Introduction: The Evolution of Sludge Drying

Did you know that wastewater treatment facilities across the United States alone process over 15 billion gallons of sewage daily, generating approximately 8 million tons of sludge annually? This massive volume presents one of the most significant challenges in environmental engineering today. Advanced sludge dryer technology has emerged as the cornerstone solution to this growing problem, transforming how industries and municipalities manage waste.

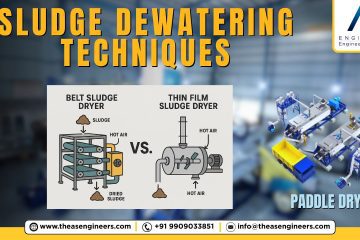

The landscape of sludge drying has undergone a remarkable transformation in recent years. Traditional drying methods that once dominated the industry are rapidly giving way to innovative technologies that prioritize efficiency, sustainability, and cost-effectiveness. Today’s paddle dryers and thermal drying systems represent just the beginning of a technological revolution that promises to reshape waste management practices worldwide.

Whether you’re an environmental engineer, wastewater treatment professional, or industry decision-maker, understanding cutting-edge sludge drying technologies is essential for making informed choices that impact both operational success and environmental stewardship. This comprehensive guide explores the latest innovations in sludge drying technology, providing you with actionable insights to optimize your waste management processes.

Table of contents

- The Critical Importance of Efficient Sludge Drying

- Understanding the Fundamentals of Advanced Sludge Dryer Technology

- Cutting-Edge Paddle Dryer Technology: The Industry Standard Evolves

- Thermal Drying Innovations: Beyond Traditional Approaches

- Solar Sludge Drying: Sustainable Innovation in Action

- Real-Time Monitoring and Control: The Digital Transformation

- Energy Efficiency Breakthroughs in Sludge Drying

- Environmental Performance and Sustainability Considerations

- Economic Considerations and ROI Analysis

- Future Trends and Emerging Technologies

- Conclusion: Selecting the Right Sludge Drying Technology

The Critical Importance of Efficient Sludge Drying

Why Sludge Drying Matters More Than Ever

The efficient drying of sludge isn’t merely a technical process—it’s a critical component of sustainable waste management with far-reaching implications. Sludge drying technologies directly impact environmental compliance, operational costs, and public health outcomes. Here’s why mastering these technologies has become increasingly important:

Environmental Impact

Untreated or improperly dried sludge poses significant environmental risks. When inadequately processed sludge reaches landfills or is applied to land, it can leach contaminants into soil and groundwater systems. Modern sludge drying technology reduces these risks by effectively removing moisture and pathogens, creating a safer end product.

Regulatory Compliance

Environmental regulations governing sludge disposal continue to tighten globally. Advanced drying processes help facilities meet increasingly stringent requirements for biosolids management, reducing the risk of penalties and operational disruptions. The EPA’s 503 Biosolids Rule and similar international standards mandate specific treatment levels that modern drying technologies are designed to achieve.

Economic Considerations

The financial implications of sludge management extend far beyond initial equipment costs. Traditional disposal methods—particularly landfilling—face escalating fees and transportation costs. By reducing volume by up to 90%, advanced sludge dryers dramatically decrease these expenses while potentially creating valuable byproducts.

The Evolution of Drying Methods

Sludge drying technologies have progressed significantly from simple solar beds to sophisticated thermal systems. This evolution reflects growing awareness of efficiency needs and environmental concerns:

- First Generation (1950s-1970s): Simple dewatering and air drying with limited controls and high energy consumption

- Second Generation (1980s-1990s): Introduction of mechanical drying systems with improved efficiency but still energy-intensive

- Third Generation (2000s-2010s): Development of indirect heating and more sophisticated paddle dryer systems with enhanced energy recovery

- Fourth Generation (Current): Smart, hybrid systems utilizing multiple energy sources, advanced automation, and data-driven optimization

This progression has led to today’s advanced sludge drying landscape, where technology choices directly impact operational success and sustainability goals.

