Industrial facilities processing over 50 million gallons of wastewater daily face a critical challenge: efficiently dewatering sludge while minimizing operational costs and environmental impact. The wrong sludge paddle dryer selection can cost facilities upwards of $500,000 annually in energy waste, maintenance downtime, and regulatory compliance issues. Choosing the right sludge paddle dryer transforms your waste management operation from a costly burden into an efficient, profitable system that meets strict environmental standards while maximizing resource recovery.

This comprehensive guide reveals the exact framework industry experts use to select sludge paddle dryers that deliver optimal performance, reduce operational expenses, and ensure long-term reliability. You’ll discover proven evaluation criteria, avoid costly selection mistakes, and implement a systematic approach that guarantees the best return on your equipment investment.

Table of contents

- Understanding Sludge Paddle Dryer Technology and Applications

- Critical Factors for Sludge Paddle Dryer Selection

- Equipment Specifications and Technical Requirements

- Installation and Maintenance Considerations

- Cost Analysis and Return on Investment

- Vendor Selection and Procurement Strategy

- Frequently Asked Questions

- Conclusion

Understanding Sludge Paddle Dryer Technology and Applications

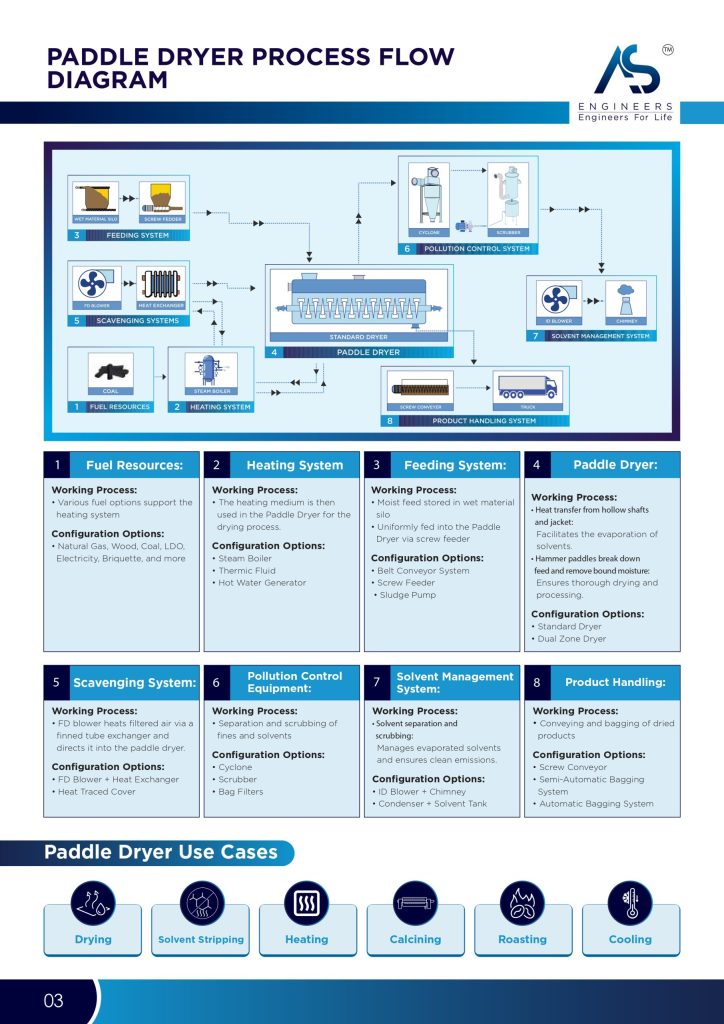

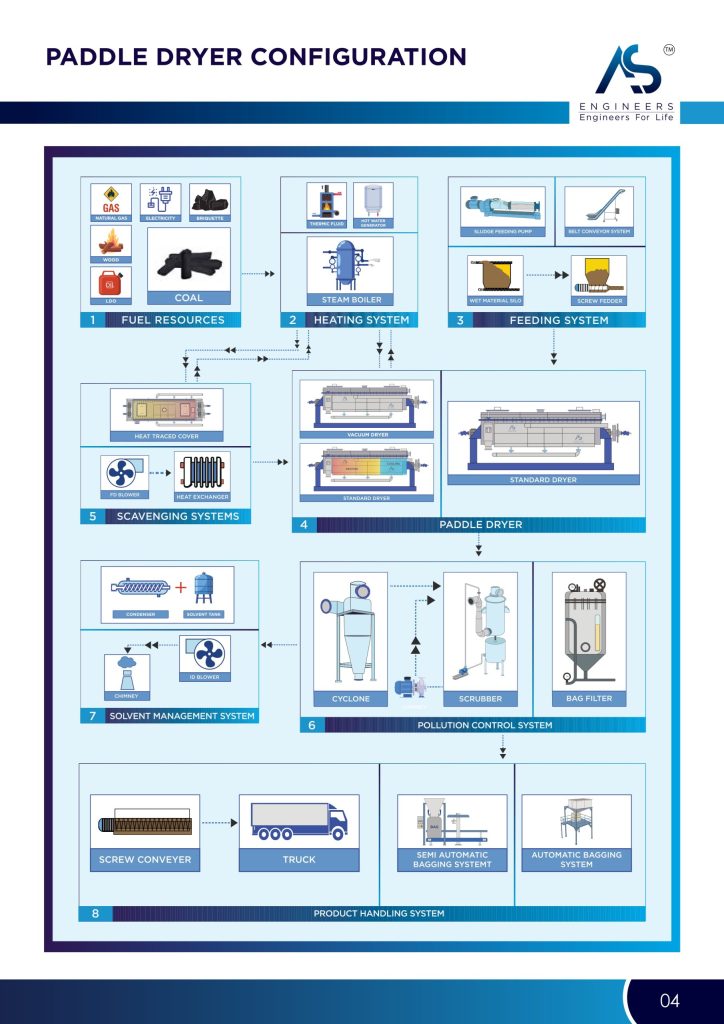

Sludge paddle dryers represent advanced indirect heating technology specifically engineered for processing high-moisture waste materials in industrial and municipal applications. These thermal drying systems utilize heated paddles rotating within an enclosed chamber to transfer heat efficiently while continuously mixing and conveying sludge through the drying process.

The fundamental operating principle involves steam or thermal oil circulation through hollow paddle shafts and chamber walls, creating controlled heat transfer without direct contact between heating medium and processed material. This indirect heating method prevents contamination while enabling precise temperature control essential for different sludge types and desired moisture reduction levels.

