Municipal wastewater treatment plants across North America generate over 7 million dry tons of sludge annually, with disposal costs reaching $500-800 per dry ton. Traditional thermal drying systems consume massive amounts of energy, driving operational expenses through the roof. What if there was a way to harness free solar energy to transform this waste management challenge into an environmental and economic opportunity?

Solar drying of wastewater sludge represents a revolutionary approach that reduces moisture content from 80% to as low as 10%, creating valuable biosolids while cutting energy costs by up to 70%. This comprehensive guide reveals exactly how municipal facilities and industrial operations can implement solar sludge drying systems to achieve sustainable waste management goals while generating significant cost savings.

What Is Solar Drying of Wastewater Sludge?

Solar drying of wastewater sludge is a natural dehydration process that uses solar radiation and ambient air circulation to remove moisture from sewage sludge, transforming it from a wet, difficult-to-handle waste product into dry, stable biosolids. This thermal treatment method harnesses renewable solar energy to achieve moisture reduction levels comparable to conventional thermal dryers without the associated energy costs.

The process involves spreading dewatered sludge in thin layers across specially designed drying beds or greenhouse-style structures where solar heat and natural ventilation work together to evaporate water content. Modern solar drying systems can achieve final moisture contents between 10-30%, depending on climate conditions and system design.

Key Components of Solar Sludge Drying Systems

Solar sludge drying installations typically include several critical components that work together to maximize drying efficiency:

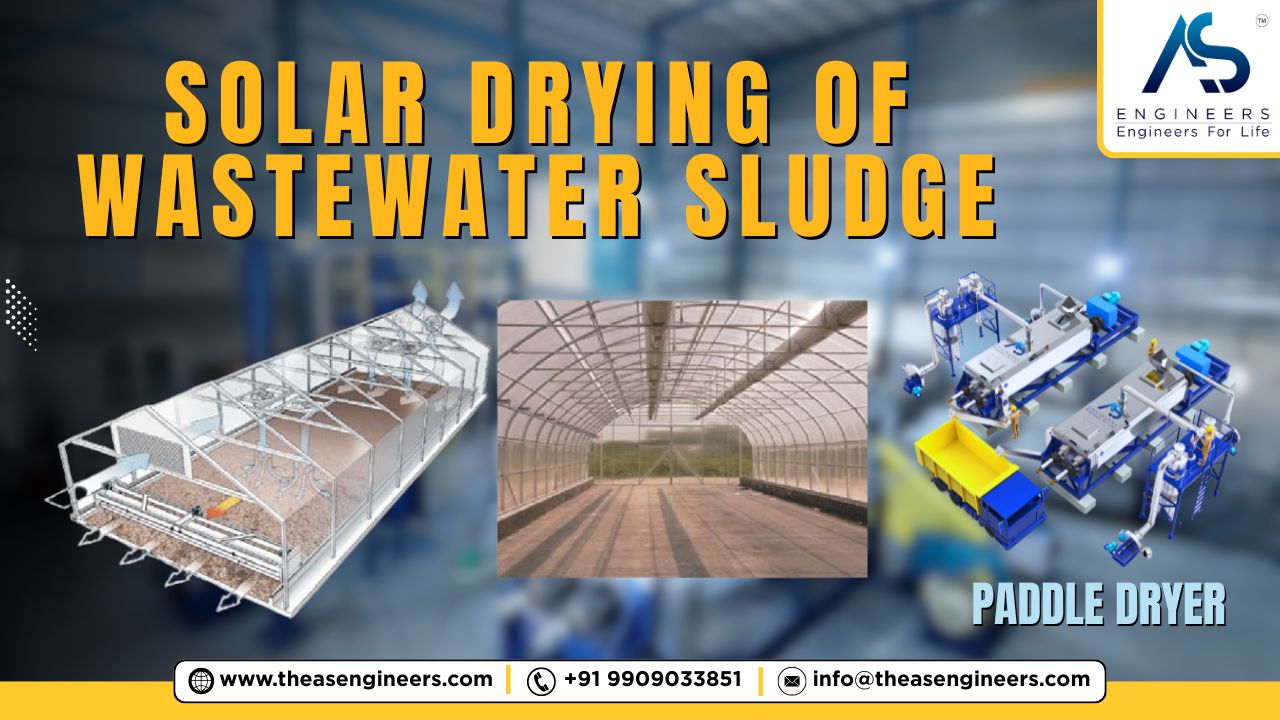

Greenhouse Structures: Transparent or translucent enclosures that trap solar heat while protecting sludge from precipitation. These structures create a controlled microclimate that accelerates the drying process even during cooler months.

