Have you ever wondered what happens to the waste that goes down your drain? Modern wastewater treatment plants do a fantastic job of cleaning water, but this process creates a byproduct called sewage sludge. Managing this material is a significant challenge for communities everywhere. Proper sludge treatment and disposal are essential for environmental protection and public health. This guide will walk you through the methods and best practices for handling waste water treatment sludge, from its creation to its final use or disposal.

Table of contents

- Key Highlights

- Understanding Waste Water Treatment Sludge

- Key Stages of Sludge Production in Indian Sewage Treatment Plants

- Specific Sludge Treatment Steps (Thickening, Digestion, Dewatering, Stabilization, Incineration)

- Main Methods for Treating Waste Water Sludge

- Advanced Sludge Treatment Techniques

- Sludge Uses and Applications (Agriculture, Landscaping, Soil Erosion, Fuel, Ceramics)

- Contaminants in Sludge (Pathogens, Heavy Metals, Micro-pollutants, Hazardous Substances)

- Safe Disposal Practices for Wastewater Sludge

- Opportunities for Recycling and Reuse

- Environmental Risks and Regulation

- Frequently Asked Questions

- Conclusion

Key Highlights

Here are the key takeaways about wastewater treatment sludge:

- Wastewater treatment creates a semi-solid byproduct known as sewage sludge.

- The sludge treatment process involves steps like thickening, digestion, and dewatering to reduce volume and hazards.

- Proper sludge disposal is crucial for environmental protection and includes landfilling, incineration, or land application.

- Treated sludge, or biosolids, can be beneficially reused in agriculture as a soil amendment.

- Regulations govern the quality and use of sewage sludge to manage risks from contaminants.

- Sustainable sludge management focuses on resource recovery and contributing to a circular economy.

Understanding Waste Water Treatment Sludge

Wastewater treatment sludge is the residual, semi-solid material produced during the cleaning of municipal or industrial wastewater. Essentially, it’s the concentrated solids removed from the water during the treatment process. This material can’t simply be discarded; it requires its own careful sludge treatment.

Understanding how this sludge is formed, its composition, and its different types is the first step toward effective management. Let’s explore the specifics of what sludge is, how it’s made, and the factors that influence its characteristics.

Definition and Composition of Sludge

So, what exactly is wastewater treatment sludge? It is the semi-solid byproduct generated when suspended solids are separated from water in a sewage treatment plant. Before treatment, it is often called “raw” sludge and contains a high percentage of water along with a mixture of organic and inorganic materials.

The composition of sludge can vary greatly depending on the source of the wastewater. It is primarily made up of water, organic matter from human waste and food products, and inorganic materials like sand and grit. It also contains valuable plant nutrients, making it a potential resource.

However, sludge can also contain trace elements, organic chemicals, and pathogens. Because of its potentially hazardous nature, raw sludge must undergo a thorough treatment process before it can be safely used or disposed of, which is a key part of sludge treatment.

Formation of Sludge in Wastewater Treatment Plants

Sludge is formed at different stages during the treatment of wastewater. The process begins with preliminary screening to remove large objects. After this, the water flows into primary settling tanks, where about half of the suspended solid matter settles out through gravity. This collection of solids is known as primary sludge.

Following the primary stage, the water undergoes secondary treatment. This is often an accelerated biological treatment, such as the activated sludge process. In this step, microorganisms are used to consume dissolved and suspended organic material.

These microorganisms and other fine solids then settle out in secondary sedimentation tanks, forming secondary sludge. In some plants, a tertiary treatment stage is also used, which generates a third type of sludge. All these sludges are typically combined for further processing.

Types of Sludge Produced

Wastewater treatment plants generate several different types of sludge, each with unique characteristics based on the treatment stage it comes from. The main distinction is between raw primary sludge and secondary sludge.

These sludges are often combined before they undergo further treatment. The specific type of sludge produced depends on the technologies used at the plant.

Here are the main types of sludge:

- Primary Sludge: This is formed during primary treatment when heavier solid materials settle out from the wastewater in sedimentation tanks.

- Secondary Sludge: Also known as activated sludge, this is generated during the biological treatment process. It consists mainly of microbial cell mass that has consumed organic matter.

