Industrial facilities worldwide generate over 45 million tons of sludge annually, creating a massive environmental and economic challenge that demands innovative treatment solutions. Modern sludge treatment facilities are turning to advanced conductive sludge dryers that use paddle dryer technology to transform this problematic waste into valuable resources while dramatically reducing disposal costs by up to 80%.

Conductive sludge dryers represent a revolutionary approach to sludge treatment, utilizing indirect heating through paddle dryer mechanisms to achieve superior dewatering performance. This technology addresses the critical need for sustainable waste management while providing facilities with cost-effective solutions that meet increasingly stringent environmental regulations.

Table of contents

- Understanding Sludge Treatment Fundamentals

- Conductive Sludge Dryers: Revolutionary Technology Overview

- Paddle Dryer Technology: The Heart of Conductive Systems

- How Conductive Sludge Dryers Use Paddle Dryer Systems

- Thermal Drying System Components and Integration

- Indirect Heating Dryer Applications and Benefits

- Sludge Dewatering and Volume Reduction Performance

- Advanced Process Optimization Strategies

- Environmental Impact and Sustainability Considerations

- Future Developments and Technology Trends

- Frequently Asked Questions

- Conclusion

Understanding Sludge Treatment Fundamentals

Sludge treatment encompasses the comprehensive processing of semi-solid waste materials generated from wastewater treatment plants, industrial processes, and municipal water systems. The primary objective involves reducing sludge volume, eliminating pathogens, and creating stable end products suitable for disposal or beneficial reuse.

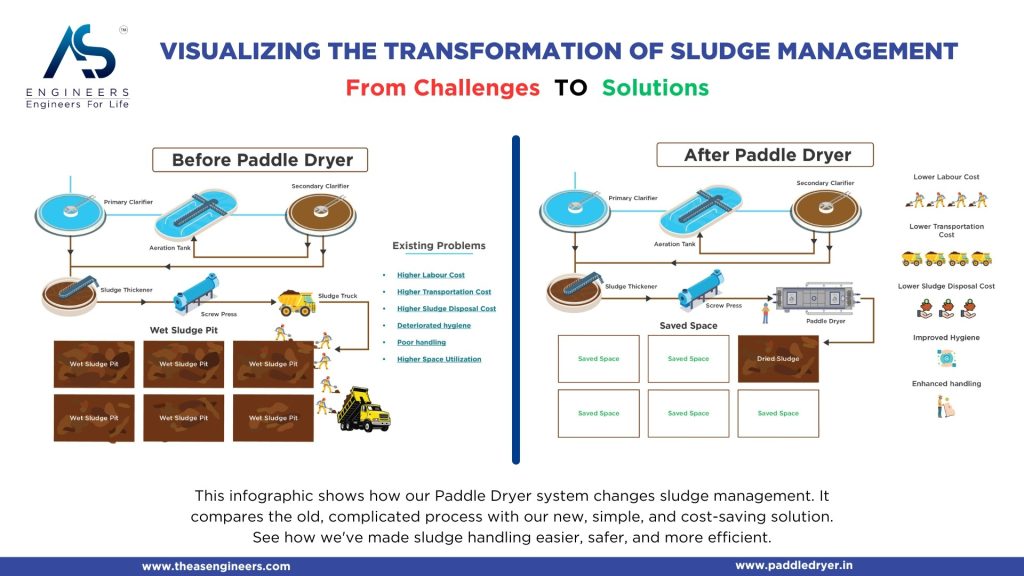

Traditional sludge treatment methods face significant limitations including high energy consumption, lengthy processing times, and inconsistent moisture removal. These challenges have driven the development of advanced thermal drying technologies, particularly conductive drying systems that offer superior performance characteristics.

The composition of sludge varies dramatically depending on its source, containing organic matter, inorganic solids, water, and potentially hazardous substances. Municipal sludge typically contains 95-99% water content, while industrial sludge characteristics depend on specific manufacturing processes and treatment protocols employed.