Modern paddle dryer systems achieve moisture reduction from typical inlet levels of 75-85% down to final moisture contents of 10-40%, depending on application requirements and downstream processing needs. The continuous mixing action ensures uniform heat distribution and prevents hot spots that could damage temperature-sensitive materials or create operational inefficiencies.

Industrial applications span diverse sectors including municipal wastewater treatment plants, pharmaceutical manufacturing, food processing facilities, chemical production sites, and pulp and paper operations. Each application presents unique challenges regarding sludge composition, throughput requirements, environmental regulations, and final product specifications that directly influence equipment selection criteria.

Critical Factors for Sludge Paddle Dryer Selection

Sludge Characteristics Analysis

The foundation of effective sludge paddle dryer selection begins with comprehensive analysis of your specific sludge characteristics. Material properties directly determine equipment sizing, configuration requirements, and operational parameters essential for optimal performance.

Moisture content represents the primary parameter influencing dryer selection and energy requirements. Higher inlet moisture levels demand increased heat transfer surface area and longer residence times to achieve target dryness levels. Calculate your facility’s typical moisture range and seasonal variations to ensure equipment capacity matches actual processing demands.

Sludge composition affects heat transfer efficiency, material handling characteristics, and equipment wear patterns. Organic content influences heating requirements and potential for thermal decomposition, while inorganic components impact abrasiveness and corrosion considerations. Fibrous materials require special attention to prevent bridging and ensure consistent material flow.

Particle size distribution determines mixing effectiveness and heat transfer rates within the paddle dryer chamber. Fine particles may create dust handling challenges, while larger particles could affect residence time uniformity. Understanding your sludge’s physical properties enables proper equipment configuration and auxiliary system selection.

Chemical composition analysis reveals potential corrosion concerns, emission control requirements, and compatibility with heating media. Aggressive chemicals necessitate specialized materials of construction, while volatile compounds require enhanced vapor handling systems and safety considerations.

