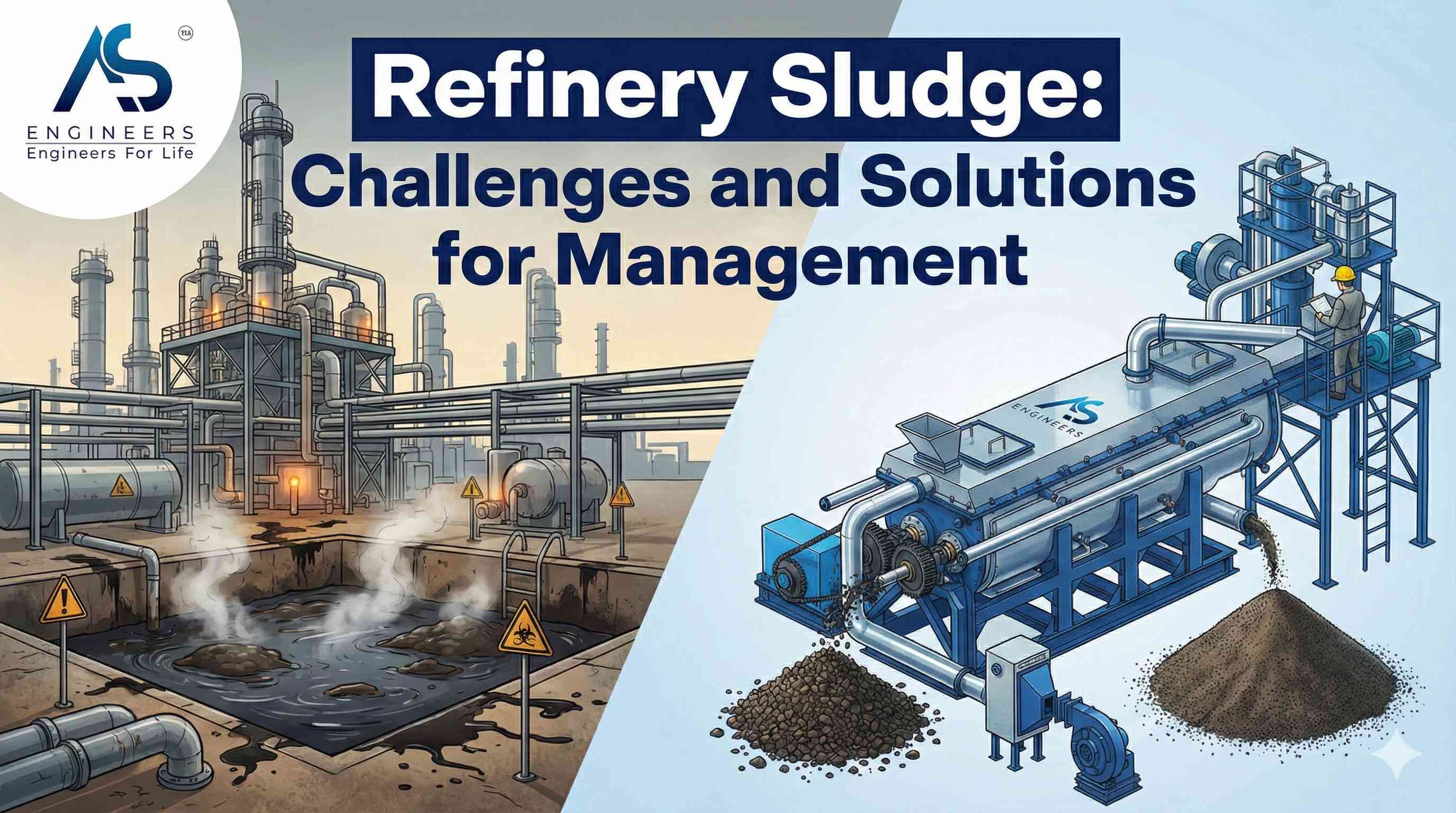

Oil refineries are essential for our modern world, but they also produce a challenging byproduct: refinery sludge. This material is a complex and toxic mixture that accumulates during the refining process, classifying it as a hazardous waste. Managing and disposing of this sludge has become a major concern for the industry in recent years.

