Did you know that wastewater treatment facilities in the United States alone process approximately 34 billion gallons of wastewater daily, generating over 8 million tons of sludge annually? Managing this massive volume efficiently has become one of the most pressing challenges for municipalities and industries worldwide. At the heart of modern sludge management is a critical equipment piece: the sludge dryer. This powerful technology can reduce sludge volume by up to 80%, dramatically cutting disposal costs while creating opportunities for beneficial reuse.

Whether you’re an environmental engineer, wastewater treatment plant operator, or sustainability manager, understanding sludge dryers is essential for optimizing your waste management processes. In this comprehensive guide, we’ll explore everything you need to know about sludge dryers—from basic principles to advanced selection criteria—helping you make informed decisions that benefit both your operations and the environment.

Table of contents

- What Is a Sludge Dryer and Why Is It Important?

- Types of Sludge Dryers: Finding the Right Fit for Your Needs

- The Science Behind Sludge Drying: Understanding the Process

- Benefits of Implementing a Sludge Drying System

- Key Considerations for Selecting the Right Sludge Dryer

- Energy Efficiency and Sustainability Considerations

- Installation and Commissioning Best Practices

- Operation and Maintenance Strategies for Long-Term Success

- Future Trends in Sludge Drying Technology

- Conclusion: Making the Right Choice for Your Facility

What Is a Sludge Dryer and Why Is It Important?

A sludge dryer is specialized equipment designed to remove moisture from various types of sludge, including municipal wastewater sludge, industrial process residues, and agricultural waste. The primary function of these systems is to reduce the water content in sludge, resulting in significant volume reduction, easier handling, and expanded disposal or reuse options.

The importance of sludge dryers in modern waste management cannot be overstated. As environmental regulations tighten and disposal costs rise, efficient dewatering and drying technologies have become essential components of sustainable waste management strategies. A properly implemented sludge drying system offers multiple benefits:

- Cost Reduction: Lower transportation and disposal costs due to reduced weight and volume

- Environmental Compliance: Meets increasingly stringent environmental regulations

- Resource Recovery: Creates opportunities for beneficial reuse of dried sludge

- Operational Efficiency: Improves overall plant efficiency and capacity

The Evolution of Sludge Drying Technology

Sludge drying has evolved considerably over the past few decades. Early methods often relied on simple solar drying beds—large, open areas where sludge was spread thinly and left to dry naturally. While effective in suitable climates, these methods were land-intensive and weather-dependent.

Modern sludge dryers utilize sophisticated mechanical and thermal processes to remove moisture quickly and efficiently, regardless of weather conditions. This technological evolution has been driven by several factors:

- Stricter environmental regulations limiting disposal options

- Rising costs for landfill disposal

- Growing interest in resource recovery and circular economy approaches

- Advancements in energy efficiency and heat recovery systems

Today’s sludge dryers represent the culmination of years of engineering innovation, offering solutions that are more compact, energy-efficient, and versatile than ever before.

Types of Sludge Dryers: Finding the Right Fit for Your Needs

The market offers several distinct types of sludge dryers, each with unique operational characteristics, advantages, and limitations. Understanding these differences is crucial for selecting the appropriate technology for your specific application.

Direct Dryers

Direct dryers bring the drying medium (typically hot air or combustion gases) into direct contact with the sludge. This direct heat transfer offers excellent thermal efficiency but requires careful attention to emissions and odor control.

Common types of direct dryers include:

Rotary Drum Dryers

Rotary drum dryers consist of a large, rotating cylindrical drum through which sludge moves as hot air flows through. The tumbling action provides good mixing and heat transfer, resulting in uniform drying. These systems are robust and can handle sludge with varying characteristics.

Key advantages:

- Proven technology with extensive track record

- Capable of handling high throughput

- Relatively simple mechanical design

- Good for producing Class A biosolids

Limitations:

- Relatively large footprint

- Can generate dust and require robust air pollution control

- Moderate to high energy consumption

Flash Dryers

Flash dryers use high-velocity hot air to simultaneously dry and transport sludge particles. The intense mixing and large surface area exposure result in very rapid moisture removal.

