Imagine a wastewater treatment plant processing thousands of gallons of sewage every day. Once the treatment is complete, tons of sludge remain – thick, muddy, and filled with water. Disposing of it directly would be costly and harmful to the environment. This is where the sludge drying bed comes into play.

A sludge drying bed is one of the oldest and most widely used methods for sludge dewatering. Simple in design yet highly effective, it reduces water content in sludge through natural processes like drainage and evaporation. For decades, municipalities, industries, and treatment facilities have relied on sludge drying beds as a cost-effective solution for managing sludge volumes.

In this article, we’ll explore:

Table of contents

By the end, you’ll have a clear understanding of why sludge drying beds remain a cornerstone in sludge management, and how industries can optimize them for efficiency.

What is a Sludge Drying Bed and How It Works

Definition

A sludge drying bed is a natural, low-cost method of dewatering sludge from wastewater treatment processes. It consists of a shallow, rectangular bed filled with layers of sand and gravel, underlain by drainage pipes. Sludge is spread evenly across the surface, where water drains downward through the bed and evaporates upward into the atmosphere. Over time, this leaves behind dried sludge with much lower moisture content.

Key Components of a Sludge Drying Bed

To understand its effectiveness, let’s break down its construction:

- Permeable Top Layer (Sand Layer)

- Usually 200–300 mm thick.

- Provides the filtration surface where sludge is placed.

- Prevents clogging while allowing water to drain downward.

- Support Layer (Gravel Bed)

- Typically 250–300 mm thick.

- Made of graded gravel (larger particles at the bottom, smaller near the top).

- Supports the sand layer and distributes water evenly to the drains.

- Drainage System

- A network of perforated pipes embedded in the gravel layer.

- Collects filtrate (water) and directs it back to the treatment plant for further processing.

- Sludge Inlet and Outlet Arrangements

- Ensures uniform sludge distribution across the bed.

- Outlets help in removing drained water without contamination.

- Protective Embankments

- Prevent sludge spillage and ensure safety during operation.

Working Principle

The operation of a sludge drying bed relies on two key mechanisms:

- Drainage – Immediately after sludge is spread, water drains through the sand and gravel layers into the underdrains. This removes free water quickly.

- Evaporation – Over several days or weeks, sunlight and natural airflow evaporate additional moisture, further drying the sludge.

Together, these processes can reduce sludge moisture content from 95–98% down to 60–70%, depending on climate conditions and bed design.

Typical Drying Cycle

- Loading: Fresh sludge is applied to the bed in layers (200–300 mm depth).

- Drainage Phase: Rapid removal of free water within the first 24–48 hours.

- Evaporation Phase: Slower drying over several days to weeks, influenced by weather conditions.

- Removal: Once sufficiently dry, the sludge is manually or mechanically removed for disposal, composting, or further use.

In short, sludge drying beds are effective because they combine natural forces (gravity and sunlight) with a simple engineered design to achieve cost-efficient sludge volume reduction.

Types of Sludge Drying Beds

While the conventional sand drying bed is the most common, variations have been developed to suit different climates, sludge characteristics, and space constraints. Below are the main types:

1. Conventional Sand Drying Bed

- Description: The traditional and most widely used design.

- Structure: Multiple rectangular beds with sand, gravel, and underdrains.

- Operation: Relies entirely on natural drainage and evaporation.

- Best Suited For: Small to medium-sized treatment plants with ample land availability and favorable weather conditions (warm, dry climates).

- Limitation: Slow drying in cold or rainy conditions; requires significant land area.

2. Paved Drying Beds

- Description: Instead of sand and gravel, the bed is paved with concrete or bricks.

- Structure: The base is sloped to allow water runoff; drainage pipes are optional.

- Advantages: Easy to clean, sludge removal is faster, less risk of clogging.

- Best Suited For: Plants where sludge is mechanically thickened before drying, reducing reliance on sand filtration.

- Limitation: Reduced filtration efficiency compared to sand-based beds.

3. Artificial Media Drying Beds

- Description: Replaces sand with artificial materials such as geotextiles, plastic media, or porous tiles.

- Advantages: Higher drainage rates, less clogging, and longer operational life compared to sand beds.

- Best Suited For: Facilities with high sludge volumes or limited maintenance resources.

- Limitation: Higher installation cost.