Finding effective, economical, and environmentally safe solutions is not just a regulatory requirement but a critical step toward sustainable operations. Are you aware of the complexities involved in handling this waste?

Table of contents

- Key Highlights

- Understanding Refinery Sludge

- Causes and Characteristics of Refinery Sludge

- Environmental and Regulatory Challenges

- Conventional Refinery Sludge Treatment Methods

- Innovative Solutions for Refinery Sludge Management

- Sustainable and Value-Added Uses for Treated Sludge

- AS Engineers: Leading Paddle Dryer Manufacturer for Refinery Sludge Treatment

- Conclusion

- Frequently Asked Questions

Key Highlights

- Refinery sludge is a significant hazardous waste generated by the petroleum industry, posing major management challenges.

- Improper disposal of this oil sludge leads to severe environmental pollution, contaminating soil and water resources.

- Conventional treatment methods often have limitations in terms of cost, efficiency, and environmental impact.

- Innovative solutions like shoe paddle dryers offer a superior method for sludge treatment and valuable oil recovery.

- Treating sludge effectively not only prevents pollution but also creates opportunities for energy recovery and a circular economy.

- Proper management of refinery sludge is crucial for environmental safety and operational efficiency in refineries

Understanding Refinery Sludge

The term oily sludge refers to the residue that settles at the bottom of crude oil storage tanks and other equipment within a petroleum refinery. It’s an unavoidable consequence of storing and processing crude oil.

This sludge is not a simple substance. It’s a thick, viscous emulsion of oil, water, and solids. Understanding its formation, composition, and sources is the first step toward developing effective management strategies for oil refineries. Let’s explore what this material is made of and where it comes from.

Definition and Formation in Oil Refineries

Refinery sludge is formally defined as the semi-solid waste that accumulates at the base of tanks used for storing crude oil and other petroleum products. Its formation is a natural process driven by changes in the physical and chemical properties of crude oil during storage and processing in a petroleum refinery.

Several factors contribute to the creation of this oily sludge. The process can be triggered by cooling oil below its cloud point, the evaporation of lighter hydrocarbon fractions, or the mixing of incompatible materials. Each of these events disrupts the stability of the crude oil mixture, causing heavier components to separate and settle.

Furthermore, the introduction of water is a primary cause of sludge formation. Water can mix with the oil to form stable emulsions, trapping solids and heavy hydrocarbons. This creates the thick, difficult-to-handle material that poses significant challenges for oil refineries. The result is a reduction in storage capacity and a complex hazardous waste problem.

Typical Composition and Chemical Properties

The composition of petroleum sludge is incredibly complex and variable, which is a major reason it is so difficult to manage. It is a messy combination of organic compounds and inorganic materials, officially categorized as a form of solid waste. The primary component is, of course, petroleum hydrocarbons, including valuable oils that could be recovered.

Beyond the hydrocarbons, the sludge contains water, asphaltenes, and paraffin. It is also laden with inorganic solids like sand and iron oxides. What makes it particularly hazardous is the presence of numerous toxic substances. These include a cocktail of heavy metals such as zinc, lead, chromium, copper, and nickel.

This hazardous mix of chemicals and heavy metals makes the sludge a direct threat to the environment if not handled properly. The presence of these components requires specialized treatment methods to either neutralize their toxicity or separate them for safe disposal and recovery.

Common Sources and Locations of Accumulation

The most common place to find refinery sludge is right where you would expect it: at the tank bottom of crude oil storage tanks. Over time, as crude oil and other petroleum products sit in these large storage facilities, heavier components and contaminants naturally settle out due to gravity.