Key advantages:

- Extremely short residence time

- Compact design

- Suitable for heat-sensitive materials

Limitations:

- Requires relatively uniform particle size

- Higher wear rates due to high velocities

- More complex control systems

Belt Dryers

Belt dryers move sludge on a perforated conveyor belt while hot air passes through both the belt and the sludge layer. This design offers good control over residence time and drying conditions.

Key advantages:

- Gentle drying process with minimal dust generation

- Excellent temperature control

- Modular design allows for easy capacity expansion

- Good energy efficiency with heat recovery options

Limitations:

- Larger footprint than some alternatives

- Belt maintenance requirements

- Potential for uneven drying if feed distribution is poor

Indirect Dryers

In indirect dryers, the heating medium does not contact the sludge directly. Instead, heat transfers through a conductive surface, keeping the drying medium and sludge physically separated. This design offers distinct advantages for certain applications.

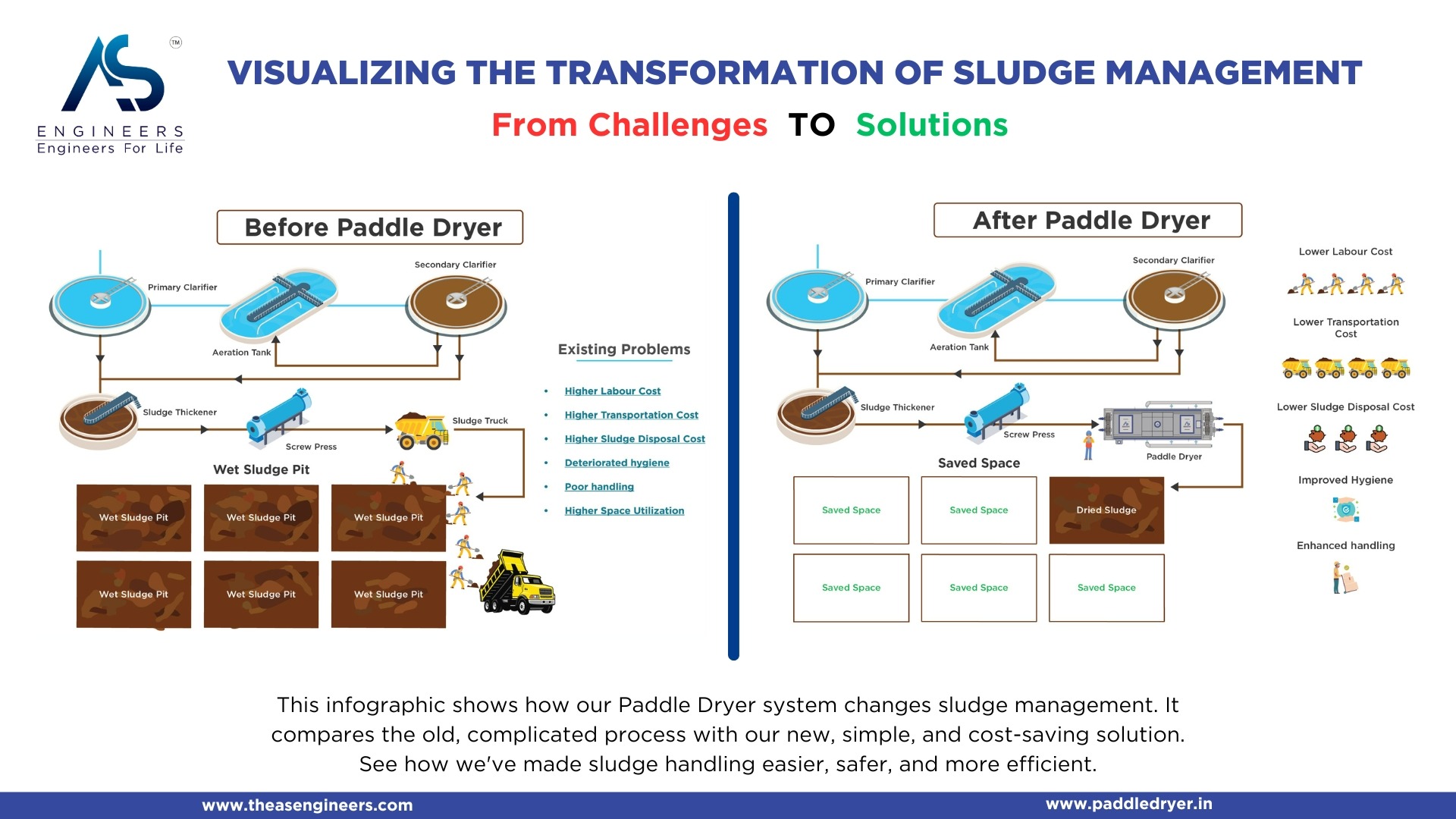

Paddle Dryers

Paddle dryers (also called hollow-flight dryers) use hollow shafts and paddles that are heated internally, typically by steam or thermal oil. The rotating paddles simultaneously mix and convey the sludge while transferring heat through their surfaces.

Key advantages:

- Excellent mixing and heat transfer

- Compact footprint

- Lower exhaust air volumes, simplifying air treatment

- Reduced odor and dust issues

- Good energy efficiency

Limitations:

- Mechanical complexity

- Higher capital cost

- Limited capacity compared to some direct dryers

- Potential for material buildup on heat transfer surfaces

Disc Dryers

Disc dryers utilize a series of hollow discs mounted on a rotating shaft. The discs are heated internally and provide the heat transfer surface for drying the sludge.

Key advantages:

- High surface area for heat transfer

- Good for sticky or pasty materials

- Contained process with minimal emissions

- Self-cleaning action of discs

Limitations:

- More complex mechanical design

- Higher maintenance requirements

- Limited turndown capacity

Thin-Film Dryers

