Industrial wastewater treatment generates millions of tons of sludge annually across India, creating a massive disposal challenge that costs companies up to 40% of their total treatment expenses. Traditional sludge management methods consume enormous energy while failing to meet increasingly strict environmental regulations. The solution lies in advanced sludge dryer technology that transforms wet, problematic waste into valuable, manageable dry matter.

AS Engineers has revolutionized sludge treatment across India by manufacturing cutting-edge ETP sludge dryers that reduce disposal costs by 75% while ensuring complete regulatory compliance. This comprehensive guide reveals everything you need to know about sludge dryers, from selection criteria to operational excellence, helping you make informed decisions for sustainable wastewater management.

Table of contents

- What Is a Sludge Dryer and Why Your Industry Needs One

- Types of Sludge Dryers: Choosing the Right Technology

- Technical Specifications: Understanding Performance Parameters

- Benefits of Professional Sludge Dryer Implementation

- Selection Criteria: Choosing the Right Sludge Dryer

- AS Engineers: Leading ETP Sludge Dryers Manufacturer from India

- Installation and Commissioning Best Practices

- Maintenance and Operational Excellence

- Frequently Asked Questions About Sludge Dryers

- Future Trends in Sludge Drying Technology

- Conclusion: Transforming Waste Management with Advanced Sludge Drying

What Is a Sludge Dryer and Why Your Industry Needs One

A sludge dryer represents advanced thermal processing equipment designed to remove moisture from industrial sludge through controlled heating mechanisms. These sophisticated systems transform wet sludge containing 75-85% water content into dry solids with less than 10% moisture, dramatically reducing volume and disposal costs.

Modern sludge dryers operate through indirect heating principles, ensuring no direct contact between heating medium and sludge material. This approach prevents contamination while maintaining product integrity throughout the drying process. The technology proves essential for industries generating significant sludge volumes, including pharmaceuticals, chemicals, textiles, food processing, and municipal wastewater treatment facilities.

The Critical Business Case for Sludge Drying

Raw sludge disposal creates multiple operational challenges that directly impact your bottom line. Transportation costs escalate exponentially due to high water content, while landfill fees continue rising across Indian states. Environmental compliance requirements demand sophisticated treatment approaches that traditional methods cannot deliver.

Implementing professional sludge dryer systems addresses these challenges systematically. Volume reduction reaches 80-90%, translating to proportional savings in transportation and disposal expenses. The dried product often qualifies as alternative fuel or soil conditioner, creating revenue opportunities from waste streams.

Types of Sludge Dryers: Choosing the Right Technology

Paddle Dryer Systems

Paddle dryers represent the most versatile solution for diverse sludge characteristics. These systems feature specially designed paddle assemblies that provide gentle mixing while ensuring uniform heat distribution. The indirect heating mechanism protects sensitive materials from thermal degradation while achieving consistent moisture removal.

AS Engineers’ paddle dryer technology incorporates advanced steam jacket designs that maximize heat transfer efficiency. Variable speed drives allow precise control over residence time, enabling optimization for different sludge types. The sealed construction prevents odor emissions while maintaining operator safety standards.

Disc Dryer Technology

Disc dryers excel in high-capacity applications requiring continuous operation. Multiple heated discs rotate within an enclosed chamber, creating maximum surface area for heat transfer. This design achieves superior drying rates while minimizing energy consumption per unit of processed sludge.

The technology proves particularly effective for municipal wastewater treatment plants and large industrial facilities. Automatic discharge systems ensure continuous operation without manual intervention, reducing labor costs while maintaining consistent product quality.

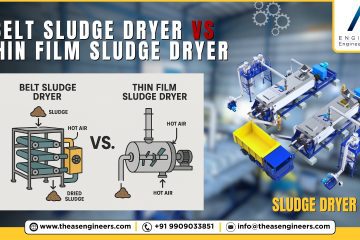

Belt Dryer Solutions

Belt dryers offer gentle treatment for heat-sensitive materials requiring precise temperature control. Perforated conveyor belts transport sludge through controlled temperature zones, enabling gradual moisture removal without thermal shock. This approach preserves valuable components while achieving required dryness levels.

Multi-stage heating zones allow temperature profiling to match specific sludge characteristics. Advanced air circulation systems ensure uniform drying across the entire belt width, eliminating hot spots that could damage sensitive materials.

Technical Specifications: Understanding Performance Parameters

Moisture Reduction Capabilities

Professional sludge dryers achieve final moisture contents between 5-15%, depending on application requirements. Initial sludge typically contains 75-85% water, representing substantial volume reduction potential. The precise moisture control capabilities enable end-product optimization for specific disposal or utilization pathways.

AS Engineers‘ systems incorporate advanced moisture monitoring technology that provides real-time feedback for process optimization. Automated control systems maintain consistent product quality while minimizing energy consumption through precise temperature management.