Key Challenges in Conventional Sludge Treatment

Conventional sludge treatment faces multiple operational hurdles that impact both efficiency and cost-effectiveness. High moisture content creates transportation difficulties, increases disposal costs, and limits beneficial reuse opportunities. Traditional dewatering methods like belt presses and centrifuges achieve only 15-25% dry solids content, leaving substantial volumes requiring further treatment.

Energy consumption represents another critical challenge, with conventional thermal drying systems requiring extensive heat input to achieve target moisture levels. Direct heating methods create additional complications including odor generation, emissions concerns, and potential fire hazards when processing volatile organic compounds.

Process reliability issues plague many traditional systems, with frequent maintenance requirements, inconsistent output quality, and sensitivity to sludge composition variations. These factors contribute to higher operational costs and reduced system availability for critical sludge treatment operations.

Conductive Sludge Dryers: Revolutionary Technology Overview

Conductive sludge dryers utilize indirect heating principles to achieve superior drying performance while minimizing environmental impact and operational complexity. These systems transfer heat through heated surfaces rather than direct contact with hot gases, providing precise temperature control and consistent moisture removal across diverse sludge types.

The technology operates on the principle of conductive heat transfer, where thermal energy passes through heated metal surfaces into the sludge material. This approach eliminates the need for large volumes of heated air, reducing energy consumption and simplifying downstream gas treatment requirements.

Modern conductive drying systems achieve remarkable efficiency improvements over conventional methods, reducing energy consumption by 30-50% while achieving higher dry solids content. The controlled heating environment prevents thermal degradation of organic compounds and maintains product quality for beneficial reuse applications.

Advantages of Conductive Drying Technology

Conductive sludge dryers offer multiple operational advantages that make them ideal for modern waste treatment facilities. Energy efficiency stands as the primary benefit, with heat recovery systems capturing and reusing thermal energy throughout the drying process. This closed-loop approach minimizes external energy requirements and reduces operational costs significantly.

Environmental benefits include reduced emissions, minimal odor generation, and elimination of combustion-related air pollutants. The indirect heating process prevents oxidation of organic compounds, preserving valuable nutrients in biosolids applications while meeting strict environmental discharge standards.

Operational flexibility allows conductive systems to process various sludge types without significant modifications, accommodating seasonal variations and different waste streams within the same facility. Automated control systems maintain optimal operating conditions regardless of feed material characteristics.

Paddle Dryer Technology: The Heart of Conductive Systems

Paddle dryer technology forms the core component of advanced conductive sludge drying systems, utilizing rotating heated paddles to provide both heat transfer and material mixing functions. These specialized heat exchangers feature hollow paddles filled with heating medium, typically steam or thermal oil, creating extensive heat transfer surface area within compact equipment footprints.

The paddle design incorporates multiple engineering considerations including heat transfer coefficient optimization, material flow patterns, and residence time control. Modern paddle dryers achieve heat transfer coefficients exceeding 150 W/m²K, significantly higher than conventional drying technologies.

Material movement within paddle dryers follows carefully engineered patterns that ensure uniform heat exposure while preventing material buildup or hot spots. The self-cleaning action of rotating paddles eliminates the need for manual cleaning interventions and maintains consistent performance over extended operating periods.

Paddle Dryer Design Features

Contemporary paddle dryer designs incorporate advanced features that maximize heat transfer efficiency while ensuring reliable operation. Double-shaft configurations provide redundant mixing action and increased heat transfer surface area, enabling higher throughput rates within smaller equipment footprints.

Specialized paddle geometries optimize material movement patterns, creating controlled mixing zones that enhance heat and mass transfer rates. Variable pitch paddle arrangements allow fine-tuning of residence time distribution, ensuring complete moisture removal while preventing over-drying or thermal damage.

Heat medium distribution systems within paddle dryers utilize sophisticated flow control mechanisms to maintain uniform temperature profiles across all heating surfaces. These systems incorporate temperature monitoring and automatic control features that respond to process variations and maintain optimal drying conditions.

