Industrial facilities processing wastewater generate millions of tons of sludge annually, with treatment costs reaching up to $2,000 per ton using conventional methods. Paddle dryer configuration represents the most energy-efficient solution for thermal sludge treatment, reducing disposal costs by 80% while meeting stringent environmental regulations. This comprehensive guide reveals how proper paddle dryer configuration can transform your sludge management operations from a costly burden into an optimized, sustainable process.

Understanding the intricacies of paddle dryer configuration enables plant operators to achieve maximum drying efficiency, minimize energy consumption, and ensure consistent output quality. Whether you’re designing a new sludge treatment facility or upgrading existing equipment, mastering these configuration principles will deliver measurable improvements in performance and profitability.

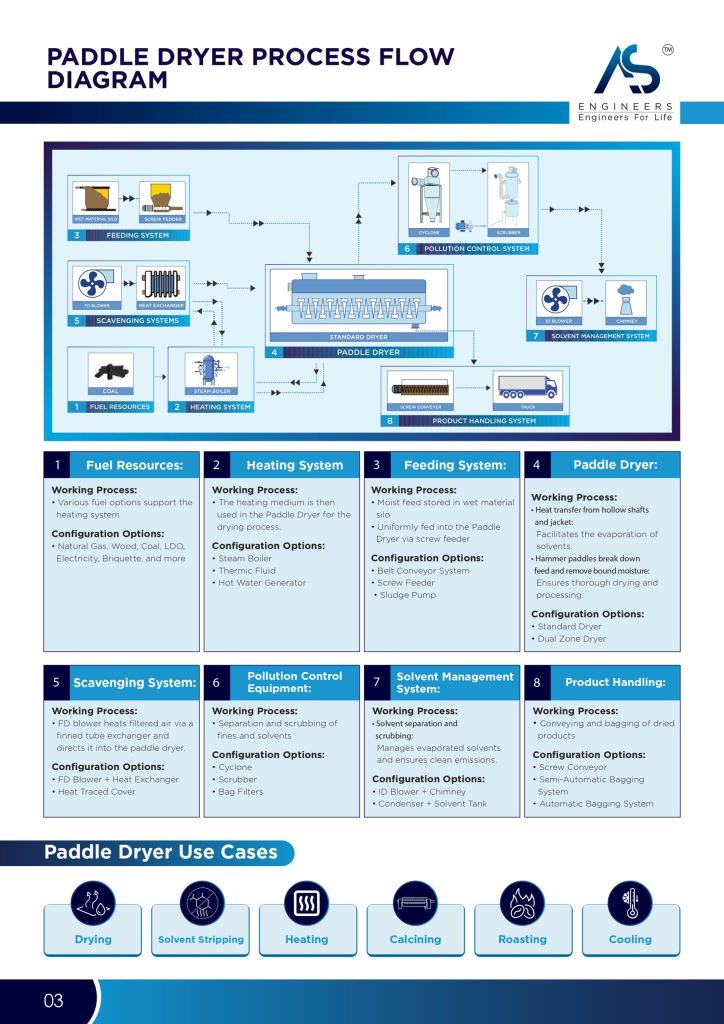

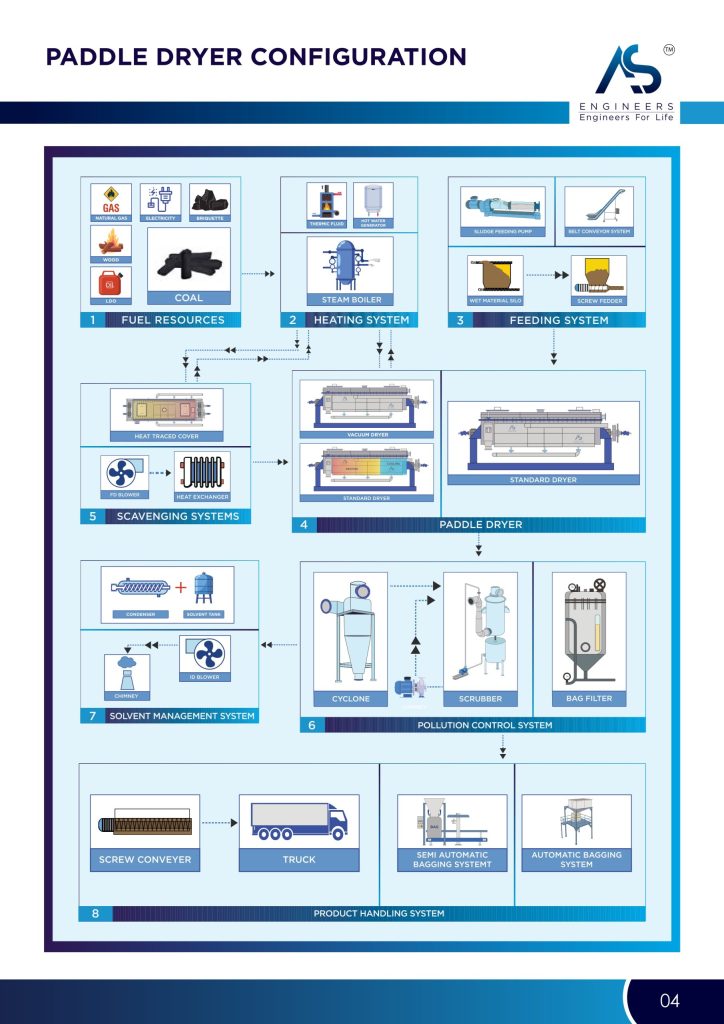

Understanding Paddle Dryer Configuration Fundamentals

Paddle dryer configuration encompasses the systematic arrangement of heating elements, mechanical components, and process control systems that work together to remove moisture from sludge materials. This indirect heating technology uses heated surfaces rather than direct contact with hot gases, making it ideal for processing heat-sensitive materials and reducing emissions.

The configuration process begins with understanding your specific sludge characteristics. Municipal sewage sludge typically contains 75-85% moisture content, while industrial sludge can vary dramatically based on the source process. These variations directly impact the optimal paddle dryer configuration for your application.

Core Components of Paddle Dryer Systems