4. Vacuum-Assisted Drying Beds

- Description: A modified system where vacuum pumps are connected to the drainage system to accelerate water removal.

- Advantages: Faster dewatering cycle (up to 50% quicker than conventional beds).

- Best Suited For: Urban areas with limited land or where rapid turnaround of beds is essential.

- Limitation: Requires energy input and higher operational costs.

5. Covered (Greenhouse) Drying Beds

- Description: Beds are enclosed with transparent roofing (like a greenhouse) to prevent rainwater entry and enhance evaporation.

- Advantages: Year-round operation, protection from weather, higher evaporation efficiency.

- Best Suited For: Regions with high rainfall or cold climates.

- Limitation: Higher construction cost compared to open-air beds.

6. Solar Sludge Drying Beds

- Description: Advanced version of greenhouse beds with solar panels, forced ventilation, or mechanical mixing.

- Advantages: Greatly accelerates drying, reduces footprint, sustainable energy use.

- Best Suited For: Modern treatment plants focused on energy efficiency and circular economy goals.

- Limitation: High capital investment required.

Key Insight:

The choice of sludge drying bed depends on climate, land availability, sludge characteristics, and budget. For example, rural plants with land abundance often opt for conventional sand beds, while urban facilities lean toward vacuum-assisted or solar drying solutions.

Design Considerations for Sludge Drying Beds

Designing a sludge drying bed is not just about laying sand and gravel; it requires careful planning to ensure efficient dewatering, durability, and ease of operation. Below are the critical factors engineers consider during design.

1. Bed Dimensions and Layout

- Typical Size: Each bed is usually 6–12 m wide and 15–30 m long.

- Depth: Sludge loading depth ranges from 200–300 mm per batch.

- Layout: Multiple beds are arranged in parallel to allow rotation—while one bed is drying, another can be loaded.

- Access: Paths for wheelbarrows, trucks, or loaders are incorporated for easy sludge removal.

2. Filter Media (Sand and Gravel Layers)

- Sand Layer:

- Thickness: 200–300 mm.

- Grain size: 0.5–1.0 mm to balance filtration and permeability.

- Gravel Layer:

- Thickness: 250–300 mm.

- Graded gravel (3–50 mm) arranged with larger sizes at the bottom to prevent clogging.

- Media Replacement: Periodically required, as fine particles in sludge can clog sand pores.

3. Drainage System

- Pipes: PVC or perforated concrete pipes placed within the gravel layer.

- Slope: Minimum of 1–2% to ensure smooth water flow.

- Discharge Point: Filtrate is returned to the head of the treatment plant for reprocessing.

- Capacity: Designed to handle both the liquid from drainage and additional rainfall.

4. Hydraulic and Solids Loading Rates

- Hydraulic Loading: Usually 100–200 kg of dry solids per square meter per year.

- Sludge Loading Depth: 200–300 mm per cycle; exceeding this slows drying and risks anaerobic conditions.

- Drying Time: 10–15 days in warm, dry climates; up to several weeks in colder or humid areas.

5. Climate Considerations

- Sunlight and Temperature: Crucial for evaporation efficiency.

- Rainfall: Requires protective covers or improved drainage in high-rainfall areas.

- Wind: Enhances evaporation but may lead to odor issues if beds are not well-managed.

6. Bed Lining and Embankments

- Lining: Clay or concrete lining prevents groundwater contamination.

- Embankments: Raised edges (300–500 mm) to contain sludge and prevent overflow.

7. Operational Flexibility

- Number of Beds: At least two or more to allow continuous operation.

- Mechanical Aids: Some facilities use scrapers, front loaders, or vacuum pumps to reduce labor.

- Reuse of Dried Sludge: Design may include provisions for transporting dried sludge for composting, landfilling, or energy recovery.

Example Case

In a municipal treatment plant in India, engineers optimized bed design by:

- Reducing sludge depth from 300 mm to 200 mm.

- Installing greenhouse covers to extend operation into monsoon season.

- Using geotextile media instead of sand to reduce clogging.

This resulted in a 40% faster drying cycle and reduced annual maintenance costs.

Well-designed sludge drying beds can last decades, provided media replacement and drainage cleaning are carried out regularly.

