What happens to the water after it leaves your bathroom, kitchen, or washing machine? While most of us never think twice about it, that water—full of organic waste, grease, pathogens, and chemicals—doesn’t just vanish. It needs to be treated before it’s safe to release back into the environment or reused. That’s exactly where an STP (Sewage Treatment Plant) comes in.

In today’s rapidly urbanizing world, STPs have become essential for residential complexes, commercial buildings, hospitals, hotels, and industries. With water scarcity growing and environmental laws becoming more stringent, having a reliable, compliant, and efficient STP is no longer optional—it’s a responsibility.

This blog will walk you through:

- What an STP is and how it works

- The complete treatment process from inlet to outlet

- Types of STP technologies like MBBR, SBR, and MBR

- Treated water reuse options

- Legal norms and how to stay compliant

- A real-world case study of a residential STP

Let’s begin with the basics: what exactly is an STP, and why does every facility generating sewage need one?

What is STP (Sewage Treatment Plant)?

An STP (Sewage Treatment Plant) is an engineered system designed to treat domestic or municipal sewage, making the water clean enough for safe disposal or reuse. It removes contaminants such as:

- Suspended solids

- Organic waste

- Nutrients (nitrogen, phosphorus)

- Disease-causing microbes

- Oils and grease

The treated water—called treated effluent—can be discharged to the environment or reused for non-potable purposes like gardening, flushing, and cooling tower operations.

How STP Differs from ETP

| Feature | STP (Sewage Treatment Plant) | ETP (Effluent Treatment Plant) |

|---|---|---|

| Input Wastewater | Domestic sewage (toilets, kitchens, etc.) | Industrial effluent (process wastewater) |

| Contaminants | BOD, COD, pathogens, solids | Chemicals, oils, heavy metals, TDS |

| Treatment Method | Biological (mainly aerobic) | Depends on industry—chemical, biological |

| Reuse Potential | Gardening, flushing, cooling | Depends on industry; often requires polishing |

| Legal Requirement | Mandatory for residential & commercial | Mandatory for manufacturing/processing units |

Who Needs an STP?

As per CPCB and local development control regulations, the following projects must have an STP:

- Residential societies with >20,000 sq. m built-up area

- Hotels and resorts with >100 rooms

- Hospitals with >100 beds

- Commercial complexes, malls, and IT parks

- Educational and institutional campuses

- Industrial estates (for domestic sewage portion)

Note: Many local authorities now mandate 100% reuse of treated water within the premises (e.g., flushing, landscaping), making STPs even more critical.

STPs and Environmental Compliance

Failing to install or maintain an STP can result in:

- Denial of Occupancy Certificate (OC)

- Fines or closure notices by the State Pollution Control Board

- Contamination of groundwater and surface water

- Negative impact on brand image and stakeholder trust

Why STPs Are Essential Today

As cities grow and water resources shrink, sewage treatment is no longer just a civic responsibility—it’s an operational necessity. Whether you’re a builder, facility manager, or sustainability officer, a functional and compliant STP is key to avoiding environmental violations, managing water efficiently, and future-proofing your infrastructure.

Here’s why STPs are more essential than ever:

1. Rising Urbanization and Sewage Load

With rapid real estate growth and population density in urban areas, the pressure on municipal sewage lines is overwhelming. In many cities:

- Centralized sewage networks are either overloaded or non-existent

- Untreated sewage often finds its way into lakes, rivers, or groundwater

Installing localized STPs in societies, hotels, or tech parks reduces this burden and ensures on-site treatment of wastewater.

2. Regulatory Compliance and Occupancy Approvals

In India, agencies like the CPCB and respective State Pollution Control Boards (SPCBs) have made STPs mandatory for specific categories of development.

Failure to comply can lead to:

- Rejection of project approvals and completion certificates

- Heavy fines, including retrospective environmental compensation

- Legal action and public complaints

Common mandates include:

- BOD < 20 mg/L

- TSS < 30 mg/L

- pH 6.5–8.5

- On-site reuse of treated sewage

3. Water Reuse for Non-Potable Needs

STPs allow facilities to reuse treated sewage for:

- Toilet flushing

- Gardening and landscaping

- Cooling towers

- Construction and floor washing

This reduces:

- Water tanker dependency

- Monthly water bills

- Borewell stress and overextraction

For green buildings and LEED-certified structures, in-house STPs and water reuse systems are mandatory benchmarks.