This accumulation is not limited to just the primary crude oil tanks. It can also occur in other vessels and storage facilities throughout the refinery that handle various intermediate and finished petroleum products. Every tank will eventually accumulate some level of sludge, but those holding crude oil face the biggest problem.

This buildup is more than just an inconvenience. It actively reduces the operational storage capacity of the tanks, leading to economic losses. The removal and cleaning of this sludge from the tank bottom is a critical and recurring maintenance practice for any refinery.

Causes and Characteristics of Refinery Sludge

The generation of oil sludge is primarily caused by changes to the crude oil’s properties due to external conditions like temperature shifts and mixing with other substances. This results in a complex material that complicates sludge management efforts.

Sludge samples reveal a challenging mixture existing in different phases: a valuable oil phase, a contaminated water phase, and a hazardous solid phase. The physical and chemical nature of this material, along with the factors influencing its volume, dictates the best approach for treatment. We will examine these characteristics more closely.

Main Process Steps Leading to Sludge Generation

During the exploration and production of petroleum, several waste streams are generated that contribute to the overall oil sludge problem. The journey from oil extraction to refining is dotted with processes that create these hazardous byproducts.

The main sources include:

- Drilling fluids used during the extraction process.

- Petroleum wastewater from various refining operations.

- Sludge from effluent treatment plants.

- The infamous bottom sludge from crude oil storage tanks.

These processes cause the properties of crude oil to change. As a result, solid particles, water, and heavy hydrocarbons separate from the main oil stream. This separation and settling process is the fundamental mechanism behind the generation of oil sludge, creating a persistent challenge for the industry.

Physical and Chemical Characteristics

The physical characteristics of refinery sludge make it notoriously difficult to handle. Its high viscosity means it doesn’t flow easily and can fix itself into the pores of soil if spilled, creating a continuous, impermeable layer. It is also hydrophobic, meaning it repels water, which further complicates cleanup efforts.

Chemically, the sludge is a stubborn mix of organic matter and inorganic matter. The organic components, primarily heavy petroleum hydrocarbons, are recalcitrant. This means they resist breaking down due to their heavy molecular weight and low solubility in water, making natural degradation extremely slow.

This combination of physical and chemical properties makes standard chemical treatment methods challenging. The sludge’s thick, oily nature can prevent treatment agents from effectively reaching and reacting with the hazardous compounds trapped within, requiring more advanced and powerful solutions.

Factors Influencing Sludge Quantity and Quality

The amount and specific makeup of the refinery sludge you have to deal with are not always the same. The sludge quantity and sludge quality can vary significantly based on several key factors, impacting your solid waste management strategy.

One of the most important factors is the type of crude oil being processed. Different crude oils have different compositions, with varying levels of heavy hydrocarbons, asphaltenes, and contaminants that can settle out. The specific operational processes within the refinery also play a major role in determining the final sludge characteristics.

Additionally, environmental conditions during storage, such as temperature fluctuations, can accelerate sludge formation. The amount of water introduced into the system and the length of storage time also directly influence the final volume and properties of the sludge, making each batch a unique challenge.

Environmental and Regulatory Challenges

The improper disposal of refinery sludge presents serious environmental and regulatory hurdles. As a classified hazardous waste, its management is strictly controlled to prevent widespread environmental pollution. The potential environmental risks are severe and can have long-lasting consequences for ecosystems and human health.

Navigating these challenges requires a deep understanding of the specific risks associated with the sludge and the complex web of regulations governing its handling. Let’s look at the dangers of poor disposal practices, the rules in place, and the long-term impacts on our environment.

Risks of Improper Disposal

Allowing oil sludge to enter the environment without proper treatment is a recipe for disaster. This hazardous waste can cause significant and immediate damage to the surrounding ecosystem. The environmental risks are numerous, stemming from the toxic nature of its components.

When improperly disposed of on land, the sludge can lead to:

- Major changes in the chemical and physical properties of soil.

- Stunted growth and nutrient deficiency in local vegetation.

