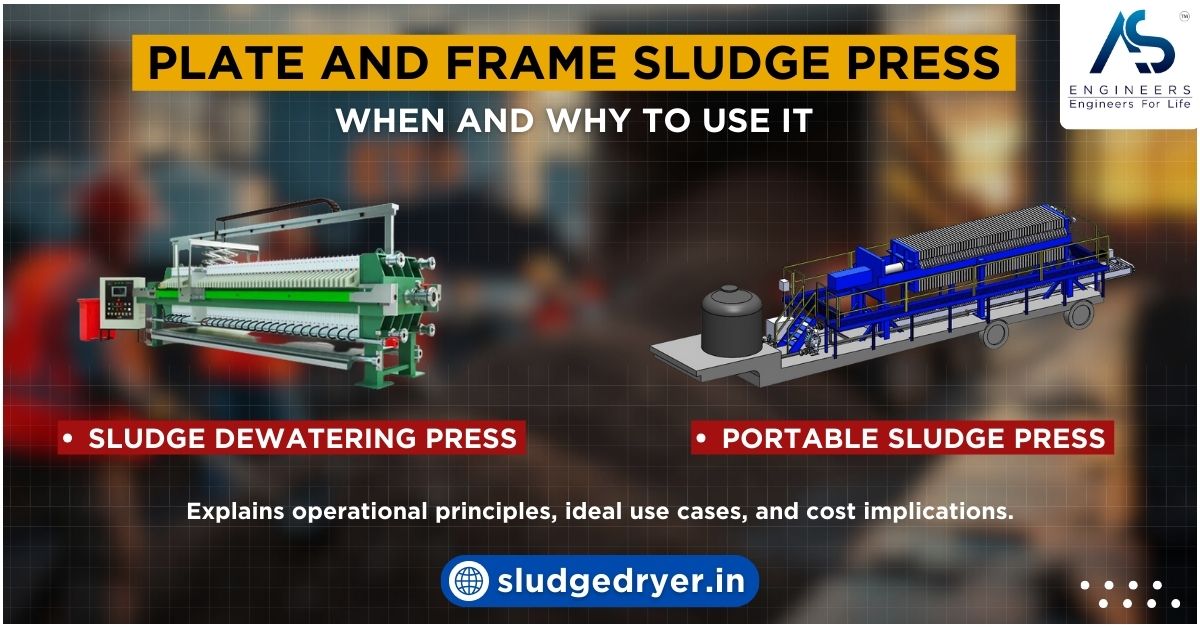

Ever wondered how industrial facilities, municipalities, and wastewater treatment plants handle large volumes of sludge daily? The answer often lies in a robust solution known as the plate and frame sludge press. This technology excels at separating liquids from solids, drastically reducing sludge volume and disposal costs.

By reading this comprehensive guide, you will learn how plate and frame presses operate, why they remain a top choice in sludge dewatering, and what considerations go into their cost and maintenance. If you want an in-depth look at how to optimize sludge management, especially for your unique industry needs, this post will show you exactly when and why to use a plate and frame sludge press.

Table of contents

- Understanding Sludge Dewatering

- What Is a Plate and Frame Sludge Press?

- How Does a Plate and Frame Sludge Press Work?

- Advantages of Using a Plate and Frame Sludge Press

- When and Why to Use a Plate and Frame Sludge Press

- Comparing Plate and Frame Sludge Press with Other Dewatering Technologies

- The Role of a Sludge Dewatering Press in Different Industries

- Spotlight on the Portable Sludge Press

- Cost Implications and Maintenance Best Practices

- Step-by-Step Guide to Operating a Plate and Frame Sludge Press

- Real-World Performance Indicators

- FAQ: Quick Answers for Common Questions

- Myth-Busting Plate and Frame Presses

- Improving E-E-A-T: Leveraging Industry Expertise and Trust

- Common Operational Challenges and How to Solve Them

- Maximizing ROI: Strategies for Long-Term Gains

- Step-by-Step Checklist for Buyers

- Future Trends: Innovations in Plate and Frame Presses

- Conclusion

Understanding Sludge Dewatering

Before diving into the plate and frame system, it’s essential to grasp the basics of sludge dewatering. Sludge dewatering is the process of separating water from sludge, thereby reducing the overall weight and volume of waste material. It helps organizations cut disposal costs, meet environmental regulations, and potentially recover valuable byproducts from the waste stream.

Why Sludge Dewatering Matters

- Cost Reduction: Minimizing water content in sludge lowers transportation and landfill fees.

