Every day, wastewater treatment facilities across the globe process billions of gallons of contaminated water, generating massive volumes of sludge that require precise handling. Without proper sludge pumping systems, treatment plants would face catastrophic failures, environmental violations, and operational shutdowns. Sludge pumps are heavy-duty pumps engineered to move sludge, slurry, or other thick and abrasive fluids, playing a crucial role in managing the by-products of the treatment process.

This comprehensive guide reveals everything facility managers, engineers, and operators need to know about selecting, operating, and maintaining sludge pumps wastewater treatment systems for maximum efficiency and reliability.

Table of contents

- Understanding Sludge Pumps in Wastewater Treatment Applications

- Types of Sludge Pumps for Wastewater Treatment

- Pump Selection Criteria for Optimal Performance

- Installation and Design Best Practices

- Operation and Maintenance Strategies

- Energy Efficiency and Cost Optimization

- Safety and Environmental Considerations

- Future Trends and Technology Innovations

- Frequently Asked Questions

- Conclusion

Understanding Sludge Pumps in Wastewater Treatment Applications

Sludge pumps wastewater treatment systems represent the backbone of modern sewage processing facilities. These specialized machines handle one of the most challenging aspects of water treatment: moving viscous, solid-laden materials through complex processing stages.

Pumping sewage sludge into and through treatment facilities means moving solids within the wastewater, including human excrement and urine, inorganic solids, food waste, organic waste, microorganisms, and even traces of chemicals. The complexity of this material demands pumps that can withstand extreme conditions while maintaining consistent performance.

What Makes Sludge Different from Regular Wastewater

Sludge characteristics create unique pumping challenges that standard water pumps cannot handle effectively. The material contains high concentrations of suspended solids, exhibits non-Newtonian flow properties, and varies dramatically in consistency throughout treatment processes.

Primary sludge typically contains 3-7% solids content, while thickened sludge can reach 8-12% solids. Digested sludge presents different challenges with altered viscosity and gas content. These variations require pumps designed specifically for sludge pumps wastewater treatment applications.

Critical Role in Treatment Plant Operations

In wastewater treatment plants, sludge pumps are used to transport raw sewage, treated sludge, and other waste products through the various stages of treatment, with the ability to handle solid-laden materials efficiently. The pumps facilitate movement between primary clarifiers, secondary treatment systems, thickening tanks, digesters, and dewatering equipment.

Without reliable sludge pumping, treatment plants experience process bottlenecks, reduced treatment efficiency, and potential regulatory compliance issues. The pumps must operate continuously with minimal downtime to maintain plant capacity and meet discharge requirements.

Types of Sludge Pumps for Wastewater Treatment

Selecting the appropriate pump type determines operational success in sludge pumps wastewater treatment systems. Each pump technology offers distinct advantages based on specific application requirements.

Centrifugal Sludge Pumps

Centrifugal pumps remain popular for certain sludge applications due to their simplicity and lower initial costs. they are good for low viscosity sludge with very little solids, making them suitable for primary sludge handling and dilute waste streams.

These pumps work best with sludge concentrations below 4% solids and provide high flow rates at moderate pressures. However, their efficiency decreases significantly as sludge viscosity increases, limiting their effectiveness in thickened sludge applications.

Modern centrifugal designs incorporate vortex impellers and enlarged passages to handle higher solids content while reducing clogging risks. Some facilities use them successfully for return activated sludge (RAS) pumping where solids concentrations remain relatively low.

Progressive Cavity Pumps (PCP)

Progressive cavity pumps are great for sludge applications because they impart little to no shear on the sludge and generate low pulsation rates. These positive displacement pumps excel in handling thick, viscous sludge with high solids content.

The helical rotor and stator design creates sealed cavities that move sludge smoothly through the pump without turbulence. This gentle action preserves sludge structure and prevents breakdown of larger particles, making PCPs ideal for biological sludge handling.

Progressive cavity pumps maintain consistent flow rates regardless of system pressure variations, providing reliable performance across different sludge types. They handle solids up to 12% concentration effectively while maintaining high volumetric efficiency.

Peristaltic Pumps

Peristaltic pumps offer unique advantages for specific sludge pumps wastewater treatment applications. The tube-based design eliminates metal contact with sludge, reducing corrosion and wear issues while providing reversible operation for line clearing.

These pumps excel in polymer feed applications and small-scale sludge transfer where precise dosing is required. The ability to run dry without damage makes them suitable for intermittent operation scenarios common in smaller treatment facilities.

Diaphragm Pumps

Air-operated double diaphragm (AODD) pumps provide reliable service in challenging sludge applications. Their positive displacement action handles varying viscosities while the air operation eliminates electrical hazards in wet environments.