4. Environmental and Public Health Impact

Untreated sewage is one of the largest sources of water pollution, leading to:

- Groundwater contamination

- Spread of waterborne diseases

- Algal blooms and oxygen depletion in lakes

- Toxic build-up in aquatic ecosystems

STPs prevent this by removing organic matter, pathogens, and nutrients before the water is reused or released.

5. Sustainability, ESG, and CSR Goals

Corporate and residential projects alike are now evaluated based on:

- Environmental footprint

- Water conservation strategies

- Community safety

An STP adds measurable value to:

- ESG performance reports

- Sustainability certifications (ISO 14001, GRI, etc.)

- Green building scorecards

Summary: Why STPs Are Indispensable

| Reason | Key Benefit |

|---|---|

| Overloaded sewer systems | Localized treatment, less burden |

| Regulatory compliance | Avoid fines, secure approvals |

| Water reuse | Lower cost and reduced water demand |

| Public and environmental health | Prevents pollution and disease spread |

| Green certifications & ESG | Higher project value, reputation |

How an STP Works – Step-by-Step Process

An STP transforms contaminated domestic sewage into clear, pathogen-free water through a series of physical, biological, and chemical processes. Each stage plays a crucial role in reducing pollutants and preparing the water for safe discharge or reuse.

Here’s a breakdown of the complete sewage treatment process:

1. Preliminary Treatment

Purpose: Remove large solids and floating debris that can damage pumps or clog downstream equipment.

Key Units:

- Bar Screen Chamber: Captures plastics, rags, and solids

- Grit Removal Chamber: Settles sand, gravel, and non-biodegradable particles

- Oil & Grease Trap: Separates floatable oils and scum from kitchen and wash water

These units act as the plant’s first line of defense, ensuring mechanical safety and smoother operation downstream.

2. Primary Treatment

Purpose: Settle suspended solids and equalize wastewater flow and characteristics.

Process:

- Equalization Tank: Balances hydraulic load variations

- Primary Clarifier/Sedimentation Tank: Allows heavier solids to settle by gravity

- pH Adjustment: Ensures optimal range (6.5–8.5) for biological treatment ahead

Sludge generated here is stored separately and later processed in the sludge handling unit.

3. Secondary (Biological) Treatment

Purpose: Biodegrade organic matter (BOD, COD) using aerobic microorganisms.

Several technologies can be used at this stage:

a) Activated Sludge Process (ASP)

- Air is bubbled through an aeration tank

- Microbes consume organic pollutants

- Followed by secondary clarifier to separate biomass (sludge)

b) Moving Bed Biofilm Reactor (MBBR)

- Uses plastic media for biofilm growth

- Offers compact, efficient treatment in less space

- Ideal for retrofits or space-limited STPs

c) Sequential Batch Reactor (SBR)

- Batch-wise aerobic treatment in a single tank

- Combines aeration, settling, and decanting in cycles

- Best suited for residential STPs with fluctuating loads

d) Membrane Bioreactor (MBR)

- Combines activated sludge with membrane filtration

- Produces ultra-clear water—suitable for high-end reuse

- Higher cost, but compact and advanced

The biological stage is where 80–90% of pollution is removed from the sewage.

4. Tertiary Treatment

Purpose: Polish the biologically treated water and disinfect it for reuse or discharge.

Units Typically Include:

- Pressure Sand Filter (PSF): Removes fine particles and turbidity

- Activated Carbon Filter (ACF): Removes color, odor, and organic traces

- Disinfection Unit (UV/Chlorine): Eliminates pathogens like bacteria, viruses, coliforms

📌 After this stage, treated water meets norms for toilet flushing, gardening, and non-potable use.

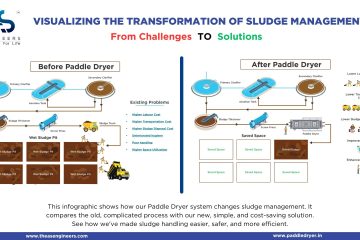

5. Sludge Handling and Drying

Purpose: Safely manage solid waste generated from clarifiers and biological units.