- Environmental Compliance: Regulatory bodies often set strict limits on the volume and composition of waste. Effective dewatering ensures compliance.

- Resource Recovery: In some processes, captured solids contain recyclables, nutrients, or raw materials that can be sold or reused.

Common Sludge Dewatering Methods

Several methods exist for sludge dewatering, and each has unique advantages and constraints:

- Centrifuges

- High-speed rotation separates liquids from solids.

- Suitable for large-scale operations but tends to consume more energy.

- Belt Presses

- Sludge is squeezed between permeable belts.

- Generally efficient but might require higher polymer dosing.

- Screw Presses

- Utilizes a slowly rotating screw within a cylindrical screen.

- Energy-efficient but can be slower in throughput.

- Plate and Frame Sludge Press (Focus of This Guide)

- Highly effective at producing a very dry cake.

- Has been a mainstay in industries where reliability and dryness levels are paramount.

What Is a Plate and Frame Sludge Press?

A plate and frame sludge press, sometimes referred to as a filter press, uses pressure filtration to separate liquids from solids. In simple terms, you have a series of rectangular plates covered with filter media—typically cloth or specialized membranes. Between each pair of plates is a frame that creates a chamber for sludge accumulation. As liquid-filled sludge flows into these chambers, pressure forces water through the filter medium, leaving behind a cake of solids.

Key Components

- Plates: These are rigid structures, often made of metal or reinforced polymer. Each plate has channels that allow the filtrate (water) to exit.

- Frames: Frames create the space in which sludge accumulates and dewaters.

- Filter Media: Usually cloth or synthetic membranes that filter out solids.

- Hydraulic System: Exerts the pressure to hold plates and frames tightly together, preventing leaks.

- Filtrate Ports: Channels that guide water out once it has passed through the filter media.

Because of the press’s design, many facilities turn to it for a consistent and low-moisture sludge cake, which eases disposal or further processing. While its design is simple, a plate and frame system is quite powerful in terms of dryness levels and reliability—two factors that weigh heavily when selecting a sludge dewatering press.

How Does a Plate and Frame Sludge Press Work?

To fully appreciate when and why you should use a plate and frame system, you need a clear understanding of its operational principles. Let’s break down the typical cycle of a plate and frame sludge press:

- Filling

- Sludge is pumped into the empty chambers formed between plates and frames.

- The filter cloth or membrane captures solids, and water begins to pass through.

- Pressurization

- The hydraulic system applies pressure to the plates.

- This compresses the sludge and forces additional water out, yielding a drier cake.

- Filtration

- Solids accumulate in each chamber until no more water can pass through.

- The solids (often called “cake”) fill up the frame cavity.

- Cake Discharge

- Once the pressure cycle finishes, plates are separated.

- The now-dewatered sludge cake drops off the filter cloth.

- Operators often collect the cake on a conveyor or bin for disposal or further processing.

- Cleaning & Reset

- Operators may clean or wash the filter cloths.

- The press is reassembled, and the cycle begins again.

This step-by-step process highlights the mechanical efficiency of using a plate and frame sludge press. Thanks to high-pressure filtration, you typically get a sludge cake with lower moisture content than many alternative methods.

Advantages of Using a Plate and Frame Sludge Press

Why do so many industries continue to invest in plate and frame technology, even with multiple competing methods available?

1. High Cake Solids Content

Plate and frame systems often produce some of the driest sludge cakes. A dry cake means lighter overall weight and, therefore, lower hauling and disposal costs. For industries dealing with large volumes of waste, these cost savings can be substantial.

2. Reliable Operation

Because the design uses robust materials—like steel plates and synthetic filter media—it tends to have fewer moving parts compared to other mechanical dewatering systems. Fewer moving parts often translate to fewer breakdowns and less frequent maintenance.

3. Flexibility

You can tailor the plate and frame press to your sludge type by adjusting filter cloth materials, feed pressure, and cycle time. Some operations even integrate add-on features, such as automated cloth washing or special chemical dosing, to further boost efficiency.

4. Potential for High Purity Filtrate

When using well-maintained filter media, the resulting filtrate (the liquid that passes through) can be relatively clean. Facilities that need to recycle or reuse water find this especially beneficial. They may pump the filtrate back into their processes, reducing overall fresh water consumption.

5. Modular Expansion

As your processing needs evolve, you can add more plates to accommodate higher sludge volumes. This modularity allows you to scale operations without redesigning the entire system.