The foundation of effective paddle dryer configuration rests on eight interconnected systems that must work in harmony. Each component plays a critical role in the overall drying process, and improper configuration of any single element can compromise the entire operation.

Fuel resources form the primary energy input for the system. Gas, coal, and biomass represent the most common fuel options, with natural gas offering the cleanest combustion and most precise temperature control. The heating system configuration depends entirely on fuel selection, as different fuels require specific burner designs and safety systems.

Heating system integration connects fuel combustion to heat transfer mechanisms. Steam boilers provide consistent, controllable heat transfer through the paddle elements, while thermal fluid systems offer higher temperature capabilities for specialized applications. The configuration choice between steam and thermal fluid significantly impacts operating costs and maintenance requirements.

Optimal Feeding System Configuration

The feeding system configuration determines material introduction rates and consistency, directly affecting drying uniformity and energy efficiency. Proper paddle dryer configuration requires precise material feeding to maintain optimal residence time and heat transfer coefficients.

Screw feeders provide the most reliable material introduction method for sludge applications. The feeding rate must match the dryer’s thermal capacity to prevent overloading or underutilization. Advanced configurations incorporate variable-speed drives and load cells to maintain consistent feed rates regardless of material variations.

Material Preparation Requirements

Wet materials require specific preparation before entering the paddle dryer. Screening removes oversized particles that could damage paddle elements or cause uneven heating. Conditioning agents may be added to improve material flow characteristics and enhance heat transfer efficiency.

