Managing agrochemical waste effectively is a significant challenge for many in the agricultural sector. This type of waste often has a high moisture content, making it heavy, difficult to handle, and costly to dispose of. This is where specialized drying equipment comes in. By investing in the right machinery, you can transform wet, bulky agricultural waste into a manageable, stable material. This guide will walk you through everything you need to know to choose the best agrochemical waste drying equipment for your operation.

Table of contents

- Key Highlights

- Understanding Agrochemical Waste Drying Equipment

- Types of Agrochemical Waste Suited for Drying

- Key Features to Look for in Agrochemical Waste Dryers

- Paddle Dryer Technology in Agrochemical Waste Management

- Selecting the Right Equipment for Your Operation

- Reliable Manufacturers and Suppliers in India

- Maintenance and Longevity of Agrochemical Waste Drying Machines

- Frequently Asked Questions

- Conclusion

Key Highlights

Here’s a quick look at what we’ll cover:

- Understanding how agrochemical waste drying equipment works is the first step toward better waste management.

- The right drying process depends on the type of agrochemicals and their initial moisture content.

- Paddle dryers offer an efficient solution for drying various waste forms, including slurries and pastes.

- Key features to consider in drying equipment include energy efficiency, safety mechanisms, and production capacity.

- Proper maintenance ensures the longevity and optimal performance of your drying systems.

- Choosing the right manufacturer in India can provide access to innovative and cost-effective solutions.

Understanding Agrochemical Waste Drying Equipment

Before you can choose the right dryer, it’s important to grasp what this machinery does. Agrochemical waste drying equipment is designed to remove moisture from various waste materials generated by the agricultural industry. These drying systems are not one-size-fits-all; the best choice depends on your specific needs, the type of waste you handle, and your desired final product quality.

Understanding the fundamentals will help you make an informed decision. We will look into what this equipment is and the basic principles behind its operation.

Definition and Role in Waste Management

Agrochemical waste drying equipment is a category of industrial machinery specifically designed to reduce or eliminate the moisture content from waste products in the agricultural chemical industry. These wastes can include everything from sludge and slurries to pastes and powders. The primary goal is to transform wet, unstable material into a dry, solid form.

This equipment plays a crucial role in modern waste management strategies. By removing water, you significantly reduce the weight and volume of the agrochemical waste. This makes transportation and disposal much cheaper and easier.

Furthermore, drying stabilizes the waste, preventing the growth of mold and reducing the risk of environmental contamination. This process is a vital step in converting a liability into a more manageable substance, ensuring safer handling and disposal while complying with environmental regulations.

How Agrochemical Waste Drying Equipment Works

The fundamental principle behind all agrochemical waste drying equipment is heat transfer. The drying process involves applying energy to the wet material to cause the water within it to turn into vapor through evaporation. This vapor is then carried away, leaving behind a drier product.

Different drying systems use various methods for this heat transfer. Some are direct dryers, where hot air is blown directly over the material. Others are indirect dryers, which use a heated surface—like rotating blades or paddles—to transfer heat to the material through conduction. This method is often more efficient and allows for the recovery of solvents if needed.

The ultimate goal is the effective removal of moisture. The efficiency of the operation depends on factors like the temperature applied, how much surface area of the waste is exposed to the heat, and how quickly the evaporated moisture is removed from the system.

Types of Agrochemical Waste Suited for Drying

A wide variety of agrochemical and agricultural waste can be processed using modern drying equipment. The technology is versatile enough to handle materials in different physical states, from liquid slurry to dense, wet materials. The key is matching the waste type to a dryer designed to handle its specific properties.

Whether you are dealing with pastes, filter cakes, powders, or granules, there is a drying solution available. Understanding the characteristics of your waste is the first step in identifying which types of drying systems will be most effective for your needs.

Common Agrochemical and Agricultural Waste Materials

The agrochemical industry produces a diverse range of waste materials, many of which are ideal candidates for drying. Processing these materials helps in volume reduction and stabilization, making them easier and safer to handle. Drying is a common step for managing byproducts from the production of specialty chemicals and other agricultural products.

