Sludge treatment stands at the heart of modern wastewater and industrial process management. Although “sludge” may sound like a minor byproduct, it can contain pathogens, nutrients, heavy metals, and even valuable resources. If you handle sludge carelessly, you risk environmental pollution, regulatory penalties, and missed opportunities for energy recovery or resource reuse. Luckily, today’s sludge treatment strategies offer robust, cost-effective paths for safe disposal and resource optimization.

In this comprehensive guide, you will learn about sludge treatment processes that cover physical, chemical, and biological approaches. You will also gain insights into sludge treatment and disposal methods, ensuring compliance with regulations and promoting sustainable operations. Whether you manage a municipal wastewater plant or an industrial facility, this article shows you how to choose the right method and apply it successfully.

Why Sludge Treatment Matters

Organizations generate sludge through wastewater purification, industrial processes, and even agricultural runoff. Sludge often contains a blend of organic substances, pathogenic microbes, and chemical additives. When you ignore proper sludge treatment processes, you expose your operation to several risks:

- Environmental Damage

Untreated sludge can contaminate groundwater, rivers, or fields. This runoff may harm wildlife and local communities. - Regulatory Fines

Agencies such as the U.S. Environmental Protection Agency (EPA) or the European Commission impose strict standards on sludge management. Violations lead to hefty penalties, bad publicity, or forced closures. - Wasted Opportunities

Treated sludge can yield biogas for energy production or provide rich nutrients for land application. Failing to capture these resources means higher operational costs and lost revenue.

Effective sludge treatment bridges compliance, community safety, and environmental stewardship. It also delivers an opportunity to repurpose a byproduct into something useful.

Key Regulatory Requirements

Regulatory bodies typically mandate the following for sludge operations:

- Pathogen Reduction

Authorities demand that you reduce harmful microbes below certain thresholds. Processes such as heat treatment, pH adjustment, or digestion can achieve these levels. - Heavy Metal Limits

Wastewater sludge often carries metals like lead, mercury, or cadmium. Regulators set strict concentration caps to protect soil and water quality. - Permitting and Documentation

Many jurisdictions require permits for transport, storage, and disposal. Detailed record-keeping proves compliance and traceability. - Emission Controls

Incineration or thermal drying may release air pollutants. Operators must install air pollution control devices to comply with emission standards.

Staying abreast of these requirements avoids legal troubles and keeps local ecosystems safe.

Physical Sludge Treatment Processes

Physical processes usually serve as the first line of defense against high sludge volumes. These treatments remove water or concentrate solids before more advanced steps occur.

1. Thickening

Objective: Concentrate the sludge by removing excess water.

Method:

- Gravity Thickening: Uses sedimentation. Sludge settles at the bottom, and the clearer liquid on top overflows.

- Dissolved Air Flotation (DAF): Introduces tiny air bubbles that attach to sludge particles and lift them to the surface for removal.

Applications:

- Municipal wastewater treatment plants use thickening to cut operational costs and reduce the sludge’s total volume.

- Industrial facilities integrate thickening to streamline chemical usage in later treatments.