Understanding the Fundamentals of Advanced Sludge Dryer Technology

Core Principles of Modern Sludge Drying

At its essence, sludge drying involves removing moisture from waste materials to reduce volume, stabilize organic content, and create a safer end product. However, modern approaches to this process incorporate sophisticated engineering principles that optimize every aspect of the drying journey:

Heat Transfer Mechanisms

Today’s advanced sludge dryers utilize three primary heat transfer methods, often in strategic combination:

- Conduction: Direct heat transfer through physical contact between sludge and heated surfaces (common in paddle dryers)

- Convection: Heat transfer via moving air or gas streams passing through or over the sludge

- Radiation: Thermal energy transferred through electromagnetic waves without direct contact (utilized in infrared and solar systems)

The most efficient systems optimize these mechanisms based on sludge characteristics and operational requirements.

Moisture Removal Dynamics

Understanding evaporation rates and moisture behavior is crucial for system design. Modern sludge drying technology accounts for:

- Bound vs. Free Water: Advanced systems address both easily removed free water and chemically bound moisture requiring more energy

- Evaporation Zones: Progressive drying through controlled temperature gradients

- Vapor Management: Sophisticated handling of water vapor to prevent condensation issues and capture thermal energy

Classification of Advanced Drying Systems

Modern sludge dryers can be categorized based on several key characteristics:

By Heat Transfer Method

- Direct Dryers: Process where hot gas directly contacts the sludge

- Advantages: Efficient heat transfer, good mixing

- Limitations: Potential dust issues, odor management challenges

- Indirect Dryers: Heat transfer occurs through a physical barrier

- Advantages: Better odor control, reduced emissions

- Applications: Industries with strict air quality requirements

- Hybrid Systems: Combining direct and indirect principles

- Advantages: Optimized energy efficiency, flexibility

- Rising popularity due to adaptability to varying sludge conditions

By Operation Mode

- Continuous Systems: Uninterrupted processing of sludge

- Advantages: Consistent output quality, suitable for large volumes

- Examples: Belt dryers, flash dryers

- Batch Operations: Processing defined quantities in cycles

- Advantages: Precise control over drying parameters

- Applications: Specialty applications or smaller facilities

Key Performance Parameters

Understanding performance metrics is essential for selecting and optimizing sludge drying technology:

- Specific Energy Consumption: Energy required per kg of water evaporated (typically 800-4,500 kJ/kg)

- Throughput Capacity: Volume of sludge processed per unit time

- Final Moisture Content: Achieved dryness level (typically 10-20% for most applications)

- Thermal Efficiency: Percentage of input energy effectively utilized for moisture removal

- Emissions Profile: Levels of particulates, VOCs, and other pollutants

Modern control systems continuously monitor these parameters, making real-time adjustments to optimize performance regardless of input variations.

Cutting-Edge Paddle Dryer Technology: The Industry Standard Evolves

The Mechanics of Advanced Paddle Dryers

The paddle dryer has emerged as one of the most versatile and efficient sludge drying technologies, particularly for municipal and industrial applications. These systems have evolved significantly from their early iterations:

Design Principles

Modern paddle dryers feature hollow shafts equipped with heated paddles that simultaneously transfer thermal energy and physically manipulate the sludge. This dual action provides several advantages:

- Continuous mixing prevents material from adhering to heated surfaces

- Enhanced surface area exposure maximizes evaporation rates

- Consistent material progression ensures uniform drying

- Self-cleaning action reduces maintenance requirements

Heat Recovery Innovations

Today’s advanced paddle dryers incorporate sophisticated heat recovery systems that dramatically improve energy efficiency:

- Vapor Recompression: Capturing and recompressing evaporated moisture to reuse thermal energy

- Heat Exchangers: Transferring energy from output streams back to incoming material

- Thermal Oil Circulation: Using intermediate heat transfer fluids for more precise temperature control

These innovations have reduced energy consumption in modern paddle dryers by up to 40% compared to previous generations.