- Reduced water retention and air exchange in the soil.

- Contamination of groundwater with toxic organic pollutants.

The high viscosity of the sludge causes it to clog soil pores, effectively suffocating the land. Furthermore, harmful petroleum hydrocarbons and heavy metals can leach from the sludge, infiltrating the soil profile and posing a grave menace to underground water sources and aquatic systems.

Regulations Governing Waste Management in India

In countries around the world, including India, refinery sludge is designated as a hazardous material, and its handling is governed by strict environmental regulations. These rules are designed to ensure that this waste is managed safely from its generation to its final disposal, a process often referred to as “cradle-to-grave” management.

These regulations are typically enforced by central and state pollution control boards. They mandate specific protocols for the storage, transport, and oil sludge treatment. The primary goal is to prevent the release of harmful substances into the environment and protect public health. This framework is a core part of any refinery’s solid waste management plan.

Compliance is not optional; refineries must use approved treatment and disposal technologies. Failure to adhere to these environmental regulations can result in severe penalties, including fines and operational shutdowns. Therefore, choosing a compliant treatment method is a critical business decision.

Long-Term Environmental Impacts

Beyond the immediate damage, the long-term environmental impacts of untreated sludge can be devastating. Many of the organic pollutants found in the sludge, such as polycyclic aromatic hydrocarbons (PAHs), are persistent and do not easily break down in the environment. This leads to chronic environmental pollution.

These toxic compounds can accumulate in the soil and food chain over time. PAHs, for example, are known to be genotoxic, meaning they can cause genetic damage to humans and animals exposed to them. The slow leaching of these pollutants can contaminate groundwater for decades, making water sources unsafe for drinking and agriculture.

This persistent contamination decreases the diversity of soil microorganisms, which are vital for healthy ecosystems. Effective petroleum sludge treatment is therefore not just about immediate cleanup but about preventing a legacy of pollution that can affect generations to come.

Conventional Refinery Sludge Treatment Methods

Historically, a variety of treatment technologies have been used to manage petroleum refinery sludge. These conventional methods for oil sludge treatment can be broadly categorized into mechanical, chemical, biological, and thermal approaches, each with its own set of pros and cons.

These techniques are designed to either recover valuable oil from the solid waste, reduce its hazardous nature, or prepare it for final disposal. However, many of these older methods are not economically sustainable or fully effective. Let’s examine some of these conventional approaches and their limitations.

Mechanical and Chemical Approaches

Mechanical and chemical treatment methods focus on physically or chemically separating the sludge into its core components: oil, water, and solids. Solvent extraction is a common chemical treatment where a solvent is used to dissolve and remove oil from the sludge. The oil is then separated from the solvent through distillation. Toluene has shown recovery rates as high as 75%.

Another approach is centrifugation, a mechanical treatment that uses a high-speed rotating device. The strong centrifugal forces separate the components based on their different densities. This method is often enhanced by pre-treating the sludge with heat or chemicals to reduce its viscosity and improve separation efficiency.

These methods can be effective but come with trade-offs. Below is a comparison of these two common approaches.

| Method | Principle | Key Outcome |

|---|---|---|

| Solvent Extraction | Uses a solvent (e.g., toluene) to dissolve and recover oil. | High oil recovery but may require solvent recovery step. |

| Centrifugation | Uses centrifugal force to separate oil, water, and solids. | Clean separation but can be costly and noisy. |

Limitations of Biotreatment and Anaerobic Digestion

Biotreatment methods, such as landfarming and composting, use microorganisms to break down the hazardous hydrocarbons in petroleum oily sludge. These approaches are often favored for their low operational costs and simplicity. In landfarming, the sludge is mixed with soil, and natural degradation processes are allowed to take place over time.

However, the major limitation of biotreatment is time. These processes are extremely slow, often taking many months or even years to achieve significant degradation. Landfarming requires vast areas of land, which may not be available or practical for many refineries. There are also significant environmental risks, including the potential for heavy metals to leach into the soil.