Many drying systems are specifically designed to handle challenging materials. The robust construction and efficient heat transfer mechanisms allow them to process even the most difficult agricultural waste streams effectively.

Common types of waste that can be processed include:

- Sludge: Effluent treatment plant sludge from production processes.

- Filter Cakes: Residual solids collected from filtration systems.

- Pastes: Thick, viscous byproducts from chemical synthesis.

- Biomass: Organic waste materials from agricultural sources.

- Wet Powders and Granules: Products that require a final drying step.

Challenges in Processing Various Waste Types

Processing different types of agrochemical waste presents unique challenges. The initial moisture content is a major factor, as it directly impacts the required drying time and energy consumption. Highly wet materials like sludge or a slurry require a system with a high evaporation capacity to be processed efficiently.

Another challenge is the physical consistency of the waste. Sticky pastes can clog machinery, while fine powders might become airborne. The right equipment must be designed to handle these properties without compromising performance. For instance, a system with agitated blades can prevent material from sticking and ensure uniform heat transfer.

Failing to address these challenges can lead to inefficient drying, spoilage, or even mold growth in the final product. Therefore, when choosing a machine, you must consider whether a continuous or batch operation is more suitable and how the dryer’s design addresses the specific hurdles your waste presents.

Key Features to Look for in Agrochemical Waste Dryers

When you’re ready to invest in agrochemical waste drying equipment, it’s essential to look beyond the basic function. Modern dryers come with a variety of features that can significantly impact your operational costs, final product quality, and workplace safety. Paying attention to these details will ensure you get the best value for your investment.

Important aspects to evaluate include the machine’s energy efficiency, its eco-friendly components, and the built-in safety mechanisms. Let’s explore what makes a dryer truly effective and reliable for the long term.

Energy-Saving and Eco-Friendly Components

High energy efficiency is a hallmark of a well-designed dryer. Machines with superior thermal efficiency use less fuel to achieve the desired level of dryness, directly lowering your operating costs. This is often achieved through superior insulation and efficient heat transfer mechanisms, such as in indirect dryers where heat is conducted directly into the material.

Many innovative systems also incorporate eco-friendly features. For example, some dryers are designed to operate under a vacuum, which lowers the boiling point of water and allows drying at a lower temperature, saving energy. Others include solvent recovery systems, which capture and condense solvents evaporated during the drying process for reuse.

Look for these key energy-saving and eco-friendly features:

- High thermal efficiency for reduced fuel consumption.

- Indirect heating for precise and efficient heat transfer.

- Solvent recovery systems to capture and reuse valuable chemicals.

- Low-temperature operation to minimize energy use.

- Continuous operation designs that minimize energy spikes associated with startup and shutdown.

Safety Mechanisms and Operational Considerations

Safety is paramount when handling agrochemicals. The drying equipment you choose must have robust safety features to protect your operators and your facility. This includes automated controls that maintain steady operating conditions and emergency shutdown mechanisms. Since some agrochemicals can be hazardous, a contained system that prevents dust or vapor from escaping is crucial.

Beyond built-in features, there are important operational considerations. Proper training for all operators is essential to ensure they understand how to handle the material and operate the machinery correctly. Consistent monitoring of moisture levels during the process helps ensure the final product is stable and safe for storage or packaging.

Key safety and operational considerations include:

- Automated controls for stable and predictable operation.

- Enclosed systems to contain dust and vapors.

- Proper ventilation for the work area.

- Comprehensive operator training on procedures and emergency protocols.

- Regular checks to ensure safety interlocks are functioning correctly.

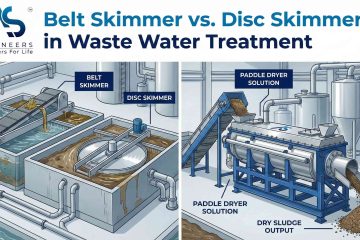

Paddle Dryer Technology in Agrochemical Waste Management

Among the various drying systems available, the paddle dryer stands out for its effectiveness in agrochemical applications. As a type of indirect dryer, it offers a highly efficient and controlled drying process. This technology is particularly well-suited for processing wet, pasty materials like slurries and filter cakes, which are common in the agrochemical industry.

