Ever looked at murky wastewater and wondered what happens to all that muddy residue left behind? That thick, semi-solid material is called sludge, and it plays a surprisingly central role in many environmental and industrial processes. Whether it’s generated by municipal wastewater plants or industrial facilities, sludge often contains everything from organic matter and nutrients to chemicals and pathogens. Handling it the wrong way can result in pollution, regulatory fines, or missed opportunities for resource recovery.

In this comprehensive guide, you’ll discover exactly what sludge is, why it matters, and how sludge treatment and sludge management practices ensure it doesn’t become a hazard. By the end, you’ll have a clear grasp of the basics—plus a few insider tips on making your operations more efficient and eco-friendly.

Defining Sludge: More Than Just Waste

Before diving into the complexities of sludge treatment and sludge management, let’s clarify what “sludge” actually is. In simplest terms, sludge is a thick, semi-solid by-product that forms when solids separate from liquids during various processes. While the concept sounds straightforward, sludge often contains a wide variety of compounds—some beneficial, some harmful—that require careful handling.

- Physical State: Sludge typically has a texture similar to mud or thick paste.

- Origins: It can come from municipal wastewater, industrial processes (like paper manufacturing or food processing), or even natural sedimentation in bodies of water.

- Composition: Organic matter (such as plant or animal residues), microbial communities, chemicals, minerals, and sometimes heavy metals or pathogens.

Is Sludge the Same as Sewage?

Not exactly. Sewage generally refers to wastewater from households or businesses. Sludge is the solid portion that separates out of that wastewater, though sludge can also come from industries that have little to do with household wastewater.

Main Sources of Sludge

Sludge can originate from various places, and understanding these sources is key to choosing the right sludge management strategy. Here are the most common ones:

- Municipal Wastewater Treatment Plants

- Description: Domestic and commercial sewage passes through multiple treatment stages. The solids that settle out in primary and secondary stages become sludge.

- Typical Composition: Organic matter, suspended solids, and microorganisms.

- Industrial Processes

- Description: Industries like mining, textile manufacturing, and food processing produce their own unique sludges.

- Typical Composition: May contain hazardous chemicals, heavy metals, or high levels of nutrients.

- Water Treatment Plants

- Description: Even facilities that purify drinking water end up with residual solids such as silt, sand, and chemical coagulants.

- Typical Composition: Mainly inorganic compounds and treatment chemicals.

- Agricultural Runoff Ponds

- Description: Farms often store excess runoff in lagoons, where solids settle at the bottom and form sludge.

- Typical Composition: Manure, fertilizers, pesticides, and organic detritus.

Each source demands its own careful approach to sludge treatment, particularly if the sludge contains toxins or pathogens.

Why Sludge Matters: The Importance of Proper Management

It’s tempting to dismiss sludge as “just waste,” but that perspective overlooks its significant environmental and economic impacts.

Environmental Concerns

- Potential Pollution

If left untreated, sludge can leach harmful substances into soil and waterways, jeopardizing ecosystems and public health. - Pathogen Spread

Disease-causing organisms can thrive in untreated sludge, making disposal a critical health concern.

Economic Implications

- Energy Recovery

Properly managed sludge can yield biogas (primarily methane) when subjected to anaerobic digestion. This can offset energy costs at treatment facilities. - Valuable Nutrients

Biosolids (treated sludge suitable for reuse) can enrich farmland, reducing the need for chemical fertilizers.

Regulatory Pressures

Government bodies worldwide, including the U.S. Environmental Protection Agency (EPA) and the European Commission, impose strict guidelines on sludge disposal to minimize health risks. Non-compliance can lead to hefty fines, reputational damage, and operational shutdowns.

Thus, sludge management isn’t merely about waste removal; it’s about responsibly harnessing potential resources and safeguarding communities.

Key Components Found in Sludge

Sludge composition can vary widely, but most samples contain:

- Organic Matter

- Examples: Proteins, carbohydrates, fats, and microbial biomass.

- Importance: High organic content makes sludge an ideal candidate for composting or biogas production.

- Inorganic Materials

- Examples: Sand, silt, salts, and metals.

