In India’s growing industrial sector, managing waste and processing materials efficiently is more critical than ever. Paddle dryers have become a premier solution for many businesses, offering an effective way to handle sludge drying and other industrial heat transfer tasks. This advanced paddle dryer technology provides cost-effective and energy-efficient drying solutions. If you’re looking for a reliable partner, this guide will walk you through the world of paddle dryers and introduce you to India’s leading manufacturers.

Table of contents

- Key Highlights

- AS Engineers – Leading Paddle Dryer Manufacturer in India

- What Is a Paddle Dryer? Understanding the Technology

- Applications of Paddle Dryers Manufactured in India

- Selecting the Right Paddle Dryer Manufacturer in India

- Customization Options in Paddle Dryer Solutions

- Manufacturing Excellence at AS Engineers

- Cost, Pricing, and Investment in Paddle Dryers

- Conclusion

- Frequently Asked Questions

Key Highlights

- AS Engineers is a leading paddle dryer manufacturer in India, providing innovative drying solutions with advanced paddle dryer technology.

- Our paddle dryers offer superior thermal efficiency for sludge drying, reducing energy consumption and operating costs.

- We provide extensive customization in capacity, material, and automation to meet diverse industry needs and enhance product quality.

- Our equipment serves various sectors, including the chemical, pharmaceutical, food processing, and wastewater treatment industries.

- With state-of-the-art facilities and a robust distribution network, we guarantee high-performance, reliable, and low-maintenance drying solutions.

- AS Engineers offers comprehensive after-sales support, ensuring your investment delivers long-term value and operational excellence.

AS Engineers – Leading Paddle Dryer Manufacturer in India

When searching for the leading paddle dryer manufacturers in India, one name consistently stands out: AS Engineers. We have established ourselves as the top manufacturer, designer, and supplier, building a strong reputation for engineering excellence and unparalleled product quality. Our commitment to innovation and customer satisfaction makes us the trusted choice for industries nationwide.

Our expertise spans a wide range of applications, from the chemical and food processing industries to pharmaceutical and wastewater treatment plants. AS Engineers delivers paddle dryers known for their uniform drying, low maintenance, and high thermal efficiency, ensuring your drying process is both effective and economical.

Company Overview and Our Journey in Paddle Dryer Manufacturing

As a premier paddle dryer manufacturer in India, AS Engineers has a rich history rooted in decades of specialized engineering. Our journey began with a clear mission: to provide superior thermal drying solutions that address the specific challenges of Indian industries. We combine deep technical knowledge with hands-on industry experience to create equipment that sets new standards.

Over the years, our focus on continuous improvement has driven significant progress in our paddle dryer technology. We have mastered the art of designing drying solutions that are not only powerful but also remarkably efficient. This dedication has cemented our position as a leader in the field.

What truly sets us apart is our comprehensive approach. We view each project as a unique engineering puzzle, considering everything from material characteristics to long-term operational costs. This allows us to deliver customized paddle dryer solutions that provide optimal performance throughout their entire operational lifespan.

Reputation and Recognition Across Indian Industries

AS Engineers has earned widespread recognition across India for delivering high-quality and reliable paddle dryers. Our name is synonymous with trust and excellence in sectors ranging from food processing and chemical manufacturing to the pharmaceutical industry. We have built lasting partnerships by consistently exceeding our clients’ expectations.

Our success stories speak for themselves. For instance, we helped a major municipal corporation drastically reduce its sludge disposal costs by implementing a custom paddle dryer system. This solution not only cut expenses but also created a valuable agricultural byproduct, showcasing our ability to turn waste management challenges into profitable opportunities.

In the pharmaceutical sector, we designed a specialized dryer that enabled a leading manufacturer to safely process sensitive materials while recovering valuable solvents. These achievements highlight our commitment to providing tailored solutions that improve efficiency, enhance safety, and deliver a strong return on investment.