How Conductive Sludge Dryers Use Paddle Dryer Systems

The integration of paddle dryer technology into conductive sludge drying systems creates highly efficient thermal processing capabilities that transform wet sludge into dry, stable solids. The process begins with sludge feeding systems that deliver material at controlled rates to the paddle dryer inlet, ensuring consistent material distribution across the heated surfaces.

Within the paddle dryer, wet sludge contacts heated paddle surfaces where conductive heat transfer initiates rapid moisture evaporation. The rotating paddles continuously move material through the drying chamber, exposing fresh surfaces to heated elements while preventing material adhesion or fouling.

Vapor generation occurs throughout the drying process as moisture transitions from liquid to gaseous state. The paddle dryer design incorporates vapor space above the material bed, allowing efficient vapor removal without material entrainment. This controlled vapor management prevents operational issues and maintains consistent drying performance.

Process Control and Optimization

Advanced process control systems monitor multiple parameters throughout the sludge drying operation, including inlet temperature, outlet temperature, material moisture content, and residence time. These control loops automatically adjust operating conditions to maintain target dry solids content regardless of feed material variations.

Temperature profiling along the paddle dryer length allows optimization of heat input distribution, concentrating thermal energy where moisture removal rates are highest. This approach minimizes energy consumption while ensuring complete moisture removal throughout the material volume.

Residence time control mechanisms adjust material flow rates and paddle rotation speeds to achieve desired moisture targets. Longer residence times accommodate higher moisture content feeds, while shorter cycles increase throughput for partially dewatered materials.

Thermal Drying System Components and Integration

Complete conductive sludge drying systems incorporate multiple integrated components that work together to achieve optimal performance. Feed preparation systems condition incoming sludge to optimal consistency and temperature, often incorporating pre-heating to improve drying efficiency and reduce thermal shock.

Heat supply systems provide thermal energy to the paddle dryer heating medium, utilizing various heat sources including steam boilers, thermal oil heaters, or waste heat recovery systems. Heat exchangers optimize energy transfer efficiency and incorporate safety systems to prevent overheating or thermal runaway conditions.

Vapor handling systems manage moisture-laden gases generated during the drying process, incorporating condensation, odor control, and emission treatment as required by environmental regulations. These systems often include heat recovery components that capture thermal energy from hot vapors for process reuse.

Auxiliary Equipment and Safety Systems

Material handling equipment facilitates sludge transport throughout the drying system, including feed pumps, conveyor systems, and discharge mechanisms. These components require specialized design considerations to handle the varying consistency of sludge materials from wet paste to dry granules.

Safety systems protect personnel and equipment from operational hazards including high temperatures, pressure conditions, and potentially hazardous vapor emissions. Emergency shutdown systems, fire suppression equipment, and atmospheric monitoring ensure safe operation under all conditions.

Quality control systems monitor output material characteristics including moisture content, particle size distribution, and pathogen reduction effectiveness. These monitoring capabilities ensure consistent product quality and regulatory compliance throughout system operation.

Indirect Heating Dryer Applications and Benefits

Indirect heating dryer technology finds applications across diverse industries requiring efficient moisture removal from challenging materials. Municipal wastewater treatment facilities utilize these systems to process biosolids, achieving regulatory pathogen reduction requirements while creating valuable soil amendment products.

Industrial applications include pharmaceutical sludge treatment, chemical processing waste management, and food processing byproduct recovery. Each application benefits from the precise temperature control and gentle heating characteristics of indirect drying technology.

The scalability of indirect heating systems accommodates facilities ranging from small industrial plants to large municipal treatment complexes. Modular designs allow capacity expansion without complete system replacement, providing investment flexibility as treatment requirements evolve.

Economic Benefits and Return on Investment

Conductive sludge dryers using paddle dryer technology deliver substantial economic benefits through reduced disposal costs, energy savings, and potential revenue generation from dried products. Volume reduction of 70-80% dramatically decreases transportation and landfill disposal expenses.