Technologies:

- Filter Press / Centrifuge: Dewaters sludge to reduce volume

- Paddle Dryer (AS Engineers): Dries sludge to <20% moisture for safe TSDF disposal

- Drying Beds (for small STPs): Sun-drying option, less suitable in monsoon or high-volume setups

Proper sludge management is essential to complete the treatment cycle and meet compliance norms.

Key Components of a Sewage Treatment Plant (STP)

A sewage treatment plant is more than just a set of tanks—it’s a precisely engineered system where each component plays a vital role in transforming raw sewage into clean, reusable water.

Here’s a detailed look at the essential STP components:

1. Bar Screen Chamber

Purpose: Captures large floating debris (plastic, paper, rags) from raw sewage before it enters the treatment system.

- Reduces clogging risk in pumps and downstream equipment

- Must be cleaned regularly to maintain flow efficiency

2. Grit Chamber

Purpose: Removes heavy inorganic solids like sand, gravel, and grit.

- Prevents abrasion and sediment buildup in tanks and pipelines

- Often designed as a horizontal flow or vortex-type separator

3. Oil & Grease Trap

Purpose: Separates lighter-than-water floatables such as oils and fats.

- Especially important for STPs treating kitchen or food-processing wastewater

- Prevents biofilm inhibition in biological reactors

4. Equalization Tank

Purpose: Buffers flow and quality fluctuations in incoming sewage.

- Maintains a steady hydraulic and organic load

- Equipped with air diffusers to prevent settling and odor

5. Aeration Tank / Biological Reactor

Purpose: Enables aerobic microbial digestion of organic pollutants (BOD/COD).

- Can use technologies like ASP, MBBR, SBR, or MBR

- Requires diffused aeration or mechanical aerators

- Needs consistent oxygen supply to sustain biomass activity

6. Secondary Clarifier / Settling Tank

Purpose: Separates microbial biomass (sludge) from treated water after aeration.

- Settled sludge is either returned to aeration tank (in ASP systems) or removed for dewatering

- Clear supernatant flows to tertiary treatment

7. Tertiary Treatment Units

Components:

- Pressure Sand Filter (PSF): Removes fine suspended particles

- Activated Carbon Filter (ACF): Absorbs color, odor, and organic residues

- Disinfection System (UV or Chlorination): Eliminates bacteria and viruses

8. Treated Water Storage Tank

Purpose: Stores final treated water for reuse in flushing, gardening, or utilities.

- Often equipped with level sensors and recirculation pumps

- Needs proper labeling and separation from drinking water lines

9. Sludge Handling System

Components:

- Sludge Holding Tank: Stores thickened sludge from clarifiers

- Filter Press / Centrifuge: Dewaters sludge to reduce volume

- Paddle Dryer: Reduces sludge moisture to <20% for safe TSDF disposal

- Drying Beds (for small STPs): Natural drying option in favorable climates

Component Summary Table

| Component | Function |

|---|---|

| Bar Screen | Removes large solids |

| Grit Chamber | Settles sand and grit |

| Oil & Grease Trap | Separates floatables |

| Equalization Tank | Stabilizes flow and quality |

| Aeration Tank | Biodegrades organic load |

| Secondary Clarifier | Separates sludge from treated water |

| PSF + ACF | Polishes treated water |

| Disinfection Unit | Kills pathogens |

| Sludge Handling Unit | Manages and dries solid waste |

| Treated Water Tank | Stores reusable water |

Types of STP Technologies

While all STPs aim to treat sewage effectively, the core biological treatment process varies based on the selected technology. Below are the most common types of STP systems, their working principles, and ideal use cases.

1. Activated Sludge Process (ASP)

How It Works:

- Wastewater is aerated in a tank where bacteria break down organic matter.

- After aeration, the water flows into a secondary clarifier, where the biomass settles.

- Part of the sludge is returned to the aeration tank (Return Activated Sludge – RAS), and the rest is removed.

Best For:

- Municipal STPs

- Large residential or commercial complexes with consistent sewage flow

Pros:

- Proven, widely used system

- Handles large volumes

Cons:

- Requires more space

- Sludge management is intensive

2. Moving Bed Biofilm Reactor (MBBR)

How It Works:

- Plastic media carriers are suspended in the aeration tank.

