specific pollutants like heavy metals, toxic organic compounds, or trace elements that are not typically found in domestic sewage.

- Treatment Complexity: The presence of hazardous materials may require specialized treatment methods to render the sludge safe for disposal or reuse.

- Regulatory Scrutiny: Industrial sludge is often subject to stricter environmental regulations due to its potential for contamination.

Conventional Bio Sludge Treatment Methods

Before bio sludge can be disposed of or reused, it must undergo several treatment processes to reduce its volume and stabilize its components. Conventional methods have been used for decades and typically involve a multi-step approach, including thickening, stabilization, and dewatering.

Techniques like using a gravity thickener or filter presses help remove water, while processes like composting or digestion reduce pathogens and odors. These methods prepare the sludge for final disposal, but they often come with their own set of limitations. The following sections will explore these traditional techniques in more detail.

Stabilization and Thickening Techniques

Stabilization and thickening are often the first steps in sludge treatment. The main goal of thickening is to reduce the volume of the sludge by removing some of its water content. This makes the sludge easier to handle and reduces the size of subsequent treatment units.

Gravity thickening is a common method where sludge is allowed to settle in a tank, and the thickened sludge is drawn from the bottom while the separated water is returned to the treatment plant. This process can increase the solids concentration significantly, preparing the sludge for the next stage.

Stabilization is a process designed to reduce pathogens, eliminate odors, and decrease the potential for organic matter to decompose further. This is typically achieved through biological processes like aerobic or anaerobic digestion. A stable sludge is much safer to handle and store before its final disposal or reuse.

Dewatering: Sludge Thickener Solutions

Dewatering is a critical step that follows thickening and stabilization. Its purpose is to remove even more water from the sludge, transforming it from a liquid into a semi-solid or solid cake. This drastically reduces the sludge volume and weight, which in turn lowers transportation and disposal costs.

Various mechanical systems are used for dewatering. These devices apply pressure or force to squeeze water out of the sludge. Common sludge thickener and dewatering solutions include belt filter presses, centrifuges, and screw presses. The choice of technology depends on the sludge characteristics and the desired final solids content.

Here are some popular dewatering methods:

- Belt Filter Presses: Sludge is squeezed between two porous belts that pass over rollers, pressing the water out.

- Centrifuges: High-speed spinning separates the denser solids from the liquid, similar to a washing machine’s spin cycle.

- Drying Beds: A simple, low-cost method where sludge is spread on sand beds and dried by evaporation and drainage, though it is time-consuming.

Composting as a Form of Bio Sludge Recycling

Composting is an effective method for recycling bio sludge and turning it into a valuable product. This aerobic process involves mixing dewatered sludge with a source of carbon, such as wood chips, sawdust, or yard waste. Microorganisms then break down the organic matter, generating heat that kills pathogens.

The end product is a stable, nutrient-rich material similar to humus, which can be used as a soil conditioner or fertilizer. Composting not only diverts sludge from landfills but also creates a beneficial product for agricultural use, landscaping, and land reclamation projects. It is a sustainable approach to sludge management.

Composting offers several benefits:

- Resource Recovery: It recycles the organic matter and nutrients in sludge, turning waste into a resource.

- Pathogen Reduction: The heat generated during the aerobic digestion process effectively destroys harmful microorganisms.

- Improved Soil Health: The final compost improves soil structure, water retention, and fertility, reducing the need for chemical fertilizers.

Limitations of Traditional Bio Sludge Disposal

While conventional bio sludge treatment methods are well-established, they come with significant limitations. Disposal options like land application and landfilling are facing increasing scrutiny due to their potential environmental impact and risks to public health.

The presence of contaminants, odors, and the sheer volume of sludge make these traditional approaches unsustainable in the long run. As regulations become stricter and land becomes scarcer, the need for more advanced and reliable solutions is more apparent than ever. Let’s examine the specific challenges associated with these older methods.

Land Application and Its Challenges

Land application has long been a common method for disposing of treated bio sludge. The nutrient-rich material can act as a soil conditioner and fertilizer, improving soil fertility and crop yields on agricultural land. However, this practice is not without its challenges.

One of the biggest concerns is the potential for contamination. If the sludge is not treated properly, it can introduce heavy metals, pathogens, and toxic organic compounds into the soil and water systems. This poses a risk to crops, livestock, and human health. Public perception and opposition can also be a significant barrier to land application programs.

Here are some of the main challenges:

- Contaminant Buildup: Repeated application can lead to the accumulation of heavy metals and other pollutants in the soil over time.

