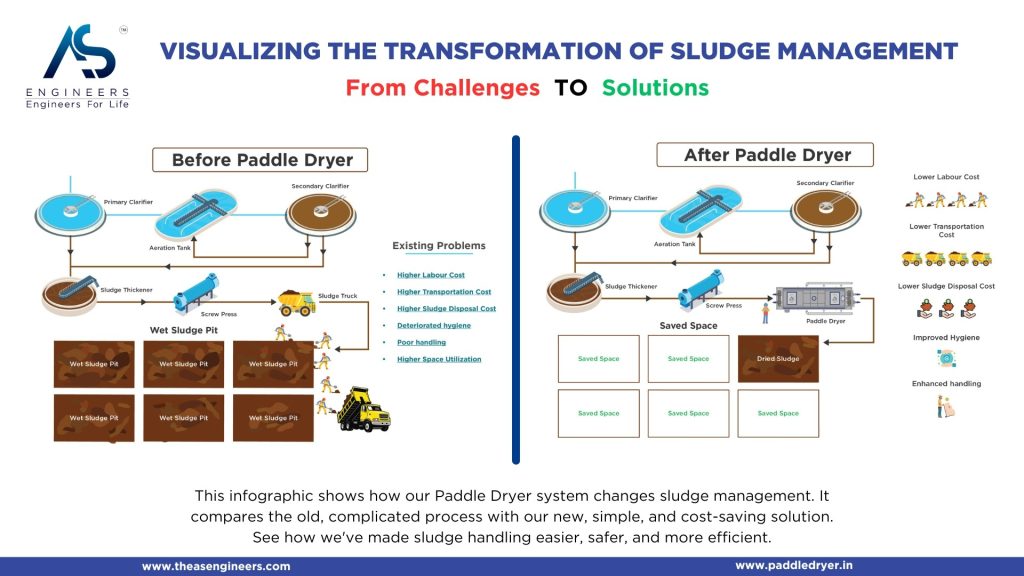

Imagine running a busy wastewater treatment plant where trucks haul away heavy, waterlogged sludge every week. You pay for drivers, fuel, disposal fees, and equipment upkeep—only to get rid of what’s mostly water. Meanwhile, environmental regulations tighten each year, forcing you to improve efficiency and reduce your operational footprint. This is where sludge dewatering comes in. By removing water from sludge, you cut transportation costs, reduce landfill volumes, and unlock potential resources, such as biogas or valuable nutrients. In short, sludge dewatering is one of the smartest moves you can make to improve waste management, save money, and stay on the right side of environmental laws.

In this article, you’ll learn why sludge dewatering is crucial for efficient waste management. You will discover how the process works, the types of sludge dewatering equipment available, and the cost savings you can achieve. You’ll also see how well-designed sludge dewatering systems can boost sustainability and meet regulatory requirements. By the end, you’ll have the roadmap you need to dewater sludge effectively—whether you manage a municipal treatment plant or an industrial facility.

Understanding Sludge Dewatering

Sludge dewatering is the practice of separating water from the solid waste that remains after wastewater treatment or industrial processes. This solid waste, known as sludge, can be as much as 90–98% water. Hauling it around in its raw form wastes money, fuel, and labor hours. By dewatering, you significantly reduce the water content so the resulting “sludge cake” is denser and more compact.

Why It Matters

- Lower Disposal Costs: Dewatered sludge requires fewer trips to landfills or incinerators.

- Reduced Environmental Impact: Smaller volumes reduce carbon emissions during transportation and minimize the space needed in landfills.

- Easier Handling: Employees face fewer risks when dealing with a drier, more stable form of sludge.

- Resource Recovery: Dewatered sludge may contain valuable nutrients or energy sources you can reclaim.

Dewatering is not a one-size-fits-all solution. You must consider factors like feed sludge composition, operational budgets, and regulatory standards to pick the right method.

Economic Rationale: Cutting Costs and Generating Value

Transportation Savings

If you pay by weight or volume for sludge removal, any extra water left in the sludge effectively adds to your bottom line. By removing a significant percentage of the water, you lower the weight, which reduces how much you pay in hauling fees. Some operators report cutting disposal and transport expenses by 50% or more after installing an efficient sludge dewatering system.