Capacity and Throughput Considerations

Sludge dryer capacity ranges from laboratory-scale units processing 10 kg/hour to industrial systems handling 10,000 kg/hour or more. Proper sizing requires careful analysis of sludge generation rates, peak flow conditions, and storage capabilities. Oversized equipment wastes energy, while undersized systems create processing bottlenecks.

Throughput calculations must account for sludge characteristics including solids content, viscosity, and thermal properties. Seasonal variations in sludge generation require flexible capacity management to maintain efficient operations throughout the year.

Energy Efficiency Metrics

Modern sludge dryers achieve thermal efficiencies exceeding 85% through advanced heat recovery systems. Steam consumption typically ranges from 1.2-1.8 kg steam per kg water evaporated, depending on system design and operating conditions. Heat pump integration can reduce energy requirements by up to 50% compared to conventional systems.

AS Engineers incorporates proprietary heat recovery technology that captures waste heat from exhaust streams for preheating incoming sludge. This innovation significantly reduces operational costs while improving overall system sustainability.

Benefits of Professional Sludge Dryer Implementation

Environmental Compliance and Sustainability

Sludge dryers enable complete compliance with stringent environmental regulations governing waste disposal. The controlled drying process eliminates pathogenic organisms while reducing volatile organic compound emissions. Dried sludge meets regulatory requirements for land application or alternative fuel utilization.

The technology supports circular economy principles by converting waste streams into valuable resources. Energy recovery from dried sludge reduces dependence on fossil fuels while generating carbon credits through reduced landfill methane emissions.

Economic Advantages and ROI

Investment in professional sludge drying technology delivers rapid return on investment through multiple cost reduction mechanisms. Transportation expenses decrease by 80-90% due to volume reduction, while disposal fees drop proportionally. Many facilities achieve payback periods under 24 months through operational savings alone.

Revenue generation opportunities enhance economic benefits through dried sludge sales. High-quality dried material commands premium prices as soil conditioner, fertilizer component, or alternative fuel. These revenue streams often exceed operational costs, transforming waste treatment from expense center to profit generator.

Operational Excellence and Reliability

Modern sludge dryers provide fully automated operation with minimal manual intervention requirements. Advanced control systems monitor all critical parameters while adjusting operating conditions to maintain optimal performance. Predictive maintenance capabilities prevent unexpected downtime while extending equipment life.

AS Engineers’ systems feature robust construction designed for continuous industrial operation. Wear-resistant materials and precision engineering ensure reliable performance under demanding conditions. Comprehensive service support maintains peak efficiency throughout equipment lifecycle.

Selection Criteria: Choosing the Right Sludge Dryer

Sludge Characterization Analysis

Proper sludge dryer selection begins with comprehensive waste stream analysis. Key parameters include solids content, particle size distribution, thermal properties, and chemical composition. Corrosive materials require specialized construction materials, while abrasive particles demand enhanced wear protection.

Seasonal variations in sludge characteristics require flexible system designs that accommodate changing conditions. Pilot testing programs provide valuable data for optimizing equipment specifications and operating parameters before full-scale implementation.

Process Integration Requirements

Successful sludge dryer integration requires careful consideration of upstream and downstream processes. Feed preparation systems must deliver consistent material properties, while product handling equipment manages dried solids efficiently. Utility requirements including steam, electricity, and cooling water need adequate capacity and reliability.

Emission control systems prevent environmental impacts while maintaining regulatory compliance. Advanced odor control technology ensures community acceptance, particularly for facilities in urban areas.

Maintenance and Service Considerations

Equipment accessibility determines maintenance efficiency and associated costs. Modular designs enable component replacement without major system shutdowns, minimizing production impacts. Standardized components reduce spare parts inventory while simplifying maintenance procedures.

AS Engineers provides comprehensive service support including preventive maintenance programs, emergency repair services, and performance optimization consulting. Local service capabilities ensure rapid response times while reducing maintenance costs.

AS Engineers: Leading ETP Sludge Dryers Manufacturer from India

Manufacturing Excellence and Innovation

AS Engineers stands as India’s premier manufacturer of ETP sludge dryers, combining decades of engineering expertise with cutting-edge technology. Our state-of-the-art manufacturing facilities produce equipment meeting international quality standards while delivering cost-effective solutions for Indian industries.

Our research and development team continuously advances sludge drying technology through innovative design approaches and advanced materials. Collaboration with leading technical institutes ensures our products incorporate latest scientific developments while maintaining practical applicability for industrial operations.

Comprehensive Product Portfolio

AS Engineers offers complete sludge dryer solutions tailored to diverse industrial requirements. Our product range includes paddle dryers, disc dryers, belt dryers, and specialized systems for unique applications. Custom engineering capabilities address specific client needs while maintaining proven design principles.