- Tertiary Sludge: Produced during advanced treatment stages, this sludge results from processes designed to remove specific nutrients like nitrogen and phosphorus.

Factors Influencing Sludge Characteristics

The characteristics of sludge, such as its sludge volume and composition, are not uniform. They are influenced by a variety of factors, which can present challenges for handling and disposal. The original source of the wastewater is a major determinant.

For example, wastewater from industrial areas may contain different pollutants than purely municipal wastewater. The specific treatment process used at the facility also plays a crucial role in the final characteristics of the sludge generated.

Several key factors shape the nature of sewage sludge:

- Wastewater Composition: The mix of residential, commercial, and industrial wastewater impacts the levels of organic material and inorganic solids.

- Treatment Process: The technologies used, such as the activated sludge process versus a trickling filter, affect sludge production and quality.

- Industrial Pretreatment: Rules requiring industries to pretreat their waste can significantly reduce the concentration of heavy metals and other pollutants.

Key Stages of Sludge Production in Indian Sewage Treatment Plants

The production of sludge in sewage treatment plants, whether in India or elsewhere, generally follows a multi-stage process. Each step of sewage treatment is designed to remove different types of contaminants from the water, and each creates its own kind of sludge.

These stages include primary, secondary, and sometimes tertiary treatment, which produce primary sludge, secondary sludge, and tertiary sludge, respectively. The following sections will break down how sludge is generated at each of these key stages.

Primary Sludge Generation

The very first step in sludge generation occurs during primary treatment. After raw sewage enters the treatment plant and passes through initial screens, it moves into large basins called primary settling tanks. Here, the flow of water is slowed down considerably.

This allows gravity to do its work. Heavier suspended solids sink to the bottom of the tank. This settled material is what we call primary sludge. This process can remove approximately 50% of the suspended solids from the wastewater.

This primary sludge is considered “raw” or “fresh” and must be removed from the tank before it begins to decompose and create odors. It is then typically combined with sludge from other treatment stages for further processing.

Secondary (Activated) Sludge Process

After primary treatment, the wastewater moves to the secondary treatment stage, where the activated sludge process is commonly used. This is a biological process that relies on a thriving population of microorganisms to clean the water.

These bacteria and protozoa consume the dissolved organic matter that wasn’t removed in the primary settling tanks. They convert this organic material into carbon dioxide and more microbial cells. This mass of microorganisms is the key component of secondary sludge.

The activated sludge process is a carefully controlled environment where:

- Air or oxygen is supplied to encourage the growth of aerobic bacteria.

- The microorganisms digest suspended and dissolved organic pollutants.

- The resulting microbial cell mass settles in secondary sedimentation tanks.

- This settled material is collected and removed as secondary sludge.

Tertiary Sludge and Specialized Treatments

Some wastewater treatment plants include a third stage, known as tertiary treatment, to achieve an even higher quality of discharged water. This stage is designed to remove any remaining nutrients, suspended solids, or other specific contaminants.

These specialized treatments often involve chemical or physical processes. For instance, chemicals may be added to cause phosphorus to precipitate out of the water and settle. Filtration methods might also be used to capture very fine particles.

The solid material captured during this advanced stage is known as tertiary sludge. Like primary and secondary sludge, this material is typically combined with the others and sent for further sludge treatment and processing before its final disposal.

Specific Sludge Treatment Steps (Thickening, Digestion, Dewatering, Stabilization, Incineration)

Once sludge is collected from the different wastewater treatment stages, it is far from ready for final disposal. Raw sludge is mostly water and is biologically unstable. It must undergo several treatment steps to reduce its volume, stabilize it, and reduce pathogens.

Key steps in this process include sludge thickening, digestion, and dewatering to produce dewatered sludge. Further treatments like stabilization and incineration prepare the material for safe reuse or disposal. Let’s look at these crucial methods in more detail.

Main Methods for Treating Waste Water Sludge

There are several main methods for treating wastewater sludge, each designed to make the material safer and easier to handle. The goal of these sludge treatment methods is to reduce water content, decrease volume, and eliminate harmful pathogens and odors.

