Wastewater treatment facilities worldwide process over 380 billion cubic meters of sewage annually, generating massive volumes of sludge that require efficient dewatering solutions. Advanced sludge dewatering techniques represent a revolutionary approach to managing this challenge, reducing disposal costs by up to 75% while improving environmental compliance and operational efficiency.

This comprehensive guide reveals how modern dewatering technologies transform traditional wastewater management, delivering measurable benefits that impact your bottom line and environmental footprint. You’ll discover proven strategies, cutting-edge equipment options, and implementation best practices that industry leaders use to optimize their sludge management operations.

Table of contents

- Understanding Advanced Sludge Dewatering Technology

- Primary Benefits of Advanced Sludge Dewatering Techniques

- Types of Advanced Sludge Dewatering Technologies

- Implementation Strategies for Maximum Benefits

- Cost-Benefit Analysis of Advanced Dewatering

- Maintenance and Operational Best Practices

- Frequently Asked Questions About Advanced Sludge Dewatering

- Conclusion: Maximizing Your Wastewater Treatment Investment

Understanding Advanced Sludge Dewatering Technology

Advanced sludge dewatering techniques encompass innovative mechanical and chemical processes designed to remove water from sewage sludge more efficiently than conventional methods. These sophisticated systems achieve higher dry solids content while reducing energy consumption and operational complexity.

Traditional dewatering methods typically achieve 15-25% dry solids content, requiring extensive downstream processing and creating significant disposal challenges. Advanced techniques consistently deliver 30-45% dry solids content, dramatically reducing sludge volume and associated handling costs.

Key Components of Modern Dewatering Systems

Advanced dewatering systems integrate multiple technologies to maximize water removal efficiency. Centrifugal decanters, belt filter presses, and screw presses form the mechanical foundation, while polymer conditioning systems optimize sludge characteristics for enhanced separation.

These systems incorporate automated controls that continuously monitor sludge consistency, flow rates, and chemical dosing requirements. Real-time adjustments ensure optimal performance across varying sludge compositions and treatment volumes.

Primary Benefits of Advanced Sludge Dewatering Techniques

Dramatic Cost Reduction in Sludge Management

Advanced sludge dewatering techniques deliver immediate and long-term cost savings across multiple operational areas. Reduced sludge volume translates directly to lower transportation costs, decreased disposal fees, and minimized landfill requirements.

Treatment facilities typically experience 60-80% reduction in sludge volume when upgrading from conventional to advanced dewatering systems. This volume reduction creates cascading cost benefits throughout the entire sludge management chain.

Operational data from municipal treatment plants shows average annual savings of $150,000-$500,000 depending on facility size and sludge production volumes. These savings often justify equipment investments within 18-24 months of implementation.

Enhanced Environmental Performance

Advanced dewatering techniques significantly improve environmental outcomes through reduced transportation emissions, minimized landfill impact, and improved resource recovery potential. Higher dry solids content enables beneficial reuse applications including agricultural land application and biosolids composting programs.

These systems reduce truck traffic by 70-85% compared to conventional dewatering methods, cutting transportation-related carbon emissions and community impact. Improved sludge quality opens opportunities for beneficial reuse programs that generate additional revenue streams.

Superior Operational Efficiency

Modern dewatering equipment operates with minimal operator intervention, reducing labor requirements and improving process consistency. Automated systems maintain optimal performance parameters continuously, eliminating manual adjustments and reducing human error potential.

Advanced process controls integrate with existing SCADA systems, providing comprehensive monitoring and reporting capabilities. Operators gain real-time visibility into system performance, enabling proactive maintenance and optimization strategies.