Performance Optimization in Modern Systems

Several technological advances have enhanced paddle dryer performance:

Advanced Materials Science

Material innovations have addressed historical challenges in paddle dryer operations:

- Anti-Fouling Surfaces: Specialized coatings that minimize material adhesion

- Wear-Resistant Alloys: Extended service life in abrasive applications

- Corrosion-Resistant Components: Better performance with chemically challenging sludges

Precision Control Systems

Modern paddle dryers feature sophisticated automation that optimizes performance:

- Adaptive Heat Control: Real-time adjustment based on moisture content

- Variable Speed Drives: Optimizing residence time for different sludge characteristics

- Predictive Maintenance: Monitoring system parameters to anticipate service needs

Case Study: Municipal Wastewater Treatment Optimization

A mid-sized municipal wastewater treatment plant in the Pacific Northwest replaced its aging belt dryer with a new-generation paddle dryer system, resulting in:

- 35% reduction in energy consumption

- 25% increase in throughput capacity

- 99.8% system availability (up from 92%)

- Return on investment achieved in under three years

The implementation included heat recovery from both the dried biosolids and exhaust vapor streams, dramatically improving overall system efficiency.

Thermal Drying Innovations: Beyond Traditional Approaches

Advanced Thermal Technologies Redefining the Field

While paddle dryers represent a significant advancement, other thermal drying innovations are expanding the possibilities for sludge management:

Fluidized Bed Systems

Fluidized bed technology has evolved to address specific sludge drying challenges:

- Principle: Suspending sludge particles in a heated air stream to create fluid-like behavior

- Advantages: Exceptional heat transfer efficiency, rapid drying rates

- Applications: Ideal for granular materials and specific industrial sludges

- Innovations: Multi-stage systems with progressive temperature zones for optimized energy use

Rotary Drum Advancements

Traditional rotary drums have been reimagined with modern engineering:

- Design Improvements: Enhanced flight patterns for better material distribution

- Thermal Efficiency: Triple-pass designs with countercurrent air flow

- Emissions Control: Integrated condensers and scrubbers for vapor management

- Applications: Versatile solution for varying sludge characteristics

Belt Dryer Evolution

Belt drying technology has seen significant advancements:

- Multi-Belt Systems: Staged drying for optimized energy use

- Air Recirculation: Sophisticated air management reducing energy consumption by up to 30%

- Controlled Atmosphere: Preventing dust issues and managing VOCs effectively

- Automation: Precise belt speed and temperature control based on real-time monitoring

Hybrid Systems: Combining Technologies for Optimal Results

One of the most promising developments in sludge drying technology is the integration of multiple drying approaches into unified systems:

Solar-Enhanced Thermal Drying

These innovative systems combine conventional thermal drying with solar energy:

- Configuration: Greenhouse structures with supplemental thermal systems

- Energy Efficiency: Reducing conventional energy needs by 40-70%

- Adaptability: Automatic adjustment between solar and conventional energy based on conditions

- Limitations: Geographic constraints and seasonal variations in performance

Multi-Stage Processing

Advanced facilities increasingly implement sequential drying technologies:

- Primary Mechanical Dewatering: Removing bulk moisture through pressing or centrifugation

- Low-Temperature Drying: Initial thermal processing at optimized temperatures

- Finishing Systems: Final moisture reduction using more intensive techniques

This staged approach maximizes energy efficiency by applying the most appropriate technology to each phase of the drying process.