Thin-film dryers spread sludge in a thin layer over a heated surface, typically using rotor blades to maintain the thin film and move material through the dryer.

Key advantages:

- Very short residence time

- Suitable for heat-sensitive materials

- Small footprint

- Minimal air handling requirements

Limitations:

- Lower capacity than other systems

- Not ideal for abrasive materials

- Higher specific energy consumption

Hybrid Systems

Hybrid drying systems combine multiple drying technologies or incorporate both direct and indirect heat transfer mechanisms. These systems aim to capitalize on the advantages of different approaches while minimizing their respective limitations.

Key advantages:

- Optimized energy efficiency

- Greater operational flexibility

- Ability to handle varying feed characteristics

- Often incorporate heat recovery to reduce energy costs

Limitations:

- Higher system complexity

- More sophisticated control requirements

- Potentially higher capital costs

Solar Dryers

Modern solar dryers have evolved significantly from traditional drying beds. These systems use greenhouse structures with controlled ventilation and optional mechanical assistance to harness solar energy for sludge drying.

Key advantages:

- Minimal energy consumption

- Low operating costs

- Simple operation

- Environmentally friendly

Limitations:

- Weather-dependent performance

- Large land requirements

- Slower drying process

- Seasonal variations in capacity

The Science Behind Sludge Drying: Understanding the Process

To select and operate a sludge dryer effectively, it’s essential to understand the fundamental science of the drying process. Sludge drying involves complex mass and heat transfer mechanisms that occur in several distinct phases.

Phases of the Drying Process

- Initial Warming Phase: The sludge temperature rises to the point where significant evaporation begins.

- Constant Rate Phase: Water evaporates from the surface at a relatively steady rate, with the rate limited primarily by the heat transfer to the material.

- Falling Rate Phase: As surface moisture depletes, water must migrate from within the sludge particles to the surface, slowing the drying rate.