- Environmental Impact: Runoff from fields treated with sludge can pollute nearby rivers and groundwater.

- Public Opposition: Concerns about safety, odors, and health risks often lead to community resistance against the use of biosolids on nearby farms.

Environmental Impacts and Risks

The environmental impact of improper bio sludge management can be severe. Even after treatment, sludge can retain contaminants that pose a threat to ecosystems and public health. When landfilled, sludge can produce harmful leachate that contaminates groundwater, and it contributes to the release of methane, a potent greenhouse gas.

When used for land application, the risks are more direct. Heavy metals like cadmium, lead, and mercury can accumulate in the soil and be taken up by plants, entering the food chain. Similarly, pathogens that survive the treatment process can contaminate crops and water sources, leading to disease outbreaks.

Effective pathogen reduction and the management of toxic chemicals are therefore critical components of any sludge treatment plan. Without them, the risks associated with bio sludge can outweigh its benefits as a fertilizer. A thorough risk assessment is necessary to ensure that disposal or reuse is done safely.

Regulatory Concerns in Bio Sludge Management

Bio sludge management is governed by a complex web of local, state, and federal regulations. Bodies like the U.S. Environmental Protection Agency (EPA) have established strict regulatory guidelines to protect public health and the environment. For example, the EPA’s Part 503 rule sets limits on pollutant concentrations and requires specific levels of pathogen reduction for biosolids applied to land.

Meeting these standards can be a challenge for wastewater treatment facilities, especially those using older technologies. The costs of monitoring, testing, and reporting can be substantial. Failure to comply can result in heavy fines and legal action.

Key regulatory concerns include:

- Pollutant Limits: Sludge must be tested for heavy metals and other toxic chemicals to ensure they are below legally mandated thresholds.

- Pathogen Reduction: Treatment processes must achieve specific standards for killing harmful bacteria, viruses, and parasites.

- Risk Assessment: Facilities must conduct a thorough risk assessment to demonstrate that their sludge management practices are safe for the intended use or disposal method.

Advanced Solution – Paddle Dryer for Bio Sludge

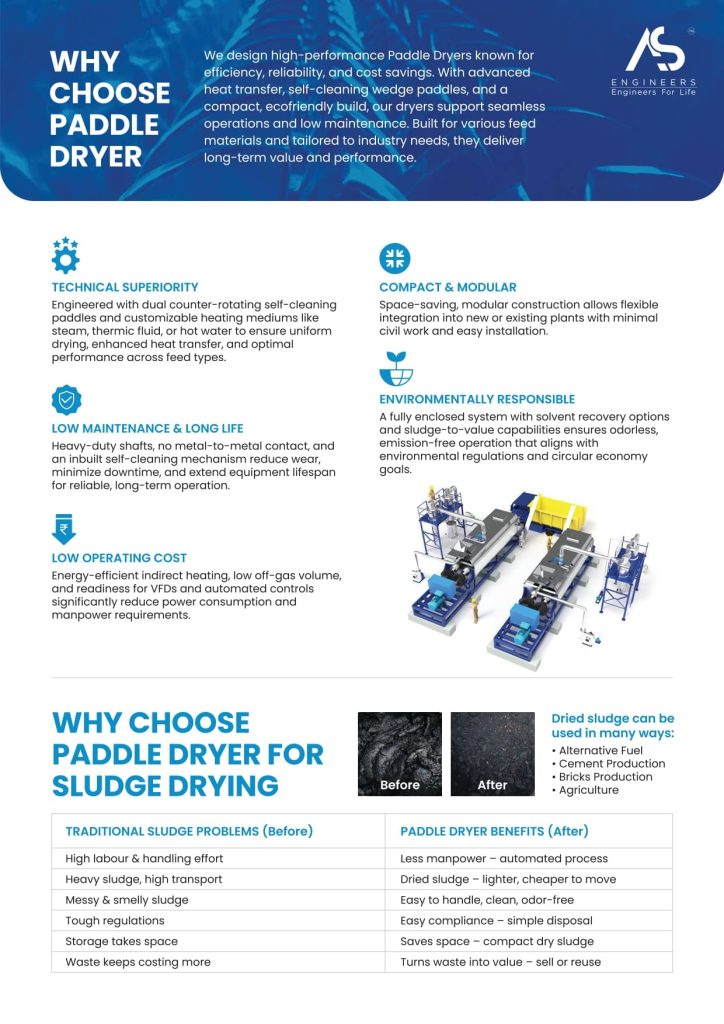

Faced with the limitations of traditional methods, the wastewater industry is turning to advanced technologies like the AS Engineers Paddle Dryer. This innovative system offers a superior solution for treating bio sludge, transforming it from a wet, problematic waste into a dry, stable, and valuable product.