These pumps self-prime and can run dry, making them excellent for emergency backup service and portable applications. The pulsing action helps prevent sludge settling in transfer lines during intermittent operation.

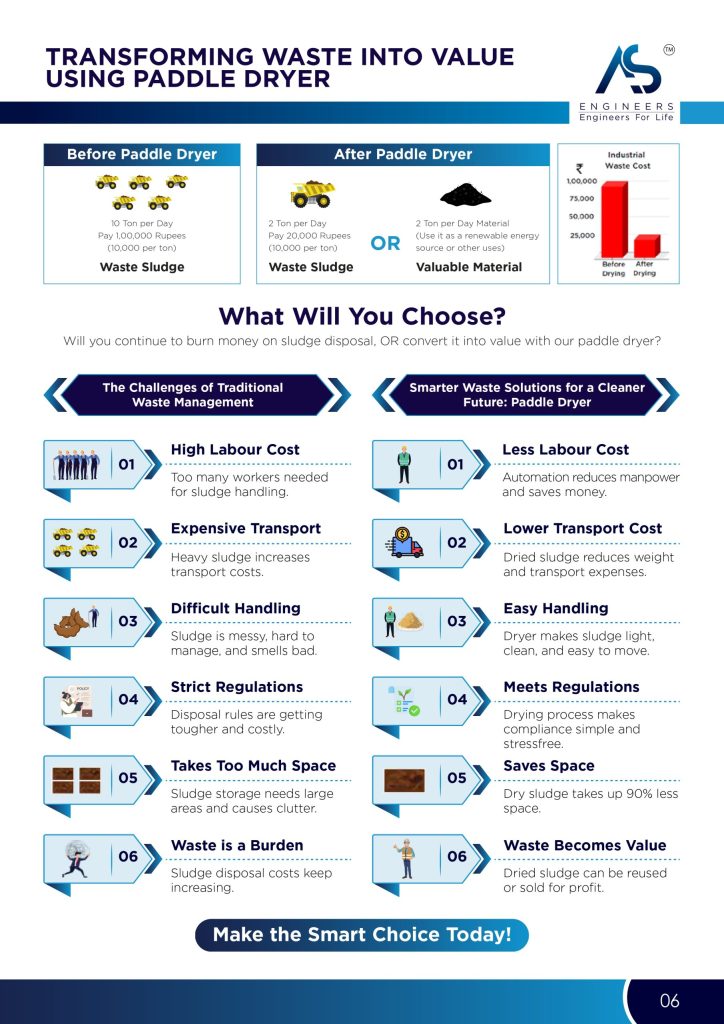

At AS Engineers, we understand the real-world challenges industries face with sludge management. That’s why we designed our paddle dryer to do more than just dry sludge—it transforms a messy, costly problem into a manageable, efficient process. Our paddle dryer uses indirect heating to gently remove moisture, reducing sludge volume, lowering disposal costs, and helping businesses meet environmental norms with ease. It’s a silent worker behind the scenes, making plants cleaner, safer, and more sustainable. Whether you run an ETP, STP, or industrial unit, our paddle dryer simplifies your sludge drying needs—reliably, efficiently, and with minimal human intervention.

The paddle sludge dryer offers significant cost savings by reducing sludge volume and moisture content, which cuts down transportation and disposal expenses. Its low energy consumption, thanks to indirect heating and efficient heat transfer, minimizes operational costs. With low maintenance needs, continuous operation, and the ability to recover heat, it ensures long-term savings. Additionally, the dried sludge can be reused as fuel, further adding to the economic benefits and sustainability of your operations.

Pump Selection Criteria for Optimal Performance

Successful sludge pumps wastewater treatment selection requires careful evaluation of multiple factors that impact long-term performance and operational costs.

Sludge Characteristics Analysis

Understanding sludge properties drives pump selection decisions. Key parameters include:

- Solids Content: Concentration levels determine pump type suitability. Low solids (0-4%) work with centrifugal pumps, while high solids (6-12%) require positive displacement designs.

- Viscosity: Variable viscosity affects pump performance and power requirements. Progressive cavity pumps handle viscosity variations better than centrifugal designs.

- Particle Size: Large particles demand pumps with generous clearances and non-clog designs. Vortex impellers and progressing cavity pumps accommodate larger solids effectively.

- Abrasiveness: Grit and sand content accelerates wear. Hard-faced wetted parts and replaceable wear components extend service life in abrasive applications.

Flow Rate and Pressure Requirements

Positive displacement pumps excel at high-pressure and low flow rate applications with viscous fluids, while centrifugal pumps work best for high-volume, low-pressure scenarios.

Determine peak and average flow requirements based on plant capacity and process needs. Consider system head losses through piping, valves, and elevation changes. Match pump performance curves to actual operating conditions for optimal efficiency.