Each system incorporates proprietary heat recovery technology that significantly reduces energy consumption compared to conventional designs. Advanced automation packages provide intelligent process control while minimizing operator requirements and human error potential.

Project Execution and Support Services

Our experienced project management team ensures seamless equipment installation and commissioning. Comprehensive testing and validation procedures guarantee performance compliance before system handover. Training programs prepare operating personnel for safe, efficient equipment operation.

Ongoing technical support maintains optimal system performance throughout equipment lifecycle. Performance monitoring services identify optimization opportunities while predictive maintenance programs prevent unexpected failures.

Installation and Commissioning Best Practices

Site Preparation Requirements

Proper site preparation ensures successful sludge dryer installation and long-term reliability. Foundation design must accommodate equipment loads while providing adequate vibration isolation. Utility connections require appropriate capacity and backup systems for critical applications.

Environmental considerations include noise control, emission management, and emergency response procedures. Local regulations may impose specific requirements for equipment placement, utility connections, and safety systems.

Commissioning and Performance Validation

Systematic commissioning procedures verify all system components operate according to design specifications. Performance testing under actual operating conditions validates guaranteed capabilities while identifying optimization opportunities. Documentation of all test results provides baseline data for ongoing performance monitoring.

Operator training during commissioning ensures proper understanding of equipment operation and maintenance requirements. Comprehensive documentation including operating manuals, maintenance procedures, and troubleshooting guides supports long-term operational success.

Maintenance and Operational Excellence

Preventive Maintenance Programs

Regular maintenance prevents equipment failures while extending operational life. Scheduled inspections identify wear patterns and potential problems before they impact production. Lubrication programs maintain mechanical components while cleaning procedures prevent buildup that reduces heat transfer efficiency.

AS Engineers provides customized maintenance programs based on specific operating conditions and equipment configurations. Predictive maintenance technologies monitor equipment condition while scheduling maintenance activities to minimize production impacts.

Performance Optimization Strategies

Continuous performance monitoring identifies opportunities for efficiency improvements and cost reduction. Process parameter optimization reduces energy consumption while maintaining product quality. Heat recovery system enhancement can significantly improve overall thermal efficiency.

Regular system audits evaluate performance against design specifications while identifying upgrade opportunities. Technology updates and component improvements maintain competitive advantages while extending equipment lifecycle.

Frequently Asked Questions About Sludge Dryers

- What is the typical payback period for sludge dryer investment?

Most facilities achieve payback periods between 18-36 months through reduced disposal costs, transportation savings, and potential revenue from dried products.. - What maintenance is required for sludge dryers?

Regular maintenance includes lubrication, cleaning, wear part inspection, and control system calibration, typically requiring 2-4 hours weekly for most systems. - Can sludge dryers handle different types of industrial sludge?

Yes, properly designed systems accommodate various sludge types through adjustable operating parameters and specialized construction materials for specific applications. - What environmental permits are required for sludge dryer operation?

Requirements vary by location but typically include air emissions permits and waste handling authorizations, with AS Engineers providing regulatory compliance support.

Future Trends in Sludge Drying Technology

Energy Recovery and Heat Pump Integration

Advanced heat pump technology represents the future of energy-efficient sludge drying. These systems recover waste heat from multiple sources while achieving coefficient of performance values exceeding 3.0. Integration with renewable energy sources further reduces operational costs while supporting sustainability objectives.

Solar thermal integration provides supplementary heating during favorable weather conditions. Thermal storage systems enable continuous operation while maximizing renewable energy utilization. These innovations position sludge drying as environmentally sustainable technology aligned with global decarbonization efforts.

Automation and Industry 4.0 Integration

Smart sludge dryer systems incorporate artificial intelligence for predictive process control and optimization. Machine learning algorithms analyze operational data to identify efficiency improvements while preventing equipment failures. Remote monitoring capabilities enable expert support regardless of facility location.

Digital twin technology provides virtual system modeling for optimization studies and operator training. Augmented reality maintenance support reduces service times while improving repair quality. These technological advances ensure sludge drying equipment remains competitive in rapidly evolving industrial environments.

Conclusion: Transforming Waste Management with Advanced Sludge Drying

Sludge dryer technology represents a transformative solution for industrial waste management challenges, converting problematic waste streams into valuable resources while ensuring environmental compliance. The substantial economic benefits, including 75% disposal cost reduction and potential revenue generation, make professional sludge drying systems essential for sustainable industrial operations.

AS Engineers continues leading India’s sludge dryer manufacturing sector through innovative technology, comprehensive service support, and proven project execution capabilities. Our commitment to excellence ensures clients receive optimal solutions that deliver long-term value while supporting environmental stewardship objectives.

Ready to transform your sludge management challenges into competitive advantages? Contact AS Engineers today for expert consultation and customized sludge dryer solutions that deliver measurable results. Subscribe to our technical newsletter for the latest insights on wastewater treatment innovation and sustainable industrial practices.