Advantages of Sludge Drying Beds

Sludge drying beds have stood the test of time because they combine simplicity, cost-effectiveness, and efficiency. When designed and managed properly, they offer several compelling advantages over other dewatering methods.

1. Low Capital and Operating Costs

- Construction: Requires basic materials like sand, gravel, pipes, and masonry.

- Operation: Relies mostly on natural processes (sunlight, gravity, and wind) rather than expensive machinery.

- Energy Independence: No electricity is needed unless using vacuum-assisted or solar-enhanced designs.

- Result: Ideal for small and medium-sized wastewater treatment plants with limited budgets.

2. Ease of Operation and Maintenance

- Simple Technology: Requires minimal technical expertise.

- Maintenance: Routine cleaning of drains and occasional sand replacement are usually sufficient.

- Flexibility: Can be operated manually, reducing reliance on mechanical equipment.

3. Effective Dewatering Performance

- Moisture Reduction: Reduces water content in sludge from ~95% down to 60–70%.

- Stable Output: Produces semi-solid sludge suitable for transport, composting, or further treatment.

- Natural Drying: Combines drainage and evaporation, ensuring efficient water removal without high costs.

4. Environmentally Friendly

- No Chemical Additives: Unlike some mechanical dewatering processes, sludge drying beds don’t require polymers or coagulants.

- Low Carbon Footprint: Minimal energy consumption compared to centrifuges or belt presses.

- Groundwater Protection: With proper lining, they pose little risk of leaching.

5. Long Service Life

- With periodic maintenance, a sludge drying bed can remain operational for decades.

- Sand and gravel may need periodic replacement, but the basic civil structure is highly durable.

6. Adaptability to Different Conditions

- Climate: Works well in warm, dry climates but can be adapted with covers in rainy or cold regions.

- Sludge Types: Suitable for municipal sludge, industrial sludge, and even certain types of agricultural waste.

- Scalability: Easily scaled by adding more beds in parallel to handle larger sludge volumes.

7. Resource Recovery Potential

- Dried Sludge Reuse: Can be composted, used as soil conditioner, or even as alternative fuel in industries.

- Circular Economy Fit: Encourages sustainable sludge management by converting waste into usable resources.

Key Takeaway:

The biggest strength of sludge drying beds lies in their simplicity and reliability. For municipalities and industries seeking low-cost, environmentally responsible sludge management, they remain a practical solution – especially where land is available.

Limitations and Challenges of Sludge Drying Beds

Despite their many benefits, sludge drying beds also come with operational and practical limitations that restrict their use in certain contexts. Understanding these challenges helps operators make informed decisions and adopt improvements where necessary.

1. Large Land Requirement

- Footprint: Sludge drying beds need extensive land area, especially for medium to large treatment plants.

- Comparison: Mechanical dewatering equipment (like centrifuges) handles the same sludge volume with a much smaller footprint.

- Problem: In densely populated urban areas, land scarcity makes sludge drying beds less feasible.

2. Weather Dependency

- Rainfall: Heavy rains slow drying, re-wet sludge, and can overflow beds if drainage isn’t adequate.

- Cold Climates: Low temperatures reduce evaporation rates, extending drying cycles.

- Wind and Humidity: High humidity decreases evaporation efficiency, further delaying sludge removal.

3. Slow Drying Time

- Duration: Drying cycles can take 10–15 days in warm climates, but extend to several weeks in humid or cold regions.

- Impact: Limits the number of cycles per year, reducing overall treatment capacity.

4. Labor-Intensive Operation

- Manual Work: Removing dried sludge often requires shoveling, wheelbarrows, or loaders.

- Maintenance: Sand replacement, drain cleaning, and sludge hauling demand continuous effort.

- Result: Higher labor costs compared to automated mechanical processes.

5. Potential for Odor and Vector Problems

- Odor: Anaerobic conditions may develop if sludge layers are too thick or drying is too slow.

- Vectors: Stagnant sludge can attract flies, mosquitoes, and rodents, posing public health risks.

- Mitigation: Proper bed depth (≤300 mm), regular monitoring, and covers help reduce these issues.

6. Risk of Sand Clogging

- Fine particles in sludge can clog the sand layer, reducing filtration efficiency.

- Clogged sand needs replacement, which adds to maintenance costs.