A paddle dryer works by using heated, rotating paddles to simultaneously agitate and dry the material. This design maximizes heat and mass transfer, resulting in a fast and uniform drying process. Its unique capabilities make it an excellent choice for integration into a comprehensive waste management system.

Principles and Design of Paddle Dryers

A paddle dryer consists of a horizontal, trough-like vessel containing rotating shafts with wedge-shaped paddles. A heating medium, such as steam or hot oil, circulates through the hollow shafts and paddles, as well as an outer jacket. This design creates a massive surface area for heat transfer, making the process highly efficient.

As the shafts rotate, the paddles agitate the waste material, whether it’s a slurry, paste, or powder. This constant movement continually exposes new surfaces of the material to the heated paddles, ensuring uniform drying and preventing sticking. This precise control over the process helps maintain high product quality.

These dryers are typically constructed from durable materials like stainless steel to resist corrosion from chemicals and withstand continuous operation. The enclosed design also allows for operation under a vacuum, which enables low-temperature drying for heat-sensitive materials and facilitates solvent recovery.

Advantages of Paddle Dryers in Drying Agrochemical Waste

Using a paddle dryer for agrochemical waste offers several significant advantages over other drying technologies. Their primary benefit is exceptional thermal efficiency, which leads to lower energy consumption and reduced operational costs. The large heat transfer area allows them to process large volumes of waste quickly.

The design also allows for low-temperature drying, which is crucial when handling heat-sensitive specialty chemicals. This gentle approach preserves the integrity of the material while effectively removing moisture. The short drying time and continuous operation capability make it a highly productive choice for industrial-scale waste management.

Key advantages of using a paddle dryer include:

- High Evaporation Capacity: Efficiently removes large amounts of moisture.

- Excellent Thermal Efficiency: Lowers fuel and energy consumption.

- Compact Installation: Requires less floor space compared to other dryer types.

- Continuous Operation: Ideal for processing large volumes of waste without interruption.

- Versatility: Suitable for slurries, filter cakes, pastes, and powders.

Selecting the Right Equipment for Your Operation

Choosing the right drying equipment is a critical decision that impacts your entire operation. The ideal machine must align with your production capacity, the specific needs of your waste material, and your budget. Rushing this decision can lead to purchasing a system that is either too small to keep up or too large and inefficient for your needs.

To make the best choice, you need to assess several factors, from initial cost to long-term operational expenses. It is also important to consider how the new drying systems will integrate with your existing processes.

Cost Factors and Value Assessment

The initial purchase price of agrochemical drying equipment is just one of several cost factors to consider. While some dryers manufactured in countries like China or India may have a lower upfront cost, it’s crucial to perform a full value assessment. This includes evaluating long-term expenses like energy consumption, maintenance, and labor.

A machine with higher thermal efficiency may have a larger initial price but could save you a significant amount in fuel costs over its lifespan. Likewise, a dryer with a higher production capacity (measured in kg or tons per hr) might be a better investment if you anticipate future growth. The material of construction, such as stainless steel, also affects the price but ensures longevity and resistance to corrosion.

When assessing cost, consider the following factors:

| Cost Factor | Description |

|---|---|

| Initial Purchase Price | The upfront cost of the machinery, which can range from 20,00,000 to 30,00,000 INR or more depending on size and features. |

| Production Capacity | The volume of material (kg/hr or T/hr) the dryer can process. Higher capacity generally means a higher cost. |

| Energy Consumption | The amount of fuel or electricity required to operate the dryer. More efficient models have lower long-term costs. |

| Maintenance & Parts | The expected cost of routine maintenance and replacement parts over the machine’s life. |

| Installation & Labor | The cost associated with setting up the equipment and training personnel to operate it. |

Integration with Existing Waste Management Systems

Yes, new drying equipment can almost always be integrated into an existing waste management system. A successful integration requires careful planning to ensure a smooth and continuous operation from start to finish. Whether you are adding continuous indirect dryers or smaller batch dryers, the goal is to create a seamless workflow.