Specialization in Paddle Dryers and Related Equipment

At AS Engineers, our core specialization lies in the design and manufacturing of advanced paddle dryers. Unlike competitors who may offer generic equipment, we focus on creating tailored drying solutions. Our expertise allows us to engineer systems that perfectly match your unique process requirements, ensuring maximum thermal efficiency and performance.

Our specialization extends to a deep understanding of different heating media, including steam and thermal oil, and how to optimize their use in our hollow shaft designs. We also innovate in areas like self-cleaning mechanisms and optimized paddle geometry to handle even the most challenging materials without compromising the drying process.

Beyond standard paddle dryers, we also offer advanced options like the vacuum paddle dryer, which is ideal for heat-sensitive materials. Our comprehensive portfolio, which includes related equipment like rotary dryers, ensures we can provide a complete and integrated solution for any industrial drying need you may have.

What Is a Paddle Dryer? Understanding the Technology

A paddle dryer is an indirect conduction heating device designed for drying various materials like pastes, powders, and granules. The technology works by using a set of heated, rotating paddles inside a horizontal cylindrical shell. This design ensures efficient heat transfer without direct contact between the heating source and the material being processed.

The core of the paddle dryer technology lies in its hollow shaft and paddles, through which a heating medium like steam or thermal oil flows. This setup provides a large heat transfer surface within a compact effective volume, making it a highly efficient solution for sludge drying and other industrial applications that demand uniform product quality and low maintenance.

Working Principle and Design Features

The working principle of a paddle dryer is both simple and highly effective. Inside a jacketed shell, two parallel hollow shafts rotate at a low speed. These shafts are fitted with special wedge-shaped, hollow paddles that are interleaved to ensure thorough mixing and agitation of the material.

A heating medium, such as steam or hot oil, is introduced through a rotary joint and circulates through the hollow shafts and paddles. As material is fed into the dryer, the rotating paddles continuously stir and move it across the heated surfaces. This constant agitation not only facilitates excellent heat transfer but also creates a self-cleaning effect, preventing material from sticking.

The design ensures a high heat transfer rate and uniform drying. The evaporated moisture is vented out, while the dried material is discharged from the other end. This indirect heating mechanism results in minimal off-gas emissions and high thermal efficiency, making it an environmentally friendly and cost-effective drying process.

Distinguishing Standard Paddle Dryers from Rotary Vacuum Paddle Dryers

While both standard and rotary vacuum paddle dryers operate on similar principles of indirect heating, they serve different purposes. The primary distinction lies in the operating environment. A standard paddle dryer operates at atmospheric pressure, making it suitable for a wide range of materials with good thermal stability.

In contrast, a rotary vacuum paddle dryer operates under a vacuum. This allows the moisture content to be removed at a much lower temperature, which is ideal for processing heat-sensitive materials that could be damaged by high heat. This method is also perfect for applications where recovering solvents during the drying process is necessary.

The choice between the two depends entirely on your specific material and process requirements. Here is a simple comparison:

| Feature | Standard Paddle Dryer | Rotary Vacuum Paddle Dryer |

|---|---|---|

| Operating Pressure | Atmospheric | Under Vacuum |

| Drying Temperature | Higher | Lower |

| Best For | Thermally stable materials | Heat-sensitive materials, solvent recovery |

| Complexity | Simpler design and operation | More complex due to vacuum system |

Key Advantages of Paddle Dryer Technology

Paddle dryer technology offers a host of advantages that make it a superior choice for many industrial applications. Its design is focused on maximizing efficiency while minimizing operational costs, making it a smart investment for any business looking to optimize its drying process. The compact structure also means it occupies a smaller footprint compared to other types of dryers.

One of the most significant benefits is its high thermal efficiency. Because it uses an indirect heating method, almost all the heat is utilized for drying the material, leading to substantially lower energy consumption. This not only saves you money but also reduces your environmental impact. The uniform drying it provides ensures consistent product quality without hot spots or degradation.

Here are some core benefits:

- Low Operating Costs: Reduced energy consumption and minimal material loss contribute to lower overall expenses.