Capacity and Throughput Requirements

Accurate capacity determination ensures your sludge paddle dryer investment delivers required performance without oversizing penalties or operational limitations. Start by calculating your facility’s current and projected sludge production volumes, including peak flow conditions and seasonal variations that impact processing demands.

Daily throughput requirements establish baseline equipment sizing, but consider hourly processing rates for operational flexibility. Many facilities benefit from equipment sized for 150-200% of average production to accommodate maintenance schedules, process upsets, and future expansion plans without creating operational bottlenecks.

Moisture removal capacity calculations require balancing inlet and outlet moisture targets with available energy input and heat transfer surface area. Higher moisture reduction rates demand proportionally increased energy consumption and equipment sizing, directly impacting capital and operational costs.

Residence time requirements vary significantly based on sludge characteristics and desired final moisture content. Typical paddle dryer residence times range from 30 minutes to 4 hours, with longer times needed for difficult-to-dry materials or very low final moisture targets. Proper residence time calculation prevents incomplete drying or unnecessary energy consumption.

Material handling considerations include feed system compatibility, discharge method requirements, and integration with upstream dewatering equipment and downstream processing systems. Coordinated system design ensures smooth operation and prevents costly bottlenecks that reduce overall facility efficiency.

Energy Efficiency and Operational Costs

Energy consumption represents the largest operational expense for sludge paddle dryer systems, making efficiency optimization crucial for long-term economic viability. Modern paddle dryers achieve thermal efficiencies of 85-95% through advanced heat recovery systems and optimized heat transfer design.

Heat source selection significantly impacts operational costs and environmental performance. Steam heating offers excellent temperature control and uniform heat distribution but requires on-site boiler capacity and steam distribution infrastructure. Thermal oil systems provide higher operating temperatures and improved heat transfer coefficients but require specialized handling and safety systems.

Heat recovery integration captures valuable thermal energy from exhaust vapors and discharged dried material, reducing overall energy consumption by 20-40% in properly designed systems. Consider condensate recovery, vapor recompression, and sensible heat exchangers when evaluating different equipment options and configurations.

Auxiliary power requirements include drive motors, fans, pumps, and control systems that contribute to total energy consumption. Energy-efficient motor selection, variable frequency drives, and optimized control strategies reduce parasitic power consumption while improving operational flexibility and process control.

Life cycle cost analysis compares initial capital investment with projected operational expenses over expected equipment life to identify the most economical solution. Include energy costs, maintenance expenses, replacement parts, labor requirements, and potential productivity improvements when evaluating different equipment options.

Equipment Specifications and Technical Requirements

Heat Transfer Design and Performance

Heat transfer efficiency directly determines sludge paddle dryer performance, energy consumption, and operational reliability. Effective heat transfer design maximizes thermal contact between heating medium and processed material while maintaining consistent temperature profiles throughout the drying chamber.

Paddle configuration significantly influences heat transfer rates and mixing effectiveness. Hollow paddle designs provide maximum heat transfer surface area while creating turbulent mixing that enhances mass and heat transfer. Paddle spacing, angle, and rotational speed optimization ensures uniform material exposure without excessive power consumption or mechanical wear.

Chamber design affects residence time distribution and heat transfer uniformity across the entire drying zone. Proper length-to-diameter ratios prevent short-circuiting while maintaining adequate mixing intensity. Internal baffles and flow control devices optimize material flow patterns and heat exposure time distribution.

Heat transfer surface area calculations must account for sludge properties, desired moisture reduction, and available temperature differential between heating medium and processed material. Insufficient surface area results in incomplete drying or excessive residence times, while oversized equipment increases unnecessary capital costs and energy consumption.

Temperature control systems maintain optimal processing conditions while preventing overheating that could damage temperature-sensitive materials or create safety hazards. Advanced control strategies monitor multiple temperature points and adjust heating medium flow rates to maintain consistent performance despite feed variations.

Materials of Construction and Durability

Proper materials selection ensures long-term reliability and minimizes maintenance costs in demanding sludge processing applications. Corrosive sludge components, abrasive particles, and thermal cycling create challenging operating conditions requiring specialized materials and protective coatings.

Chamber construction typically utilizes carbon steel with protective coatings for standard applications, while stainless steel grades provide enhanced corrosion resistance for aggressive sludge types. Specialized alloys may be required for extreme conditions involving high chloride content, acidic materials, or elevated temperature operations.