Solar Sludge Drying: Sustainable Innovation in Action

Harnessing Solar Energy for Sludge Processing

Solar drying represents one of the most sustainable approaches to sludge management, with recent technological advances dramatically improving its viability:

Advanced Greenhouse Systems

Modern solar dryers utilize sophisticated greenhouse designs that optimize natural energy capture:

- Enhanced Glass/Polycarbonate Materials: Improved light transmission with better durability

- Automated Ventilation Systems: Optimizing airflow based on humidity and temperature conditions

- Reflective Surfaces: Maximizing energy capture throughout the structure

- Thermal Mass Integration: Heat storage components for continued drying during non-daylight hours

Mechanical Assistance Innovations

Today’s solar dryers incorporate mechanical elements that enhance natural processes:

- Automated Turning Equipment: Specialized sludge mixers that ensure uniform drying

- Intelligent Floor Heating: Supplemental heat during suboptimal conditions

- Air Circulation Systems: Forced ventilation optimized through computational fluid dynamics

- Humidity Control: Active dehumidification to maintain optimal evaporation rates

Performance and Implementation Considerations

While solar drying offers significant advantages, successful implementation requires understanding several key factors:

Climate Suitability Analysis

Performance varies significantly based on geographic location:

- Solar Radiation Levels: Direct correlation with system capacity

- Seasonal Variations: Performance fluctuations throughout the year

- Humidity Patterns: Impact on evaporation efficiency

- Temperature Ranges: Effects on biological activity and drying rates

Advanced modeling tools now enable accurate prediction of performance based on local climate data.

Space Requirements and Optimization

Land utilization is a critical consideration:

- Area Efficiency: Typical requirement of 0.5-1.5 m² per annual ton of dry solids

- Vertical Integration: Multi-level systems for space-constrained facilities

- Layout Optimization: Strategic orientation and configuration for maximum solar exposure

Case Study: Mediterranean Municipal Implementation

A coastal municipality in southern Europe implemented a 3,500 m² solar drying facility with mechanical assistance, achieving:

- 85% reduction in conventional energy use compared to thermal drying

- Final dry solids content of 75-80% year-round

- Return on investment period of 4.2 years

- Significant reduction in carbon footprint

The system incorporated weather prediction algorithms that adjusted mechanical assistance based on forecast conditions, optimizing energy use throughout seasonal variations.

Real-Time Monitoring and Control: The Digital Transformation

Smart Systems Revolutionizing Sludge Drying

The integration of advanced digital technologies has fundamentally transformed sludge dryer operations:

Sensor Technology Advancements

Modern systems utilize sophisticated monitoring devices:

- Multi-Parameter Probes: Continuous measurement of moisture, temperature, and material properties

- Spectroscopic Analysis: Real-time composition assessment during the drying process

- Emissions Monitoring: Continuous evaluation of exhaust streams for process optimization and compliance

- Energy Consumption Meters: Precise tracking of thermal and electrical inputs

AI and Machine Learning Applications

Artificial intelligence is increasingly central to advanced sludge drying:

- Predictive Analytics: Anticipating system behavior based on input variations

- Adaptive Control Algorithms: Self-optimizing systems that adjust parameters in real time

- Anomaly Detection: Early identification of developing issues before they impact performance

- Process Optimization: Continuous refinement of operating parameters based on historical data

Data-Driven Operation and Maintenance

The digital transformation extends beyond monitoring to fundamentally change operational approaches:

Predictive Maintenance Strategies

Modern systems utilize data patterns to anticipate service needs:

- Vibration Analysis: Early detection of mechanical issues

- Thermal Imaging: Identifying heat distribution anomalies

- Power Consumption Patterns: Recognizing efficiency degradation

- Component Lifetime Tracking: Scheduling replacements based on actual wear rather than calendar intervals

Remote Monitoring and Management

Connectivity enables new operational paradigms:

- Cloud-Based Dashboards: Real-time visibility across multiple facilities

- Remote Intervention: Parameter adjustments without physical presence

- Expert Systems: Automated diagnosis and recommendation engines

- Performance Benchmarking: Comparison across similar installations to identify optimization opportunities

Case Study: Industrial Implementation of Smart Drying Systems

A pharmaceutical manufacturer implemented a fully digitalized paddle dryer system for biological waste sludge:

- Machine learning algorithms predicted optimal drying parameters based on input characteristics

- Automated adjustments maintained precisely controlled final moisture content within ±0.5%

- Energy consumption reduced by 27% through continuous optimization

- System availability increased to 99.5% through predictive maintenance

The system incorporated a digital twin model that simulated performance under varying conditions, enabling operators to test process adjustments virtually before implementation.