- Equilibrium Phase: The final moisture content reaches equilibrium with the surrounding conditions.

Understanding these phases helps explain why drying becomes progressively more energy-intensive as the sludge gets drier. The energy required to remove the last percentage points of moisture is significantly higher than that needed for the initial drying stages.

Key Parameters Affecting Drying Efficiency

Several factors influence the efficiency and effectiveness of sludge drying:

Moisture Content and Sludge Characteristics

The initial moisture content of sludge typically ranges from 65-85% after mechanical dewatering. The physical and chemical properties of the sludge—including its viscosity, surface tension, and bound water content—significantly impact how easily moisture can be removed.

Temperature and Heat Transfer

Higher temperatures accelerate drying but must be carefully controlled to prevent unwanted side effects such as dust generation, odor problems, or in extreme cases, combustion risks. Different dryer types operate at different temperature ranges:

- Direct dryers: Typically 150-600°C (inlet air)

- Indirect dryers: Usually 180-250°C (heat transfer surface)

- Solar dryers: Ambient to 70°C (depending on climate and design)

Residence Time

The time sludge spends in the dryer directly affects final moisture content. Longer residence times generally result in drier end products but require larger equipment for a given throughput capacity.

Particle Size and Surface Area

Breaking down sludge into smaller particles or creating a thin layer increases the surface area available for evaporation, enhancing drying efficiency. However, excessively small particles can cause dust problems and material handling challenges.

Benefits of Implementing a Sludge Drying System

Installing a well-designed sludge drying system offers numerous advantages across financial, operational, and environmental dimensions. Let’s explore the key benefits that make sludge dryers an increasingly essential technology for waste management professionals.

Economic Advantages

Transportation and Disposal Cost Reduction

The most immediate financial benefit of sludge drying is the dramatic reduction in transportation and disposal costs. By removing 70-80% of the water content, drying can reduce the overall volume by up to 4-5 times. For facilities that transport sludge significant distances to disposal sites, this volume reduction translates directly into substantial savings.

Case studies have shown return on investment periods as short as 2-4 years solely from transportation and disposal savings, particularly for facilities located far from disposal sites or in regions with high disposal fees.

Energy Recovery Opportunities

Dried sludge has a calorific value ranging from 8-12 MJ/kg, making it a potential energy source. Some facilities use dried sludge as an auxiliary fuel in cement kilns, power plants, or dedicated sludge-to-energy facilities. This energy recovery creates additional value streams while further reducing disposal needs.

Reduced Labor and Equipment Requirements

Handling dried sludge requires less labor and equipment compared to wet sludge. The granular nature of properly dried sludge makes it easier to store, transport, and manage with conventional bulk material handling equipment.

Environmental Benefits

Reduced Carbon Footprint

While sludge drying itself requires energy, the overall carbon footprint is often reduced when accounting for:

- Fewer transportation trips

- Reduced methane emissions from landfills (due to lower organic content)

- Potential fossil fuel displacement when dried sludge is used as an alternative fuel

- Opportunities for heat recovery and integration with renewable energy sources

Pathogen Destruction and Stabilization

The high temperatures in thermal drying processes effectively destroy pathogens, producing a biologically stable end product that poses minimal health risks. Many dryers can produce Class A biosolids as defined by EPA regulations, opening additional beneficial use options.

Odor Reduction

Properly dried sludge produces significantly less odor than wet biosolids, reducing nuisance concerns at both the treatment facility and final disposal location. This aspect is particularly important for facilities located near residential areas.

Operational Advantages

Process Flexibility and Resilience

A sludge drying system provides operational flexibility by:

- Creating buffer capacity during peak production periods

- Enabling storage of treated material for optimal disposal timing

- Providing multiple end-product options based on market conditions

- Reducing vulnerability to disposal site disruptions or restrictions

Beneficial Reuse Options

Dried sludge opens numerous beneficial reuse pathways that may not be available for wet biosolids:

- Agricultural Use: Dried biosolids can serve as soil amendments or fertilizers, returning valuable nutrients to agricultural land.