Paddle materials must withstand continuous thermal cycling, mechanical stress, and abrasive wear while maintaining heat transfer efficiency. Cast iron provides excellent thermal conductivity and wear resistance for standard applications, while stainless steel offers superior corrosion resistance for challenging sludge compositions.

Seal systems prevent vapor leakage and contamination while accommodating thermal expansion and mechanical movement. High-temperature seals, expansion joints, and purge systems ensure reliable operation while minimizing maintenance requirements and environmental emissions.

Protective coatings extend equipment life in corrosive environments while maintaining heat transfer performance. Ceramic coatings, polymer linings, and specialized surface treatments provide enhanced durability without significantly impacting thermal conductivity or operational efficiency.

Control Systems and Automation Features

Modern sludge paddle dryer systems incorporate advanced control technologies that optimize performance, reduce operational labor, and ensure consistent product quality. Comprehensive automation systems monitor critical parameters and automatically adjust operating conditions to maintain optimal performance despite feed variations.

Process control strategies regulate temperature, residence time, and mixing intensity based on real-time monitoring of sludge characteristics and drying performance. Adaptive control algorithms learn from operating experience and automatically optimize settings for maximum efficiency and product quality consistency.

Safety systems include emergency shutdown capabilities, temperature monitoring, pressure relief systems, and vapor handling controls that protect equipment and personnel while ensuring regulatory compliance. Integrated safety interlocks prevent unsafe operating conditions and provide comprehensive documentation for regulatory reporting.

Data acquisition systems collect and analyze operational data to identify optimization opportunities, predict maintenance requirements, and document regulatory compliance. Historical trending capabilities enable performance comparison and continuous improvement initiatives that maximize equipment effectiveness.

Remote monitoring capabilities allow expert support and troubleshooting from off-site locations, reducing response times for operational issues and enabling predictive maintenance programs that minimize unplanned downtime and maximize equipment availability.

Installation and Maintenance Considerations

Site Requirements and Infrastructure Needs

Successful sludge paddle dryer installation requires careful evaluation of site conditions, utility availability, and infrastructure requirements that support reliable long-term operation. Inadequate site preparation creates operational limitations and increases total project costs through retrofit requirements and performance compromises.

Foundation requirements depend on equipment size, operating loads, and soil conditions at your installation site. Proper foundation design prevents vibration transmission, accommodates thermal expansion, and provides stable support for rotating equipment and associated piping systems.

Utility requirements include electrical power for motors and controls, steam or thermal oil for heating, cooling water for condensers, and compressed air for instrumentation and controls. Verify existing utility capacity and upgrade requirements during early project planning to avoid costly surprises during installation.

Building and structural considerations include adequate clearance for equipment installation and maintenance access, proper ventilation for vapor handling, and structural support for equipment loads and piping systems. Indoor installations require climate control and fire protection systems appropriate for the processing environment.

Environmental compliance requirements vary by location and application but typically include air emission controls, noise abatement measures, and proper waste handling procedures. Early consultation with regulatory authorities ensures permit requirements are properly addressed during system design and installation.

Preventive Maintenance Programs

Comprehensive preventive maintenance programs maximize sludge dryer reliability, extend equipment life, and minimize unplanned downtime that disrupts facility operations. Well-designed maintenance programs balance inspection frequency with operational requirements to optimize equipment availability and maintenance costs.

Mechanical component maintenance includes bearing lubrication, seal replacement, drive system service, and wear part inspection and replacement. Regular maintenance schedules based on operating hours and manufacturer recommendations prevent premature failures and ensure optimal performance throughout equipment life.

Heat transfer system maintenance focuses on cleaning heat transfer surfaces, checking thermal oil quality, and inspecting heating system components for corrosion or fouling that reduces efficiency. Regular cleaning schedules maintain optimal heat transfer rates and prevent performance degradation over time.

Control system maintenance includes calibration of instruments, software updates, backup procedures, and replacement of consumable components. Properly maintained control systems ensure accurate process monitoring and reliable automated operation that maximizes efficiency and product quality.

Documentation requirements include maintenance records, performance monitoring data, and regulatory compliance documentation. Comprehensive record keeping supports warranty claims, regulatory reporting, and continuous improvement initiatives that optimize long-term equipment performance.