A paddle dryer is an indirect heat transfer device that efficiently removes water from sludge. This process dramatically reduces sludge volume, lowers disposal costs, and minimizes environmental risks. It also opens the door to creating high-value by-products, making sludge management not just a necessity but an opportunity.

How Paddle Dryers Work as Bio Sludge Dryers

A paddle dryer works by using indirect heat to dry bio sludge efficiently. The machine consists of a jacketed trough and two counter-rotating shafts with hollow, wedge-shaped paddles. A heating medium, such as steam or hot oil, circulates through the jacket and the paddles, transferring heat to the sludge through conduction.

As the sludge moves through the dryer, the intermeshing paddles continuously mix and agitate it, ensuring uniform heating and preventing material from sticking. This mechanical agitation enhances the drying process, allowing the sludge to pass through various phases—from a wet cake to a plastic, sticky phase, and finally to a dry, granular product. The final moisture content can be precisely controlled.

The key features of an AS Engineers paddle dryer include:

- Indirect Heating: This method is highly energy-efficient and creates a minimal amount of off-gas, simplifying environmental permitting.

- Mechanical Agitation: The unique paddle design provides self-cleaning action and can handle a wide range of sludge characteristics without pre-conditioning.

- Enclosed Process: The system is totally enclosed, eliminating fugitive emissions and ensuring a safe operating environment with low oxygen levels.

Energy Efficiency and Operational Advantages

One of the main advantages of using a paddle dryer is its exceptional energy efficiency. Because it uses an indirect drying process, nearly all the heat from the heating medium is transferred directly to the sludge, with very little energy loss. An AS Engineers paddle dryer can achieve thermal efficiencies of approximately 98%, leading to significant reductions in energy consumption and operational costs.

The operational advantages extend beyond energy savings. These sludge dryer systems are designed for continuous, automated operation, requiring minimal operator attention. Their robust design ensures long-term reliability and low maintenance, even when handling difficult materials. The system can handle feeds with varying solids concentrations without needing to recycle dried product, which simplifies the process.

Key operational benefits include:

- Low Off-Gas Volume: Since no air is used to convey the product, the volume of exhaust gas is minimal, reducing the size and cost of air pollution control equipment.

- Process Flexibility: The high-torque design allows the dryer to handle sludge through its stickiest phases without shutting down.

- Compact Footprint: The high heat transfer rate allows for a compact machine, saving valuable space in the treatment plant.

Comparison of Paddle Dryers to Other Drying Technologies

When compared to other drying technologies, the paddle dryer stands out for its efficiency, safety, and versatility. Traditional direct dryers, which use hot air to evaporate water, are less energy-efficient and produce large volumes of off-gas that require extensive treatment. Other dewatering methods like filter presses don’t achieve the same level of dryness.

The indirect heating mechanism of a paddle dryer makes it inherently safer, especially when processing combustible materials, as it operates in a low-oxygen environment. While dewatering technologies like belt presses reduce water content, they typically only achieve 20-35% solids. A paddle dryer can take that same sludge and dry it to 90% solids or more.

The table below compares the AS Engineers paddle dryer to other common technologies used in sludge management.

| Feature | AS Engineers Paddle Dryer | Direct Air Dryer | Belt Filter Press |

|---|---|---|---|

| Thermal Efficiency | Very High (~98%) | Low to Moderate | N/A (Dewatering only) |

| Final Solids % | 90%+ | 90%+ | 20-35% |

| Off-Gas Volume | Very Low | Very High | Low |

| Safety | High (Low oxygen) | Lower (Risk of dust explosion) | High |

| Footprint | Compact | Large | Moderate |

Transforming Bio Sludge into Value Using Paddle Dryers

The true innovation of a bio sludge dryer lies in its ability to do more than just dispose of waste. The conversion process a paddle dryer facilitates turns wet, costly sludge into dry, valuable by-products. This transformation shifts the focus from sludge management to resource recovery.

By producing a stable, granular product, facilities can create new revenue streams. The dried organic materials can be used as a slow-release fertilizer or as a renewable fuel source, generating energy that can power the plant itself. This is how modern technology creates a circular economy within the wastewater treatment sector.