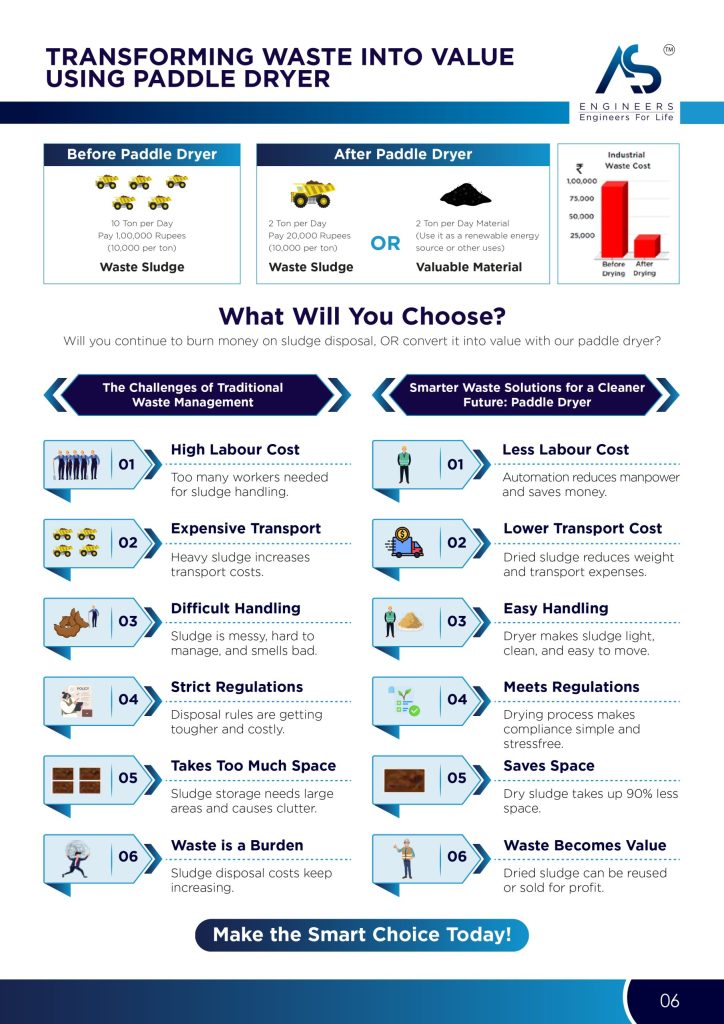

We understand the real-world challenges industries face with sludge management. That’s why we designed our paddle dryer to do more than just dry sludge—it transforms a messy, costly problem into a manageable, efficient process. Our paddle dryer uses indirect heating to gently remove moisture, reducing sludge volume, lowering disposal costs, and helping businesses meet environmental norms with ease. It’s a silent worker behind the scenes, making plants cleaner, safer, and more sustainable. Whether you run an ETP, STP, or industrial unit, our paddle dryer simplifies your sludge drying needs—reliably, efficiently, and with minimal human intervention.

Types of Advanced Sludge Dewatering Technologies

Centrifugal Dewatering Systems

Centrifugal decanters represent the most widely adopted advanced dewatering technology, utilizing high-speed rotation to separate water from sludge particles. These systems consistently achieve 25-35% dry solids content while processing large volumes efficiently.

Modern centrifugal systems incorporate variable speed drives and automated controls that optimize separation performance across varying sludge characteristics. Advanced bowl designs and scroll configurations maximize retention time and improve cake dryness.

Belt Filter Press Technology

Advanced belt filter presses combine mechanical pressure with extended drainage time to achieve superior dewatering performance. These systems excel in applications requiring consistent cake quality and minimal operator intervention.

Contemporary belt press designs feature improved belt materials, enhanced drainage systems, and automated wash cycles that maintain optimal performance. Variable speed controls allow operators to adjust processing rates based on sludge characteristics and desired cake dryness.

Screw Press Dewatering

Screw press technology offers unique advantages for facilities requiring continuous operation with minimal maintenance requirements. These systems achieve excellent dewatering performance while handling variable sludge compositions effectively.

Advanced screw press designs incorporate multiple compression zones and automated back-pressure controls that optimize cake formation. These features enable consistent performance across wide ranges of sludge types and flow rates.

Implementation Strategies for Maximum Benefits

Comprehensive System Assessment

Successful implementation begins with thorough evaluation of existing sludge characteristics, production volumes, and disposal constraints. Professional assessment identifies optimal technology combinations and sizing requirements for specific applications.

System designers evaluate multiple factors including sludge composition variability, peak flow requirements, and integration constraints with existing infrastructure. This comprehensive approach ensures selected technologies deliver maximum benefits within operational parameters.

Pilot Testing and Optimization

Advanced dewatering systems require careful optimization to achieve maximum performance benefits. Pilot testing programs enable operators to evaluate multiple technology options and identify optimal operating parameters before full-scale implementation.

Pilot programs typically span 30-90 days and evaluate performance across varying sludge conditions. These programs generate valuable data for system sizing, chemical dosing optimization, and operational procedure development.

Integration with Existing Infrastructure

Successful advanced dewatering implementation requires careful integration with existing treatment processes and infrastructure. Professional engineering ensures seamless integration while minimizing disruption to ongoing operations.

Integration planning addresses electrical requirements, structural modifications, and process connections required for optimal system performance. Proper planning minimizes installation time and ensures reliable long-term operation.