Reduced Disposal Fees

Landfill tipping fees or incineration costs typically scale with sludge volume. Water-laden sludge demands more space and energy for disposal. Dewatering can convert a giant sludge pond into just a fraction of its original size, helping your organization avoid surcharges or overage costs.

Lower Operational Overheads

Well-chosen sludge dewatering equipment requires regular but predictable maintenance. In contrast, the hidden expenses of frequent hauling or storing large amounts of unprocessed sludge can quickly outstrip the cost of a new dewatering unit. Plus, streamlined waste management frees up staff to focus on core operations instead of routine sludge handling.

Resource Recovery Opportunities

Many industrial and municipal treatment facilities discover that dewatered sludge contains useful components, such as phosphorus, nitrogen, or even organic matter suitable for composting. Extracting these elements can generate secondary revenue streams or offset costs related to fertilizer or energy.

Key Sludge Dewatering Methods

Several methods exist for dewatering sludge, each with its own efficiency levels, capital costs, and operating requirements. Below are the most common technologies in wastewater and industrial settings.

1. Belt Filter Presses

How They Work: A belt filter press sends sludge between two moving porous belts. As it travels, rollers squeeze out water. Filtrate (the water that’s removed) drains through the belt fabric, leaving a semi-solid “cake” behind.

Pros:

- Straightforward to operate once set up

- Relatively low energy consumption

- Can handle a range of sludge types

Cons:

- Requires consistent maintenance to avoid belt clogs or fabric wear

- Produces moderate cake dryness compared to some other methods

2. Centrifuges

How They Work: A centrifuge spins sludge at high speeds. The difference in density forces solids to one end while water drains off to the other. This results in a drier, more concentrated sludge.

Pros:

- High throughput, making it ideal for larger plants

- Produces relatively dry cake

- Performs well with various sludge compositions

Cons:

- High capital and energy costs

- Noise and vibration issues if not installed properly

3. Plate and Frame Presses

How They Work: Also known as filter presses, these units compress sludge between a series of plates lined with filter cloth. As pressure rises, water seeps through the cloth, and solids form a thick cake on the plates.

Pros:

- Excellent cake dryness

- Proven technology with many installations worldwide

- Suitable for facilities seeking high solid content in the final product

Cons:

- Slow batch operation, not continuous

- Labor-intensive operation due to manual plate cleaning and cake removal

4. Screw Presses

How They Work: A screw press features a slow-turning auger that moves sludge through a cylinder. Compression builds as the sludge advances, forcing water out through small openings.

Pros:

- Low-speed, low-noise, and minimal energy usage

- Continuous operation, fewer operator requirements

- Self-cleaning design in many models

Cons:

- May not achieve the same dryness levels as a centrifuge or plate and frame press

- Could require frequent checks to avoid clogs from fibrous materials

Choosing the Right Sludge Dewatering Equipment

Selecting the best sludge dewatering machine involves more than checking a price tag. You should evaluate:

- Sludge Characteristics

- Is your sludge primarily organic or mineral-based?

- Does it include abrasive particles, fats, or oils that could damage equipment?

- Throughput Needs

- How many gallons or cubic meters of sludge must you process daily?

- Can your facility handle a slower batch process, or do you need continuous operation?

- Budget and Lifecycle Costs

- Compare the total cost of ownership, factoring in installation, energy consumption, repairs, and operator training.

- Calculate potential savings in disposal and transport fees.

- Regulatory Standards

- Sludge disposal laws vary by region. If you aim for land application, you need certain dryness and contaminant thresholds. If you plan to incinerate, dryness levels may matter more.

- Space Constraints

- Some dewatering systems require large footprints, while others, like screw presses, can fit into compact spaces.

Armed with a clear picture of these factors, you can choose an effective sludge dewatering system that aligns with your facility’s demands.

Environmental Benefits of an Effective Sludge Dewatering System

Reduced Carbon Footprint

Every trip to the landfill or incineration facility translates into fuel consumption and emissions. By cutting sludge volume, you also reduce the transportation burden, lowering greenhouse gas emissions. Your organization can advertise this shift as part of a broader sustainability strategy.