Cost Analysis and Return on Investment

Capital Investment Evaluation

Sludge paddle dryer capital costs vary significantly based on equipment size, materials of construction, automation level, and auxiliary system requirements. Understanding cost components and their relative importance enables effective budget planning and vendor comparison during equipment selection.

Equipment costs typically represent 60-70% of total project investment, with balance comprising installation, engineering, auxiliary systems, and project management expenses. Larger units achieve better economies of scale, while specialized materials or complex configurations increase unit costs proportionally.

Installation costs include site preparation, foundation work, mechanical installation, electrical connections, and commissioning services. Complex installations requiring extensive infrastructure modifications or specialized installation techniques increase total project costs beyond basic equipment purchase prices.

Engineering and design costs cover process design, equipment specification, installation drawings, and commissioning support. Experienced engineering support ensures proper equipment selection and installation while minimizing costly field modifications or performance issues.

Auxiliary system costs include feed systems, discharge handling, vapor treatment, heat recovery equipment, and control systems that integrate the paddle dryer into your overall facility operation. Proper auxiliary system design ensures reliable operation and maximizes overall system efficiency.

Operational Cost Benefits

Effective sludge paddle dryer selection delivers significant operational cost savings through reduced waste disposal costs, energy recovery opportunities, and improved process efficiency. Quantifying these benefits supports investment justification and equipment selection decision-making.

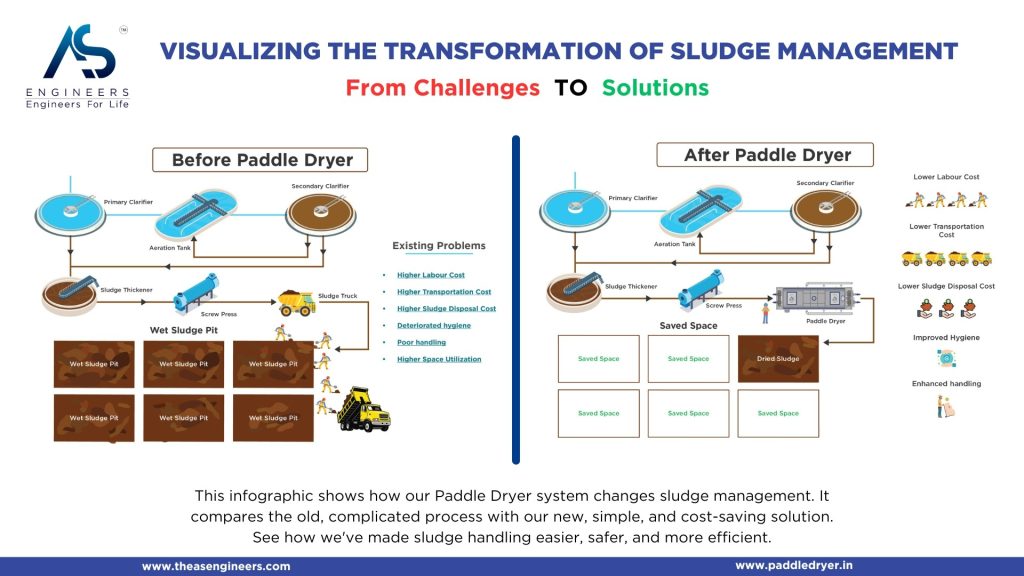

Waste disposal cost reduction represents the most immediate benefit from sludge drying operations. Moisture reduction from 80% to 40% reduces waste volume by 67%, directly reducing transportation and disposal costs that typically range from $50-200 per ton depending on location and disposal method.

Energy recovery opportunities include heat recovery from exhaust vapors, steam generation from waste heat, and biogas production from dried organic materials. Properly designed systems recover 20-40% of input energy, significantly reducing net energy consumption and operational costs.

Labor cost reduction results from automated operation, reduced waste handling requirements, and eliminated manual processes associated with traditional sludge management methods. Modern paddle dryer systems operate with minimal supervision while providing consistent performance and regulatory compliance.

Maintenance cost optimization through proper equipment selection prevents premature wear, reduces repair frequency, and minimizes replacement part requirements. Quality equipment with appropriate materials and design features delivers lower total maintenance costs over equipment life.