7. Limited Year-Round Use

- In regions with long rainy or snowy seasons, sludge drying beds may be unusable for months.

- This requires either storage of wet sludge (which creates additional problems) or alternative dewatering technologies.

8. Lower Efficiency for Certain Sludge Types

- Oily or Greasy Sludge: Slows drainage and clogs filter media.

- High-Inorganic Content: May settle and harden, complicating removal.

- Industrial Sludge: May require pre-treatment before drying on beds.

Key Insight:

Sludge drying beds are best suited for small-to-medium plants in warm, dry climates with available land. For large urban plants or facilities facing stricter environmental regulations, mechanical alternatives often become necessary.

Modern Improvements and Innovations in Sludge Drying Beds

While traditional sludge drying beds remain widely used, advancements in materials, design, and technology have helped address many of their drawbacks. These innovations make them more adaptable to modern wastewater treatment challenges.

1. Geotextile and Artificial Media Layers

- What Changed: Replacing conventional sand with geotextiles, porous tiles, or synthetic filter media.

- Benefits:

- Reduced clogging compared to natural sand.

- Higher drainage capacity.

- Longer life cycle with less frequent media replacement.

- Example: Municipal plants in Europe have reported up to 30% faster drainage cycles using geotextile media.

2. Greenhouse-Covered Drying Beds

- Design: Transparent roofing (similar to agricultural greenhouses) covers the bed.

- Advantages:

- Protects sludge from rainwater infiltration.

- Traps heat, accelerating evaporation.

- Allows year-round operation, even in humid or rainy regions.

- Case Study: In Brazil, greenhouse-covered beds reduced drying time from 20 days to 7–10 days.

3. Solar-Assisted Drying Beds

- Integration: Combines greenhouse designs with solar panels or solar heaters.

- Benefits:

- Enhances evaporation with sustainable energy.

- Reduces reliance on grid power.

- Aligns with circular economy and renewable energy goals.

4. Vacuum-Assisted Systems

- How It Works: Vacuum pumps attached to underdrains increase suction, accelerating water removal.

- Advantages:

- Cuts drying time by up to 50%.

- Useful in urban plants where quick bed turnaround is essential.

- Drawback: Higher operational costs due to energy consumption.

5. Hybrid Systems (Mechanical + Natural)

- Concept: Use mechanical pre-dewatering (centrifuge or belt press) before sludge is placed on beds.

- Outcome:

- Reduces initial sludge water content, making drying faster.

- Minimizes odor and vector problems.

- Increases bed throughput without needing extra land.

6. Automation and Monitoring

- Sensors: Some modern designs include moisture sensors, temperature probes, and automated drainage control.

- Benefits:

- Provides real-time data for operators.

- Reduces guesswork in sludge removal timing.

- Improves operational efficiency.

7. Reuse-Oriented Designs

- Focus: Transform dried sludge into valuable by-products.

- Applications:

- Co-processing in cement kilns.

- Soil conditioner for agriculture (after stabilization).

- Alternative fuel in thermal processes.

- Trend: Many countries now design sludge drying beds not just for dewatering but for resource recovery.

Key Insight:

Modern sludge drying beds are no longer just passive systems—they are evolving into smart, sustainable, and resource-oriented solutions. By integrating renewable energy, advanced materials, and automation, they bridge the gap between traditional simplicity and modern efficiency.

Applications of Sludge Drying Beds in Different Industries

Sludge drying beds are not limited to municipal wastewater treatment plants. Their versatility and cost-effectiveness make them useful across various industries where sludge management is a critical challenge.

1. Municipal Wastewater Treatment

- Primary Use: Drying sludge from sewage treatment plants.

- Why Preferred:

- Low-cost solution for towns and smaller cities.

- Minimal technical expertise needed.

- Produces stable sludge suitable for land application or disposal.

- Example: In rural India, municipal plants often rely on conventional sand drying beds due to abundant land availability.

2. Food and Beverage Industry

- Source of Sludge: Effluents from dairies, breweries, and food processing units.

- Why Suitable:

- Sludge is often biodegradable and less contaminated.

- Drying beds provide a natural, low-energy method of handling it.

- Added Value: Dried sludge may be composted and used as a soil enhancer.

3. Textile and Dyeing Industry

- Source of Sludge: Sludge containing dyes, chemicals, and suspended solids from effluent treatment plants.