Common approaches include sludge thickening, the digestion process (both aerobic and anaerobic), dewatering, and composting. The choice of method depends on the sludge characteristics and the intended final use or disposal. Below, we’ll explore some of these key techniques.

Thickening Processes

A critical first step in sludge treatment is thickening. Raw sludge can be more than 99% water, so reducing this water content is essential to decrease the overall volume of sludge. This makes subsequent treatment, handling, and transportation more efficient and less costly.

Sludge thickening is a process that concentrates the solid particles in the sludge. This can be achieved through methods like gravity settling, where solids sink to the bottom of a tank, or dissolved air flotation, where air bubbles cause solids to float to the surface for skimming.

The thickening process transforms the sludge into a more concentrated liquid, but it is still fluid enough to be pumped to the next stage of the treatment process.

| Treatment method | Description | Effects on sludge |

|---|---|---|

| Thickening | Sludge solids are concentrated by gravity settling or by introducing air to float the solids. | Solids content is increased to 5-6%, but sludge remains a liquid. |

Digestion – Aerobic and Anaerobic Approaches

After thickening, sludge often undergoes a digestion process to stabilize the organic matter. This biological process reduces odors, pathogens, and the total volume of solids. The two main approaches are anaerobic and aerobic digestion.

Anaerobic digestion, one of the most widely used methods, involves holding sludge in an oxygen-free environment. Bacteria break down organic pollutants, producing methane gas that can be captured and used as an energy source. Aerobic digestion uses oxygen to achieve similar goals, though it typically results in some nitrogen loss.

Key benefits of the digestion process include:

- Reduces the volume of volatile solids.

- Decreases the number of viable pathogens.

- Reduces unpleasant odors.

- Anaerobic digestion conserves plant nutrients and can produce biogas for energy.

Dewatering Technologies

Even after thickening and digestion, sludge still contains a large amount of water. The next step, sludge dewatering, aims to remove as much of this remaining water as possible. This process transforms the sludge from a liquid into a semi-solid or solid cake-like material, known as dewatered sludge.

Reducing the water content so drastically makes the sludge much lighter and easier to handle, transport, and dispose of. Common dewatering technologies include air drying on sand beds, which is a slow but effective process, and mechanical methods like centrifugation or belt pressing.

While centrifugation and filtration are fast, they can result in some loss of nutrients from the sludge. The choice of dewatering technology depends on the desired final solids content and the specific needs of the treatment process.

Composting and Stabilization Techniques

Composting is a sustainable method for stabilizing sludge and converting it into a valuable product. For this process, dewatered sludge is mixed with a high-carbon organic material like sawdust or wood chips. This mixture is then composted under aerobic conditions, with temperatures reaching high enough levels to eliminate most pathogens.

Another stabilization technique is alkaline stabilization. This involves adding an alkaline material, such as lime, to raise the pH of the sludge. This high pH effectively reduces pathogens and volatile solids, creating a more stable product.

These techniques are excellent for preparing sludge for beneficial reuse as biosolids:

- Composting: Creates a stable, soil-like product, reduces odors, and stabilizes organic matter.

- Alkaline Stabilization: Rapidly decreases pathogens and stabilizes sludge for land application.

- Both methods prepare the organic material for safe use as a soil conditioner.

Advanced Sludge Treatment Techniques

Beyond the standard methods, advanced sludge treatment techniques offer further options for reducing volume, destroying contaminants, and recovering resources. These methods often involve thermal treatment at high temperatures, chemical conditioning, and other emerging technologies.

These advanced processes can help meet stricter environmental regulations and support a more circular approach to sludge management. Let’s examine some of these sophisticated techniques, including heat drying, chemical treatments, and innovative new approaches.

Heat Drying and Thermal Processing

Heat drying is an advanced thermal treatment that uses high temperatures to remove even more water from dewatered sludge. This process can produce a final product with a very high solids content, often in the form of dry granules or pellets. This significantly reduces the final volume and weight, making storage and transport much cheaper.

The high temperatures used in heat drying and other thermal processing methods also effectively destroy any remaining pathogens, producing a Class A biosolid product that has fewer restrictions for use.

