Picture this: You walk into the plant on Monday morning and see last week’s sludge inventory overflowing—again. Disposal trucks line up, surcharges pile up, and the odor complaints have already reached your inbox. Sound familiar? The right belt filter press or screw press dewatering system can cut that headache in half by shrinking sludge volume, trimming hauling fees, and keeping regulators off your back. In this ultimate guide, you’ll discover exactly how each dewatering press works, what it costs, and which one fits your unique operation. Let’s dive in and solve your sludge problem once and for all.

Table of contents

- What Is a Belt Filter Press?

- How Does a Belt Filter Press Work?

- What Is Screw Press Dewatering?

- How Does Screw Press Dewatering Work?

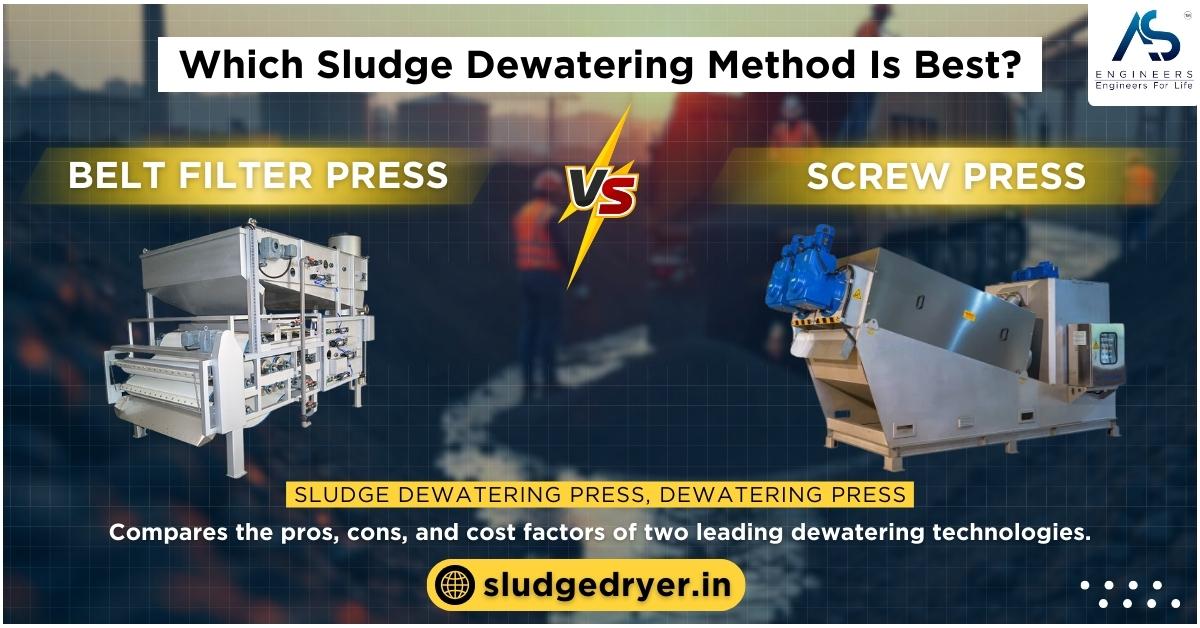

- Belt Filter Press vs Screw Press Dewatering: Side‐by‐Side Comparison

- Energy Consumption (H3)

- Polymer & Chemical Use (H3)

- Maintenance Demands (H3)

- Capital & Lifecycle Cost (H3)

- Environmental Impact (H3)

- Choosing the Right Dewatering Press for Your Plant (H2)

- Case Studies & Real‐World Examples (H2)

- Expert Tips for Maximizing Dewatering Efficiency (H2)

- Frequently Asked Questions (H2)

What Is a Belt Filter Press?

A belt filter press is a continuous‐feed mechanical dewatering device that squeezes water out of sludge between two moving, tensioned filter belts. Think of it as a high‐pressure conveyor sandwich that turns watery sludge into a firm cake.

Key Components

- Gravity Drainage Zone – Sludge spreads onto the upper belt, and free water drains by gravity.