Conversion Process from Wet Sludge to Valuable By-products

The conversion process begins the moment wet sludge enters the paddle dryer. The machine takes a material that is difficult to handle—often a slurry, paste, or filter cake—and systematically removes water through controlled, indirect heating and mechanical agitation. This journey transforms the sludge’s physical and chemical properties.

As the treated sludge moves through the dryer, its moisture content drops dramatically, often from 80% down to 10% or less. This results in a stable, dry, and granular product that is easy to store, transport, and use. The high heat of the process also ensures significant pathogen reduction, often achieving Class A biosolids standards.

The benefits of this conversion process include:

- Volume Reduction: Drying can reduce the final sludge volume by up to 90%, drastically cutting transportation and disposal costs.

- Product Creation: The output is a consistent, marketable product, not a waste material.

- Elimination of Pre-conditioning: The AS Engineers paddle dryer accepts wet cake directly, eliminating the need for complex and costly back-mixing systems.

Generating Energy from Dried Bio Sludge

One of the most exciting opportunities created by drying bio sludge is the ability to generate energy. The dried product, with its high organic content, has significant fuel value and can be used as a renewable energy source. This helps reduce reliance on fossil fuels and lowers a treatment plant’s overall energy consumption.

The dried biosolids can be co-fired in cement kilns or incinerated in waste-to-energy plants to produce electricity. The energy generated can often be enough to power the drying system and other equipment at the facility, creating a self-sustaining operation. This is especially valuable as energy costs continue to rise.

Energy can also be generated through anaerobic digestion. While digestion produces methane gas from wet sludge, dewatering and drying the sludge beforehand can optimize the digestion process.

- Fuel for Boilers: Dried sludge can be used as a fuel source in on-site boilers.

- Improved Digestion: Pre-drying can enhance the efficiency of the anaerobic digestion process, leading to higher methane gas yields.

- Reduced Carbon Footprint: Using sludge as fuel reduces the plant’s carbon footprint and provides a sustainable energy solution.

Bio Sludge Fertilizer: Agricultural Applications

When dried to meet regulatory standards, bio sludge becomes a high-quality bio sludge fertilizer. This product, often known as Class A biosolids, is rich in essential plant nutrients like nitrogen and phosphorus, as well as valuable organic matter. It serves as an excellent alternative to synthetic chemical fertilizers.

This bio sludge fertilizer can be used in a variety of agricultural applications, from large-scale farming to commercial landscaping. Applying these biosolids to land improves soil quality, enhances water retention, and stimulates plant growth. It is a prime example of closing the loop on nutrient recycling.

Agricultural benefits include:

- Improved Soil Quality: The organic matter in biosolids enhances soil structure and fertility.

- Nutrient Recycling: It returns essential nutrients to the soil, reducing the need for manufactured fertilizers.

- Sustainable Farming: The land application of biosolids is a sustainable practice that supports a circular economy and reduces waste.

Safe Use and Quality Control in Bio Sludge Products

Transforming bio sludge into a valuable product requires a strong commitment to safety and quality control. The presence of toxic chemicals, heavy metals, and pathogens in raw sludge means that treatment must be thorough and effective to protect public health and the environment.

Advanced treatment systems like the AS Engineers Paddle Dryer are designed to meet these challenges. They are a key part of a comprehensive management strategy that includes rigorous testing and adherence to quality standards. This ensures that the final products, whether used as fertilizer or fuel, are safe and beneficial.

Managing Toxic Chemicals Through Treatment

A primary concern in bio sludge management is the presence of toxic chemicals and heavy metals. These contaminants can originate from industrial discharge or common household products. If not managed properly, they can end up in the final biosolid product and pose a risk to the environment.

The treatment process plays a critical role in managing these substances. While drying itself does not destroy heavy metals, the high temperatures can help remove some volatile organic compounds. More importantly, a robust treatment system is part of a larger strategy that includes source control—preventing contaminants from entering the wastewater system in the first place.

Effective management strategies include:

- Thermal Desorption: High-temperature drying can remove certain hazardous volatile organic compounds from the sludge.

- Source Control Programs: Working with industries to pre-treat their wastewater reduces the load of toxic chemicals on the municipal plant.

- Rigorous Testing: A thorough risk assessment and regular testing of the final product ensure it meets safety limits for all regulated contaminants before it is used.