When and Why to Use a Plate and Frame Sludge Press

The central question is: When does a plate and frame sludge press outperform other sludge dewatering technologies? The answer hinges on specific scenarios and goals.

Situations That Demand Higher Cake Dryness

If your compliance requirements or disposal costs hinge on achieving extremely low moisture content, a plate and frame press may be your best bet. Industries like metal finishing, chemical processing, and pharmaceutical manufacturing often produce sludge that demands maximum dryness for safe disposal.

Facilities Facing Disposal or Transport Challenges

Plate and frame presses can significantly minimize sludge weight, which is a massive advantage if you pay by the ton for hauling. Remote facilities, or plants that face long transport distances to disposal sites, also gain from the reduced volume of sludge.

Operations Requiring Batch Processing

Unlike continuous systems (e.g., belt presses), a plate and frame press typically operates in batch mode. If your facility can plan around batch cycles—where you fill, press, discharge, and reset—this approach often yields a more cost-effective solution. Batch processing also allows you to adapt chemical dosing or other parameters from one cycle to another.

When Filtrate Quality Matters

If water reuse or discharge regulations are strict, the plate and frame system often achieves lower turbidity and fewer suspended solids in its filtrate. Some municipal and industrial plants reuse filtrate in their processes or treat it further with minimal strain on downstream equipment.

Consistency and Reliability

Plate and frame presses have a longstanding track record. If you need a proven, time-tested approach that consistently produces expected results, you’ll find comfort in the simplicity and reliability of plate and frame solutions.

Comparing Plate and Frame Sludge Press with Other Dewatering Technologies

To make an informed decision, you must consider how a plate and frame system holds up against other available sludge dewatering solutions.

Plate and Frame vs. Belt Press

- Cake Solids: Plate and frame presses generally offer higher cake solids.

- Operating Method: Belt presses run continuously, whereas plate and frame presses run in batches.

- Space Requirement: Belt presses can require significant floor space due to their continuous belt configurations. Plate and frame presses often have a smaller footprint but can have tall or elongated designs.

Plate and Frame vs. Centrifuges

- Energy Consumption: Centrifuges often consume more power due to rapid rotation.

- Solids Handling: Centrifuges may struggle with certain types of sludge or require high polymer usage. Plate and frame presses can handle various sludge types, including those with tricky solids composition.

- Noise & Vibration: Centrifuges generate noise and vibration. Plate and frame systems are generally quieter and have fewer rotating parts.

Plate and Frame vs. Screw Press

- Maintenance: Screw presses run continuously and have fewer frequent maintenance intervals but can be limited in the dryness level they achieve.

- Adjustability: Plate and frame presses allow you to tweak cycle times, feed pressures, and chemical additions more precisely for each batch.

- Investment Cost: Screw presses can sometimes be more cost-effective in smaller-scale operations, whereas plate and frame presses provide better results for large volumes and dryness demands.

The Role of a Sludge Dewatering Press in Different Industries

A sludge dewatering press is not a one-size-fits-all piece of equipment. Different industries leverage the plate and frame approach based on their waste streams, compliance needs, and operational conditions.

Municipal Wastewater Treatment

Municipalities frequently rely on plate and frame presses to handle biosolids. The relatively high dryness achieved cuts landfill or incineration fees, while the consistent performance aligns well with regulatory requirements. The batch nature also works fine for municipalities that can schedule operations based on daily or weekly sludge generation.

Mining and Mineral Processing

Mining operations generate tailings (a slurry of fine particles) that require dewatering. A plate and frame press ensures tailings have minimal free water, reducing the need for large tailings ponds. This helps with environmental management and site reclamation.

Chemical and Pharmaceutical

High-value or hazardous constituents often require meticulous treatment. Plate and frame presses can isolate these components effectively, ensuring minimal waste volume. In some cases, the dewatered cake can be further processed for valuable compound recovery.

Food and Beverage

Food processing facilities produce sludge that can be high in organic content. A plate and frame press can help recover water for reuse. Some byproducts even have commercial value or can be repurposed as animal feed.

Metals and Metalworking

Metalworking fluids, plating baths, and finishing sludges often contain heavy metals. Strict regulations demand low-moisture output. Plate and frame presses excel here, assisting with safer disposal of potentially toxic materials.

Spotlight on the Portable Sludge Press

While many plate and frame presses exist in fixed installations, a portable sludge press option can prove invaluable for certain facilities:

- Temporary Projects

- Some sites only need dewatering for a limited time. A portable sludge press can be brought in on a trailer, used for the duration of the project, and then removed.