Energy Efficiency Breakthroughs in Sludge Drying

The Quest for Lower Energy Consumption

Energy typically represents 60-80% of operational costs in sludge drying, making efficiency improvements economically critical:

Heat Recovery Systems

Modern installations maximize energy recapture:

- Condensation Heat Recovery: Capturing latent heat from evaporated moisture

- Exhaust Gas Heat Exchangers: Transferring energy from output airstreams

- Product Cooling Recovery: Utilizing heat from the dried product

- Process Integration: Connecting drying systems with other facility processes for energy exchange

These systems can reduce primary energy requirements by 30-50% compared to non-recovery configurations.

Low-Temperature Drying Innovations

Emerging technologies enable efficient drying at reduced temperatures:

- Vacuum-Enhanced Systems: Lowering the boiling point of water to enable drying below 100°C

- Zeolite Wheel Technology: Using desiccant materials to enhance evaporation at lower temperatures

- Heat Pump Integration: Providing efficient heating while simultaneously managing humidity

Alternative Energy Integration

Advanced sludge dryers increasingly incorporate renewable energy sources:

- Biogas Utilization: Using treatment plant-generated biogas for drying energy

- Solar Thermal Integration: Preheating air or thermal fluids through solar collectors

- Waste Heat Recovery: Capturing energy from nearby industrial processes or power generation

Balancing Energy Use with Performance Requirements

Optimizing energy efficiency requires understanding several key relationships:

Moisture Content and Energy Requirements

The relationship between final dryness and energy consumption is non-linear:

- Reducing moisture from 80% to 40% requires significantly less energy than from 40% to 10%

- Optimal targets balance downstream requirements with energy costs

- Staged approaches often provide the best overall efficiency

Process Optimization Strategies

Several approaches can enhance energy performance:

- Pre-Treatment Optimization: Improved dewatering reduces thermal drying requirements

- Thermal Mass Management: Strategic scheduling to minimize startup and shutdown losses

- Load Matching: Sizing and operational strategies that maintain systems in efficient operating ranges

- Process Integration: Connecting drying operations with overall facility energy flows

Case Study: Industrial Hybrid Drying Implementation

A food processing facility implemented a hybrid low-temperature/conventional system:

- Initial drying using heat pump technology to 40% dry solids

- Final drying with conventional thermal system to 90% dry solids

- Overall energy reduction of 45% compared to conventional-only approach

- Payback period of 2.7 years despite higher initial capital investment

This approach recognized the efficiency advantages of different technologies at different stages of the drying process.

Environmental Performance and Sustainability Considerations

Emissions Management in Modern Drying Systems

Advanced sludge dryers incorporate sophisticated approaches to minimize environmental impact:

Air Quality Control Systems

Comprehensive emissions management includes:

- Condensers: Capturing water vapor and volatile organic compounds

- Biofilters: Biological treatment of odorous compounds

- Thermal Oxidizers: Destroying complex organic emissions

- Scrubber Systems: Removing particulates and water-soluble compounds

Modern systems often combine these approaches based on specific emission profiles.