You should consider the entire process chain. For example, how will the wet material be fed into the dryer? This might require a conveyor system or a pump. After drying, what happens to the material? You may need a separator to remove fine particles or a cooling system before packaging.

Working with a manufacturer that offers project and engineering services can be highly beneficial. They can help you design a customized layout that connects the new drying equipment with your existing machinery, optimizing the entire operation for efficiency and minimizing bottlenecks. This ensures the dryer doesn’t just perform its function but enhances your overall waste management strategy.

Reliable Manufacturers and Suppliers in India

The market for industrial machinery in India is robust, with many reliable manufacturers offering advanced drying equipment. These suppliers often provide innovative systems that are both effective and cost-efficient. Sourcing your equipment locally from India can offer benefits like faster delivery times, easier access to support, and machinery designed for local conditions.

When searching for a supplier, it is important to look for companies with a proven track record in designing and manufacturing dryers for the chemical industry. This ensures they understand the specific challenges associated with agrochemical waste.

Major Brands in Agrochemical Waste Drying Equipment

When evaluating major brands in India, look for companies that demonstrate expertise and offer a range of drying systems. Leading manufacturers often provide customized solutions tailored to your specific production capacity and waste type. They understand that a standard machine might not be the perfect fit for every application.

A reputable brand will offer various options, from continuous systems for large-scale production to smaller units for batch operation. They should be able to provide detailed specifications about their equipment’s performance, including thermal efficiency and evaporation rates.

When considering different brands, look for these qualities:

- A portfolio that includes dryers specifically for the agrochemical industry.

- The ability to customize designs to meet specific client requirements.

- Proven experience with different types of drying systems, including paddle dryers.

- Strong engineering support to assist with installation and integration.

- A history of delivering reliable and high-performing equipment.

How to Evaluate Indian Suppliers

Evaluating suppliers in India for agrochemical drying equipment requires a thorough value assessment. Look beyond the price tag and consider the overall quality, reliability, and support offered. Start by checking their experience. How long have they been in business? Do they have case studies or testimonials from clients in the agrochemical sector?

Next, inquire about their engineering and customization capabilities. A good supplier will work with you to understand your process, from handling raw material to the final packaging stage. They should be able to advise on the best type of dryer and help design a system that fits your facility and workflow. This includes considering factors like available space and labor requirements.

Finally, discuss after-sales support. What kind of warranty do they offer? Do they provide assistance with installation, commissioning, and operator training? Reliable access to spare parts and technical support is crucial for minimizing downtime and ensuring your drying equipment operates efficiently for years to come.

Maintenance and Longevity of Agrochemical Waste Drying Machines

Investing in high-quality agrochemical waste drying machines is only half the battle. To ensure the longevity and consistent performance of your equipment, a regular maintenance schedule is essential. Proper care prevents unexpected breakdowns, maintains energy efficiency, and ensures the final product is free from issues like excess moisture or mold.

A proactive approach to maintenance is always better than a reactive one. By following a routine checklist and knowing how to handle common troubleshooting scenarios, you can keep your drying operations running smoothly and protect your investment.

Routine Maintenance Tips

Routine maintenance is key to keeping your drying machines in top condition. The most important task is regular cleaning. Residual material left in the dryer can harden, reduce efficiency, and even become a fire hazard. A consistent cleaning schedule ensures optimal heat transfer and product purity.

Beyond cleaning, it’s important to inspect all moving parts. For a paddle dryer, this means checking the rotating shafts, paddles, and bearings for signs of wear and tear. Proper lubrication according to the manufacturer’s guidelines is also crucial for preventing premature failure of these components.

Here are some essential routine maintenance tips:

- Regular Cleaning: Thoroughly clean the interior of the dryer to remove any residual material after each batch or at the end of each shift.

- Inspect Moving Parts: Check rotating blades, shafts, bearings, and drive systems for wear.

- Check Seals and Gaskets: Ensure all seals are intact to prevent leaks, especially in vacuum or contained systems.

- Lubrication: Follow the manufacturer’s schedule for lubricating bearings and other moving parts.