- Disaster Relief or Emergency Operations

- Flooded industrial or municipal sites may need rapid dewatering to resume operations. Portable units can deliver a quick fix without major capital investment.

- Shared Assets

- Contract service providers sometimes own portable presses and rent them out to multiple facilities. This approach spreads costs and reduces capital expenses for individual plants.

- Maintenance Downtime

- When a facility’s main dewatering system is offline for repairs, a portable sludge press provides a temporary backup, ensuring that production isn’t halted by a sludge backlog.

In each scenario, the portable option offers flexibility, scalability, and a practical alternative to a fixed installation, particularly for short-term needs or multi-site operations.

Cost Implications and Maintenance Best Practices

A crucial component of deciding whether to invest in a plate and frame sludge press is understanding both its initial capital outlay and ongoing operational costs.

Initial Purchase and Installation Costs

- Equipment Size: Larger presses with more plates can process higher volumes but come at a higher price.

- Materials: Corrosion-resistant materials like stainless steel elevate costs but last longer.

- Automation Level: Automated plate shifters, cloth washers, and integrated controls can streamline operations at the expense of higher purchase costs.

Operating Costs

- Energy: Plate and frame presses don’t require constant high-speed motion. As a result, energy consumption is usually moderate, primarily powering pumps and a hydraulic system.

- Maintenance: Regular tasks include checking the hydraulic system, replacing or cleaning filter cloths, and inspecting seals.

- Polymer/Chemical Use: If your sludge requires chemical conditioning, factor in the cost of polymers or coagulants.

Maintenance Tips for Longevity

- Regular Filter Cloth Cleaning

- Clogged or worn filter cloths reduce filtration efficiency. Implement routine cleanings or cloth replacements.

- Hydraulic System Checks

- Ensure the hydraulic pump, cylinder, and valves maintain proper pressure. Watch for oil leaks or unusual noises.

- Frame and Plates Inspection

- Plates can warp or crack under constant pressure over time. Early detection of minor damage helps avoid bigger problems.

- Gasket Health

- Gaskets prevent leakage and maintain pressure. Replace them proactively if they show signs of wear.

- Data Monitoring

- Keep track of cycle times, feed pressures, and cake dryness. Noting deviations can help you spot mechanical or operational issues early.

Step-by-Step Guide to Operating a Plate and Frame Sludge Press

If you’ve decided that a plate and frame sludge press is right for your facility—or if you already own one—implementing best practices can significantly improve your results. Here’s a brief, step-by-step overview:

- Pre-Treatment

- Add polymers or coagulants if your sludge requires flocculation.

- Pre-screen or separate large particles to prevent clogging.

- Setup & Inspection

- Inspect plates, frames, cloths, and gaskets for cleanliness and defects.

- Confirm that the press is properly assembled with the plates in the correct sequence.

- Filling & Pressurization

- Pump sludge into the chambers while gradually increasing hydraulic pressure.

- Monitor feed pressure gauges to avoid over-pressurizing.

- Filtration Cycle

- Allow the press to run for the recommended cycle time.

- Track the filtrate to ensure proper clarity.

- Cake Discharge

- Release the hydraulic pressure.

- Open the press and gently remove any stubborn cake using a scraper or cloth washers.

- Cleanup & Reassembly

- Rinse or wash filter cloths to maintain permeability.

- Inspect parts and reassemble for the next cycle.

Following these steps ensures efficient and consistent performance from your plate and frame system.

Real-World Performance Indicators

Diving deeper, how do you measure whether your sludge dewatering press is truly making a difference?

- Cake Dryness or Total Solids (TS)

- Higher TS content translates to lower disposal costs. For instance, an increase from 20% TS to 25% TS can save thousands in transportation fees over time.

- Filtrate Quality (TSS, Turbidity, pH)

- Depending on regulatory constraints, you might need to confirm that the discharged water meets specific standards.

- Cycle Time

- Shorter cycle times mean higher throughput. Optimizing feed pressure and polymer dosing can reduce total cycle duration.

- Downtime

- Fewer unscheduled maintenance stops improve productivity. Monitor how often you must pause operations to fix mechanical or operational issues.

FAQ: Quick Answers for Common Questions

Below are concise responses to frequently asked questions about plate and frame sludge presses. Each answer is kept short (around 40–50 words) for quick reference.