System Integration Considerations

Sludge pumps wastewater treatment systems must integrate seamlessly with existing plant infrastructure. Consider suction lift requirements, available NPSH, and piping configurations when selecting pumps.

Evaluate control system compatibility and automation requirements. Modern plants demand variable speed operation and remote monitoring capabilities for optimal performance and energy efficiency.

Installation and Design Best Practices

Proper installation determines pump performance and longevity in sludge pumps wastewater treatment applications. Following proven design practices prevents common operational problems.

Suction System Design

Adequate suction conditions prevent cavitation and ensure reliable pump operation. Design suction lines with gradual transitions and minimal fittings to reduce head losses.

Maintain minimum submergence levels in wet wells to prevent vortex formation and air entrainment. Size suction lines for velocities between 3-6 feet per second to prevent sludge settling while avoiding excessive friction losses.

Install suction strainers or screens where appropriate to protect pumps from large debris. However, avoid over-screening that creates maintenance burdens and flow restrictions.

Discharge System Optimization

Discharge piping design affects pump performance and energy consumption. Size discharge lines to maintain velocities above 4 feet per second to prevent sludge deposition while avoiding excessive pressure losses.

Install proper valve configurations for pump isolation and line flushing. Check valves prevent backflow during pump shutdown, while flush connections enable line cleaning during maintenance periods.

Consider pipe materials carefully based on sludge characteristics. Stainless steel provides excellent corrosion resistance, while HDPE offers good abrasion resistance at lower costs.

Foundation and Mounting Requirements

Solid foundations prevent vibration and misalignment issues that reduce pump life. Design foundations to handle pump weight, operating forces, and potential seismic loads.

Flexible connections accommodate thermal expansion and reduce stress on pump casings. However, avoid excessive flexibility that allows misalignment or vibration amplification.

Provide adequate access for maintenance activities including pump removal, impeller changes, and mechanical seal replacement. Consider lifting provisions for heavy components.

Operation and Maintenance Strategies

Effective maintenance programs maximize pump reliability and minimize lifecycle costs in sludge pumps wastewater treatment systems.

Preventive Maintenance Protocols

Regular inspection schedules identify developing problems before failures occur. Monitor pump performance parameters including flow, pressure, power consumption, and vibration levels.

Progressive cavity pumps present maintenance and repair challenges that operators must address proactively. Establish stator replacement schedules based on operating hours and wear patterns.

Maintain spare parts inventory for critical components including impellers, mechanical seals, and wear plates. Stock complete rotor/stator assemblies for progressive cavity pumps to minimize downtime.

Performance Monitoring Systems

Implement continuous monitoring systems to track pump performance and predict maintenance needs. Modern systems provide real-time data on flow rates, pressures, temperatures, and vibration levels.

Establish baseline performance data during commissioning and track trends over time. Gradual performance degradation indicates wear progression, while sudden changes suggest immediate attention requirements.

Use energy monitoring to optimize pump operation and identify efficiency improvements. Variable frequency drives enable pump speed adjustment to match system demands while reducing energy consumption.

Troubleshooting Common Problems

Frequent issues in sludge pumps wastewater treatment include clogging, excessive wear, and reduced flow rates. Systematic troubleshooting approaches identify root causes and appropriate solutions.

Clogging Issues: Often result from inadequate sludge screening or pump undersizing. Solutions include improved screening, pump upgrades, or operation modifications.

Premature Wear: Usually indicates abrasive conditions or improper pump selection. Consider wear-resistant materials or alternative pump technologies.

Flow Reduction: May result from wear, clogging, or system changes. Evaluate pump condition and system requirements to determine appropriate corrective actions.

Energy Efficiency and Cost Optimization

Modern sludge pumps wastewater treatment facilities prioritize energy efficiency to reduce operational costs and environmental impact.

Variable Frequency Drive Applications

VFD technology enables pump speed adjustment to match actual flow requirements, reducing energy consumption significantly. For viscous fluids, positive displacement pumps can often be 10 to 40 points more efficient than centrifugal pumps.

Implement control strategies that optimize pump operation based on sludge levels, downstream processes, and energy costs. Advanced control systems coordinate multiple pumps for maximum efficiency.

Consider soft-start capabilities that reduce electrical demand during pump startup while minimizing mechanical stress on equipment.

Lifecycle Cost Analysis

Evaluate total cost of ownership including initial purchase price, installation costs, energy consumption, and maintenance expenses. Higher-efficiency pumps often justify premium costs through reduced operating expenses.

Consider pump reliability and availability in cost calculations. Frequent failures and extended downtime create significant indirect costs through lost treatment capacity and emergency repairs.

Factor in regulatory compliance costs when evaluating pump selection. Reliable pumps reduce risks of environmental violations and associated penalties.