Drying Beds: Concrete or gravel-based surfaces designed for optimal heat absorption and drainage. The bed design directly impacts drying rates and final product quality.

Ventilation Systems: Natural or forced air circulation mechanisms that remove humid air and introduce fresh air to maintain optimal drying conditions.

Mixing Equipment: Automated or manual systems for turning and redistributing sludge to ensure uniform drying and prevent crust formation.

Collection Systems: Infrastructure for harvesting dried biosolids and preparing them for final disposal or beneficial reuse applications.

How Solar Sludge Drying Works: The Complete Process

Phase 1: Pre-Treatment and Preparation

Before solar drying begins, wastewater sludge undergoes essential preparation steps that determine the success of the entire operation. Dewatering equipment such as belt filter presses, centrifuges, or screw presses reduce initial moisture content from 95-98% down to 75-85%. This preliminary moisture reduction is crucial because excessively wet sludge forms impermeable crusts that prevent effective solar drying.

Sludge conditioning with polymers or lime may be employed to improve dewaterability and accelerate subsequent solar drying. Lime addition also provides pathogen reduction benefits and pH stabilization, creating more favorable conditions for the solar drying process.

Phase 2: Solar Energy Absorption and Heat Transfer

Once prepared sludge is placed on drying beds, solar radiation begins the evaporation process through multiple heat transfer mechanisms. Direct solar radiation heats the sludge surface, while reflected radiation from bed surfaces and enclosure walls provides additional thermal energy. Greenhouse structures create a solar collector effect, trapping warm air and maintaining elevated temperatures even when ambient conditions are suboptimal.

The greenhouse effect can increase internal temperatures by 15-25°C above ambient levels, significantly accelerating moisture evaporation rates. This temperature differential extends the effective drying season and improves process reliability in variable climate conditions.

Phase 3: Moisture Migration and Evaporation

As surface moisture evaporates, capillary action draws water from the sludge interior to replace evaporated surface water. This continuous moisture migration maintains steady evaporation rates until internal water becomes increasingly bound to organic matter. The drying rate gradually decreases as remaining moisture becomes more difficult to extract.

Regular mixing or turning breaks surface crusts and exposes moist interior material to solar heating, maintaining optimal drying conditions throughout the process. Automated mixing systems can be programmed to optimize turning frequency based on weather conditions and moisture content measurements.

Phase 4: Final Drying and Biosolids Formation

Extended solar exposure reduces moisture content to target levels, typically 10-30% depending on intended end use. At these moisture levels, the material transforms from wet sludge into stable biosolids with significantly improved handling characteristics. The dried product has a soil-like consistency and can be easily transported, stored, or applied as fertilizer.

Benefits of Solar Drying for Wastewater Sludge

Dramatic Cost Reduction

Solar drying of wastewater sludge delivers substantial economic advantages compared to conventional thermal drying methods. Energy costs represent the largest operational expense for traditional dryers, often accounting for 60-80% of total drying costs. Solar systems eliminate these energy expenses while providing comparable moisture reduction performance.

A typical 50 TPD (tons per day) solar drying facility can save $300,000-500,000 annually in energy costs compared to equivalent thermal drying capacity. These savings compound over the 20-30 year lifespan of solar drying infrastructure, generating millions in total cost avoidance.

Capital costs for solar drying systems are typically 40-60% lower than thermal alternatives, making the technology accessible to smaller municipalities and industrial facilities with limited budgets. The combination of lower capital investment and eliminated energy costs creates attractive payback periods of 3-7 years for most installations.

Environmental Sustainability

Solar sludge drying systems produce zero direct greenhouse gas emissions during operation, contrasting sharply with fossil fuel-powered thermal dryers that generate significant CO2 emissions. A medium-sized solar drying facility can avoid 1,000-2,000 tons of CO2 emissions annually compared to natural gas-fired thermal systems.

The process creates valuable biosolids that can replace commercial fertilizers, reducing demand for energy-intensive fertilizer manufacturing. When properly managed, solar-dried biosolids provide slow-release nutrients that improve soil health while reducing chemical fertilizer requirements.