Ensuring Quality and Safety Standards

To ensure the safe use of bio sludge products, they must meet strict quality and safety standards set by regulatory agencies. In the U.S., the EPA’s Part 503 rule establishes the criteria for classifying biosolids as Class A or Class B. Class A biosolids have undergone the most stringent treatment for pathogen reduction and can be used with minimal restrictions.

Achieving Class A status is a key goal for many modern treatment facilities, as it opens up the widest range of beneficial reuse options. The high temperatures and controlled process of an AS Engineers Paddle Dryer are instrumental in meeting these standards. The system effectively destroys pathogens, creating a treated sludge product that is safe for public use.

Key aspects of quality assurance include:

- Pathogen Reduction: The treatment must eliminate harmful bacteria, viruses, and parasites to below detectable levels for Class A.

- Vector Attraction Reduction: The sludge must be processed to reduce its appeal to pests like flies and rodents.

- Pollutant Limits: The final product must be tested to confirm that heavy metal concentrations are below the required quality standards.

Regulatory Guidelines for Bio Sludge in Farming

The application of biosolids in farming is heavily regulated to protect food safety, public health, and the environment. Regulatory guidelines dictate not only the quality of the biosolids but also how, where, and in what quantities they can be applied to land.

These rules, often enforced by environmental protection agencies and water associations, are based on extensive scientific research and risk assessment. They ensure that the land application of biosolids is a safe and sustainable practice. For example, regulations may specify buffer zones near water bodies or restrict application on certain types of crops.

Adherence to these guidelines is mandatory:

- Application Rates: Rates are calculated based on the nutrient needs of the crop to prevent over-application and runoff.

- Site Restrictions: There are rules about where biosolids can be applied, such as prohibiting use on flooded or frozen ground.

- Record-Keeping: Facilities must maintain detailed records of where their biosolids are applied and provide regular reports to regulators.

Conclusion

In conclusion, transforming bio sludge into valuable resources is not only a sustainable practice but also an essential step towards effective waste management. Utilizing advanced solutions like paddle dryers can significantly enhance the efficiency of bio sludge treatment, turning waste into energy and useful fertilizers while minimizing environmental impact. As we face increasing challenges in waste disposal and resource management, adopting innovative technologies offers a pathway to a greener future. If you’re interested in exploring how our paddle dryer can optimize your bio sludge processing, get in touch today for a consultation.

Frequently Asked Questions

What is the main advantage of using a paddle dryer for bio sludge treatment?

The main advantage of an AS Engineers paddle dryer is its high energy efficiency. The indirect drying process achieves up to 98% thermal efficiency, significantly lowering operational costs compared to other sludge dryer technologies. This efficient treatment process also produces a minimal amount of off-gas, simplifying environmental compliance.

Can paddle-dried bio sludge be safely used as fertilizer in agriculture?

Yes, paddle-dried bio sludge can be safely used as a bio sludge fertilizer. The high-heat process effectively reduces pathogens to meet stringent Class A standards for agricultural use. Proper testing ensures the final product’s sludge characteristics are safe for land application, protecting public health and improving soil quality.

How does a bio sludge dryer help reduce environmental risks during disposal?

A bio sludge dryer from AS Engineers reduces environmental impact by drastically cutting sludge volume, which minimizes landfill use. The process achieves significant pathogen reduction, making the final product safer. This enclosed system also prevents fugitive emissions, lowering the overall risk assessment for sludge disposal and handling.

How is bio sludge produced during wastewater treatment?

Bio sludge is produced during the wastewater treatment process when solids are separated from water. Primary treatment settles out heavy solids, creating primary sewage sludge. Secondary, or biological treatment, uses microorganisms to consume organic matter, which then settles out as secondary sludge, forming the bulk of the material.

How can bio sludge be processed to generate energy?

Bio sludge can be processed to generate energy after being dried in a sludge dryer. The dried organic matter can be incinerated to produce heat and electricity. Alternatively, drying can optimize the anaerobic digestion process, leading to a more efficient digestion process and increased production of methane gas for energy.

What methods are used to dry and treat bio sludge before disposal or reuse?

Common methods include thickening with a sludge thickener and dewatering with filter presses or centrifuges to remove some water. For maximum dryness, an advanced drying process using a paddle dryer is used. This thermal treatment is the most effective way to produce a stable, valuable, and easily handled final product.

How do regulators control the safe use of bio sludge in farming?

Regulators control the application of biosolids through strict guidelines that limit pollutant levels and mandate pathogen reduction. Based on a risk assessment, they set rules for application rates and locations to protect public health. This framework ensures that the use of biosolids on farms is safe and environmentally responsible.