Cost-Benefit Analysis of Advanced Dewatering

Capital Investment Considerations

Advanced sludge dewatering systems require significant capital investment, typically ranging from $500,000 to $3 million depending on capacity and technology selection. However, rapid payback periods make these investments financially attractive for most facilities.

Life cycle cost analysis demonstrates that advanced systems deliver superior economic performance compared to conventional alternatives. Lower operating costs, reduced maintenance requirements, and extended equipment life create compelling financial benefits.

Operational Savings Quantification

Advanced dewatering techniques generate measurable operational savings across multiple cost categories. Transportation cost reductions typically represent the largest single benefit, followed by disposal fee savings and reduced handling labor requirements.

Energy consumption often decreases despite more sophisticated equipment, as modern systems incorporate high-efficiency motors and optimized process controls. Chemical consumption may increase initially but stabilizes as operators optimize dosing strategies.

Return on Investment Timeline

Most advanced dewatering implementations achieve positive return on investment within 18-36 months of startup. Facilities with high sludge production volumes or expensive disposal costs often see payback periods under 18 months.

Long-term benefits continue accumulating throughout equipment life cycles, typically 15-20 years for properly maintained systems. Total lifetime savings often exceed initial investment by 300-500%.

The paddle dryer offers significant cost savings by reducing sludge volume and moisture content, which cuts down transportation and disposal expenses. Its low energy consumption, thanks to indirect heating and efficient heat transfer, minimizes operational costs. With low maintenance needs, continuous operation, and the ability to recover heat, it ensures long-term savings. Additionally, the dried sludge can be reused as fuel, further adding to the economic benefits and sustainability of your operations.

Maintenance and Operational Best Practices

Preventive Maintenance Programs

Advanced dewatering equipment requires structured preventive maintenance programs to ensure optimal performance and maximize equipment life. These programs incorporate manufacturer recommendations with site-specific operating conditions.

Effective maintenance programs include daily operational checks, weekly component inspections, and monthly comprehensive system evaluations. Predictive maintenance technologies help identify potential issues before they impact system performance.

Operator Training Requirements

Successful operation of advanced dewatering systems requires comprehensive operator training covering system operation, troubleshooting, and maintenance procedures. Proper training ensures operators can maximize system benefits while maintaining safe working conditions.

Training programs should include both classroom instruction and hands-on operation experience. Ongoing education keeps operators current with evolving best practices and technology improvements.

Performance Monitoring and Optimization

Continuous performance monitoring enables operators to identify optimization opportunities and maintain peak system efficiency. Key performance indicators include cake dryness, throughput rates, and chemical consumption.

Advanced monitoring systems provide real-time data analysis and trend identification capabilities. This information enables proactive adjustments that maintain optimal performance across varying operating conditions.

Frequently Asked Questions About Advanced Sludge Dewatering

- What dry solids content can advanced dewatering techniques achieve?

Advanced sludge dewatering techniques consistently achieve 30-45% dry solids content, significantly higher than conventional methods that typically reach 15-25% dry solids. - How much can facilities save with advanced dewatering systems?

Treatment facilities typically experience annual savings of $150,000-$500,000 through reduced sludge volume, lower transportation costs, and decreased disposal fees. - What is the typical payback period for advanced dewatering equipment?

Most installations achieve positive return on investment within 18-36 months, with high-volume facilities often seeing payback periods under 18 months. - Do advanced systems require specialized operator training?

Yes, comprehensive operator training covering system operation, troubleshooting, and maintenance procedures is essential for maximizing system benefits and ensuring safe operation. - Can advanced dewatering systems handle variable sludge compositions?

Modern advanced dewatering systems incorporate automated controls and variable operating parameters that adapt to changing sludge characteristics while maintaining optimal performance.

Conclusion: Maximizing Your Wastewater Treatment Investment

Advanced sludge dewatering techniques represent a transformative opportunity for wastewater treatment facilities seeking to reduce operational costs while improving environmental performance. These sophisticated systems deliver measurable benefits including dramatic cost reductions, enhanced operational efficiency, and superior environmental outcomes.

The compelling economics of advanced dewatering make implementation a strategic priority for forward-thinking facility managers. Rapid payback periods, substantial ongoing savings, and improved regulatory compliance create a powerful business case for modernizing sludge management operations.

Success requires careful technology selection, proper implementation planning, and comprehensive operator training. Facilities that invest in advanced sludge dewatering and sludge drying techniques position themselves for long-term operational excellence and financial sustainability.

Ready to explore how advanced sludge dewatering techniques can transform your facility’s operations? Contact our wastewater treatment specialists today to schedule a comprehensive system assessment and discover your potential savings.