Other thermal treatments like pyrolysis can convert sludge into biochar and syngas, offering a way to recover energy and create useful materials. These techniques are part of a growing trend to see sludge not as waste, but as a resource.

Chemical Conditioning and Treatment

Chemical conditioning is a process where chemicals are added to sludge to improve its characteristics for subsequent treatment steps, particularly dewatering. These chemicals cause the small solid particles to clump together, which makes it easier to separate the water from the solids.

In addition to conditioning, chemicals can be used for stabilization. For example, adding sufficient lime raises the sludge’s pH to a level that kills pathogens and reduces odors. This process, known as alkaline stabilization, is a common method for treating sludge before land application.

Chemical treatments can address various aspects of sludge management:

- They improve dewatering efficiency.

- Alkaline stabilization effectively reduces pathogen levels.

- Certain chemical processes can help remove or bind organic pollutants and inorganic materials like heavy metals.

Emerging Technologies in Sludge Management

The field of sludge management is constantly evolving, with several emerging technologies aimed at creating a more sustainable and circular economy. These innovations focus on resource recovery, reducing energy consumption, and minimizing the final waste volume.

One exciting area is the recovery of valuable components from sludge. For example, technologies are being developed to extract phosphorus, a finite and essential nutrient for agriculture. Other processes focus on converting the organic content of sludge into energy, such as through pyrolysis or co-combustion in power plants.

Some promising emerging technologies include:

- Pyrolysis: A thermal process that creates biochar and syngas from sludge.

- Nutrient Recovery: Extracting phosphorus and nitrogen for use as fertilizers.

- Energy Recovery: Using dried sludge as a fuel source to reduce reliance on fossil fuels.

- Advanced dewatering technologies like reverse osmosis to further reduce water content.

Sludge Uses and Applications (Agriculture, Landscaping, Soil Erosion, Fuel, Ceramics)

Once sludge has been properly treated to meet quality standards, it becomes a resource with a wide range of beneficial uses. This treated sludge, often called biosolids, can be recycled instead of being thrown away. The most common reuse is land application on agricultural land, where it acts as a valuable soil amendment and fertilizer.

The organic matter and nutrients in biosolids improve soil health and crop growth. Beyond agriculture, treated sludge has found applications in landscaping, mine reclamation, and even as an energy source. The ash from incineration can also potentially be used in construction materials like ceramics or bricks.

Here are some common applications for treated sludge:

- Agriculture: As a fertilizer and soil conditioner on agricultural land.

- Landscaping: For use in horticulture and landscaping projects.

- Land Reclamation: To restore soil on former mine sites.

- Fuel: As an energy source when co-burned with coal.

- Construction: Ash can be used as an additive in concrete or asphalt.

Contaminants in Sludge (Pathogens, Heavy Metals, Micro-pollutants, Hazardous Substances)

While treated sludge offers many benefits, it’s important to recognize that it can also contain contaminants that pose risks to public health and the environment. These contaminants become concentrated in sludge during the wastewater treatment process. They can include pathogens like bacteria and viruses, heavy metals, organic pollutants, and other hazardous substances.

Micro-pollutants, such as pharmaceuticals, personal care products, and “forever chemicals” like PFAS, are also a growing concern. The presence of these substances is one of the main challenges in sludge management and is why strict regulations and treatment standards are necessary to ensure the material is handled and used safely.

Safe Disposal Practices for Wastewater Sludge

When treated sludge cannot be beneficially reused, it must be disposed of safely. The main sludge disposal methods are sending it to a landfill, incineration, or controlled land application. Each option has its own set of environmental considerations and requires careful management to protect public health.

The choice of disposal method depends on local regulations, sludge characteristics, and economic factors. To ensure safety, these practices are governed by strict rules, especially if the material is classified as hazardous waste. Let’s explore the precautions for each of these disposal routes.

Landfill Options and Precautions

Disposing of sewage sludge in a landfill is one of the most straightforward disposal methods. The dewatered solid waste is simply transported to a licensed landfill and buried. From a management perspective, this is a relatively simple solution.