- Challenge: Higher risk of clogging due to fine particles.

- Solution: Artificial media drying beds with geotextiles, which resist clogging better than sand.

4. Chemical and Fertilizer Industry

- Source of Sludge: Effluents from chemical reactions, fertilizer production, and neutralization processes.

- Use Case: Covered drying beds to prevent contamination and manage chemical residues.

- Value Addition: Certain dried sludges may be reused in by-product recovery, depending on chemical composition.

5. Paper and Pulp Industry

- Source of Sludge: Fiber-rich sludge from paper mill effluent treatment.

- Why Drying Beds Work:

- High organic content allows relatively easy dewatering.

- Can be further used as fuel in boilers or co-processing in cement kilns.

6. Refineries and Petrochemical Industry

- Source of Sludge: Oily and chemical-laden sludge from wastewater treatment.

- Challenge: Oil and grease content slows drainage.

- Adaptation: Hybrid systems (mechanical thickening before drying beds) are used to accelerate dewatering.

7. Agricultural Applications

- Manure and Agricultural Waste: Sludge from animal farms and agro-industries.

- Benefit: Once dried, sludge can be composted or used directly as fertilizer.

- Sustainability Angle: Promotes circular economy practices in farming communities.

Key Insight:

Sludge drying beds are adaptable across industries, but their design and operation must be tailored to the sludge type. For example, oily refinery sludge needs hybrid treatment, while municipal and food industry sludge can be effectively managed with conventional beds.

Comparison of Sludge Drying Beds with Other Sludge Dewatering Methods

Sludge drying beds are one of the oldest dewatering methods, but industries now have multiple alternatives such as centrifuges, belt filter presses, and geotextile bags. Comparing these technologies helps highlight where drying beds still excel—and where they fall short.

1. Sludge Drying Beds vs. Centrifuges

- Centrifuges: Use high-speed rotation to separate water from sludge.

- Advantages over Beds:

- Much faster (hours vs. days/weeks).

- Requires less land.

- Operates independently of weather.

- Disadvantages:

- High energy consumption.

- Expensive to purchase and maintain.

- Skilled operators required.

- Conclusion: Centrifuges are best for large urban plants; beds remain viable for smaller, low-budget facilities.

2. Sludge Drying Beds vs. Belt Filter Presses

- Belt Presses: Mechanically squeeze sludge between porous belts to remove water.

- Advantages over Beds:

- Continuous operation.

- Smaller footprint.

- Produces sludge with consistent dryness (typically 15–25% solids).

- Disadvantages:

- Requires chemicals (polymers) to improve performance.

- Higher operational costs and energy needs.

- Conclusion: Belt presses offer speed and reliability, while drying beds provide simplicity and lower costs.

3. Sludge Drying Beds vs. Geotextile Bags (Geo-Bags)

- Geo-Bags: Sludge is pumped into large permeable bags; water drains while solids are retained.

- Advantages over Beds:

- Portable and flexible.

- Lower land requirements.

- Less odor nuisance if managed well.

- Disadvantages:

- Bags require replacement after multiple uses.

- Disposal of used bags adds waste.

- Conclusion: Geo-bags are suitable for temporary or mobile operations, while drying beds serve as permanent infrastructure.

4. Sludge Drying Beds vs. Vacuum Filters

- Vacuum Filters: Use suction pressure to speed up dewatering.

- Advantages over Beds:

- Much faster drying.

- Controlled and consistent results.

- Disadvantages:

- High capital and maintenance costs.

- Energy-dependent.

- Conclusion: Vacuum filters are efficient but not cost-effective for smaller plants.

5. Sludge Drying Beds vs. Thermal Dryers

- Thermal Dryers: Use direct or indirect heating to evaporate water from sludge.

- Advantages over Beds:

- Produces highly dry sludge (up to 90% solids).

- Suitable for energy recovery applications.

- Disadvantages:

- Very high capital and operational costs.

- Requires strict safety and emissions controls.

- Conclusion: Thermal dryers are best for industries where dried sludge is reused as fuel; drying beds are more economical where disposal is the goal.