- Land Reclamation: The stable nature of dried biosolids makes them suitable for mine reclamation, brownfield restoration, and similar applications.

- Alternative Fuel: The significant calorific value of dried sludge makes it usable as a supplementary fuel in various industrial processes.

- Construction Materials: Research has demonstrated the feasibility of incorporating dried sludge into certain construction materials, including brick manufacturing and lightweight aggregates.

Key Considerations for Selecting the Right Sludge Dryer

Choosing the optimal sludge dryer for your facility requires careful evaluation of numerous factors. The right choice balances technical, economic, and operational considerations specific to your situation.

Technical Considerations

Feed Characteristics and Variability

The properties of your sludge significantly influence dryer selection:

- Moisture Content: Different dryers handle varying moisture ranges efficiently

- Rheological Properties: Stickiness, plasticity, and flow behavior affect dryer performance

- Composition: The organic content, fiber content, and presence of contaminants

- Variability: How consistent the feed properties remain over time

For highly variable sludge characteristics, systems with greater operational flexibility may be preferable, even if they come at a higher capital cost.

Throughput Requirements

Determine both current and future capacity needs:

- Average Daily Load: The baseline capacity requirement

- Peak Capacity: Maximum processing needs during high-flow periods

- Growth Projections: Anticipated capacity increases over the system lifetime

- Turndown Ratio: The ability to operate efficiently at reduced capacity

Many facilities benefit from modular systems that can be expanded incrementally or operated at varying capacities as needs change.

Available Space and Site Constraints

Physical constraints often eliminate certain technologies from consideration:

- Footprint Limitations: Some technologies require significantly more space than others

- Height Restrictions: Certain dryers have vertical space requirements

- Weight Considerations: Structural limitations may impact equipment selection

- Integration with Existing Infrastructure: Connection points, access, and material flow

Indirect dryers typically offer more compact footprints but may have higher capital costs per unit capacity.

End Product Requirements

The intended use of the dried sludge dictates quality parameters:

- Final Moisture Content: Typically 10-90% dry solids, depending on application

- Particle Size and Distribution: Critical for handling characteristics and end-use

- Dustiness: Important for worker safety and material handling

- Pathogen Reduction: Required levels of sanitization

- Stability: Storage properties and shelf life

Be specific about end-product requirements when evaluating different drying technologies.

Economic Evaluation

Capital Expenditure (CAPEX)

While purchase price is important, the complete capital cost analysis should include:

- Equipment Costs: The dryer itself plus auxiliary systems

- Installation Expenses: Foundation, connections, controls integration

- Building Modifications: Any required structural changes

- Permitting Costs: Environmental and operational permits

Remember that the lowest capital cost option may not provide the lowest total cost of ownership.

Operational Expenditure (OPEX)

Long-term operational costs often outweigh initial capital investment:

- Energy Consumption: Typically the largest ongoing expense

- Maintenance Requirements: Preventive maintenance and replacement parts

- Labor Needs: Operational and maintenance staffing

- Consumables: Chemicals, lubricants, filter media, etc.

Request detailed energy consumption data and maintenance histories from equipment vendors and existing installations.

Life-Cycle Cost Analysis

A comprehensive economic evaluation considers costs over the entire system lifetime:

- Equipment Lifespan: Expected operational life before major overhaul

- Residual Value: End-of-life value or disposal costs

- Financing Costs: Interest and capital availability

- Risk Factors: Reliability, proven technology status

Most facilities find that a 15-20 year life-cycle analysis provides the most meaningful economic comparison between options.

Operational and Maintenance Factors

Reliability and Track Record

Proven performance reduces operational risk:

- Installation Base: Number of similar systems in operation

- Operational History: Years in service and performance data

- References: Feedback from current users

- Manufacturer Support: Company stability and long-term viability

For critical applications, consider visiting reference installations to gather firsthand information.