- Microorganisms form biofilm on the media surfaces and degrade organic matter.

- Settling follows in a clarifier.

Best For:

- Space-constrained sites

- Moderate-load STPs (hotels, malls, office parks)

Pros:

- Compact design

- Handles load variations well

- Easier to operate

Cons:

- Media replacement cost

- Biofilm loss if not properly maintained

3. Sequential Batch Reactor (SBR)

How It Works:

- Treatment happens in cycles within a single tank.

- Each cycle includes filling, aeration, settling, and decanting treated water.

- Sludge is withdrawn periodically.

Best For:

- Residential societies with fluctuating loads

- Standalone buildings, hotels, institutions

Pros:

- Single tank = smaller footprint

- No separate clarifier needed

- Flexible for variable flow rates

Cons:

- Requires precise cycle control

- Slightly higher automation and O&M needs

4. Membrane Bioreactor (MBR)

How It Works:

- Combines biological treatment with membrane filtration (ultrafiltration).

- Membranes replace secondary clarifiers and polish the treated water.

Best For:

- High-end applications needing ultra-pure water

- Hospitals, labs, luxury developments, export parks

Pros:

- Highest effluent quality

- Compact and odor-free

- Treated water usable for sensitive reuse (e.g., HVAC, car washing)

Cons:

- High capital and operating cost

- Membrane fouling requires monitoring

Comparison Table of STP Technologies

| Technology | Footprint | Automation | Treated Water Quality | Best Application |

|---|---|---|---|---|

| ASP | Large | Medium | Moderate | Municipal, large complexes |

| MBBR | Medium | Medium | Good | Malls, hotels, retrofits |

| SBR | Small | High | Good | Societies, small buildings |

| MBR | Very Small | High | Excellent | Hospitals, LEED buildings |

Choosing the Right STP Technology

When selecting the appropriate system, consider:

- Available space

- Daily sewage generation (KLD)

- Reuse intent (gardening vs HVAC or flushing)

- Automation capabilities and operator skills

- Initial vs long-term costs

Tip: For high-end or sensitive reuse applications (like flushing in commercial towers or pharma facilities), MBR is ideal. For societies with space limitations and seasonal load variation, SBR or MBBR is preferred.

Treated Water Reuse Options

One of the most valuable outcomes of installing an STP is the ability to reuse treated sewage water for various non-potable applications. With rising freshwater costs and groundwater extraction restrictions, recycling treated water is both economically and environmentally beneficial.

Here’s how treated sewage water can be reused effectively:

1. Toilet Flushing

Why It Works:

Flushing accounts for nearly 30–40% of total domestic water usage in residential and commercial buildings.

STP Requirement:

- Treated water should meet basic filtration and disinfection standards (e.g., UV or chlorination)

- Plumbing should include a dual piping system to separate drinking and flushing water

CPCB and several urban authorities now mandate reuse for flushing in buildings with STPs.

2. Gardening and Landscaping

Why It Works:

Irrigation systems do not require potable water, making this an ideal reuse option for:

- Parks and lawns

- Roadside plantations

- Office campuses or gated communities

STP Requirement:

- Tertiary-treated water free from suspended solids and odor

- pH levels between 6.5 and 8.5

- Pathogen-free if used near human activity

3. Cooling Towers and HVAC Systems

Why It Works:

Large commercial and industrial facilities use significant water for cooling operations. Treated STP water, when properly polished, can be reused as cooling tower makeup water.

STP Requirement:

- MBR or high-end filtration preferred to avoid fouling

- Continuous monitoring of TDS, hardness, and microbial levels

4. Construction Activities

Applications:

- Curing of concrete

- Compaction of soil

- Dust suppression at construction sites

STP Requirement:

- Secondary-treated water is often sufficient

- Reduces dependence on freshwater tankers

5. Floor Washing and Vehicle Cleaning

Treated water can also be safely used for:

- Basement and common area cleaning

- Washing of service vehicles, gardening tools, garbage bins

STP Requirement:

- Free from visible solids and odor

- No need for potable-grade treatment

Benefits of Treated Water Reuse

| Benefit | Impact |

|---|---|

| Freshwater savings | Reduces dependency on municipal/borewell water |

| Cost efficiency | Cuts down on utility bills |

| Green building credits | Essential for LEED/IGBC certification |

| CPCB/SPCB compliance | Mandatory reuse in many regions |

| Environmental responsibility | Promotes circular water economy |

Best Practices for Treated Water Reuse

- Clearly label treated water pipelines and storage tanks

- Conduct regular water testing (BOD, TSS, coliforms)

- Train facility staff on safe handling

- Maintain logbooks for treated water use and reuse volumes

- Ensure disinfection (UV or chlorine) before direct reuse

Pro Tip: Always maintain physical separation between treated water and potable water pipelines to prevent backflow or contamination.

STP Compliance: Legal Norms, Guidelines, and Documentation

Sewage treatment is not just an environmental obligation—it’s a legal mandate in many countries, including India. Governing bodies like the Central Pollution Control Board (CPCB) and State Pollution Control Boards (SPCBs) enforce strict guidelines to ensure treated sewage does not harm public health or the environment.

Failure to comply can result in:

- Denial or cancellation of Consent to Operate (CTO)

- Monetary penalties or show-cause notices

- Legal proceedings or closure orders

- Negative press and public backlash

Here’s what every STP operator or owner should know.

1. CPCB/STP Discharge Norms in India

As per CPCB’s general discharge standards, treated sewage must meet the following quality parameters:

| Parameter | CPCB Norm (Residential STP) |

|---|---|

| BOD (Biological Oxygen Demand) | ≤ 10–30 mg/L |

| TSS (Total Suspended Solids) | ≤ 10–50 mg/L |

| pH | 6.5 to 8.5 |

| Fecal Coliform | <1000 MPN/100 ml |

| Oil & Grease | ≤ 10 mg/L |

| Nitrate/Nitrogen (where required) | ≤ 10 mg/L |

Many states (like Maharashtra, Tamil Nadu, and Gujarat) have stricter norms for water reuse or discharge into surface water bodies.

2. STP Compliance for Building Approvals

Most urban local bodies (ULBs) now require:

- Functional STP design as part of building plan approval

- Consent to Establish (CTE) from SPCB before construction

- Consent to Operate (CTO) before occupancy certificate (OC) issuance

Mandatory Conditions:

- Maintain daily logs of operation, flow, and chemical dosing

- Submit monthly treated water test reports to SPCB

- Install flow meters and online monitoring (for plants >50 KLD)

3. Treated Water Reuse Compliance

If reuse is mandated:

- STP-treated water must be used for flushing, gardening, or cooling

- Reuse pipelines must be clearly marked and separated from potable lines

- Annual water reuse logs should be maintained and submitted during inspections

Municipal authorities may impose fines for non-reuse or illegal discharge.

4. Required Documentation for STP Compliance

To avoid non-compliance notices, every STP operator should maintain:

| Document Type | Purpose |

|---|---|

| Daily operation log | Records flow rate, pH, dosing |

| Lab test reports | Confirms treated water quality |

| AMC/O&M records | Proof of regular service and upkeep |

| Sludge disposal records | Ensures lawful sludge handling (with TSDF receipts) |

| Consent to Operate (CTO) | Legal permit for operating STP |

| Water reuse tracker | Confirms reuse of treated water |

5. Common Reasons for Non-Compliance

- Irregular STP operation (manual or bypass mode)

- Untrained or absent STP operator

- Lack of tertiary disinfection (UV or chlorination)

- High sludge buildup and foul odor due to poor sludge management

- No AMC or preventive maintenance in place

Tips to Stay Fully Compliant

- Appoint trained operators or outsource to a qualified O&M contractor

- Schedule preventive maintenance quarterly

- Use automation/SCADA for dosing, flow tracking, and fault alerts

- Send samples to accredited labs monthly

- Integrate a paddle dryer to reduce sludge and meet TSDF moisture norms

Common STP Mistakes and How to Avoid Them

Many sewage treatment plants underperform not because of poor technology, but due to flawed design decisions, neglect in operations, or lack of foresight. These issues can lead to foul odors, untreated discharge, sludge overflow, and ultimately, legal penalties.

Here are the most common pitfalls—and expert guidance on how to prevent them:

1. Undersized STP Capacity

Problem:

Designing the STP for less than actual sewage load leads to overload, incomplete treatment, and system breakdown.