Summary Table

| Method | Cost | Land Need | Drying Time | Energy Use | Skill Level | Typical Solids % | Suitability |

|---|---|---|---|---|---|---|---|

| Drying Beds | Low | High | Days–Weeks | Very Low | Low | 20–40% | Small/medium plants, rural areas |

| Centrifuges | High | Low | Hours | High | High | 15–30% | Large urban plants |

| Belt Presses | Medium | Medium | Hours | Medium | Medium | 15–25% | Continuous ops |

| Geo-Bags | Medium | Low | Days | Low | Low | 15–25% | Temporary/mobile sites |

| Vacuum Filters | High | Medium | Hours | High | High | 20–35% | Industrial plants |

| Thermal Dryers | Very High | Low | Hours | Very High | High | 70–90% | Energy recovery plants |

Key Insight:

Sludge drying beds win on cost, simplicity, and sustainability but lag behind in speed and land efficiency. Choosing between them and other methods depends on plant size, budget, sludge type, and disposal goals.

Best Practices for Operating Sludge Drying Beds

Operating sludge drying beds efficiently requires more than just spreading sludge and waiting. By following proven practices, operators can maximize drying speed, improve sludge quality, and extend the life of the beds.

1. Maintain Proper Sludge Loading Depth

- Optimal Depth: 200–300 mm per cycle.

- Why It Matters:

- Too shallow → inefficient use of bed space.

- Too deep → slows drainage, risks anaerobic conditions, and produces foul odors.

2. Pre-Thicken Sludge Before Loading

- Method: Use gravity thickeners, dissolved air flotation (DAF), or centrifuges to reduce water content before spreading.

- Benefit: Pre-thickened sludge shortens drying cycles and minimizes vector attraction.

3. Ensure Even Distribution Across the Bed

- Spread sludge uniformly using pipes or manual tools.

- Avoid piling sludge in one section, as uneven thickness causes inconsistent drying.

4. Optimize Drainage System Performance

- Regularly clean and flush underdrains to prevent clogging.

- Inspect gravel layers for fine sludge accumulation and replace media when needed.

- Maintain slope (1–2%) to ensure quick runoff.

5. Protect Against Weather Impacts

- Rainfall: Use covers, tarps, or greenhouse structures during wet seasons.

- Cold Climates: Employ greenhouse covers or hybrid mechanical dewatering to keep operations continuous.

- Wind & Dust: Plant vegetative buffers around drying beds to minimize dust and odor spread.

6. Monitor Moisture Content

- Use moisture meters or simple grab samples to determine dryness.

- Remove sludge once solids content reaches 20–40%, depending on intended use.

- Delaying removal too long can harden sludge and complicate disposal.

7. Implement Odor and Vector Control

- Odor: Avoid overloading beds and ensure good aeration.

- Vectors: Cover beds with netting if mosquito or fly problems arise.

- Lime Stabilization: Adding lime to sludge before drying can reduce odor and improve pathogen control.

8. Schedule Regular Maintenance

- Replace sand layer every few years (or when clogged).

- Inspect embankments for cracks or leaks.

- Maintain access roads for sludge removal vehicles.

9. Plan for Sludge Reuse or Disposal

- Reuse: Composting, land application, or energy recovery.

- Disposal: Landfilling, if reuse is not viable.

- Integration: Some plants integrate sludge drying beds into circular economy models by linking with agriculture or cement industries.

10. Rotate Multiple Beds

- Operate in cycles so one bed is loading, another drying, and another being cleaned.

- Rotation ensures continuous sludge management without interruption.

Pro Tip: Facilities that pre-thicken sludge and protect beds from rain often cut drying times by 30–40%, making sludge drying beds far more efficient.

Case Studies and Real-World Examples of Sludge Drying Beds

Case studies provide practical insights into how sludge drying beds function across different climates, industries, and scales. They highlight both successes and challenges, offering lessons for operators and decision-makers.

Case Study 1: Municipal Wastewater Treatment in India

- Context: A medium-sized town in southern India faced rising sludge volumes but had limited funds for mechanical dewatering equipment.

- Solution: Conventional sand drying beds were constructed with multiple cells and clay-lined embankments.

- Outcome:

- Drying cycles averaged 10–12 days in the summer.

- Sludge was reused in composting programs, reducing disposal costs.

- Annual O&M (operation and maintenance) costs were less than one-third of mechanical alternatives.

- Lesson: In warm, dry climates, simple sludge drying beds remain one of the most cost-effective solutions.