However, landfilling is not without its risks. The decomposition of organic matter in the sludge can produce methane, a potent greenhouse gas. There’s also a risk of nutrients and contaminants leaching into the groundwater if the landfill’s liner system fails.

To minimize risks, several precautions are necessary:

- Only properly treated and dewatered sludge should be landfilled.

- Landfills must have modern liner and leachate collection systems.

- Some regions are phasing out landfilling to conserve space and encourage recycling.

- If sludge contains high levels of certain pollutants, it may be classified as hazardous waste and require special handling.

Incineration Methods

Incineration is a final disposal method that uses high temperatures to burn dewatered sludge. This process dramatically reduces the volume of the waste, leaving behind only a small amount of ash, which is typically 10-20% of the original volume.

This process completely destroys pathogens and most organic chemicals. However, incineration comes with its own environmental concerns. It releases carbon dioxide into the atmosphere and can also release volatile pollutants if the exhaust gas is not properly cleaned.

Important considerations for incineration include:

- It is an expensive option due to the need for sophisticated air pollution control systems.

- The resulting ash is concentrated with heavy metals and must be disposed of carefully, often in a landfill.

- The heat generated during incineration can be recovered and used to produce energy.

Land Application Guidelines in India

Land application of treated sludge, or biosolids, is a common practice that recycles valuable nutrients and organic matter back to the soil. To ensure this is done safely, countries establish strict regulatory standards and guidelines. While specific rules vary, the principles are universal.

These guidelines are designed to protect human health, soil quality, and water resources. They typically set limits on the concentration of heavy metals and other pollutants in the biosolids and restrict how, when, and where the material can be applied.

General guidelines for land application often include:

- Only high-quality, treated sludge that meets pathogen reduction standards may be used.

- Limits are placed on the total amount of pollutants that can be added to a site over time.

- Setback distances are required from wells, homes, and water bodies.

- There may be restrictions on crop harvesting or animal grazing for a period after application.

Opportunities for Recycling and Reuse

Viewing sludge not as a waste but as a resource opens up numerous opportunities for recycling and reuse. Instead of disposal, sustainable sludge management focuses on converting this byproduct into valuable materials. This shift is a key part of building a more circular economy.

The most well-known opportunity is the production of biosolids for agricultural use. However, there are also growing opportunities for industrial reuse and energy recovery. Let’s delve into these exciting avenues for recycling wastewater sludge.

Conversion of Sludge to Biosolids

The conversion of sewage sludge into biosolids is a prime example of recycling. Biosolids are not just raw sludge; they are the result of a rigorous treatment process that stabilizes the material and significantly reduces pathogens. This makes the sludge solids safe for land application.

The treatment process for creating biosolids involves stabilizing the organic matter through methods like digestion or composting. This ensures the material will not create odor problems or attract pests. The term “biosolids” itself is used to distinguish this high-quality, treated product from raw, untreated sludge.

Key aspects of this conversion include:

- Undergoing a treatment process to reduce pathogens.

- Stabilizing the organic matter to prevent odors.

- Meeting strict quality criteria for pollutants like heavy metals.

- Producing a material suitable for beneficial reuse, particularly in agriculture.

Agricultural Uses of Treated Sludge

One of the most significant reuses of treated sludge is its application to agricultural land. When applied to soil, biosolids act as an excellent soil amendment and a source of essential plant nutrients. The high organic material content helps improve soil structure, water retention, and overall health.

This land application returns nutrients and organic matter that were originally taken from the land in the form of crops. However, the practice is highly regulated to protect public health and the environment from potential contaminants in the sludge.

The benefits and considerations of agricultural use include:

- Provides a slow-release source of nutrients for crops.

- Improves soil health by adding organic matter.

- Reduces the need for synthetic fertilizers.

- Requires strict monitoring and adherence to regulations to manage risks from pollutants.