While these methods can be effective under the right conditions, their slow pace and large footprint make them less ideal for facilities that generate large quantities of sludge. The high cost and complexity of more advanced biological methods like bio-slurry treatment can also be a barrier, pushing facilities to seek faster and more contained solutions.

Technologies for Tank Cleaning and Oil Recovery

Effective tank cleaning is not just about removing the sludge; it’s also a critical opportunity for oil recovery. Many technologies used for oil sludge treatment are designed to maximize the amount of recovered oil, turning a waste product back into a valuable resource. This is a key principle of sustainable refinery operation.

Methods like solvent extraction, centrifugation, and surfactant-enhanced oil recovery are all employed during tank cleaning operations. Each technique aims to break the stable emulsion of oil, water, and solids to liberate the trapped hydrocarbons. Pyrolysis, a thermal process, can also be used to heat the sludge and vaporize the oil for collection.

The goal is to recover as much oil as possible before the final disposal of the remaining solids. The quality of the recovered oil is also important, as some methods yield a higher-grade product that requires less purification. Advanced solutions like paddle dryers excel in this area, offering high recovery rates in a single, efficient process.

Innovative Solutions for Refinery Sludge Management

As conventional methods struggle to meet modern economic and environmental demands, the industry is turning to innovative treatment technologies. These advanced solutions are designed for higher efficiency, better recovery of oil, and a smaller environmental footprint.

Technologies like ultrasonic treatment, supercritical water oxidation, and advanced thermal desorption are changing the game. Among these, shoe paddle dryer technology is emerging as a particularly effective solution for refinery sludge. Let’s examine how these modern approaches, especially paddle dryers, offer a better way forward.

Paddle Dryer Technology Explained

The paddle dryer represents a significant advancement in the thermal desorption treatment of oily sludge. This technology offers a highly efficient and controlled method for separating valuable hydrocarbons from waste solids, making it a cornerstone of modern sludge management.

The process works through indirect heating. The sludge is fed into an enclosed chamber where heated, intermeshing paddles (shaped like shoes) continuously agitate and move the material. This constant mixing ensures uniform heat transfer, causing the water and volatile hydrocarbons to evaporate from the sludge.

These vapors are then collected, cooled, and condensed, allowing for the recovery of both water and oil. The final output is a dry, inert solid powder with a significantly reduced volume and hazard level. This makes the shoe paddle dryer an elegant and effective solution for turning a messy problem into recoverable resources.

Process Efficiency and Safety Benefits

The design of the shoe paddle dryer brings remarkable process efficiency and safety benefits compared to conventional methods. Its ability to handle hazardous waste in a completely enclosed system makes it an attractive option for environmentally conscious refineries.

The key advantages include:

- High Process Efficiency: The indirect heating and constant agitation provide excellent thermal efficiency, reducing energy consumption.

- Maximum Oil Recovery: The controlled heating process allows for the recovery of a high percentage of valuable oils from the sludge.

- Reduced Environmental Impact: The enclosed system prevents the release of harmful vapors into the atmosphere.

- Significant Waste Reduction: The process can reduce the final volume of hazardous waste by over 80%, drastically lowering disposal costs.

These benefits make shoe paddle dryers a superior choice for refinery sludge management. They not only solve a waste problem but also create value through enhanced oil recovery while ensuring a safer operating environment.

Comparing Shoe Paddle Dryers vs. Conventional Options

When you place a shoe paddle dryer alongside conventional treatment options, the advantages become crystal clear. This advanced thermal desorption technology outperforms older methods in nearly every key metric, from efficiency to environmental safety.

The paddle dryer focuses on recovery, while many conventional methods are purely for disposal. For example, landfarming is slow and offers no oil recovery, while incineration destroys the valuable hydrocarbons and creates air pollution concerns. The paddle dryer, by contrast, creates two valuable streams: recovered oil and inert solids.