- Importance: Excessive levels of heavy metals (like lead or mercury) can restrict disposal methods.

- Pathogens

- Examples: Bacteria (E. coli, Salmonella), viruses, and sometimes parasites.

- Importance: Proper treatment is crucial to neutralize these health hazards.

- Nutrients

- Examples: Nitrogen, phosphorus, potassium

- Importance: Treated sludge can be repurposed as a soil amendment or fertilizer.

- Chemical Additives

- Examples: Coagulants, flocculants, or leftover disinfectants.

- Importance: These can affect digestion processes and final disposal routes.

Each component can dictate how you treat and dispose of your sludge, underlining the need for thorough analysis before selecting a management strategy.

Sludge Treatment: From Raw Residue to Safe By-Product

1. Conditioning and Thickening

The first step in sludge treatment often involves changing its physical properties to make subsequent processes more efficient. This could mean:

- Adding Chemicals (Conditioning): Polymers or coagulants help particles bind together, making the sludge easier to separate from liquid.

- Mechanical Thickening: Devices like gravity thickeners or dissolved air flotation units reduce sludge volume, cutting storage and transport costs.

2. Stabilization

Stabilization processes aim to reduce odor, pathogens, and the sludge’s tendency to decompose. Common methods include:

- Aerobic Digestion: Using oxygen and microorganisms to break down organic matter.

- Anaerobic Digestion: Letting microbes work in an oxygen-free environment to produce methane-rich biogas.

- Chemical Stabilization: Adjusting pH (e.g., lime stabilization) to curb microbial growth.

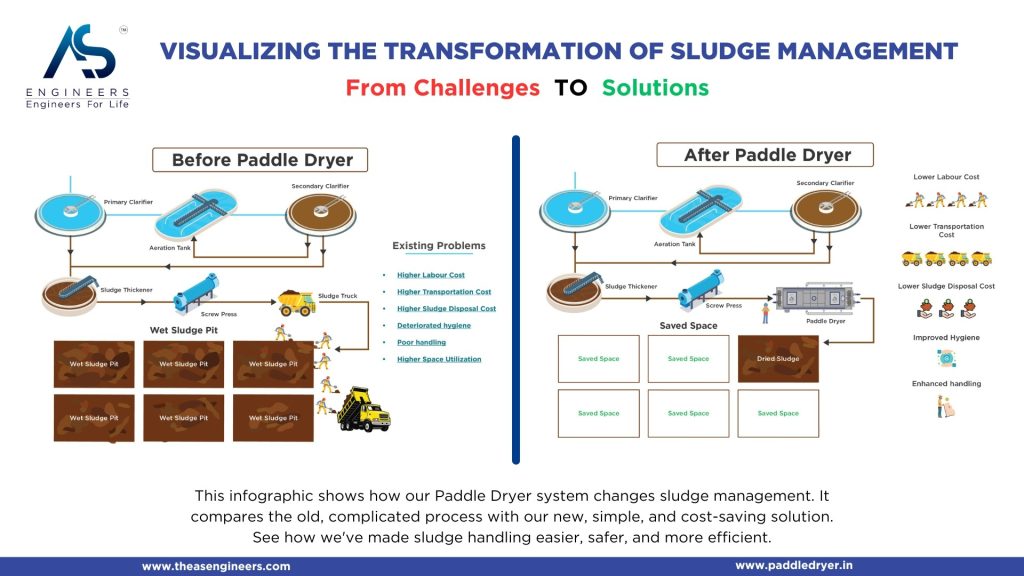

3. Dewatering

After thickening and stabilization, sludge still contains a large amount of water. Dewatering typically happens via:

- Belt Filter Press

- Centrifuge

- Screw Press

- Plate and Frame Press

Each device forces out water, yielding a cake-like material that’s lighter, cheaper to transport, and easier to handle.

4. Final Disposal or Reuse

The end goal of sludge management depends on local regulations, available technology, and economic considerations. Common routes include:

- Land Application: Biosolids used as fertilizer (subject to regulatory limits on metal content and pathogens).

- Landfilling: Often a last resort due to space limitations and potential environmental impact.