System Optimization Opportunities

Evaluate system design for optimization opportunities that reduce pumping requirements. Gravity flow systems eliminate pumping costs where site conditions permit.

Consider sludge thickening strategies that reduce pumping volumes and associated costs. Higher solids content reduces transport costs but may require different pump technologies.

Implement heat recovery systems that utilize pump waste heat for process heating requirements, improving overall plant efficiency.

Safety and Environmental Considerations

Sludge pumps wastewater treatment operations present unique safety challenges requiring comprehensive risk management approaches.

Personnel Safety Protocols

Establish confined space entry procedures for pump stations and wet wells. Provide proper ventilation, gas monitoring, and emergency rescue equipment.

Implement lockout/tagout procedures for pump maintenance activities. Multiple energy sources including electrical power, compressed air, and stored hydraulic energy require careful isolation.

Provide personal protective equipment appropriate for sludge exposure risks including chemical-resistant clothing, respiratory protection, and eye protection.

Environmental Protection Measures

Design pump stations with adequate containment to prevent environmental releases during normal operation and maintenance activities. Secondary containment should accommodate pump failures and spillage.

Implement leak detection systems that provide early warning of pump failures or piping problems. Rapid response capabilities minimize environmental impact and regulatory exposure.

Consider noise control measures for pump installations near residential areas. Enclosed pump stations and vibration isolation reduce noise transmission.

Emergency Response Planning

Develop contingency plans for pump failures that ensure continued plant operation and environmental protection. Backup pumping capabilities maintain treatment capacity during equipment outages.

Establish emergency notification procedures for pump failures, spills, or other incidents. Coordinate with regulatory agencies and emergency responders as required.

Maintain emergency repair capabilities including spare pumps, temporary piping, and qualified service technicians available on short notice.

Future Trends and Technology Innovations

Emerging technologies continue advancing sludge pumps wastewater treatment capabilities and efficiency.

Smart Pump Technologies

Internet of Things (IoT) sensors enable remote monitoring and predictive maintenance capabilities. Advanced analytics identify performance trends and optimize maintenance scheduling.

Machine learning algorithms process operational data to predict failures and recommend optimization strategies. These systems continuously improve through operational experience and feedback.

Digital twin technology enables virtual testing of pump modifications and operating strategies without disrupting plant operations.

Advanced Materials and Coatings

New materials and coating technologies extend pump life in aggressive sludge applications. Advanced ceramics and specialized alloys resist abrasion and corrosion more effectively than traditional materials.

Nano-coatings reduce friction and improve efficiency while providing superior wear resistance. These technologies become more cost-effective as manufacturing scales increase.

Energy Recovery Systems

Innovative designs capture energy from high-pressure sludge streams to offset pumping costs. Pressure exchangers and turbine systems recover energy that would otherwise be wasted.

Micro-hydroelectric generators utilize flow energy in gravity systems to produce electricity for auxiliary equipment operation.

Frequently Asked Questions

- What is the most reliable pump type for thickened sludge applications?

Progressive cavity pumps provide the most reliable performance for thickened sludge with high solids content due to their positive displacement action and gentle handling characteristics. - How often should sludge pump impellers be replaced?

Impeller replacement frequency depends on sludge characteristics and pump design, but typically ranges from 6-18 months in abrasive applications with proper maintenance. - What causes excessive vibration in sludge pumps?

Common causes include impeller imbalance, bearing wear, foundation problems, and cavitation due to inadequate suction conditions or clogged suction strainers. - Can centrifugal pumps handle digested sludge effectively?

Centrifugal pumps work adequately for digested sludge with lower viscosity and solids content, but progressive cavity pumps provide better performance and efficiency. - What maintenance schedule works best for progressive cavity pumps?

Implement monthly visual inspections, quarterly performance monitoring, and annual stator replacement based on wear patterns and operating hours.

Conclusion

Sludge pumps wastewater treatment systems represent critical infrastructure components that determine treatment plant reliability, efficiency, and compliance. Success requires careful pump selection based on sludge characteristics, proper installation following proven design practices, and comprehensive maintenance programs that maximize equipment life.

Positive displacement pumps handle variations in pressure, flow, and viscosity while remaining efficient, unlike centrifugal pumps which do not operate well off the center of their curve. This fundamental difference drives selection decisions for specific applications.

The investment in proper sludge pumps wastewater treatment equipment pays dividends through reduced maintenance costs, improved energy efficiency, and enhanced regulatory compliance. Facilities that prioritize pump system optimization achieve lower lifecycle costs while maintaining superior environmental performance.

Ready to optimize your sludge pumping operations? Contact qualified pump specialists to evaluate your specific requirements and explore advanced solutions that enhance plant performance while reducing operational costs. Share your experiences with sludge pump selection and operation in the comments below to help other facility professionals learn from your insights.