- Versatility: It can effectively handle a wide range of materials, from industrial sludge to delicate food products, without requiring significant adjustments.

- Low Maintenance: The robust design and self-cleaning function of the paddles mean less downtime and easier upkeep.

Applications of Paddle Dryers Manufactured in India

Paddle dryers manufactured in India have found applications across a vast spectrum of industries due to their versatility and efficiency. From managing municipal solid waste to processing delicate food products, these machines offer reliable drying solutions. They are particularly effective for sludge drying in wastewater treatment plants, helping businesses reduce disposal costs and meet environmental regulations.

Industries like the chemical, pharmaceutical, and food processing sectors rely on paddle dryers to handle a wide range of materials, including hazardous materials and those with high moisture content. A top manufacturer can cater to the specific needs of these industries by customizing the equipment for optimal performance and product quality.

Industrial Wastewater and Sludge Drying

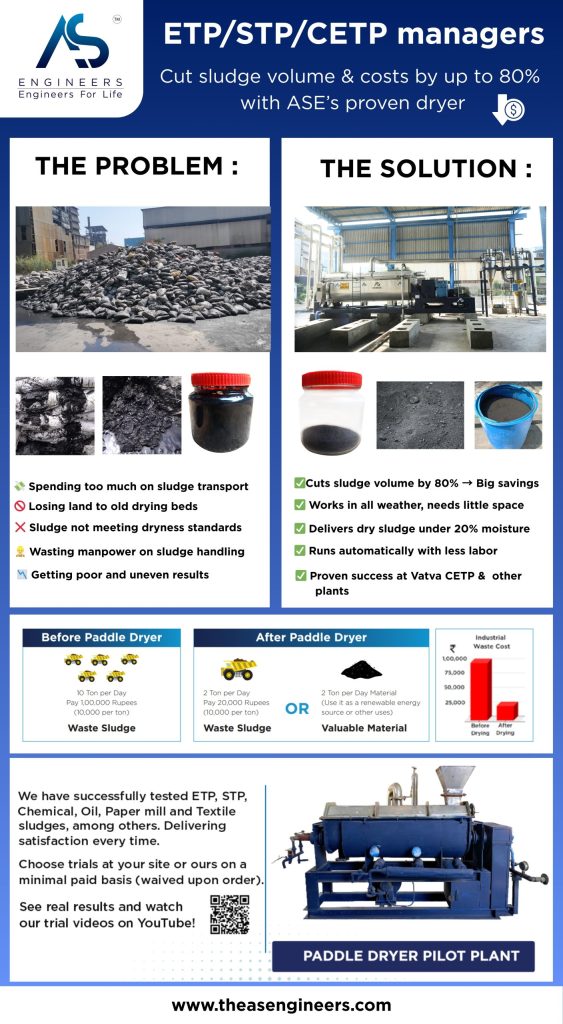

In industrial and municipal wastewater treatment, managing the resulting sludge is a significant operational challenge. Paddle dryers play a crucial role in effective sludge management by dramatically reducing sludge volume. This reduction leads to substantial savings in sludge disposal costs, including transportation and landfill fees.

The drying process in a paddle dryer is highly efficient for sludge. The technology achieves a high level of thermal efficiency, ensuring that the moisture content is reduced to the desired level with minimal energy use. The result is a dry, manageable solid that is easier and cheaper to handle.

Furthermore, the uniform drying provided by the paddles ensures that the final product is consistent, which can be important for subsequent uses like co-combustion or agricultural application. With low maintenance requirements and a high effective volume, paddle dryers from AS Engineers offer a reliable and cost-effective solution for wastewater treatment facilities.

Chemical and Pharmaceutical Industry Uses

The chemical and pharmaceutical industries often deal with materials that require careful and precise handling. Paddle dryers are exceptionally well-suited for these tough jobs, especially when processing hazardous materials or compounds with specific thermal properties. Their closed-system design ensures safe containment, minimizing worker exposure and environmental impact.