- Incineration: Controlled burning to reduce volume; can be harnessed for energy but must manage air emissions.

- Composting: Transforming sludge into nutrient-rich compost for gardening or agriculture.

Real-World Applications and Benefits

Resource Recovery and Energy

- Biogas Production: Many wastewater treatment plants harness methane from anaerobic digesters to power their facilities.

- Phosphorus Recovery: Phosphorus is a finite resource; some technologies extract it from sludge for agricultural use.

Cost Savings and Revenue Streams

- Reduced Transportation Costs: Dewatered sludge weighs less, so plants save on hauling fees.

- Sale of Biosolids: In regions where biosolids meet safety standards, farms or landscaping firms may purchase them.

Environmental Stewardship

- Lower Carbon Footprint: Capturing methane instead of letting it escape into the atmosphere helps mitigate greenhouse gas emissions.

- Soil Enrichment: Properly treated sludge improves soil structure and fertility, often replacing synthetic fertilizers.

Industrial and municipal facilities worldwide are starting to view sludge not just as a waste product, but as a resource. This shift in perspective drives innovation and spurs investments in advanced treatment technology.

Common Misconceptions About Sludge

Despite sludge’s importance, myths can cloud decision-making. Let’s clear up a few:

- Myth: “All Sludge Is Toxic.”

- Reality: While some sludge contains hazardous substances, much of it can be safely treated and reused. Thorough analysis and proper treatment processes are key.

- Myth: “Sludge Is Useless Waste.”

- Reality: Sludge often contains valuable nutrients and organic matter. Treated biosolids enrich soils, and anaerobic digestion produces biogas for renewable energy.

- Myth: “It’s Too Expensive to Treat Sludge.”

- Reality: Although treatment requires investment, resource recovery, regulatory compliance, and avoided environmental damages can offset or exceed these costs in the long term.

- Myth: “Sludge Management Is Only for Large Municipal Plants.”

- Reality: Sludge is generated by industries, small communities, and even small-scale farms. Scalable solutions exist for various sizes.

Addressing these misconceptions early helps stakeholders make informed decisions about sustainable sludge management strategies.

FAQs About Sludge

Q1: Is sludge always hazardous to human health?

A1: Not necessarily. Untreated sludge can contain pathogens or toxic chemicals, but many treatment processes drastically reduce these risks, making it safe for land application or other uses.

Q2: How long does it take to treat sludge?

A2: Treatment times vary based on the chosen method (aerobic vs. anaerobic digestion, for instance), sludge volume, and temperature conditions. It can range from a few days to several weeks.

Q3: Can I use sludge as fertilizer without further treatment?

A3: Generally, no. Most regulations require processes like stabilization, pathogen reduction, and dewatering before sludge can be land-applied. Failing to do so can risk soil contamination and public health.

Q4: What’s the difference between sludge and biosolids?

A4: Biosolids are treated sludge that meets specific regulatory standards for beneficial reuse, such as farming or land reclamation. Sludge is the raw, unprocessed material.

Q5: How do I choose the right sludge dewatering equipment?

A5: Factors include your facility’s capacity, sludge composition, budget, and disposal or reuse goals. Consulting an engineering firm or equipment supplier for site-specific recommendations is often best.

Conclusion: Making Sludge Work for You

When you peel back the layers of murky water, sludge stands out as far more than a waste product. Proper sludge treatment ensures that potential hazards—like pathogens and pollutants—are neutralized, while beneficial resources—like nutrients and energy—can be tapped. By employing strategic sludge management techniques—from thickening and stabilization to final disposal or reuse—organizations can turn what was once a liability into an asset.

Now it’s your turn:

- Are you looking to optimize your sludge processes? Check your local regulations, analyze your sludge composition, and explore technologies that best fit your budget and sustainability goals.

- Want to go deeper? Consider reaching out to an environmental consultant or wastewater engineer for specialized advice.

- Have thoughts or questions? Drop a comment below! We’d love to hear about your experiences with sludge treatment and management.

Ultimately, when handled responsibly, sludge can contribute to a healthier environment, a more sustainable economy, and a robust framework for resource recovery. Why not put sludge to work for you?