Solution:

- Always size the STP based on peak occupancy, not initial occupancy

- Factor in future expansion or additional phases of a project

- Use a buffer of at least 10–15% to accommodate peak days

2. No Tertiary Treatment or Disinfection Unit

Problem:

Skipping UV or chlorination in the design results in unsafe reuse water containing pathogens.

Solution:

- Always include UV or chlorine dosing in the final treatment stage

- Test fecal coliform monthly to ensure safe reuse or discharge

3. Ignoring Sludge Management

Problem:

Sludge is often not removed regularly, leading to odor issues, plant shutdowns, and SPCB violations.

Solution:

- Install a sludge dewatering system (filter press or centrifuge)

- Add a paddle dryer to reduce moisture and volume before disposal

- Maintain TSDF disposal records as proof of compliance

4. Poor Operator Training and No AMC

Problem:

Inadequate training causes dosing errors, equipment mishandling, and failure to respond to alarms.

Solution:

- Hire certified STP operators or outsource to an experienced O&M vendor

- Sign an Annual Maintenance Contract (AMC) for preventive servicing and 24/7 support

5. No Reuse System or Plumbing Integration

Problem:

Treated water is wasted by being discharged into the drain because no reuse piping was planned.

Solution:

- Design dual plumbing systems during building construction

- Include treated water tanks and booster pumps in the plan

- Use reuse water for flushing, gardening, and HVAC makeup

6. Lack of Automation and Monitoring

Problem:

Manual systems miss flow surges, dosing lapses, or equipment faults, leading to non-compliance.

Solution:

- Use SCADA or PLC-based automation for dosing, pump control, and flow balancing

- Install online pH, flow, and ORP sensors with data logging

- For larger STPs, integrate with real-time data submission to SPCB if mandated

7. Wrong Technology Selection

Problem:

Choosing an STP process (e.g., ASP) not suited to the load variation or footprint of the facility results in inefficiency and high O&M cost.

Solution:

- For variable loads: use SBR or MBBR

- For small footprints: opt for MBR

- Conduct treatability study and consult experienced STP designers

Summary Table: STP Mistakes vs. Solutions

| Mistake | Consequence | Preventive Solution |

|---|---|---|

| Undersized capacity | Overflow, untreated discharge | Design for peak load + 15% buffer |

| No disinfection unit | Unsafe water reuse | Add UV or chlorination |

| Sludge mismanagement | Odor, SPCB penalties | Use filter press + paddle dryer |

| Poor operator training | Equipment damage, non-compliance | Hire trained O&M team + AMC |

| No reuse plumbing | Treated water wasted | Plan dual pipelines and tanks |

| Manual-only operation | Data gaps, treatment failure | Add automation and real-time sensors |

| Wrong technology | Inefficiency, cost overrun | Select process based on usage profile |

STP in Action: A Residential Case Study

Project Overview

- Type: Residential Housing Complex

- Location: Pune, Maharashtra

- Sewage Generation: 500 KLD (kiloliters per day)

- STP Technology Used: Sequential Batch Reactor (SBR)

- Treated Water Reuse: Flushing + Gardening

- Sludge Management: Filter press + Paddle Dryer

- Regulatory Body: Maharashtra Pollution Control Board (MPCB)

The Challenge

This gated society of over 800 apartments faced multiple issues:

- No access to a municipal sewer line

- High dependency on water tankers for daily supply

- Rising water costs and community complaints

- Threat of delay in Occupancy Certificate (OC) due to missing STP plan

- Lack of clarity on treated water reuse and sludge disposal

The Solution

The society’s committee worked with a certified environmental consultant and implemented a turnkey STP solution that included:

- Designing a 500 KLD SBR-based STP to handle fluctuating load based on occupancy

- Adding tertiary treatment (PSF, ACF, UV) to ensure safe reuse

- Installing dual plumbing lines for flushing and irrigation reuse

- Implementing a paddle dryer to reduce sludge moisture content and cut TSDF disposal costs

- Appointing a trained O&M partner with monthly reporting and SPCB documentation support