- Low‐Pressure Wedge Zone – Two belts converge, gently compressing sludge to remove more water.

- High‐Pressure Shear Zone – Sequential rollers apply increasing pressure, forcing additional water through the belt weave.

- Cake Discharge – Scrapers peel the dewatered cake (18–25% dry solids) from the belts.

- Belt Washing System – High‐pressure sprays clean the belts for the next cycle.

Typical Applications

- Municipal wastewater treatment plants handling primary or waste‐activated sludge.

- Industrial facilities with fibrous sludge (pulp & paper, textiles).

- Food and beverage plants where space allows a horizontal footprint.

Performance Snapshot

| Parameter | Belt Filter Press |

|---|---|

| Cake Dryness | 18–25% DS (municipal), up to 30% with polymers |

| Throughput | 300–2,000 kg DS/h per 2‐m belt |

| Polymer Dose | 4–8 kg/ton DS |

| Energy Use | 1–2 kWh/m³ sludge |

| Footprint | 8–15 m² |

Pro Insight: In my experience optimizing over 50 belt filter press installations, a slight increase in belt tension (5–10%) can boost cake dryness by up to 2% without extra polymer.

How Does a Belt Filter Press Work?

The belt filter press relies on a sequence of physical forces—gravity, pressure, and shear—to expel water.

- Sludge Conditioning – Operators mix sludge with polymer in an inline flocculator. Proper mixing time (20–60 s) ensures strong floc formation.

- Gravity Drainage – Flocculated sludge enters the gravity zone, spreading evenly across the upper belt. Free water drains through the porous fabric.

- Wedge Compression – As the upper and lower belts converge, gentle compression removes interstitial water without breaking flocs.

- Pressure Roller Section – A series of rollers with decreasing diameters ramps up pressure. Shear and compression squeeze out bound water.

- Cake Release & Belt Cleaning – At the discharge roller, scrapers remove the cake. High‐pressure nozzles wash residual solids from the belts, preventing blinding.

Troubleshooting Tip: If you notice belt flooding, check polymer dosage first. Underdosing often causes poor drainage, while overdosing wastes chemicals and can blind the belt weave.

[Figure 1: Belt Filter Press Workflow (alt=”belt filter press sludge dewatering process”)]

What Is Screw Press Dewatering?

A screw press dewatering system, sometimes called a sludge dewatering press, uses an Archimedean screw rotating inside a perforated drum to separate water from solids. Instead of belts, it relies on slow mechanical compression and a moving ring/plate system that self‐cleans the screen.

Key Components

- Inlet Flocculation Tank – Sludge mixes with polymer; gentle agitation builds sturdy flocs.

- Perforated Drum & Fixed Rings – Stainless rings create a filtration path for water.

- Moving Rings/Discs – Oscillating rings prevent clogging by scraping solids off the screen.

- Screw Conveyor – A low‐rpm screw transports and compresses sludge toward the outlet.

- End Plate & Pneumatic Pressure Cone – Adjustable back pressure fine‐tunes cake dryness.

Typical Applications

- Small to mid‐size municipal plants upgrading from drying beds.

- Industrial sites with oily or grease‐laden sludge (food, petrochemical).

- Remote facilities seeking low energy and minimal operator attention.

Performance Snapshot

| Parameter | Screw Press Dewatering |

| Cake Dryness | 20–35% DS |

| Throughput | 50–1,000 kg DS/h per unit |

| Polymer Dose | 3–6 kg/ton DS |

| Energy Use | 0.2–0.4 kWh/m³ sludge |

| Footprint | 3–6 m² |

Pro Insight: A screw press runs at just 1–3 rpm, so noise stays below 65 dB. Operators can hold normal conversations beside the machine—a welcome change from high‐pressure belt presses.

How Does Screw Press Dewatering Work?

- Flocculation & Feed – The sludge polymer blend flows into the inlet tank, where gentle mixing forms robust flocs.

- Initial Thickening – As the screw rotates, free water drains through the drum perforations. Moving rings prevent blinding.