Case Study 2: Greenhouse-Covered Drying Beds in Brazil

- Context: A wastewater plant in a tropical region struggled with heavy rainfall disrupting conventional beds.

- Innovation: Installed greenhouse-style covered drying beds with transparent roofing and side ventilation.

- Outcome:

- Drying time reduced from 20 days (uncovered) to 7–10 days.

- Rainwater infiltration was eliminated, making the process more predictable.

- Allowed year-round operation with minimal downtime.

- Lesson: Covered beds significantly improve performance in rainy or humid climates.

Case Study 3: Industrial Effluent Sludge in Textile Industry (Turkey)

- Context: A textile dyeing plant generated sludge with fine particles that clogged sand layers.

- Solution: Replaced sand with geotextile filter media to improve drainage.

- Outcome:

- Clogging frequency reduced by 60%.

- Drying cycles shortened by 5–7 days.

- Reduced annual sand replacement costs.

- Lesson: Geotextiles are an effective alternative media for industries with fine-particle sludge.

Case Study 4: Vacuum-Assisted Beds in Urban Europe

- Context: A densely populated city lacked the land for multiple conventional drying beds.

- Innovation: Adopted vacuum-assisted drying beds to speed up dewatering.

- Outcome:

- Drying time cut nearly in half.

- Beds processed double the sludge volume compared to natural beds in the same space.

- Higher O&M costs, but offset by land savings.

- Lesson: Vacuum systems are practical in urban areas where land scarcity outweighs energy costs.

Case Study 5: Sludge-to-Energy Integration in Paper Mills (Finland)

- Context: A paper mill produced large amounts of fiber-rich sludge.

- Solution: Dried sludge using conventional drying beds during warm months, then co-processed the dried sludge in cement kilns.

- Outcome:

- Reduced waste disposal costs.

- Generated value from sludge as an alternative fuel.

- Improved sustainability credentials of the mill.

- Lesson: Sludge drying beds can support circular economy practices by linking with waste-to-energy strategies.

Key Takeaway:

Sludge drying beds are highly adaptable. Whether in low-budget rural towns, rainfall-heavy tropics, or industrial sectors, they continue to evolve with modifications like covers, geotextiles, and hybrid systems—making them relevant even in today’s advanced wastewater management world.

FAQs on Sludge Drying Beds

1. What is a sludge drying bed?

A sludge drying bed is a simple, natural system for sludge dewatering. It consists of sand, gravel, and drainage pipes that allow water to drain while sunlight and air evaporate moisture, leaving behind drier sludge for disposal or reuse.

2. How does a sludge drying bed work?

It works through two main processes:

- Drainage – Free water drains through the sand and gravel into pipes.

- Evaporation – Sunlight and air circulation gradually remove remaining moisture.

3. How long does it take for sludge to dry in a drying bed?

Drying time varies depending on climate:

- Warm and dry climates: 7–15 days

- Humid or rainy climates: 3–4 weeks or more

Use of covers or vacuum assistance can significantly reduce drying time.

4. What are the advantages of sludge drying beds?

- Low cost and simple construction.

- No electricity or chemicals required.

- Environmentally friendly with low carbon footprint.

- Long service life with minimal maintenance.

- Dried sludge can be reused as fertilizer, compost, or fuel.

5. What are the disadvantages of sludge drying beds?

- Require large land areas.

- Drying is slow and weather-dependent.

- Labor-intensive sludge removal.

- Odor and insect issues if poorly managed.

- Sand may clog and need replacement.

6. What are the types of sludge drying beds?

The main types include:

- Conventional sand drying beds

- Paved beds

- Artificial media (geotextile) beds

- Vacuum-assisted beds

- Covered (greenhouse) beds

- Solar-assisted beds

7. What happens to sludge after drying?

Once dried, sludge can be:

- Disposed of in landfills.

- Composted and applied to agricultural land.

- Co-processed in industries such as cement kilns.

- Used as fuel in certain energy recovery systems.

Conclusion

Sludge drying beds have earned their place as one of the oldest and most reliable sludge dewatering methods. They are low-cost, environmentally friendly, and effective for small to medium wastewater treatment facilities. However, they also come with limitations—chiefly slow drying cycles, large land requirements, and weather dependency.