Vendor Selection and Procurement Strategy

Supplier Evaluation Criteria

Selecting the right sludge paddle dryer supplier significantly impacts project success, long-term equipment performance, and total cost of ownership. Comprehensive supplier evaluation ensures you partner with organizations capable of delivering complete solutions that meet your specific requirements and provide ongoing support throughout equipment life.

Technical capability assessment includes engineering expertise, manufacturing quality, testing facilities, and innovation track record in sludge drying applications. Suppliers with extensive application experience and proven track records deliver solutions optimized for your specific requirements while minimizing technical risks.

Manufacturing quality standards directly influence equipment reliability, performance consistency, and maintenance requirements. ISO 9001 certification, quality control procedures, and manufacturing facility audits provide insight into supplier capabilities and commitment to quality excellence.

Service and support capabilities include installation supervision, commissioning assistance, operator training, technical support, and spare parts availability. Comprehensive service support ensures successful project implementation and provides ongoing assistance that maximizes equipment performance and availability.

Financial stability and business longevity affect supplier ability to honor warranties, provide ongoing support, and maintain spare parts availability throughout equipment life. Established suppliers with strong financial positions provide greater assurance of long-term support and business continuity.

Contract Terms and Performance Guarantees

Well-structured procurement contracts protect your investment while ensuring supplier accountability for equipment performance, delivery schedules, and long-term support commitments. Key contract elements include performance guarantees, warranty terms, payment schedules, and delivery requirements that align supplier incentives with project success.

Performance guarantees should specify measurable criteria including throughput capacity, moisture reduction performance, energy consumption, and availability targets. Clear performance metrics enable objective evaluation and provide recourse if equipment fails to meet specified requirements.

Warranty terms cover equipment defects, performance shortfalls, and component failures during initial operation. Comprehensive warranties include parts and labor coverage, response times for service calls, and performance guarantees that extend beyond basic defect coverage.

Payment terms should align with project milestones and performance achievements to maintain supplier motivation while protecting your financial interests. Progressive payment schedules tied to delivery, installation, and performance testing ensure accountability while providing reasonable working capital for suppliers.

Spare parts pricing and availability commitments ensure ongoing operational support at reasonable costs. Long-term pricing agreements and guaranteed parts availability prevent future supply disruptions and control maintenance costs throughout equipment life.

Frequently Asked Questions

- What is the typical moisture reduction capability of sludge paddle dryers?

Most sludge paddle dryers reduce moisture content from inlet levels of 75-85% down to final moisture levels of 10-40%, achieving 50-90% moisture reduction depending on sludge characteristics and system configuration. - How long do sludge paddle dryers typically last with proper maintenance?

Well-maintained sludge paddle dryers typically operate reliably for 15-25 years, with major components like chambers and paddle shafts lasting the full equipment life while wear parts require periodic replacement. - What are the main energy sources used for sludge paddle dryer heating?

Common heating sources include steam (150-400°F), thermal oil (300-750°F), and hot water systems, with thermal oil providing the highest efficiency for most industrial applications. - How much space is required for sludge paddle dryer installation?

Space requirements vary by capacity but typically need 2-3 times the equipment footprint for maintenance access, auxiliary systems, and material handling equipment integration. - What maintenance is required for reliable sludge paddle dryer operation?

Regular maintenance includes bearing lubrication, seal inspection, heat transfer surface cleaning, and control system calibration, typically requiring 4-8 hours per week depending on system size and application.

Conclusion

Selecting the right sludge paddle dryer requires systematic evaluation of your specific application requirements, thorough understanding of available technologies, and careful consideration of long-term operational and maintenance factors. The framework presented in this guide provides the foundation for making informed decisions that optimize performance, minimize costs, and ensure reliable operation throughout equipment life.

Success depends on matching equipment capabilities with your actual processing requirements while considering future needs and regulatory changes that may affect operations. Proper supplier selection and comprehensive contract terms protect your investment while ensuring ongoing support that maximizes equipment effectiveness and return on investment.

The sludge paddle dryer market continues evolving with advances in heat recovery, automation, and materials technology that improve efficiency and reduce operational costs. Staying informed about technological developments and maintaining relationships with qualified suppliers positions your facility to benefit from these improvements while achieving optimal waste management performance.

Ready to implement these selection criteria for your facility? Contact qualified sludge paddle dryer suppliers for detailed proposals and site-specific evaluations that optimize your equipment investment and operational performance.