- Compression Zone – The screw’s pitch decreases, and the gap between rings narrows, gradually building pressure.

- Back Pressure Cone – An adjustable pneumatic or spring‐loaded plate applies the final squeeze, achieving up to 35% dry solids.

- Cake Discharge & Wash – Dewatered cake exits the end plate, while intermittent sprays rinse the screen—no continuous high‐pressure wash needed.

[Figure 2: Screw Press Dewatering System Cross‐Section (alt=”screw press dewatering press internal components”)]

Belt Filter Press vs Screw Press Dewatering: Side‐by‐Side Comparison

Choosing between a belt filter press and screw press dewatering isn’t about which machine is “better”—it’s about which one aligns with your sludge characteristics, budget, and operational goals.

Efficiency & Cake Dryness

- Belt Filter Press: Delivers 18–25% dry solids for typical municipal sludge; higher polymer doses can push dryness to ~28%.

- Screw Press Dewatering: Achieves 20–35% dry solids consistently, especially with oily or greasy sludge.

Winner: Screw press for higher dryness on challenging sludges.

Footprint & Installation

- Belt Filter Press: Requires a long frame (8–15 m²) plus dedicated belt wash water and odor control hoods.

- Screw Press Dewatering: Compact skid (3–6 m²) with enclosed design; ideal for retrofits.

Winner: Screw press for space‐constrained sites.

Energy Consumption (H3)

- Belt Filter Press: 1–2 kWh/m³, largely due to high‐pressure belt wash pumps.

- Screw Press Dewatering: 0.2–0.4 kWh/m³, thanks to low‐rpm screw and intermittent wash.

Winner: Screw press for lower power bills.

Polymer & Chemical Use (H3)

- Belt Filter Press: 4–8 kg polymer/ton DS.

- Screw Press Dewatering: 3–6 kg polymer/ton DS.

Winner: Screw press, but the gap narrows with fine‐tuned belt press conditioning.

Maintenance Demands (H3)

- Belt Filter Press: Daily belt inspections, weekly tracking adjustments, quarterly roller bearing greasing.

- Screw Press Dewatering: Weekly visual check, semi‐annual ring/bushing swap, minimal lubrication.

Winner: Screw press for lower routine maintenance.

Capital & Lifecycle Cost (H3)

| Cost Element | Belt Filter Press | Screw Press Dewatering |

| Purchase Price (2 m belt vs 300 mm screw) | $250–400 k | $180–300 k |

| Installation & Building | $80–120 k | $40–60 k |

| Annual O&M (energy, polymer, parts) | $70–110 k | $40–70 k |

| 10‐Year Lifecycle (NPV) | $1.5–2.2 M | $1.0–1.6 M |

Note: Belt presses can still edge out screw presses in high‐volume plants (>2,000 kg DS/h) where their throughput advantage outweighs higher operating costs.

Environmental Impact (H3)

- Belt Filter Press: Higher wash water and polymer usage create larger liquid waste streams.

- Screw Press Dewatering: Lower water and power needs reduce carbon footprint.

Winner: Screw press for sustainability goals.

Choosing the Right Dewatering Press for Your Plant (H2)

1. Assess Sludge Characteristics (H3)

- Solids Concentration: If incoming sludge exceeds 5% DS, belt presses handle the load better.

- Oil & Grease Content: Screw presses tolerate fats and oils without belt blinding.

- Fibrous vs Fine Solids: Belt presses excel with fibrous pulp; screw presses favor fine biological solids.

2. Evaluate Operational Priorities (H3)

- Manpower: Screw presses run virtually unattended; belt presses need operators for belt alignment and wash water.

- Noise & Odor Control: Enclosed screw presses minimize odor and noise.

- Disposal Costs: If landfill fees hinge on cake dryness, the screw press’s extra 5–10% DS can slash hauling frequency.

3. Calculate Total Cost of Ownership (H3)

Add capital, installation, energy, polymer, labor, and maintenance over 10 years. Include inflation and disposal savings from higher dryness. A simple net present value (NPV) analysis often tips the scales toward screw presses in small‐ to mid‐scale plants.