For heat-sensitive products common in the pharmaceutical industry, the ability to operate at a low temperature under vacuum is a game-changer. This ensures that the product quality of active pharmaceutical ingredients (APIs) is maintained without degradation. The indirect heating method provides excellent temperature control throughout the drying process.

Moreover, the technology allows for the recovery of valuable solvents that evaporate during drying, which is a significant advantage in the chemical industry. By using different heating media, the dryer can be adapted to various processes, proving its versatility and good thermal stability for even the most demanding applications.

Food Processing and Other Specialized Applications

In the food processing industry, maintaining product quality and hygiene is paramount. Paddle dryers are ideal for these applications because their indirect heating method ensures gentle and uniform drying without scorching the product. This is crucial for processes like roasting, sterilization, and drying food by-products for animal feed.

The enclosed system helps maintain a sterile environment, preventing contamination and preserving the integrity of the food product. The high thermal efficiency of the drying process also means that nutrients and flavors are better retained, resulting in a higher-quality final product. Our dryers can be constructed from stainless steel to meet stringent food-grade standards.

Beyond food, this technology is adaptable for a wide variety of other materials. This includes processing food waste for bioenergy production and drying minerals or other specialized powders. The ability to customize the heating medium and design makes the paddle dryer a versatile workhorse for numerous specialized drying needs.

Selecting the Right Paddle Dryer Manufacturer in India

Choosing the right paddle dryer manufacturer in India is a decision that will directly impact your production efficiency and long-term costs. It is essential to look beyond the initial price and consider factors like product quality, adherence to quality standards, and the availability of certifications. A reputable manufacturer will provide equipment that is not only effective but also reliable and requires low maintenance.

Equally important is the level of after-sales support offered. A great partner provides comprehensive support, from installation guidance to ongoing technical assistance. By carefully evaluating these aspects, you can ensure you are choosing a high-quality paddle dryer manufacturer that will meet your needs for years to come.

Important Factors to Consider During Your Selection

When you begin your search for a paddle dryer manufacturer, having a clear set of criteria will help you make an informed decision. The right choice will provide you with a machine that enhances your drying process and delivers a strong return on investment. Focus on manufacturers who demonstrate a deep understanding of paddle dryer technology.

Look for a company that prioritizes quality and efficiency in its designs. This includes features that lead to lower energy consumption, high thermal efficiency, and uniform drying. The construction of the dryer, particularly the hollow stirring shaft and heating media flow, should be optimized for performance and longevity.

Here are a few critical factors to keep in mind:

- Proven Expertise and Product Quality: Verify the manufacturer’s experience, check for client testimonials, and inquire about their quality control processes.

- Customization and Drying Solutions: Ensure the manufacturer can tailor the equipment to your specific material and capacity needs, rather than offering a one-size-fits-all product.

- After-Sales Support: Confirm that they offer comprehensive support, including installation, training, and readily available spare parts to ensure low maintenance and minimal downtime.

Certifications, Quality Standards, and Compliance Requirements

To ensure you are choosing a high-quality paddle dryer, it is crucial to verify the manufacturer’s adherence to recognized quality standards and certifications. Certifications like ISO 9001:2015 indicate that the company has a robust quality management system in place, which translates to better product quality and reliability.

A reliable manufacturer should also be ableto construct equipment that complies with industry-specific regulations, such as ASME codes for pressure vessels. This compliance is a testament to their engineering capabilities and commitment to safety and performance. Don’t hesitate to ask for documentation that proves their adherence to these standards during your evaluation process.

At AS Engineers, our manufacturing process incorporates rigorous material testing, multi-stage quality control inspections, and full assembly testing before shipment. This commitment ensures that every paddle dryer we deliver meets the highest standards for performance, thermal efficiency, and low maintenance, giving you complete peace of mind.

Support and After-Sales Service Advantage

The value of a paddle dryer extends far beyond its initial purchase and installation. The quality of support and after-sales service you receive is a critical factor that impacts your total cost of ownership. A manufacturer that offers excellent support ensures your equipment continues to operate at peak performance with minimal downtime.