Results After 6 Months of Operation

| Metric | Before STP | After STP Implementation |

|---|---|---|

| Daily water tanker use | 10 tankers/day | Reduced to 2–3 tankers/day |

| Treated water reuse | 0% | 85% reused for flushing & garden |

| Sludge disposal cost | ₹35,000/month | ₹12,000/month (after drying) |

| Occupancy Certificate | Pending | Secured within 3 months |

| MPCB Compliance | Non-compliant | 100% compliant; lab reports up-to-date |

Lessons Learned

- SBR was ideal for residential complexes with variable occupancy

- Proper sludge drying was critical for reducing costs and environmental risk

- Operator training and documentation ensured smooth audits and reporting

- Clear piping for reuse helped cut down on freshwater bills and met green building criteria

Resident Feedback

“Installing the STP felt like a regulatory burden at first, but it’s now a major asset for our community. Our gardens stay green, flushing never fails, and we’re not waiting on tankers every day.”

— Secretary, Apartment Owners’ Association

FAQs on STP (Sewage Treatment Plant)

1. What is an STP in a building or society?

An STP (Sewage Treatment Plant) is a system designed to treat wastewater from toilets, kitchens, and bathrooms in residential or commercial buildings. It removes contaminants and makes the water suitable for reuse in flushing, gardening, or safe discharge.

2. Is STP mandatory for residential apartments in India?

Yes. As per CPCB and many State Pollution Control Boards, STPs are mandatory for residential complexes generating over 20 KLD of sewage or having a built-up area greater than 20,000 sq. m. Treated water reuse is also often mandated.

3. What is the difference between STP and ETP?

STPs treat domestic sewage (human waste, kitchen, bathrooms), while ETPs treat industrial effluents (chemical-heavy wastewater). STPs primarily use biological treatment; ETPs use a mix of chemical and physical processes depending on the industry.

4. Can STP-treated water be used for drinking?

No. STP-treated water is not potable. It is suitable for non-drinking purposes like flushing, gardening, HVAC cooling, and construction. For drinking, it must undergo additional processes like reverse osmosis and UV treatment approved for potable reuse.

5. How is sludge from an STP disposed of?

Sludge is first dewatered using a filter press or centrifuge, then dried using a paddle dryer or drying bed. The dried sludge is disposed of at authorized TSDFs or used as RDF (Refuse-Derived Fuel) if safe and approved.

6. What is the best STP technology for housing societies?

Sequential Batch Reactor (SBR) or Moving Bed Biofilm Reactor (MBBR) are ideal for housing societies due to their compact footprint, ability to handle fluctuating loads, and low maintenance requirements.

7. How much space is required for an STP?

The required area depends on the technology and daily sewage load. As a general rule:

- SBR: ~1.5–2 sq. m per KLD

- MBBR: ~1–1.5 sq. m per KLD

- MBR: ~0.5–1 sq. m per KLD (most compact)

Conclusion: Why STPs Are Essential for Sustainable Living and Legal Compliance

Sewage Treatment Plants (STPs) are no longer a luxury or afterthought—they are a critical infrastructure component for any residential, commercial, or institutional development. As environmental regulations tighten and freshwater resources become scarcer, implementing a well-designed, compliant, and maintainable STP offers clear, long-term benefits:

- Regulatory compliance with CPCB/SPCB discharge norms

- Cost savings through treated water reuse in flushing, gardening, and HVAC

- Environmental responsibility by preventing sewage pollution

- Sustainable certifications for green and LEED-rated buildings

- Improved community health through proper sludge handling and odor control

But to truly realize these benefits, your STP must be properly sized, operated, and maintained. And for that, working with a knowledgeable team makes all the difference.

Let’s Build a Cleaner, Greener Future Together

Whether you’re planning a new STP, upgrading an old one, or facing compliance issues—AS Engineers is here to help.

With decades of experience in drying, sludge handling, and wastewater solutions, we provide:

- Custom STP consulting and integration

- High-efficiency paddle dryers for sludge reduction

- Support for SPCB approvals, AMC, and O&M

- Solutions tailored for residential, commercial, and industrial needs

Contact us today for a site assessment or consultation.

Visit: https://theasengineers.com

Email: info@theasengineers.com

Your STP is more than a system—it’s your statement of commitment to a sustainable future. Let’s make it count.