The moisture content of incoming material significantly impacts paddle dryer configuration requirements. Materials exceeding 85% moisture content typically require pre-treatment through mechanical dewatering to optimize thermal efficiency. This pre-treatment reduces the thermal load on the paddle dryer and improves overall system economics.

Advanced Paddle Dryer Design Configurations

Modern paddle dryer configuration incorporates sophisticated heat transfer optimization through carefully engineered paddle arrangements and heating circuits. The paddle design directly influences mixing efficiency, residence time distribution, and heat transfer coefficients throughout the drying chamber.

Vacuum dryer configurations operate under reduced pressure to lower boiling points and enable drying at lower temperatures. This configuration proves particularly valuable for heat-sensitive materials or when minimizing thermal degradation is critical. Vacuum operation also enhances solvent recovery in industrial applications.

The standard dryer configuration operates at atmospheric pressure with optimized paddle spacing and heating surface area. This configuration offers the best balance of capital cost, operating efficiency, and maintenance simplicity for most municipal and industrial sludge applications.

Heat Transfer Optimization Strategies

Effective heat transfer requires proper configuration of heating circuits within the paddle elements. Counter-current flow patterns maximize temperature differentials and improve thermal efficiency. The heating medium temperature must be carefully controlled to prevent material scorching while maintaining adequate driving force for moisture removal.

Heat exchanger integration allows energy recovery from exhaust gases and water vapor, improving overall system efficiency by 15-25%. Proper configuration of these heat recovery systems requires careful attention to corrosion resistance and cleaning accessibility.

Pollution Control System Integration

Environmental compliance demands comprehensive pollution control system configuration as an integral part of paddle dryer design. The three-stage approach combines cyclone separation, wet scrubbing, and bag filtration to achieve emission levels well below regulatory requirements.

Cyclone separators remove larger particulates through centrifugal force, providing the first stage of emission control. Proper sizing and configuration of cyclone systems ensures efficient particle removal while minimizing pressure drop and energy consumption.

Scrubber systems provide secondary treatment for acid gases and fine particulates. The configuration must account for scrubbing liquid circulation rates, pH control, and waste liquid treatment. Proper scrubber design prevents scaling and corrosion while maintaining consistent removal efficiency.

Bag Filter Configuration

Bag filter systems provide final polishing of exhaust gases before atmospheric release. Filter media selection depends on operating temperature, chemical compatibility, and particulate characteristics. PTFE membrane filters offer superior performance for high-temperature applications with challenging chemical environments.

Automated cleaning systems maintain filter performance through scheduled pulse-jet cleaning cycles. The configuration must balance cleaning frequency with filter life to optimize operating costs. Differential pressure monitoring provides real-time performance feedback and predictive maintenance capabilities.

Solvent Management and Recovery Systems

Industrial applications often require solvent recovery to comply with environmental regulations and reduce operating costs. Solvent management system configuration integrates distillation, condensation, and separation equipment to recover valuable solvents from the drying process.

Condenser systems cool water vapor and solvent vapors below their dew points to achieve liquid recovery. The configuration must account for varying vapor compositions and flow rates throughout the drying cycle. Multi-stage condensation provides higher recovery efficiency than single-stage systems.

Product Handling and Packaging

The final stage of paddle dryer configuration addresses dried product handling and packaging. Screw conveyor systems transport dried material from the dryer to storage or packaging equipment. Variable-speed drives allow product flow rate matching with downstream equipment requirements.

Automated bagging systems provide consistent packaging with minimal labor requirements. The configuration must account for product bulk density changes during drying and varying moisture contents in the final product. Load cells and automatic bag changes ensure continuous operation during extended production runs.

Energy Efficiency and Process Optimization

Maximizing energy efficiency requires comprehensive optimization of all paddle dryer configuration elements. Heat integration, waste heat recovery, and process control automation work together to minimize energy consumption per unit of water removed.

Process control system configuration enables real-time optimization based on material characteristics, environmental conditions, and production requirements. Advanced control strategies maintain optimal operating conditions automatically, reducing operator workload and improving consistency.