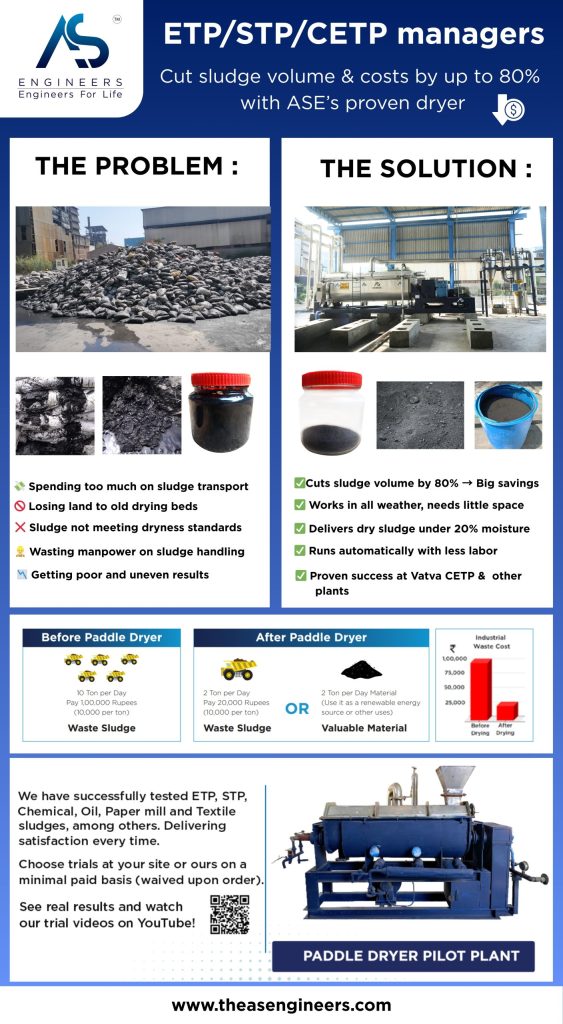

Industrial Reuse and Energy Recovery

Beyond agriculture, there are growing opportunities for industrial reuse and energy recovery from sewage sludge. Dried sludge can be used as an energy source, reducing the reliance on fossil fuels in certain industrial processes.

For example, it can be co-combusted with coal in power plants to generate electricity. This not only provides an energy source but also serves as a disposal method. The ash produced from incineration can also be repurposed in some cases, such as an additive in construction materials like concrete or asphalt.

Industrial and energy applications include:

- Co-combustion: Burning dried sludge with coal to produce electricity.

- Pyrolysis: Creating syngas for energy and biochar for soil amendment.

- Construction Materials: Using incinerator ash as a component in bricks, asphalt, or concrete.

- These industrial processes provide an alternative to landfilling and agricultural use.

Environmental Risks and Regulation

While recycling sludge is beneficial, it’s crucial to manage the associated environmental and health risks. Sludge can contain contaminants that, if not properly handled, could harm soil, water, and human health. This is why robust regulatory standards are essential for environmental protection.

Government agencies set rules to control the quality of sludge and how it is treated, used, and disposed of. The following sections will detail the potential contaminants of concern and the regulatory frameworks designed to keep us safe.

Potential Contaminants in Sludge

Sewage sludge can be a reservoir for a variety of contaminants that are removed from wastewater. The presence of these substances is a primary concern for public health and is a major challenge in sludge management.

The main categories of contaminants include pathogens, heavy metals (also known as trace elements), and a wide array of organic pollutants. Heavy metals like lead, cadmium, and mercury are a particular concern because they do not break down and can accumulate in the soil over time.

Potential contaminants found in sludge include:

- Pathogens: Bacteria, viruses, and other microorganisms that can cause disease.

- Heavy Metals: Trace elements like arsenic, cadmium, copper, lead, and zinc.

- Organic Pollutants: Substances like PCBs, dioxins, and flame retardants.

- Micro-pollutants: Pharmaceuticals, personal care products, and PFAS chemicals that can affect human health.

Regulatory Standards and Guidelines in India

To manage the risks associated with sludge contaminants, regulatory bodies like the U.S. Environmental Protection Agency (EPA) establish comprehensive standards and guidelines. While this information is based on U.S. and EU models, similar principles apply globally, including in India, where an environmental protection agency would set local rules.

These regulatory standards are designed to ensure that sludge is treated and used in a way that protects both human health and the environment. They set specific limits for pollutants and define the required treatment levels for different uses.