Pathogen Reduction and Stabilization

Extended exposure to elevated temperatures during solar drying provides effective pathogen reduction comparable to Class A biosolids requirements. Sustained temperatures above 40°C for extended periods eliminate most pathogenic bacteria, viruses, and parasites, creating safe end products suitable for agricultural applications.

The combination of heat exposure, desiccation, and pH changes during solar drying creates multiple pathogen inactivation mechanisms that ensure public health protection. This natural disinfection process eliminates the need for chemical additives or additional treatment steps.

Volume and Weight Reduction

Solar drying reduces sludge volume by 60-80%, dramatically decreasing transportation and disposal costs. A facility processing 100 wet tons daily might produce only 20-25 tons of dried biosolids, reducing hauling requirements by 75%. This volume reduction translates directly into lower transportation fuel consumption and reduced carbon footprint for final disposal or beneficial use.

The weight reduction also enables longer-distance transportation to markets for beneficial reuse, expanding options for revenue generation from biosolids sales.

Types of Solar Sludge Drying Systems

Open-Air Drying Beds

Traditional open-air solar drying represents the simplest and most cost-effective approach for facilities in arid climates with minimal precipitation. These systems consist of concrete or sand-based drying beds where sludge is spread in thin layers and allowed to dry through natural solar exposure and wind circulation.

Open-air systems work best in regions with annual precipitation below 400mm and abundant sunshine. Operating costs are minimal, but drying rates depend entirely on weather conditions, making process control challenging in variable climates.

Greenhouse-Style Solar Dryers

Enclosed greenhouse structures provide weather protection while maximizing solar energy capture through transparent roofing and walls. These systems maintain higher internal temperatures and protect sludge from precipitation, enabling year-round operation in most climates.

Greenhouse solar dryers typically achieve 30-50% faster drying rates compared to open-air systems while providing better process control and product quality consistency. Automated ventilation systems optimize air circulation based on internal temperature and humidity conditions.

Hybrid Solar-Thermal Systems

Advanced hybrid systems combine solar heating with supplemental thermal energy sources to ensure consistent performance regardless of weather conditions. Natural gas burners or biomass heating can provide backup heating during extended cloudy periods or winter months.

These systems offer the reliability of conventional thermal dryers while capturing substantial energy savings during favorable solar conditions. Intelligent control systems automatically switch between solar and thermal modes based on weather forecasts and drying requirements.

Solar Belt Dryers

Innovative solar belt dryer designs use moving conveyor systems within solar greenhouse structures to automate material handling while maximizing solar exposure. Sludge moves continuously through the drying chamber, ensuring uniform treatment and eliminating manual handling requirements.

Belt systems enable continuous operation and precise residence time control, producing consistent end product quality while minimizing labor requirements. These systems work particularly well for large-scale installations requiring high throughput capacity.

Design Considerations for Solar Sludge Drying

Climate Assessment and Site Selection

Successful solar drying implementation requires careful evaluation of local climate conditions and site characteristics. Solar radiation intensity, ambient temperature patterns, precipitation frequency, and wind conditions all influence system performance and design requirements.

Locations with annual solar radiation above 1,400 kWh/m² and fewer than 100 rainy days per year provide optimal conditions for solar drying. However, properly designed systems can operate effectively in less favorable climates with appropriate modifications and backup systems.

Site selection should prioritize areas with maximum sun exposure throughout the day while considering prevailing wind patterns for natural ventilation. Proximity to existing sludge handling infrastructure reduces material transport requirements and overall project costs.

System Sizing and Capacity Planning

Solar drying system capacity must match sludge production rates while accounting for seasonal variations in drying performance. Winter drying rates may be 40-60% lower than summer performance, requiring larger bed areas or storage capacity to maintain consistent throughput.

Design calculations should consider peak sludge production periods and include adequate capacity margin to prevent system overload during high-flow periods. Modular designs enable phased construction and capacity expansion as facility needs grow.

Material Selection and Durability

Solar drying infrastructure must withstand decades of UV exposure, temperature cycling, and chemical contact with sludge. Greenhouse covering materials should provide high solar transmission while resisting UV degradation and thermal stress.

Polycarbonate panels offer excellent durability and insulation properties, while tempered glass provides maximum solar transmission with superior longevity. Drying bed surfaces require chemical-resistant materials that facilitate easy cleaning and maintenance.

Automation and Control Systems

Modern solar drying installations benefit from automated monitoring and control systems that optimize performance while minimizing labor requirements. Temperature, humidity, and moisture content sensors provide real-time process data for control system decision-making.