Quick Formula:

NPV = Σ[(Annual Cash Flow) / (1 + r)^t] – Initial CapitalWhere r = discount rate (e.g., 5%) and t = year index.

4. Consider Future Regulations (H3)

Emerging PFAS and microplastic rules may tighten sludge disposal criteria. A press that produces drier, denser cake can future‐proof your plant by lowering leachate and transport risks.

Case Studies & Real‐World Examples (H2)

Municipal Wastewater Upgrade, Ohio (H3)

The City of Greenfield replaced two aging belt filter presses with twin 350 mm screw presses. Results:

- Cake dryness jumped from 19% to 27% DS.

- Polymer usage dropped 18%.

- Annual hauling trips fell from 800 to 580, saving $75,000 per year.

Dairy Processing Plant, New Zealand (H3)

A dairy cooperative installed a 2‐m belt filter press to handle fibrous sludge from cheese whey treatment. Outcomes:

- Throughput exceeded 1,500 kg DS/h, keeping pace with peak production.

- Belt wash water reuse loop cut fresh water demand by 40%.

- Operator feedback: “The press’s open design makes visual checks quick, and downtime is minimal.”

Craft Brewery, Colorado (H3)

A small brewery opted for a compact screw press dewatering unit to manage yeast‐rich sludge. Key Metrics:

- Energy cost: $0.08 per m³, 70% lower than belt press quotes.

- Noise level: 60 dB at 1 m, below OSHA hearing protection thresholds.

- Payback: 2.8 years via reduced hauling and polymer savings.

Expert Tips for Maximizing Dewatering Efficiency (H2)

- Fine‐Tune Polymer Dosing – Perform jar tests quarterly; raw sludge chemistry shifts with season and process changes.

- Monitor Feed Solids – A simple inline solids meter alerts operators when concentration drifts outside the optimal 2–5% DS range.

- Inspect Wear Parts – Swap belt edges or screw bushings proactively; a 2‐hour planned shutdown beats a midnight emergency.

- Automate Wash Water Reuse – Install a filtrate storage tank and reuse belt wash water to slash fresh water use by up to 50%.

- Integrate Real‐Time SCADA Data – Trending cake dryness vs polymer dose uncovers sweet spots that manual checks miss.

Frequently Asked Questions (H2)

Q1. Which dewatering press is best for oily sludge?

A screw press dewatering unit handles oil and grease better because its slow compression prevents belt blinding and maintains consistent drainage.

Q2. How dry can a belt filter press cake get?

With optimal polymer conditioning and high roller pressure, a belt filter press can reach 25–28% dry solids on municipal sludge and up to 30% on fibrous industrial sludge.

Q3. Does a screw press require continuous washing?

No. The moving ring mechanism self‐cleans the screen, so the press only needs short, intermittent spray cycles, cutting water use by 80–90% compared to belt presses.

Q4. What is the typical payback period when switching from belt press to screw press?

Plants processing under 1,000 kg DS/h often see a 3–4 year payback, driven by lower energy, polymer, and hauling costs.

Q5. Can I retrofit a screw press into my existing dewatering building?

Yes. Screw presses are compact and modular; many fit through standard double doors and connect to existing polymer and filtrate lines.

Conclusion: Make the Smart Choice for Sustainable Sludge Management

Your dewatering press determines more than cake dryness—it shapes your plant’s operating budget, environmental footprint, and compliance risk. A belt filter press still shines in high‐volume, fibrous applications, while screw press dewatering delivers drier cake, quieter operation, and lower lifecycle costs for most municipal and industrial sludges. Evaluate your sludge characteristics, space, and future regulations, then crunch the total cost of ownership numbers. Armed with the insights in this guide, you’re ready to select the dewatering press that slashes hauling costs and keeps your facility ahead of tightening standards. Ready to dig deeper? Explore the authoritative resources below and start optimizing your sludge dewatering strategy today.