- Calibrate Controls: Periodically verify that temperature gauges and control systems are accurate.

Troubleshooting Common Issues

Even with regular maintenance, you might occasionally encounter issues with your drying machines. Knowing how to troubleshoot common problems can save you significant downtime. One of the most frequent issues is inconsistent final moisture content in the product. This can be caused by uneven feeding of material, incorrect temperature settings, or blockages inside the dryer.

If you notice a drop in product quality or efficiency, it often points to a maintenance issue. For example, a decrease in the evaporation rate might indicate a buildup of material on the heated surfaces, which reduces heat transfer. Similarly, unusual noises during operation could signal worn bearings or a problem with the drive system.

Here are some common issues and their potential causes:

- Inconsistent Drying: Check for uniform material feed and look for internal blockages. Verify temperature and residence time settings.

- Reduced Efficiency: Clean heated surfaces to remove any baked-on residue. Check the heating system for proper operation.

- Unusual Noises: Inspect bearings, drive chains, and gearboxes for wear and proper lubrication.

- Material Sticking: Ensure agitators or paddles are functioning correctly and that the operating temperature isn’t too high.

- Product Degradation: This may be due to excessive temperature or residence time. Adjust settings accordingly.

Frequently Asked Questions

Can agrochemical waste drying equipment reduce overall waste disposal costs?

Absolutely. By removing moisture, drying equipment significantly reduces the volume and weight of your waste. This directly translates to lower transportation and waste disposal fees. While there are initial cost factors, the long-term savings from reduced disposal expenses make it a highly cost-effective investment for your operation.

What safety measures should operators be aware of?

Operators should always wear appropriate personal protective equipment (PPE) and be trained on the specific operational considerations of the dryer. Key safety measures include ensuring proper ventilation, following correct startup and shutdown procedures, and never bypassing safety interlocks. Regular training on handling hazardous materials and emergency protocols is also essential.

Is it possible to upgrade my current system with a paddle dryer?

Yes, integrating a paddle dryer into an existing waste management system is a common upgrade. These indirect dryers are compact and can often be fitted into existing layouts. Working with an experienced manufacturer can help ensure a smooth integration with your current conveyors, feeders, and other drying systems.

What factors should I consider when selecting agrochemical waste drying equipment?

When selecting equipment, consider your required production capacity, the physical and chemical properties of your waste, and the desired final product quality. Other key factors include the type of dryer, its energy consumption, maintenance requirements, and overall cost-effectiveness. Aligning these with your specific needs ensures the best choice.

How does the type of agrochemical waste influence the choice of drying equipment?

The waste type is a primary factor. Wet materials like a slurry or paste with high moisture content may require indirect drying systems like a paddle dryer for efficient processing. The material’s stickiness, particle size, and heat sensitivity will determine the best drying process and whether a continuous or batch operation is more suitable.

What are the benefits of using modern drying technologies for agrochemical waste management?

Modern drying equipment offers significant benefits, including superior energy efficiency, which lowers operating costs. These innovative systems provide better control over the process, leading to higher product quality and more consistent moisture removal. They also feature improved safety and automation, making your waste management process more reliable and efficient.

Are there specific regulations or standards to be aware of when choosing agrochemical waste drying equipment?

Yes, your equipment must comply with local and national environmental and safety regulations, particularly regarding emissions and waste handling. In India, standards set by pollution control boards are critical. Ensure the drying equipment you choose helps you meet safety rules for operator exposure and final product stability for storage or packaging.

Conclusion

In conclusion, selecting the right agrochemical waste drying equipment, such as paddle dryers, is vital for efficient waste management and environmental sustainability. Paddle dryers offer unique advantages, including energy efficiency and effective moisture removal, making them ideal for a variety of agrochemical materials. By understanding the key features and operational considerations, you can ensure that your choice aligns with your specific needs and integrates seamlessly into your existing systems.

Remember, investing in reliable equipment not only enhances efficiency but also contributes to reducing overall waste disposal costs. If you have any questions or need assistance in choosing the right equipment, get in touch today!