Automation and Control Requirements

Modern sludge dryers offer varying levels of automation:

- Control Sophistication: From basic manual controls to fully automated operation

- Monitoring Capabilities: Remote monitoring, data logging, predictive maintenance

- Integration: Compatibility with existing SCADA or control systems

- Alarm Management: Safety systems and response protocols

Higher automation levels generally reduce labor requirements but may increase initial costs and technical support needs.

Maintenance Accessibility

Design features that facilitate maintenance reduce downtime and costs:

- Access Points: Ability to reach key components

- Clearing Blockages: Methods for addressing material buildup

- Part Replacement: Ease of changing wear components

- Cleaning Procedures: Required frequency and difficulty

Equipment designs that prioritize maintenance accessibility often demonstrate lower long-term operating costs despite potentially higher initial investment.

Energy Efficiency and Sustainability Considerations

As energy costs rise and environmental concerns grow, the efficiency and sustainability of sludge drying systems have become increasingly important selection criteria.

Energy Recovery and Integration

Modern drying systems often incorporate sophisticated energy recovery mechanisms:

- Heat Exchangers: Capturing waste heat from exhaust air

- Vapor Recompression: Reusing evaporated moisture for additional heating

- Cogeneration Integration: Utilizing waste heat from power generation

- Thermal Storage: Balancing intermittent heat availability

Well-designed heat recovery systems can reduce energy consumption by 15-40% compared to non-optimized systems.

Alternative Energy Sources

Innovative facilities are increasingly incorporating renewable energy into their drying operations:

- Solar Thermal: Direct solar heating or solar hot water production

- Biogas Utilization: Using digester gas for dryer heating

- Biomass Heating: Wood waste or other biomass fuels

- Heat Pumps: Electrically-driven systems with high coefficient of performance

The optimal energy source depends on local availability, climate conditions, and existing infrastructure.

Emissions and Environmental Impact

All drying systems must manage potential environmental impacts:

- Air Emissions: Volatile organic compounds, particulates, odors

- Noise Pollution: Equipment operation noise levels

- Wastewater Generation: Condensate management

- Chemical Usage: Cleaning agents, anti-fouling compounds

Regulatory requirements for emissions control vary by location but are generally becoming more stringent worldwide.

Installation and Commissioning Best Practices

Proper installation and commissioning are critical for achieving expected performance from your sludge dryer. Following industry best practices significantly reduces startup problems and operational issues.

Site Preparation and Equipment Positioning

Careful planning before equipment arrival ensures smooth installation:

- Foundation Requirements: Properly designed and cured foundations

- Access Routes: Clearance for delivery and future maintenance

- Utility Connections: Power, water, steam, and drainage provisions

- Ventilation Needs: Adequate airflow for both equipment and operators

Consider three-dimensional modeling to identify potential interference issues before equipment installation.

Integration with Existing Systems

Seamless integration with upstream and downstream processes is essential:

- Feed System Compatibility: Ensuring consistent material delivery

- Discharge Handling: Proper conveyance and storage of dried product

- Control System Integration: Communication with plant-wide systems

- Emergency Responses: Coordination with facility safety protocols

Develop detailed integration plans with input from both equipment suppliers and facility personnel.

Testing and Performance Verification

Comprehensive testing confirms that the system meets specifications:

- Functional Testing: Verifying all components operate as designed

- Performance Testing: Confirming throughput, energy consumption, and product quality

- Optimization Phase: Fine-tuning parameters for peak efficiency

- Training Period: Ensuring operator proficiency before full handover

Document all testing procedures and results for future reference and warranty purposes.

Operation and Maintenance Strategies for Long-Term Success

Proper operation and maintenance practices are essential for maximizing the lifespan and efficiency of your sludge drying system.