Reliable after-sales service includes expert assistance with installation and commissioning, comprehensive operator training, and a clear preventive maintenance schedule. This proactive approach helps prevent unexpected issues and extends the lifespan of your machine, ensuring a better return on your investment. Look for a partner who is committed to your long-term success.

At AS Engineers, we pride ourselves on providing exceptional support. We offer readily available spare parts, emergency service, and ongoing technical assistance to address any challenges you might face. This commitment to service guarantees that your drying process remains efficient and your product quality consistent.

Customization Options in Paddle Dryer Solutions

One of the greatest advantages of working with a premier paddle dryer manufacturer like AS Engineers is the ability to get a customized machine. Indian paddle dryer manufacturers often offer extensive customization options, understanding that no two industrial processes are exactly alike. This means you can get a dryer with tailored designs to fit your specific capacity, material, and operational needs.

From material selection and automation levels to specialized engineering for unique challenges, customization ensures your equipment is perfectly optimized. This approach allows for enhanced performance, better energy efficiency, and a solution that seamlessly integrates into your existing workflow.

Tailored Designs for Diverse Processes and Capacities

Every industrial process has its unique demands, and a standard paddle dryer may not always be the perfect fit. That is why leading manufacturers offer tailored designs to accommodate a wide range of processes and capacities. Whether you are running a small-batch operation or a large-scale continuous process, the equipment can be scaled to meet your needs.

This customization starts with understanding your material. Factors like initial moisture content, particle size, and thermal sensitivity influence the design of the paddles, the configuration of the hollow shaft, and the overall dimensions of the dryer. AS Engineers works closely with you to engineer a solution that maximizes throughput and efficiency.

Furthermore, equipment choices can be adapted to fit your available space and utility connections. This flexibility ensures that you receive a paddle dryer that not only performs exceptionally but also integrates smoothly into your plant’s layout, making the entire drying process more streamlined.

Options for Automation and Performance Enhancements

Modern paddle dryers can be equipped with advanced automation and control systems to significantly boost productivity and ensure consistent results. These enhancements move the equipment from a manually operated machine to a sophisticated, self-regulating system. Full automation minimizes the need for constant operator supervision and reduces the chance of human error.

PLC-based control systems allow for precise management of all operating parameters, including temperature, paddle speed, and residence time. This level of process control ensures uniform drying and consistent final product quality, batch after batch. It also allows for data logging, which can be used for process optimization and quality assurance.

Here are some available automation options:

- Automated Process Control: Systems that automatically adjust parameters based on feed variations to maintain consistent output moisture.

- Remote Monitoring: Human-Machine Interfaces (HMIs) with remote capabilities allow you to monitor and control the drying process from a central control room or even off-site.

- Integrated Safety Systems: Automated shutdowns and alerts to protect both the equipment and personnel.

Material Selection and Specialized Engineering Choices

The material used to construct a paddle dryer is critical to its durability, hygiene, and performance, especially when handling corrosive or hazardous materials. Top manufacturers offer a range of material choices to suit different applications. Stainless steel, for example, is the standard for food processing and pharmaceutical applications due to its hygienic properties and resistance to corrosion.

For more demanding environments, such as those in the chemical industry, specialized alloys can be used. These materials offer enhanced resistance to highly corrosive substances, ensuring the longevity and safety of the equipment. AS Engineers provides expert guidance on selecting the right material for your specific process.

Specialized engineering choices also play a key role. This can include explosion-proof designs for handling volatile substances or reinforced paddles for abrasive materials. By making these informed choices during the design phase, you can ensure your paddle dryer is built to withstand the rigors of your operation and deliver reliable performance for years.

Manufacturing Excellence at AS Engineers

At AS Engineers, manufacturing excellence is the foundation of everything we do. Our advanced facilities are equipped with modern technology to produce paddle dryers that meet the highest quality standards. We combine precision engineering with rigorous quality control to ensure every machine delivers superior performance and reliability.