Energy efficiency improvements translate to lower utility costs, with heat recovery systems capturing up to 60% of input thermal energy for process reuse. These savings compound over system lifetime, often achieving payback periods of 3-5 years depending on local disposal costs and energy prices.

Beneficial reuse opportunities for dried sludge products create additional revenue streams, with high-quality biosolids commanding premium prices in agricultural and landscaping markets. Product consistency and pathogen reduction achieved through controlled thermal processing expand market acceptance and pricing potential.

Sludge Dewatering and Volume Reduction Performance

Advanced conductive drying systems achieve remarkable volume reduction performance, typically reducing sludge volumes by 75-85% compared to conventional mechanical dewatering methods. This dramatic volume reduction translates directly to proportional decreases in transportation costs, disposal fees, and storage requirements.

The technology achieves final dry solids content of 85-95%, compared to 20-25% from mechanical dewatering alone. This performance level enables economical transportation over longer distances and opens opportunities for beneficial reuse applications requiring low moisture content.

Consistent performance across varying sludge types and seasonal conditions provides operational predictability that facilitates planning and budgeting. Unlike weather-dependent drying methods, conductive systems maintain performance regardless of ambient conditions.

Pathogen Reduction and Regulatory Compliance

Thermal treatment within conductive dryers achieves effective pathogen reduction, meeting EPA Class A biosolids requirements for unrestricted beneficial use. Time-temperature relationships within paddle dryers ensure complete pathogen destruction while preserving beneficial nutrients.

The controlled heating environment prevents thermal damage to organic matter, maintaining fertilizer value in treated biosolids. This balanced approach satisfies both regulatory pathogen reduction requirements and market demands for high-quality soil amendment products.

Documentation and monitoring systems provide regulatory compliance verification, with continuous temperature and residence time recording demonstrating treatment effectiveness. These systems simplify permit compliance and regulatory reporting requirements.

Advanced Process Optimization Strategies

Modern conductive sludge drying systems incorporate sophisticated optimization strategies that maximize efficiency while minimizing operational costs. Predictive control algorithms analyze historical performance data to anticipate optimal operating conditions based on feed material characteristics and environmental factors.

Heat integration systems capture waste heat from various process streams, including vapor condensation, hot product cooling, and auxiliary equipment operation. These heat recovery systems can reduce external energy requirements by 40-60%, significantly improving overall system efficiency.

Variable operating parameter control allows real-time adjustment of processing conditions to accommodate changing sludge characteristics or throughput requirements. This flexibility ensures consistent performance while maximizing equipment utilization rates.

Maintenance and Operational Reliability

Conductive paddle dryer systems demonstrate exceptional operational reliability with properly designed maintenance programs. The robust construction and minimal moving parts reduce wear component replacement frequency compared to conventional drying technologies.

Predictive maintenance systems monitor equipment condition through vibration analysis, temperature profiling, and performance trending. These systems identify potential issues before failures occur, minimizing unplanned downtime and maintenance costs.

Self-cleaning paddle designs eliminate buildup-related operational issues that plague other drying technologies. The continuous scraping action maintains clean heat transfer surfaces and prevents fouling that reduces thermal efficiency.

Environmental Impact and Sustainability Considerations

Conductive sludge drying technology supports environmental sustainability through multiple pathways including waste volume reduction, energy efficiency improvements, and beneficial reuse facilitation. The technology transforms problematic waste streams into valuable resources while minimizing environmental impact.

Emission reduction benefits include lower greenhouse gas emissions through reduced transportation requirements and energy consumption. The elimination of direct combustion processes reduces NOx, SOx, and particulate emissions compared to conventional thermal drying methods.

Water resource protection occurs through effective sludge treatment that prevents contamination from inadequately treated waste materials. The technology supports circular economy principles by converting waste into beneficial products.

Carbon Footprint Reduction

Lifecycle carbon footprint analysis demonstrates significant advantages for conductive drying systems compared to conventional sludge management approaches. Reduced transportation emissions from volume reduction and energy efficiency improvements contribute to lower overall carbon intensity.