Preventive Maintenance Protocols

Develop comprehensive maintenance schedules based on:

- Manufacturer Recommendations: Following OEM guidelines

- Condition Monitoring: Using vibration analysis, thermal imaging, etc.

- Performance Trends: Tracking efficiency metrics to identify degradation

- Critical Component Management: Maintaining spare parts inventory

Properly executed preventive maintenance typically reduces total maintenance costs by 15-40% compared to reactive approaches.

Troubleshooting Common Issues

Even well-maintained systems encounter operational challenges. Common issues include:

- Product Quality Variations: Inconsistent moisture content or particle size

- Potential causes: Feed variations, heat transfer surface fouling, control system issues

- Solutions: Feed conditioning, cleaning procedures, control calibration

- Reduced Throughput Capacity:

- Potential causes: Buildup on heat transfer surfaces, exhaust restrictions, mechanical wear

- Solutions: Cleaning protocols, component inspection, system balancing

- Increased Energy Consumption:

- Potential causes: Heat exchanger fouling, insulation degradation, air leakage

- Solutions: Regular cleaning, insulation inspection, leak testing

- Mechanical Failures:

- Potential causes: Bearing wear, drive component fatigue, corrosion

- Solutions: Lubrication programs, alignment checks, corrosion monitoring

Developing standard troubleshooting procedures for these common issues reduces downtime and repair costs.

Operator Training and Knowledge Management

Well-trained operators are essential for system performance:

- Comprehensive Initial Training: Covering theory, operation, and maintenance

- Refresher Programs: Regular skill updates and best practice sharing

- Knowledge Documentation: Creating and maintaining site-specific procedures

- Succession Planning: Ensuring operational knowledge transfer

Consider developing a certification program for operators to formalize skill development and recognition.

Future Trends in Sludge Drying Technology

The field of sludge drying continues to evolve, with several emerging trends shaping future developments.

Technological Innovations

Recent and upcoming advances include:

- Advanced Materials: Heat-resistant, non-stick surfaces for improved performance

- Sensor Technology: Real-time monitoring of moisture content and product characteristics

- Artificial Intelligence: Predictive control systems for optimal operation

- Modular Designs: Scalable systems that grow with capacity needs

These innovations promise improved efficiency, reliability, and flexibility in sludge drying operations.

Regulatory Developments

Evolving regulations continue to influence sludge management approaches:

- Stricter Disposal Limitations: Further restrictions on landfilling biosolids

- Beneficial Use Requirements: Increased emphasis on resource recovery

- Energy Efficiency Standards: Potential mandates for minimum efficiency levels

- Emissions Controls: Tighter limits on air and water discharges

Facilities should consider not only current regulations but likely future developments when selecting drying technologies.

Integration with Circular Economy Principles

Forward-thinking organizations are increasingly viewing sludge not as waste but as a resource:

- Nutrient Recovery: Extracting phosphorus and other valuable components

- Advanced Material Production: Converting dried sludge into specialized products

- Biochar Production: Pyrolysis processes creating stable carbon products

- Closed-Loop Systems: Integrating drying with other recovery processes

These approaches align with broader sustainability goals while potentially creating new revenue streams.

Conclusion: Making the Right Choice for Your Facility

Selecting and implementing the optimal sludge drying solution requires careful consideration of numerous factors—technical, economic, operational, and environmental. The right system for your facility depends on your specific circumstances, including feed characteristics, capacity requirements, space constraints, and regulatory environment.

By thoroughly evaluating the different types of dryers available and understanding the key selection criteria outlined in this guide, you can make an informed decision that delivers long-term value for your organization. Remember that the lowest capital cost option rarely provides the best lifetime value; instead, focus on the system that best balances performance, reliability, efficiency, and total cost of ownership.

As regulations tighten and disposal options become more limited, sludge drying represents an increasingly important component of sustainable waste management strategies. Whether your primary goals are cost reduction, regulatory compliance, or beneficial reuse opportunities, implementing an appropriate drying system can help transform sludge management from a challenging problem into a strategic advantage.