Odor Management Strategies

Odor control has become increasingly sophisticated:

- Source Isolation: Negative pressure environments containing odorous processes

- Chemical Treatment: Neutralizing compounds added at strategic points

- Thermal Treatment: High-temperature destruction of odorous molecules

- Dispersion Engineering: Optimized stack designs for effective dilution

Noise Reduction Innovations

Advanced systems incorporate noise control from the design stage:

- Acoustic Enclosures: Containing noise at the source

- Vibration Isolation: Preventing transmission through structures

- Low-Noise Components: Fans, motors, and other equipment selected for acoustic performance

- Smart Scheduling: Operations timed to minimize community impact

The Circular Economy Approach to Sludge Management

Modern sludge drying increasingly focuses on resource recovery rather than waste disposal:

Beneficial Use of Dried Biosolids

Properly dried sludge opens multiple reuse pathways:

- Agricultural Application: Nutrient-rich soil amendment when properly treated

- Energy Recovery: Fuel source for industrial processes or power generation

- Construction Materials: Ingredient in certain building products and cement manufacturing

- Land Reclamation: Rehabilitation of depleted or contaminated sites

Life Cycle Assessment

Comprehensive evaluation guides technology selection:

- Energy Balance Analysis: Total energy inputs versus recovered energy potential

- Carbon Footprint Calculation: Direct and indirect emissions throughout the process

- Water Impact Assessment: Consumption and potential contamination risks

- Resource Recovery Potential: Nutrients, energy, and other valuable components

Case Study: Municipal Circular Economy Implementation

A Canadian municipality implemented a comprehensive sludge management system:

- Advanced paddle dryer producing 92% dry solids biosolids

- Energy recovery through biogas-powered drying

- Dried product used as supplementary fuel in cement manufacturing

- Overall system achieving carbon neutrality through energy recovery and fossil fuel displacement

This approach transformed a disposal challenge into a valuable resource stream while eliminating landfill impacts.

Economic Considerations and ROI Analysis

Investment Analysis for Advanced Drying Systems

Implementing sludge drying technology requires careful financial evaluation:

Capital Cost Factors

Initial investment comprises several key components:

- Core Equipment: The drying system itself (typically 40-60% of total capital)

- Auxiliary Systems: Material handling, emissions control, monitoring systems

- Site Preparation: Foundations, utilities connections, access requirements

- Integration Components: Connecting with existing plant systems

Costs typically range from $2-8 million for municipal systems, depending on capacity and technology selection.

Operational Cost Analysis

Ongoing expenses determine long-term viability:

- Energy: Typically the largest operational cost (60-80%)

- Maintenance: Preventive service, repairs, and component replacement (10-15%)

- Labor: Operator and technical support requirements (5-10%)

- Consumables: Chemicals, filter media, and other replaceable items (2-5%)

Advanced systems generally require higher capital investment but offer lower operational costs through efficiency improvements.

Return on Investment Calculations

Several factors contribute to financial returns:

Cost Avoidance Benefits

Implemented systems eliminate expenses:

- Disposal Cost Reduction: Lower tipping fees through volume reduction

- Transportation Savings: Fewer trips and smaller vehicles required

- Regulatory Compliance: Avoiding potential fines and penalties

- Risk Mitigation: Reduced liability for environmental incidents

Value Creation Opportunities

Dried sludge can generate positive cash flow:

- Energy Value: Calorific content comparable to low-grade coal (8-12 MJ/kg)

- Agricultural Product: Market value as soil amendment

- Industrial Raw Material: Input for various manufacturing processes

Typical Payback Periods

Return timelines vary based on technology and application:

- Municipal Systems: 3-7 years, primarily through disposal savings

- Industrial Applications: 2-5 years, often with higher disposal cost avoidance

- Advanced Hybrid Systems: Initially longer paybacks (4-8 years) but better lifetime economics

Case Study: Food Processing Industry Implementation

A dairy processing facility implemented an advanced indirect paddle dryer:

- Capital investment: $3.2 million for complete system

- Annual operational cost: $420,000 (primarily energy and maintenance)

- Annual savings: $1.1 million (disposal cost avoidance and energy recovery)

- Payback period: 2.9 years with net positive cash flow thereafter

The analysis included sensitivity testing for energy price fluctuations and regulatory changes, confirming robust economics across multiple scenarios.