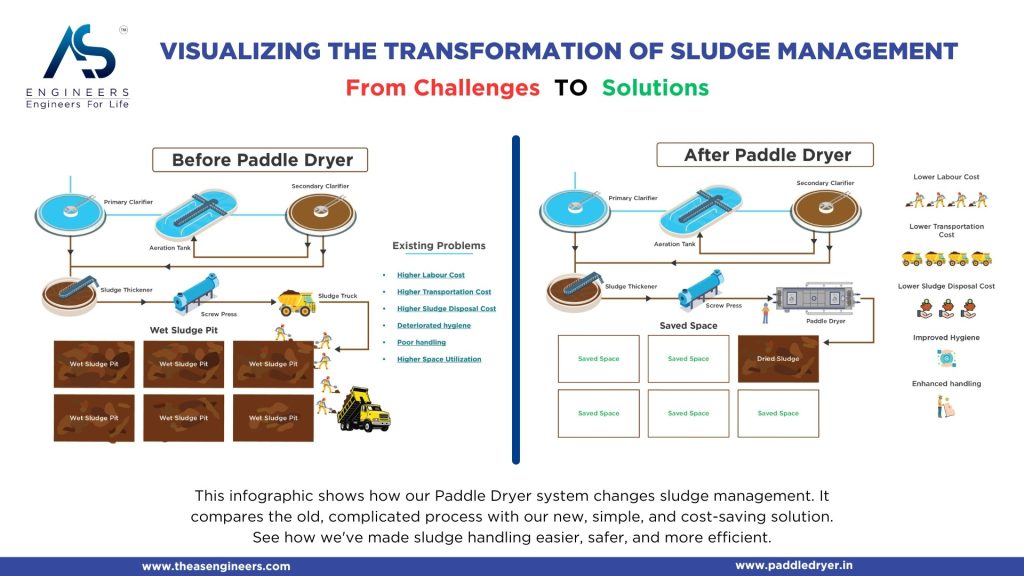

2. Dewatering

Objective: Extract as much water as possible from thickened sludge, producing a solid cake that is easier to transport and dispose of.

Common Dewatering Methods:

- Belt Filter Press: Moves sludge between permeable belts, applying pressure to remove moisture.

- Centrifuge: Spins sludge at high velocities, forcing water outward due to centrifugal force.

- Plate and Frame Press: Compresses sludge between plates lined with filter media, separating solids from liquid.

- Screw Press: Uses a slow-rotating auger that exerts pressure on sludge, squeezing out water.

Advantages:

- Reduced hauling costs

- Easier handling and storage

- Lower volume for subsequent treatments (e.g., incineration or land application)

Physical treatments serve as the foundation for advanced processes. They lower the mass of sludge and cut costs, all while setting the stage for safer handling.

Chemical Sludge Treatment Processes

Chemical methods modify sludge composition through reactions or additives. These techniques help reduce pathogens, neutralize odors, and stabilize organic matter.

1. pH Adjustment

Process: You add acids or alkaline materials (commonly lime) to sludge, shifting its pH to levels that inhibit microbial growth.

Why It Works:

- Pathogens fail to survive in highly acidic or alkaline conditions.

- Lime addition also causes certain metals or nutrients to precipitate, simplifying disposal.

Typical Use Cases:

- Facilities dealing with high pathogen loads or sludges that require quick stabilization.

- Operations looking for a cost-effective strategy that prevents odor issues and shortens digestion times.

2. Chemical Precipitation

Process: You add reagents (e.g., iron or aluminum salts) that bind with dissolved contaminants, forming solid precipitates you can separate.

Applications:

- Industrial settings that carry dissolved metals or synthetic chemicals in their sludge.

- Municipal plants requiring extra steps to meet stringent heavy metal discharge limits.

Benefits:

- Lower metal concentrations

- Potential reuse of precipitated materials if they contain valuable elements

3. Oxidation and Advanced Treatments

Oxidizing Agents: You might use chlorine, hydrogen peroxide, ozone, or peracetic acid to break down persistent organic compounds and kill bacteria.

Applications:

- Chemical oxidation helps remove color and toxicity in industrial sludges.

- Advanced oxidation processes tackle sludge with complex chemical pollutants.

Chemical treatments often work best in tandem with physical or biological methods. They address specific pollutants or pathogens that other processes may not efficiently remove.

5. Biological Sludge Treatment Processes

Biological approaches harness living organisms to decompose organic matter. They can reduce sludge volume significantly and produce valuable byproducts like biogas.

1. Aerobic Digestion

Process: Microbes break down sludge components in the presence of oxygen. Aeration tanks supply the oxygen, and microbes consume the organic matter, converting it into carbon dioxide, water, and more microbial cells.

Key Benefits:

- Relatively straightforward operations

- Reduced odors compared to anaerobic digestion

- Lower pathogen content in the final product

Drawbacks:

- Continuous aeration costs

- Less energy recovery potential (compared to anaerobic digestion)

2. Anaerobic Digestion

Process: Sludge decomposes in oxygen-free tanks. Microbes form a methane-rich biogas, which you can capture for energy.

Why Facilities Love It:

- Energy Production: Biogas powers generators or local heating systems.

- Volume Reduction: Sludge mass drops, easing disposal.

- Improved Pathogen Kill: Extended digestion periods at elevated temperatures neutralize harmful organisms.

Challenges:

- Requires careful temperature and pH monitoring

- Possible production of hydrogen sulfide, which demands additional scrubbing or filtering

Biological methods form a cornerstone of sustainable sludge treatment processes. They transform waste into energy or nutrient-rich biosolids, closing the loop on resource use.