Our commitment extends to our robust distribution network, which allows us to serve clients across India efficiently. Whether you need paddle dryer suppliers in Mumbai or other major cities, our network ensures timely delivery and accessible support. This dedication to excellence is why AS Engineers is the trusted partner for industrial drying solutions.

Advanced Production Facilities and Technology Integration

Our state-of-the-art production facilities are where our engineering vision becomes a reality. AS Engineers leverages advanced manufacturing technology, including CNC machining for critical components, to ensure every paddle dryer is built with exceptional precision. This technology integration allows us to create complex designs with tight tolerances.

The manufacturing infrastructure is designed for efficiency and quality. From the initial fabrication of the hollow shaft to the final assembly of the paddles, every step is carefully controlled and monitored. This systematic approach to production minimizes errors and ensures that each unit meets our exacting specifications.

We are also committed to continuous process improvement within our facilities. By adopting the latest manufacturing techniques and technologies, we not only enhance the quality of our drying solutions but also find ways to improve thermal efficiency and reduce production time, delivering greater value to you.

Commitment to Quality, Performance, and Reliability

Our commitment to quality, performance, and reliability is unwavering. At AS Engineers, we believe that a truly great paddle dryer is one that you can depend on day in and day out. This philosophy is embedded in our quality assurance process, which begins with sourcing the best raw materials and continues through every stage of manufacturing.

We implement multi-stage quality control inspections to verify that every component meets our standards. Before any machine leaves our facility, it undergoes full assembly testing to confirm its mechanical integrity and performance parameters. This rigorous verification process ensures our equipment performs exactly as specified from the moment it is installed.

This proactive approach to quality control guarantees the long-term reliability of our drying solutions. When you invest in an AS Engineers paddle dryer, you are investing in a machine designed for consistent performance, high thermal efficiency, and a long operational life, ensuring your drying process is always running smoothly.

Serving Mumbai, and Major Indian Cities with Robust Distribution

AS Engineers is proud to serve clients across the nation, with a strong presence in key industrial hubs like Mumbai and other major Indian cities. Our robust distribution network is designed to ensure that you receive your equipment and support when you need it, no matter where your facility is located.

Our efficient supply chain minimizes lead times and ensures prompt delivery of both new equipment and spare parts. We understand that in an industrial setting, downtime is costly. That is why we have streamlined our logistics to provide quick and reliable service, making us one of the most accessible paddle dryer suppliers in the country.

This extensive reach means that expert support is never far away. Whether you require on-site assistance with installation in Mumbai or technical advice in another city, our network of service professionals is ready to help. Our goal is to provide seamless service and support to ensure your operations run without interruption.

Cost, Pricing, and Investment in Paddle Dryers

Understanding the financial aspects of investing in a paddle dryer is key to making a smart decision. The price range for paddle dryers from Indian manufacturers can vary widely based on capacity, materials, and customization. However, the initial cost is only part of the equation. A high-quality paddle dryer is a long-term investment that offers significant value.

The real value proposition lies in the low operating costs, driven by high thermal efficiency and reduced energy consumption. When you choose a top manufacturer like AS Engineers, you are investing in a machine that will deliver a strong return through operational savings and reliable performance.

Price Range and Value Proposition for Indian Customers

While it is natural to consider the initial price range, the true value of a paddle dryer lies in its total cost of ownership. A cheaper machine may save you money upfront, but it could lead to higher energy bills, frequent maintenance, and costly downtime. An investment in a high-quality machine from AS Engineers offers superior long-term value.

Our value proposition is built on efficiency, reliability, and longevity. The high thermal efficiency of our dryers leads to direct savings on energy consumption, while the robust construction minimizes maintenance needs. This combination ensures a faster return on your investment.

Several factors influence the final price, and understanding them helps in budgeting:

- Capacity and Size: Larger machines with a higher throughput capacity will have a higher initial cost.