1. How often should I replace filter cloths?

Filter cloth replacement depends on usage and sludge characteristics. Some facilities replace cloths every 6–12 months, but the timeline varies. To extend the cloth’s service life, monitor its permeability and condition and perform routine cleanings.

2. Can a plate and frame press handle oily sludge?

Yes. However, oily sludge might require pre-treatment with conditioners or chemicals to prevent blinding (clogging) of the filter cloth. Adjust feed pressures and cycle times accordingly. High grease or oil content can demand more frequent cleaning and specialized cloth materials.

3. Is a portable sludge press as effective as a fixed installation?

A portable sludge press provides comparable dewatering performance but on a smaller scale. It’s particularly useful for short-term projects, emergency relief, or multiple-site operations. While throughput can be lower, you still achieve a high level of dryness if the unit is correctly sized.

4. What factors influence operational costs the most?

Polymer consumption, filter cloth maintenance, and energy usage typically top the list. Proper sludge conditioning, routine equipment checks, and optimized cycle times reduce these costs. In many cases, improvements in one area—like better chemical dosing—can significantly cut overall expenses.

5. Do I need specialized training to operate a plate and frame sludge press?

Basic operator training is beneficial. You should understand safe pressurization, chemical dosing, and filter cloth maintenance. Over time, familiarity with the press helps you fine-tune cycle parameters, troubleshoot minor issues, and ensure consistent performance.

Myth-Busting Plate and Frame Presses

Misinformation or outdated notions sometimes cause confusion. Let’s debunk common myths:

- Myth: Plate and frame presses are too old-fashioned.

- Reality: While the technology has a long history, modern systems incorporate automation, advanced materials, and data analytics. They are still widely used due to proven reliability.

- Myth: You can’t achieve different dryness levels.

- Reality: By adjusting feed pressures, cycle times, and chemicals, you can tailor dryness levels to specific needs.

- Myth: They are only for large-scale operations.

- Reality: Many small-scale facilities benefit from batch dewatering using smaller presses. Portable units also cater to tight spaces and lower sludge volumes.

- Myth: Maintenance is always time-consuming.

- Reality: Like any mechanical system, some maintenance is necessary. However, routine inspections, cleaning, and best practices can reduce downtime. Automation features can also streamline plate shifting and cloth washing.

Improving E-E-A-T: Leveraging Industry Expertise and Trust

High-ranking content now requires thoroughness and E-E-A-T—Experience, Expertise, Authoritativeness, and Trustworthiness. How does this guide demonstrate that, and how can you incorporate E-E-A-T into your sludge management practices?

Showcasing Industry Experience

If you’ve implemented a plate and frame sludge press for years, sharing your operational data, improvements, and lessons learned adds credibility. Highlight any operational awards, certifications, or performance benchmarks your facility has achieved.

Leveraging Expertise

Collaborate with process engineers and operators who have hands-on experience. Involving them in writing or reviewing your guidelines bolsters your content’s factual accuracy. Seek input from chemical suppliers on how to optimize polymer usage, or partner with filtration media experts to refine cloth selection.

Building Authoritativeness

Citing industry standards or guidelines, such as those from environmental regulatory bodies, reinforces the reliability of your claims. Include references to recognized organizations for best practices around sludge disposal and water treatment.

Establishing Trustworthiness

Audit your processes regularly and publish clear results. Uphold transparent record-keeping for all aspects of dewatering, from polymer dosing to landfill receipts. Facilities that follow these steps show stakeholders they manage waste responsibly and comply with local, state, and federal regulations.

Common Operational Challenges and How to Solve Them

No system is perfect. Recognizing potential hurdles and mitigating them is critical to long-term success.

1. Filter Cloth Blinding

Symptoms: Sludge flow slows dramatically, or the cake fails to form properly.

Solution: Regular cloth washing, better polymer mixing, or changing filter cloth materials can help. In extreme cases, you may need to replace cloths or incorporate additional pre-treatment steps.

2. Hydraulic Leaks

Symptoms: Oil puddles, decreased pressing force.

Solution: Inspect seals, gaskets, and hydraulic lines. Replace damaged parts immediately. Routine hydraulic fluid checks also help maintain consistent pressure.

3. Over-Pressurization

Symptoms: Excessive strain on plates, potential warping or breakage.

Solution: Monitor gauges closely. Implement automated pressure controls if necessary. Train operators to incrementally increase pressure and watch for anomalies.