Core components of these regulatory guidelines include:

- Pollutant Limits: Ceiling concentrations are set for heavy metals like cadmium and lead.

- Pathogen Reduction: Sludge is classified based on the level of pathogen reduction it has undergone (e.g., Class A or Class B).

- Management Practices: Rules for application sites, such as setback distances and crop restrictions.

- Monitoring and Reporting: Requirements for facilities to test their sludge and report the results.

Sustainable Solutions and Best Practices

Moving towards sustainable sludge management involves adopting best practices that prioritize resource recovery and minimize environmental impact. This approach aligns with the principles of a circular economy, where waste is transformed into a resource.

Sustainable solutions focus on more than just disposal; they aim to recover energy, nutrients, and other valuable materials from sludge. This helps reduce greenhouse gas emissions, like methane from landfills, which contribute to climate change.

Some key best practices for sustainable solutions include:

- Prioritizing beneficial reuse over landfilling.

- Investing in technologies for energy recovery, such as anaerobic digestion with biogas capture.

- Implementing nutrient recovery systems to extract phosphorus and nitrogen.

- Enforcing strict industrial pretreatment programs to keep pollutants out of sludge in the first place.

Frequently Asked Questions

What types of sludge are produced during wastewater treatment processes?

The main types of sludge are primary, secondary, and tertiary sludge. Primary sludge comes from the initial settling of solids. Secondary sludge, or activated sludge, is generated from the biological activated sludge process. Tertiary sludge is produced during advanced treatment stages that remove specific nutrients.

What are the most common methods for treating wastewater sludge?

The most common sludge treatment methods include thickening to reduce volume, a digestion process (aerobic or anaerobic) to stabilize organic matter, and sludge dewatering to create a solid cake. Further treatments like composting for reuse or incineration for disposal are also widely used.

How can wastewater treatment plants effectively manage and dispose of sludge?

Effective management starts with a thorough sludge process to create stable, dewatered sludge. For sludge disposal, plants can choose between landfilling, incineration, or beneficial reuse of the treated sludge as biosolids for land application. The best choice depends on regulations, sludge quality, and local needs.

What best practices should be followed to ensure the safe handling of treated sludge?

Best practices for handling treated sludge include following all regulatory guidelines for testing and application. This ensures that contaminant levels are low and pathogens are reduced, protecting human health and public health. For sludge disposal, using modern, controlled methods like lined landfills or clean incineration is crucial.

What are the different types of sludge generated during wastewater treatment processes?

Wastewater treatment generates three main types of sludge. Primary sludge consists of settled solids from initial treatment. Secondary sludge is the microbial mass from biological treatment. Tertiary sludge is formed during advanced polishing steps. Together, these make up the bulk of sewage sludge that requires further processing.

How are the methods for treating wastewater sludge determined?

The methods for the treatment process are determined by several factors. These include the sludge characteristics (like its water and organic content), the regulatory requirements for disposal or reuse, the desired final product, and the economic feasibility of the treatment options available to the facility.

What best practices should be followed for handling and disposing of treated sludge?

Best practices for handling and disposing of treated sludge include regular monitoring for contaminants, proper storage to prevent leaks, using appropriate transportation methods, ensuring compliance with local regulations, and exploring beneficial reuse options such as soil amendment or energy generation to minimize environmental impact.

Can wastewater treatment sludge be repurposed or reused in any way?

Yes, wastewater treatment sludge can be repurposed or reused in several ways. It can be processed into biosolids for land application, used as a soil amendment to enhance fertility, or converted into energy through anaerobic digestion, thereby promoting sustainability in waste management.

Conclusion

In summary, understanding and effectively managing wastewater treatment sludge is crucial for both environmental sustainability and regulatory compliance. With various methods available – from thickening and digestion to advanced treatments – it’s essential to choose the right approach based on the specific characteristics of the sludge at hand. By adopting best practices for sludge handling and exploring opportunities for recycling and reuse, we can minimize the environmental impact while optimizing resource use. If you’re looking to enhance your knowledge or get tailored advice on wastewater management strategies, don’t hesitate to book a free consultation with our experts today!