Sludge Treatment and Disposal: Common Endpoints

Once you stabilize and reduce sludge volume, you need a final disposal or reuse plan. Consider these primary options:

1. Land Application

Purpose: Spread treated sludge (often called biosolids) onto farmland or reclaim mine sites.

Advantages:

- Valuable nutrients for soil improvement

- Lower synthetic fertilizer usage

- Potential carbon sequestration benefits

Regulatory Notes:

- Biosolids must meet specific quality standards (e.g., Class A or B in the U.S.) that limit pathogens and toxic substances.

- Farmers often welcome biosolids when proven safe, but public perception matters.

2. Incineration

Process: You burn sludge at high temperatures, reducing it to ash.

Pros:

- Significant volume reduction (up to 90%)

- Energy recovery if you harness heat from incineration

- Quick disposal for large urban areas

Cons:

- Capital costs for incinerators and air pollution control systems

- Potential production of dioxins or other harmful gases if incineration lacks proper temperature control

3. Landfilling

Method: You place dewatered sludge in engineered landfills. Landfills have liners, leachate collection, and gas management systems to prevent environmental harm.

When to Use It:

- You cannot meet land application standards, or incineration is too costly.

- Temporary solution if you search for better technologies.

Landfilling is a legal option in many regions, but rising disposal fees and public opposition often drive facilities to more sustainable alternatives like land application or beneficial reuse.

Common Misconceptions

Even seasoned professionals carry misconceptions about sludge treatment. Let’s clarify a few:

- “Sludge Treatment Always Requires Expensive Tech.”

Operators can adopt scalable solutions. Smaller plants might rely on simpler methods like aerobic digestion and basic dewatering systems. - “All Sludge Is Hazardous.”

Some sludge streams contain harmful chemicals or pathogens, but many achieve safe biosolids status through proper treatment. - “Biological Methods Cannot Handle Industrial Sludge.”

Although some industrial sludges demand chemical or thermal steps, biological digestion often complements other treatments and handles a wide range of organic pollutants. - “Regulatory Limits Never Change.”

Agencies frequently revise standards as new science emerges. Stay current or risk compliance issues.

FAQs about Sludge Treatment Methods and Their Applications

Q1: How do I decide which sludge treatment process is best?

A1: Evaluate your sludge characteristics, budget, desired end use, and regulatory obligations. Each method has unique costs and benefits. Municipal plants often use anaerobic digestion for biogas, while some industrial sites rely on chemical or thermal processes.

Q2: Is land application safe for my crops?

A2: Yes, provided your sludge meets stringent biosolids regulations. Testing for metals and pathogens ensures that you do not harm soil, water, or crops.

Q3: Do I need both thickening and dewatering?

A3: Many operations use thickening first, then proceed to dewatering. Thickening cuts volume early and slashes chemical or energy requirements later.

Q4: Can I mix multiple treatments?

A4: Absolutely. Many successful systems blend physical, chemical, and biological steps. For example, you might thicken sludge, chemically stabilize it, and then run anaerobic digestion before final disposal.

Q5: Does incineration always recover energy?

A5: Not always. You need a dedicated energy-recovery system to harness heat from incineration. Without such a setup, incineration only reduces volume, although you still must manage air pollution.

Conclusion and Next Steps

Effective sludge treatment hinges on a smart blend of physical, chemical, and biological processes. You can capture valuable resources, minimize environmental harm, and comply with strict regulations when you tailor your approach to your sludge’s composition and your organization’s goals. Whether you prefer the simplicity of belt filter presses or the energy-generating potential of anaerobic digestion, your plant’s success depends on selecting methods that match your specific requirements.

When you treat sludge properly, you gain more than regulatory compliance. You unlock possibilities for cost savings, energy production, nutrient recovery, and a greener public image. Sludge no longer seems like a messy byproduct. It transforms into a resource that can drive sustainability and innovation.

What are your experiences with sludge treatment processes? Share your thoughts below or contact our team for a personalized consultation. Stay ahead of evolving regulations and industry best practices by subscribing to our newsletter, and explore our related guides to dive even deeper into sludge management technologies.

By prioritizing sludge treatment, you protect local ecosystems and advance your facility’s reputation for responsible waste management. You also fulfill vital regulatory requirements and avoid costly penalties. The best part? Sludge treatment can create tangible benefits, from renewable energy in the form of biogas to nutrient-rich biosolids for agriculture. Make sludge your ally instead of an environmental risk. Embrace the right sludge treatment methods and shape a sustainable future for both your operation and the community you serve.