4. Uneven Cake Formation

Symptoms: Partial frames fill, while others remain empty or under-filled.

Solution: Confirm even sludge distribution. Check for blockages in feed channels and ensure feed pump capacity matches the press’s requirements.

5. Inconsistent Polymer Mixing

Symptoms: Sludge either remains too watery or forms lumps.

Solution: Fine-tune polymer dosing rates, mixing times, and polymer solution strengths. Some facilities use inline mixers to optimize floc formation.

Maximizing ROI: Strategies for Long-Term Gains

A plate and frame sludge press represents a significant investment. The following strategies help you maximize returns over the equipment’s lifespan.

1. Optimize Polymer Use

Polymers improve solids capture but can become expensive. Experiment with different types, dosing levels, and mixing techniques. Even small reductions in polymer usage—while maintaining dryness levels—yield sizable savings over time.

2. Embrace Data Analytics

Modern systems can integrate sensors to track cycle times, feed pressures, filtrate clarity, and energy consumption. Analyzing this data helps you spot trends, set benchmarks, and make data-driven adjustments.

3. Implement Preventive Maintenance

Rather than waiting for parts to fail, schedule regular inspections and part replacements. Downtime for planned maintenance is far cheaper than emergency repairs or extended production halts.

4. Consider Energy Recovery

Some facilities use the press’s filtrate for cooling or cleaning, reducing fresh water needs. Others integrate heat exchangers. By capturing and reusing energy or water, you cut operational costs.

5. Continuous Operator Training

The better your operators understand the press, the more likely they’ll catch early signs of trouble and optimize cycle parameters. Regular training sessions—possibly hosted by the equipment manufacturer—pay dividends in efficiency and cake dryness.

Step-by-Step Checklist for Buyers

If you’re currently in the market for a plate and frame sludge press, below is a practical checklist to guide your decision-making process:

- Determine Sludge Characteristics

- Test total solids, particle size distribution, and chemical composition.

- Estimate Volume and Growth

- Know your current sludge output. Project future growth. Size the press to handle peak loads.

- Evaluate Space Constraints

- Calculate available floor space and overhead clearance. Confirm you have room to maneuver plates for cake discharge.

- Check Local Regulations

- Ensure you understand discharge requirements, hauling fees, and disposal guidelines.

- Budget for Consumables

- Include cloths, polymers, and potential chemical pretreatments in your cost estimates.

- Review Automation Needs

- Evaluate whether you need semi-automatic or fully automatic plate shifting, data logging, or remote monitoring.

- Ask About Warranty & Support

- Manufacturer support can significantly reduce downtime. Check the terms and conditions of the warranty.

- Seek References

- Ask the manufacturer for references from similar industries or sludge profiles. Real-world experiences often reveal the press’s strengths and weaknesses.

Future Trends: Innovations in Plate and Frame Presses

While the fundamental technology behind a plate and frame sludge press is time-tested, manufacturers continue to innovate. Keeping an eye on new developments can help you maintain a competitive edge.

- Automated Cloth Washing

- Built-in washing systems reduce labor time and ensure consistent cloth performance.

- Membrane Filter Presses

- Instead of just cloth, some plates have membranes that inflate and further squeeze the sludge, increasing dryness levels.

- Integrated Sensors

- Smart sensors track moisture levels, temperature, and cycle time in real-time. This data helps operators fine-tune the system.

- Hybrid Systems

- Some setups combine plate and frame presses with other technologies, like belt thickeners, to handle a broader range of sludge consistencies.

- Remote Monitoring and Control

- Advanced control panels enable operators to manage the press remotely via smartphones or computers, optimizing performance and diagnosing issues instantly.

Conclusion

Choosing a plate and frame sludge press can significantly reduce sludge volume, meet strict regulatory requirements, and lower long-term disposal costs. This guide has walked you through how the technology works, its advantages over alternative methods, and key factors, from polymer usage to maintenance planning. Whether you’re aiming for exceptionally dry cakes or seeking a user-friendly system that operators can master, the plate and frame press stands out for its reliability, flexibility, and proven track record. Put this knowledge into practice by evaluating your sludge dewatering needs, training your team, and exploring innovations that streamline operations. Ready to enhance your facility’s sludge management? Start by mapping out your priorities and see how a plate and frame press can fit into your overall wastewater strategy.

We’d love to hear from you! Share your experiences, questions, or operational tips in the comments. To stay updated on the latest in sludge dewatering and water treatment, subscribe to our newsletter and explore related resources.