This table highlights the stark differences between a paddle dryer and two common conventional options.

| Feature | Shoe Paddle Dryer (Thermal Desorption) | Land Farming | Incineration |

|---|---|---|---|

| Oil Recovery | High; recovers valuable hydrocarbons. | None; focuses on degradation. | None; destroys valuable hydrocarbons. |

| Footprint | Small, compact system. | Requires a very large land area. | Medium; requires large equipment. |

| Byproducts | Recovered oil and dry, inert solids. | Treated soil with potential contamination. | Ash and flue gases (air pollution). |

| Efficiency | Fast, continuous, and highly efficient. | Extremely slow (months to years). | Fast but has high energy costs and emissions. |

Sustainable and Value-Added Uses for Treated Sludge

Effective sludge management isn’t just about disposal; it’s about embracing a circular economy. Instead of viewing waste sludge as a liability, modern technologies allow us to see it as a resource. The byproducts of advanced treatment can be repurposed for energy and other valuable applications.

This approach transforms a linear waste stream into a cyclical one, where materials are reused and recycled. This not only reduces the environmental burden but also creates new economic value. Let’s explore how treated sludge can be used for energy recovery and even in construction.

Energy Recovery Opportunities

One of the most significant benefits of advanced sludge treatment is the opportunity for energy recovery. The oil recovered from the waste sludge is not waste; it is a valuable energy source. This is a direct result of effective oil recovery processes.

Technologies like pyrolysis and thermal desorption (used in paddle dryers) are specifically designed to separate the hydrocarbons from the sludge. The recovered oil often shares properties with low-grade petroleum distillates. This oil can be blended back into the refinery process or used directly as fuel, for instance, in diesel engines or industrial furnaces.

This turns a costly disposal problem into a revenue-generating or cost-saving opportunity. By recovering and reusing the energy content trapped in the sludge, refineries can improve their overall efficiency and reduce their reliance on fresh crude oil, making a tangible step toward sustainability.

Potential Use in Construction Materials

After the valuable oil has been recovered, you are left with a dry, solid waste. But does this material have to end up in a landfill? Research shows that with the right processing, it has potential for use in construction materials.

The key is a process called stabilization/solidification (S/S). This involves mixing the treated solid waste with a binder like Portland cement. This process encapsulates the remaining hazardous contaminants, preventing them from leaching into the environment. The result is a stable, solid block with concrete-like properties.

To improve the quality of the final product, other materials like high-carbon fly ash or rice husk ash can be added to the mix. These additives can enhance the strength and contaminant-binding properties of the material. The end product from S/S can potentially be used as a non-hazardous construction material, turning a liability into an asset.

Soil Enhancement and Environmental Remediation

While direct application of raw sludge for soil enhancement is dangerous due to its toxic organic components, the byproducts of advanced treatment present different possibilities. The stabilized solid material can play a role in certain environmental remediation applications.

After undergoing S/S treatment, the encapsulated material is considered non-hazardous. Its potential uses in environmental applications include:

- Use as a non-hazardous fill material.

- Application in land reclamation projects.

- Potential use as a base layer in road construction.

- Safe disposal in standard landfills without the risks of hazardous waste.

It’s crucial to understand that using any sludge-derived product for soil enhancement or remediation requires rigorous testing. The goal is to ensure that all organic matter and hazardous components are fully inert and pose no risk to the environment. With proper treatment and verification, what was once a pollutant can help in restoring land.

AS Engineers: Leading Paddle Dryer Manufacturer for Refinery Sludge Treatment

When it comes to implementing innovative treatment technologies for refinery sludge, having the right partner is essential. AS Engineers stands out as a leading manufacturer of shoe paddle dryers, providing state-of-the-art solutions for oil sludge treatment. Their expertise in sludge management helps refineries tackle one of their toughest environmental challenges safely and efficiently.