Automated mixing systems, ventilation controls, and material handling equipment reduce manual labor while ensuring consistent operation. Remote monitoring capabilities enable operators to track performance and identify maintenance needs from off-site locations.

Operational Best Practices

Loading and Distribution Techniques

Proper sludge loading and distribution directly impacts drying efficiency and final product quality. Sludge should be spread in uniform layers 10-20cm thick to ensure adequate solar penetration while preventing anaerobic conditions that generate odors.

Mechanical spreaders or custom-designed distribution equipment ensure uniform thickness and eliminate manual handling hazards. Proper distribution techniques can improve drying rates by 20-30% compared to uneven manual spreading.

Mixing and Turning Protocols

Regular mixing prevents surface crust formation while exposing moist interior material to solar heating. Optimal mixing frequency depends on sludge characteristics, weather conditions, and moisture content, typically ranging from daily to weekly intervals.

Automated mixing systems can be programmed based on moisture content measurements or time intervals, ensuring consistent mixing without over-handling that might create dust problems or damage fragile dried material.

Monitoring and Quality Control

Continuous monitoring of moisture content, temperature, and drying rates enables operators to optimize performance and identify potential problems early. Portable moisture analyzers provide rapid field measurements for process control decisions.

Regular sampling and laboratory analysis ensure final product meets regulatory requirements for pathogen reduction, metals content, and other quality parameters. Documentation systems track batch processing data for regulatory compliance and process optimization.

Seasonal Operation Strategies

Solar drying performance varies significantly with seasonal weather patterns, requiring adaptive operational strategies. Summer operation focuses on maximizing throughput during optimal conditions, while winter operation may require reduced loading rates or backup heating systems.

Stockpiling capabilities enable facilities to store excess production during high-performance periods for processing during less favorable conditions. Strategic scheduling optimizes system utilization throughout the year.

Economic Analysis and ROI Calculations

Capital Cost Comparisons

Solar drying systems require lower capital investment compared to conventional thermal dryers, with typical costs ranging from $1,200-2,500 per dry ton of daily capacity. Equivalent thermal drying systems cost $3,000-5,000 per dry ton capacity, making solar systems 40-60% less expensive to install.

The cost differential increases for smaller installations where thermal dryer economics become less favorable due to fixed equipment costs. Solar systems scale more linearly, maintaining cost advantages across a wider range of facility sizes.

Operating Cost Analysis

Operating costs for solar drying systems primarily include labor, maintenance, and utilities for ventilation and mixing equipment. Annual operating costs typically range from $50-150 per dry ton processed, compared to $200-400 per dry ton for thermal systems.

Energy savings represent the largest operational advantage, with solar systems eliminating $150-300 per dry ton in annual fuel costs. These ongoing savings compound over the system lifetime, generating substantial total cost avoidance.

Payback Period Calculations

Simple payback periods for solar drying investments typically range from 3-7 years, depending on system size, local energy costs, and sludge disposal alternatives. Larger installations achieve faster paybacks due to economies of scale and higher absolute savings.

Net present value calculations over 20-year system lifespans typically show positive returns of $2-5 million for medium-sized installations, making solar drying highly attractive from a financial perspective.

Regulatory Compliance and Standards

Biosolids Quality Requirements

Solar-dried sludge must meet applicable biosolids quality standards for beneficial use or disposal. Class A biosolids requirements include pathogen reduction standards, vector attraction reduction, and metals concentration limits.

Proper solar drying processes can achieve Class A pathogen reduction through time-temperature relationships that eliminate harmful microorganisms. Documentation systems must track treatment conditions to demonstrate regulatory compliance.

Environmental Permitting

Solar drying facilities typically require air quality permits, solid waste handling permits, and potentially groundwater protection measures. Permitting requirements vary by jurisdiction but generally involve environmental impact assessments and operating plan approvals.

Early coordination with regulatory agencies streamlines the permitting process and ensures system designs meet all applicable requirements. Professional environmental consulting services can accelerate permit approvals and ensure regulatory compliance.

Occupational Safety Requirements

Solar drying operations involve potential exposure to biosolids, elevated temperatures, and mechanical equipment hazards. Comprehensive safety programs must address personal protective equipment, confined space entry, and emergency response procedures.

Worker training programs ensure safe operation while minimizing liability exposure. Regular safety audits and equipment inspections maintain safe working conditions throughout system operation.