Temperature profiling throughout the dryer length ensures optimal heat utilization and prevents overheating. Multi-zone temperature control allows fine-tuning of the drying profile to match specific material requirements and quality specifications.

Maintenance and Reliability Considerations

Proper paddle dryer configuration includes accessibility features for routine maintenance and cleaning. Removable access panels, inspection ports, and cleaning connections reduce maintenance time and improve safety. Predictive maintenance systems monitor bearing temperatures, vibration levels, and power consumption to identify potential issues before failure occurs.

Spare parts inventory management becomes critical for maintaining high availability. The configuration should specify standardized components where possible to reduce inventory requirements and simplify maintenance procedures.

Cost-Benefit Analysis and ROI Calculations

Understanding the economic impact of different paddle dryer configurations enables informed decision-making during system design. Initial capital costs must be balanced against operating expenses, maintenance requirements, and expected service life to determine the optimal configuration for specific applications.

Energy costs typically represent 60-70% of total operating expenses for thermal drying systems. Configuration choices that improve thermal efficiency provide the highest return on investment over the system lifecycle. Heat recovery systems, insulation upgrades, and process control improvements offer measurable economic benefits.

Performance Metrics and Benchmarking

Key performance indicators for paddle dryer configuration include specific energy consumption, moisture removal efficiency, and product quality consistency. Benchmarking against industry standards helps identify optimization opportunities and validate system performance.

Typical specific energy consumption ranges from 1,000-1,500 kWh per ton of water removed, depending on material characteristics and system configuration. Advanced configurations with heat recovery can achieve consumption levels below 800 kWh per ton through effective energy integration.

Frequently Asked Questions

- What factors determine the optimal paddle dryer configuration?

Material characteristics, moisture content, throughput requirements, and environmental regulations are the primary factors influencing paddle dryer configuration. Each application requires specific evaluation to determine the most suitable design approach. - How does vacuum operation affect paddle dryer configuration?

Vacuum operation requires additional equipment including vacuum pumps, condensers, and vapor recovery systems. This configuration enables lower-temperature drying but increases capital and operating costs compared to atmospheric pressure systems. - What maintenance requirements apply to paddle dryer systems?

Regular maintenance includes paddle element inspection, bearing lubrication, heat exchanger cleaning, and control system calibration. Proper configuration design facilitates these maintenance activities through accessible component arrangement and standardized replacement parts. - How do emission control requirements impact configuration choices?

Environmental regulations mandate specific pollution control equipment integration. The configuration must accommodate cyclones, scrubbers, and bag filters while maintaining process efficiency and meeting emission limits for particulates and acid gases. - What energy recovery options improve paddle dryer efficiency?

Heat exchanger integration, vapor condensation, and waste heat recovery systems can improve overall efficiency by 15-25%. The configuration must balance energy savings against additional capital costs and system complexity.

Conclusion

Mastering paddle dryer configuration represents a critical success factor for industrial sludge treatment operations. The systematic integration of fuel resources, heating systems, feeding mechanisms, and pollution control equipment creates a comprehensive solution that transforms waste sludge into valuable dried products while meeting environmental requirements.

The eight-system approach outlined in this guide provides the framework for optimizing paddle dryer performance across diverse applications. From municipal wastewater treatment to specialized industrial processes, proper configuration ensures maximum efficiency, minimal environmental impact, and sustainable long-term operation.

Successful paddle dryer configuration requires careful attention to material characteristics, energy integration, and maintenance accessibility. The investment in proper system design delivers measurable returns through reduced operating costs, improved product quality, and enhanced environmental compliance.

Take action on your sludge treatment challenges by evaluating your current paddle dryer configuration against these optimization principles. Contact our technical team for a comprehensive system assessment and discover how advanced configuration strategies can transform your operation’s performance and profitability.