The potential for renewable energy integration enhances sustainability benefits, with systems designed to utilize biogas, solar thermal, or other renewable heat sources. These integrations can achieve carbon-neutral or carbon-negative operations depending on local energy resources.

Product substitution benefits occur when dried sludge replaces synthetic fertilizers or soil amendments, avoiding carbon emissions associated with manufacturing these products from virgin materials.

Future Developments and Technology Trends

Emerging technologies promise further improvements in conductive sludge drying performance and cost-effectiveness. Advanced materials development focuses on enhanced heat transfer surfaces and corrosion-resistant components that extend equipment life and improve thermal efficiency.

Process intensification research explores methods to increase drying rates while reducing equipment size and energy consumption. These developments include novel paddle geometries, enhanced heat transfer fluids, and innovative vapor management systems.

Digitalization trends incorporate artificial intelligence and machine learning capabilities into process control systems, enabling autonomous optimization and predictive performance management. These smart systems continuously improve operation based on accumulated experience and changing conditions.

Integration with Circular Economy Principles

Future sludge treatment systems will increasingly integrate with circular economy frameworks, maximizing resource recovery while minimizing waste generation. Advanced processing techniques will enable recovery of specific valuable components including phosphorus, nitrogen, and organic matter fractions.

Biorefinery concepts envision sludge treatment facilities as resource recovery centers that produce multiple valuable products including biofuels, biochemicals, and soil amendments. Conductive drying technology provides the thermal processing foundation for these integrated systems.

Regional resource management networks will coordinate sludge treatment with other waste streams and beneficial use applications, optimizing transportation and maximizing value recovery across entire geographic areas.

Frequently Asked Questions

- How do conductive sludge dryers differ from conventional thermal dryers?

Conductive sludge dryers use indirect heating through heated surfaces rather than direct hot gas contact, providing better temperature control, higher energy efficiency, and reduced emissions while achieving superior moisture removal performance. - What maintenance requirements do paddle dryer systems have?

Paddle dryer systems require routine inspections of heating medium systems, paddle wear monitoring, and bearing lubrication, but self-cleaning paddle action eliminates most fouling issues, resulting in lower maintenance compared to conventional dryers. - Can conductive dryers handle different types of sludge materials?

Yes, conductive paddle dryers accommodate various sludge types including municipal biosolids, industrial waste, and food processing residues, with adjustable operating parameters to optimize performance for specific material characteristics. - What energy efficiency improvements can facilities expect?

Facilities typically achieve 30-50% energy consumption reduction compared to conventional thermal drying, with heat recovery systems capturing up to 60% of input thermal energy for process reuse applications. - How does the technology ensure regulatory compliance for biosolids?

Time-temperature monitoring systems document pathogen destruction effectiveness, with typical operations achieving EPA Class A biosolids requirements through controlled thermal processing that ensures complete pathogen elimination while preserving beneficial nutrients.

Conclusion

Conductive sludge dryers utilizing paddle dryer technology represent the future of efficient, sustainable sludge treatment for modern facilities. This advanced thermal processing approach delivers superior performance through energy-efficient indirect heating, achieving remarkable volume reduction while creating valuable end products that support circular economy principles.

The integration of paddle dryer systems within conductive drying processes provides facilities with reliable, cost-effective solutions that address both environmental compliance requirements and economic optimization objectives. As regulatory standards continue evolving and disposal costs increase, this technology offers proven pathways to sustainable sludge management.

Investing in conductive sludge drying technology positions facilities for long-term success through reduced operational costs, improved environmental performance, and enhanced resource recovery capabilities. The combination of proven technology, economic benefits, and environmental advantages makes conductive paddle dryer systems the optimal choice for forward-thinking waste treatment operations.

Ready to transform your sludge treatment operations? Contact our technical specialists to discuss how conductive paddle dryer technology can optimize your facility’s performance and profitability.