Troubleshooting Common Issues

Poor Drying Performance

Inadequate drying rates often result from excessive sludge thickness, insufficient mixing, or unfavorable weather conditions. Systematic evaluation of loading practices, mixing frequency, and ventilation effectiveness typically identifies root causes.

Solutions may include modified loading procedures, increased mixing frequency, or supplemental heating during challenging weather periods. Process monitoring data helps identify performance trends and optimize operational parameters.

Odor Management

Odor generation typically occurs when sludge becomes anaerobic due to excessive thickness or poor ventilation. Proper aeration, appropriate loading rates, and regular mixing prevent anaerobic conditions that generate offensive odors.

Biofilters or chemical scrubbing systems can control residual odors if natural management techniques prove insufficient. Strategic facility siting away from sensitive receptors minimizes odor impact potential.

Product Quality Issues

Inconsistent moisture content or contamination problems usually result from uneven drying, inadequate mixing, or foreign material introduction. Standardized operating procedures and quality control sampling identify quality issues early.

Corrective actions may include modified mixing protocols, improved material handling practices, or enhanced screening to remove contaminants before drying.

Future Innovations and Technology Trends

Advanced Control Systems

Artificial intelligence and machine learning technologies enable predictive control systems that optimize drying performance based on weather forecasts, sludge characteristics, and historical performance data. These systems automatically adjust operational parameters to maximize efficiency while maintaining product quality.

Smart sensors and IoT connectivity provide real-time monitoring capabilities that enable remote operation and predictive maintenance scheduling. Cloud-based data analytics identify optimization opportunities and performance trends.

Integrated Energy Recovery

Emerging technologies combine solar drying with energy recovery systems that capture waste heat from other facility processes. Heat pumps and thermal storage systems can extend effective drying periods and improve performance during suboptimal weather conditions.

Biogas capture from anaerobic sludge treatment processes can provide supplemental heating for hybrid solar-thermal systems, creating integrated waste-to-energy solutions.

Enhanced Material Handling

Automated material handling systems reduce labor requirements while improving workplace safety and product consistency. Robotic systems can perform loading, mixing, and harvesting operations with minimal human intervention.

Conveyor-based systems enable continuous processing that maximizes equipment utilization while maintaining consistent product quality.

Frequently Asked Questions

- How long does solar drying of wastewater sludge take?

Solar drying typically requires 7-21 days to achieve target moisture content, depending on climate conditions, sludge characteristics, and system design. Warm, dry climates with abundant sunshine achieve faster drying rates than cool, humid environments. - What moisture content can solar drying achieve?

Well-designed solar drying systems can reduce moisture content to 10-30%, comparable to conventional thermal dryers. Final moisture content depends on drying time, weather conditions, and specific system configuration. - Does solar drying eliminate pathogens in sludge?

Yes, extended exposure to elevated temperatures during solar drying effectively eliminates most pathogens, including bacteria, viruses, and parasites. Proper temperature monitoring ensures compliance with Class A biosolids pathogen reduction requirements. - Can solar drying work in northern climates?

Solar drying can operate effectively in northern climates with proper system design and seasonal operational strategies. Greenhouse enclosures and thermal backup systems enable year-round operation even in challenging climate conditions. - What are the maintenance requirements for solar drying systems?

Solar drying systems require minimal maintenance compared to thermal dryers. Regular cleaning of greenhouse surfaces, mechanical maintenance of mixing equipment, and periodic replacement of covering materials constitute primary maintenance activities.

Conclusion

Solar drying of wastewater sludge represents a transformative technology that addresses both environmental sustainability and economic efficiency challenges facing modern wastewater treatment facilities. By harnessing free solar energy, facilities can achieve moisture reduction performance comparable to expensive thermal systems while eliminating substantial energy costs and reducing greenhouse gas emissions.

The technology offers compelling advantages including 70% energy cost savings, reduced capital investment requirements, and creation of valuable biosolids suitable for beneficial use applications. With proper design and operation, solar drying systems provide reliable, cost-effective sludge management solutions across diverse climate conditions and facility sizes.

As environmental regulations become increasingly stringent and energy costs continue rising, solar drying of wastewater sludge emerges as an essential technology for sustainable waste management. Forward-thinking facilities implementing solar drying systems today position themselves for decades of operational cost savings while contributing to environmental protection goals.

Ready to explore solar drying solutions for your facility? Contact our wastewater treatment experts to discuss your specific requirements and develop a customized solar drying system design that maximizes your operational efficiency and cost savings potential.