Future Trends and Emerging Technologies

The Next Generation of Sludge Drying Innovation

Several developing technologies promise to further transform sludge management:

Microwave and Radio Frequency Drying

Electromagnetic drying offers unique advantages:

- Volumetric Heating: Energy delivered directly throughout the material

- Selective Heating: Water molecules absorb energy preferentially

- Rapid Processing: Significantly shorter residence times

- Compact Equipment: Smaller spatial footprint than conventional systems

Current limitations include high energy costs and scale-up challenges, but rapid progress is being made.

Supercritical Water Oxidation

This advanced technique operates beyond conventional phase boundaries:

- Process: Treatment at temperatures and pressures above water’s critical point

- Advantages: Complete destruction of organic materials with minimal residuals

- Challenges: Materials engineering for extreme conditions

- Status: Demonstration plants operating with commercial deployment beginning

Hydrothermal Carbonization

This thermochemical process transforms sludge into valuable carbon products:

- Process: Treatment under pressure at moderate temperatures (180-250°C)

- Products: Hydrochar with properties similar to lignite coal

- Applications: Energy resource or advanced material precursor

- Status: Early commercial implementation underway

Integration with Broader Resource Recovery

Future systems increasingly view sludge as a resource rather than waste:

Nutrient Recovery Systems

Advanced processes selectively extract valuable components:

- Phosphorus Recovery: Extraction of this increasingly scarce nutrient

- Nitrogen Capture: Conversion to concentrated fertilizer products

- Rare Earth Elements: Recovery of valuable metals present in certain sludges

- Biopolymer Extraction: Harvesting naturally occurring polymers for industrial use

Energy-Positive Processing

Next-generation facilities aim for net energy production:

- Integrated Anaerobic Digestion: Biogas production prior to drying

- Combined Heat and Power: Utilizing biogas for drying energy

- Pyrolysis Integration: Thermal decomposition producing oils and synthesis gas

- Comprehensive Heat Recovery: Capturing and reusing all available thermal energy

The Digital and Autonomous Future

Advancing technology is creating increasingly self-managing systems:

Fully Automated Facilities

Human intervention requirements continue to decrease:

- Self-Optimizing Systems: Continuous adjustment for optimal performance

- Predictive Operations: Anticipating and preparing for input variations

- Autonomous Troubleshooting: Self-diagnosis and resolution of many operational issues

- Remote Expert Support: AI-assisted connections to specialized knowledge when needed

Digital Twin Technology

Virtual modeling enables new operational approaches:

- Real-Time Simulation: Parallel virtual system reflecting actual operations

- Scenario Testing: Evaluating potential adjustments before implementation

- Operator Training: Safe learning environment for complex procedures

- Predictive Maintenance: Precise service scheduling based on actual conditions

Conclusion: Selecting the Right Sludge Drying Technology

The landscape of advanced sludge dryer technology offers more options than ever before, making informed selection crucial for success. Modern paddle dryers represent a proven solution for many applications, while emerging technologies continue to expand the possibilities for efficient, sustainable sludge management.

When evaluating sludge drying solutions, consider not only initial capital costs but the complete lifecycle economic picture. Energy efficiency, maintenance requirements, and potential for beneficial end-product use all contribute significantly to long-term value. The most appropriate technology depends on your specific circumstances, including sludge characteristics, facility constraints, and regulatory environment.

The future of sludge drying lies in integrated systems that combine multiple technologies to maximize efficiency and sustainability. As digital capabilities continue to advance, expect increasingly autonomous operations with continuous optimization. These smart systems will further reduce operating costs while improving environmental performance.

Whether you’re upgrading existing facilities or planning new infrastructure, understanding these advanced sludge drying technologies provides the foundation for making choices that will deliver value for decades to come. The best solutions balance technical performance, economic efficiency, and environmental responsibility to transform what was once considered a waste disposal challenge into a resource recovery opportunity.