- Material of Construction: The use of specialized alloys or high-grade stainless steel will affect the price compared to standard carbon steel.

- Automation and Controls: The level of automation, from basic manual controls to fully integrated PLC systems, will impact the investment.

Estimating Installation and Operating Costs

Beyond the purchase price, it is important to budget for installation and long-term operating costs. Installation costs typically include site preparation, foundation work, utility connections, and commissioning. A reputable manufacturer like AS Engineers provides detailed guidance to help you plan for these expenses accurately.

Operating costs are primarily driven by three factors: energy consumption, maintenance, and labor. Thanks to its high thermal efficiency, a paddle dryer’s energy consumption is significantly lower than that of direct dryers. The choice of heating media, whether steam or thermal oil, will also influence this cost.

Regular maintenance is essential for longevity but is generally low for well-designed paddle dryers. Costs include lubricants, seals, and occasional wear part replacements. By following a preventive maintenance schedule, you can minimize unexpected repairs and keep your operating costs predictable and manageable, ensuring your machine delivers excellent product quality for years.

Conclusion

In summary, AS Engineers stands out as a leading paddle dryer manufacturer in India, dedicated to delivering high-quality, customized solutions to meet diverse industrial needs. Our advanced technology and commitment to excellence ensure that our paddle dryers are not only efficient but also reliable and tailored to your specific requirements. We cater to various applications across multiple industries, providing the support and after-sales service that our clients value. Choosing AS Engineers means partnering with a trusted expert in paddle dryer manufacturing. If you have any questions or would like more information about our products and services, get in touch with us today. Your success is our priority!

Frequently Asked Questions

Are sludge dryers and paddle dryers the same or distinct equipment?

While the terms are often used interchangeably, a paddle dryer refers to a specific technology, whereas a sludge dryer is defined by its application. A paddle dryer is one of the most effective types of sludge dryers due to its efficient indirect heating process that effectively reduces the moisture content in sludge.

How do I ensure I am choosing a high-quality paddle dryer manufacturer in India?

To choose a high-quality manufacturer, look for their experience, industry reputation, and adherence to quality certifications like ISO. Verify that they offer comprehensive after-sales support and can provide customized drying solutions. A top manufacturer like AS Engineers will demonstrate expertise in paddle dryer technology and a commitment to product quality.

What customization options are available for paddle dryers manufactured in India?

Leading Indian manufacturers offer extensive customization. Options include tailored designs for specific capacities, choice of construction materials like stainless steel or special alloys, and various levels of automation. You can also customize the hollow shaft design and heating system to optimize thermal efficiency for your unique drying process.

What are the key features to look for when selecting a paddle dryer manufacturer in India?

Look for a manufacturer that emphasizes high product quality, low maintenance designs, and superior thermal efficiency. Key features include robust construction, advanced control systems, and proof of certifications. Also, ensure they provide excellent after-sales support and can customize the drying process to your specific needs.

How does choosing the right paddle dryer manufacturer impact production efficiency?

Choosing the right manufacturer directly impacts production efficiency. A high-quality machine ensures better thermal efficiency, leading to lower energy consumption and faster drying times. Reliable equipment from a top manufacturer like AS Engineers also means less downtime, consistent product quality, and a more streamlined overall drying process.

What industries commonly utilize paddle dryers, and how can a manufacturer cater to their specific needs?

Paddle dryers are common in the chemical, pharmaceutical, food processing, and wastewater treatment industries. A manufacturer caters to their needs by offering customized drying solutions, such as using stainless steel for food-grade applications, providing vacuum systems for heat-sensitive pharmaceuticals, or designing robust systems for abrasive sludge drying.

What quality assurance processes should a reliable paddle dryer manufacturer have in place?

A reliable manufacturer should have a multi-faceted quality assurance process. This includes rigorous testing of raw materials, in-process inspections at every manufacturing stage, non-destructive testing of welds, and a final performance verification test before shipment. Adherence to certifications like ISO 9001 is also a key indicator of strong quality control.