Less Landfill Space

Many landfills already operate near capacity. Dewatering sludge slashes the space required for final disposal. Over time, this can delay the need for new landfill sites, a crucial advantage in regions with scarce land resources.

Easier Pathogen Control

Some dewatering methods, such as heated filter presses or thermal processes, can help inactivate pathogens. The drier the sludge, the lower the potential for bacterial regrowth during transport or storage.

Facilitates Resource Recovery

Dry, stable sludge is more amenable to nutrient extraction or composting. If your treatment process includes anaerobic digestion prior to dewatering, you can capture biogas as well. This synergy turns what used to be a waste product into a valuable asset.

Common Misconceptions About Sludge Dewatering

- “Dewatering Only Matters for Large Municipal Plants.”

Smaller operations also gain financial and environmental benefits from effective sludge dewatering. Even a modest production line generating a few tons of sludge can save thousands per year in disposal fees. - “All Sludge Dewatering Equipment Is the Same.”

Each dewatering method offers unique advantages and drawbacks. The best choice depends on sludge composition, load size, and end-use requirements. - “Sludge Dewatering Systems Are Too Expensive.”

Upfront costs might be high, but long-term savings on transport, disposal, and potential resource recovery usually offset the investment. Many operators recoup their initial outlays in just a few years. - “We Already Use Thickening. Dewatering Is Redundant.”

Thickening is a valuable step that concentrates solids, but it doesn’t always produce a cake dry enough to realize major disposal or transportation savings. Dewatering goes further by extracting more water, achieving a higher solids percentage.

Frequently Asked Questions

Q1: How often should I service a sludge dewatering machine?

A1: Maintenance intervals vary by equipment type. Belt filter presses may need weekly belt cleaning and routine wear checks, while centrifuges require regular inspection of bearings and seals. Always follow the manufacturer’s guidelines.

Q2: Can dewatering reduce odors at my facility?

A2: Yes, removing water reduces anaerobic conditions where foul-smelling bacteria thrive. Combined with proper ventilation and covering, dewatering can help you manage odors more effectively.

Q3: Is it possible to retrofit an existing plant with new sludge dewatering equipment?

A3: Many facilities upgrade from older technologies like drying beds to more modern presses or centrifuges. Space constraints and process compatibility are the main considerations, but retrofit projects can yield significant cost savings in the long run.

Q4: Do I need special permits for a sludge dewatering system?

A4: Regulations vary by location. In many jurisdictions, a standard operating permit suffices. However, if you generate emissions (for example, in thermal drying), you might need additional air quality permits.

Q5: Can I sell my dewatered sludge to farmers or other industries?

A5: Possibly. You must meet stringent quality standards for heavy metals, pathogens, and other contaminants. Some facilities process sludge further into Class A biosolids for agricultural use.

Conclusion and Next Steps

Sludge dewatering shapes the future of waste management by making disposal cheaper, greener, and more efficient. When you invest in a solid sludge dewatering system, you free up valuable space, reduce hauling costs, and cut back on your facility’s environmental footprint. You also open the door to resource recovery, transforming what used to be a messy liability into a viable asset.

What’s your next move?

- Consider conducting a sludge audit to pinpoint your facility’s exact dewatering needs.

- Consult with an engineering firm or equipment supplier to compare technologies like belt filter presses, centrifuges, and screw presses.

- Map out how your sludge cake will be used or disposed of. Can you partner with local farmers, or will you incinerate it for energy recovery?

Most importantly, remember that sludge dewatering involves more than just minimizing water content. It’s a strategic approach to reducing operational costs, meeting environmental standards, and showcasing your commitment to sustainability. By choosing the right sludge dewatering machine and tailoring it to your operational goals, you can set a new standard for efficient waste management.

Sludge dewatering doesn’t just decrease the amount of sludge you handle. It also delivers tangible benefits like lower transportation fees, a safer work environment, and better compliance with waste regulations. When you treat sludge as an asset, you unlock opportunities for cost recovery and brand enhancement. The time to explore sludge dewatering is now, whether you operate a municipal wastewater plant or a specialized industrial process. By integrating a well-suited sludge dewatering system, you will keep pace with environmental demands, reduce overhead, and invest in a cleaner, more profitable future.