For municipalities or industries with abundant land and warm climates, sludge drying beds remain a practical choice. But for plants looking to handle larger sludge volumes, minimize land use, or achieve year-round efficiency, advanced technologies offer better results.

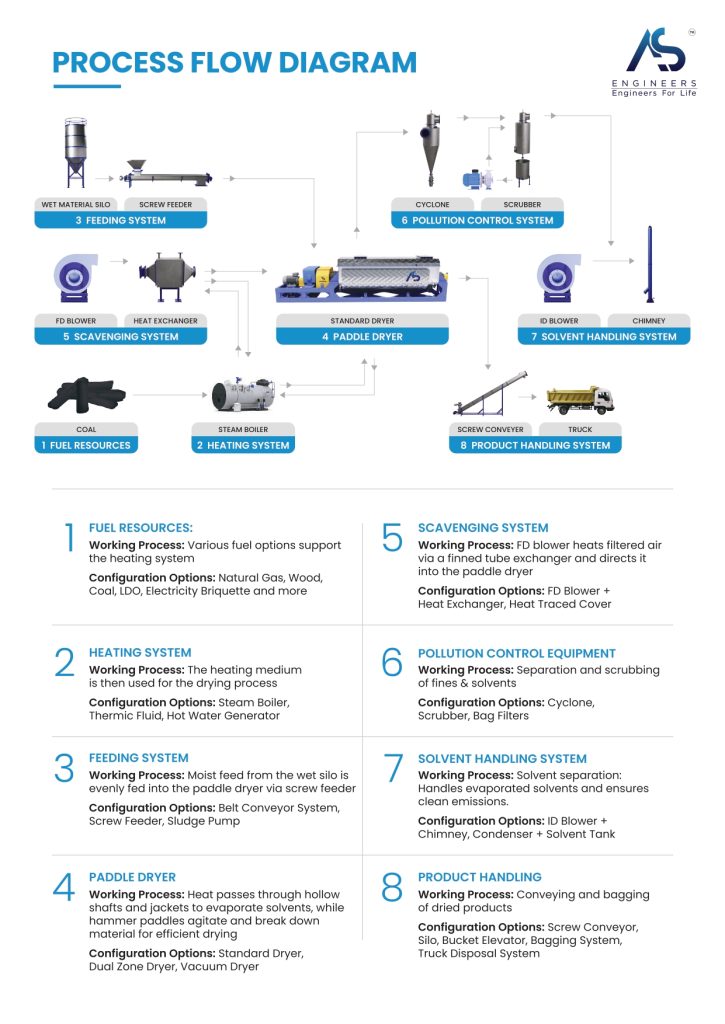

Why Consider Paddle Dryers as an Alternative?

This is where AS Engineers’ Paddle Dryer comes into play. Unlike sludge drying beds that rely heavily on climate conditions, paddle dryers deliver:

- Faster Drying Cycles: Reduces sludge moisture content to as low as 10–20%, far beyond what natural beds achieve.

- Compact Design: Requires only a fraction of the land compared to drying beds.

- Energy Efficiency: Uses indirect heating (steam or thermic fluid), making it safer and more cost-effective in the long run.

- Hygienic and Odor-Free: Operates in controlled conditions, eliminating odor, insects, and vector problems associated with open beds.

- Resource Recovery: Produces dried sludge that can be reused as fuel in cement kilns, power plants, or even as a soil conditioner after treatment.

With over 25 years of expertise and more than 800 dryers in successful operation, AS Engineers has become the trusted leader in sludge and waste drying solutions. Our paddle dryers are built for durability, efficiency, and customization—designed to meet the unique needs of municipal plants, chemical industries, paper mills, refineries, and more.

Final Thought

If sludge drying beds represent the past and present of sludge management, paddle dryers are the future – compact, efficient, and capable of meeting modern environmental standards.

Whether you are operating a municipal plant, a textile effluent facility, or a large-scale industrial unit, AS Engineers’ Paddle Dryer & Sludge Dryers provides the reliable and cost-effective alternative you need to transform sludge management from a problem into an opportunity.

Looking for a smarter, faster, and more sustainable sludge drying solution?

Get in touch with AS Engineers today to discuss how our paddle dryers can reduce your sludge disposal costs, optimize your operations, and help you achieve your environmental compliance goals.