AS Engineers is at the forefront of deploying advanced paddle dryer systems that offer superior performance in oil recovery and waste reduction. By focusing on robust engineering and reliable operation, they provide refineries with the tools they need to meet stringent environmental regulations, reduce operational costs, and move toward a more sustainable, circular economy. Their solutions are not just equipment; they are a comprehensive approach to modern sludge management.

Customized Sludge Drying Solutions Offered

AS Engineers understands that every refinery’s sludge management needs are unique. The composition, moisture content, and volume of sludge can vary widely, which is why a one-size-fits-all approach to treatment technologies simply doesn’t work.

This is where their commitment to providing a customized solution makes a difference. AS Engineers works closely with clients to design and build paddle dryer systems that are perfectly tailored to their specific operational requirements. They analyze the sludge characteristics and processing goals to engineer a system that delivers optimal performance.

Whether you need a compact unit for a smaller waste stream or a large-scale system for a high-volume operation, AS Engineers delivers a customized paddle dryer solution. This bespoke approach ensures maximum efficiency, reliability, and return on investment, solidifying their position as a premier partner in sludge management.

Conclusion

In summary, addressing the challenges of refinery sludge requires innovative solutions that prioritize efficiency and sustainability. The shoe paddle dryer technology stands out as a highly effective method for managing sludge, offering superior processing capabilities and safety benefits compared to conventional approaches.

As a leader in the field, AS Engineers provides customized drying solutions tailored to meet the specific needs of refineries, ensuring compliance with environmental regulations while also exploring value-added applications for treated sludge. By adopting advanced technologies like the shoe paddle dryer, refineries can enhance their operational efficiency while contributing to a more sustainable future. If you’re interested in learning more about how our solutions can optimize your refinery operations, feel free to reach out to us!

Frequently Asked Questions

What makes shoe paddle dryers ideal for refinery sludge management?

Shoe paddle dryers are ideal for oil sludge treatment due to their high process efficiency and ability to maximize recovered oil. As one of the best treatment technologies, the enclosed system safely handles hazardous waste, significantly reduces sludge volume, and turns a disposal problem into a value recovery opportunity.

Can treated refinery sludge be safely reused or recycled?

Yes, treated waste sludge can be repurposed. Effective sludge management allows for energy recovery from the collected oil. The remaining solids, when stabilized, have the potential for use in construction materials. This minimizes environmental risks and promotes a circular approach to handling what was once considered waste.

How do paddle dryers help meet environmental regulations in India?

Paddle dryers help refineries in India comply with environmental regulations by providing effective oil sludge treatment. They drastically reduce the volume of hazardous waste, prevent the release of pollutants, and offer a controlled sludge management system that meets the stringent requirements set by pollution control boards for handling hazardous waste.

What are the main components of refinery sludge and why is it challenging to manage?

Refinery sludge is a complex emulsion of petroleum hydrocarbons, water, solids, heavy metals, and other organic matter. Its high viscosity, stable emulsion state, and hazardous components make it extremely challenging for oil refineries to separate and treat using simple methods, requiring advanced technological solutions.

What environmental regulations apply to refinery sludge management?

Refinery sludge is classified as a hazardous waste under most environmental regulations. These rules mandate that every petroleum refinery must follow strict solid waste management protocols for the treatment and disposal of oil sludge to prevent environmental contamination and ensure public health and safety.

What innovative technologies are currently being used to treat or recycle refinery sludge?

Innovative treatment technologies focus on efficiency and oil recovery. Key examples include thermal desorption systems like the paddle dryer, ultrasonic treatment to break emulsions, supercritical water oxidation, and advanced solvent extraction. These methods are far superior to older, less effective disposal techniques.

How can effective management of refinery sludge impact overall refinery operations and efficiency?

Effective sludge management directly boosts the process efficiency of oil refineries. By maximizing oil recovery, it turns waste into a valuable asset. This reduces disposal costs, increases the yield of recovered oil, and improves the overall sustainability and profitability of the refinery’s operations.