Municipal wastewater treatment facilities process over 34 billion gallons of sewage daily across the United States, generating approximately 7.1 million dry tons of biosolids annually. The challenge? Converting this wet, bulky sludge into manageable, dry material while minimizing energy consumption and operational costs. Two leading technologies dominate this critical process: belt sludge dryers and thin film sludge dryers.

Understanding the fundamental differences between belt sludge dryer vs thin film sludge dryer systems can save your facility hundreds of thousands of dollars in operational costs while dramatically improving processing efficiency. This comprehensive comparison examines every aspect of both technologies, from heat transfer mechanisms to maintenance requirements, helping you make an informed decision for your specific application.

Table of contents

- Understanding Sludge Drying Technology Fundamentals

- Belt Sludge Dryer Technology Deep Dive

- Thin Film Sludge Dryer Technology Analysis

- Performance Comparison: Belt vs Thin Film Dryers

- Economic Analysis: Capital and Operating Costs

- Environmental Impact and Regulatory Considerations

- Maintenance and Operational Requirements

- Application-Specific Selection Criteria

- Future Technology Trends and Innovations

- Frequently Asked Questions

- Conclusion

Understanding Sludge Drying Technology Fundamentals

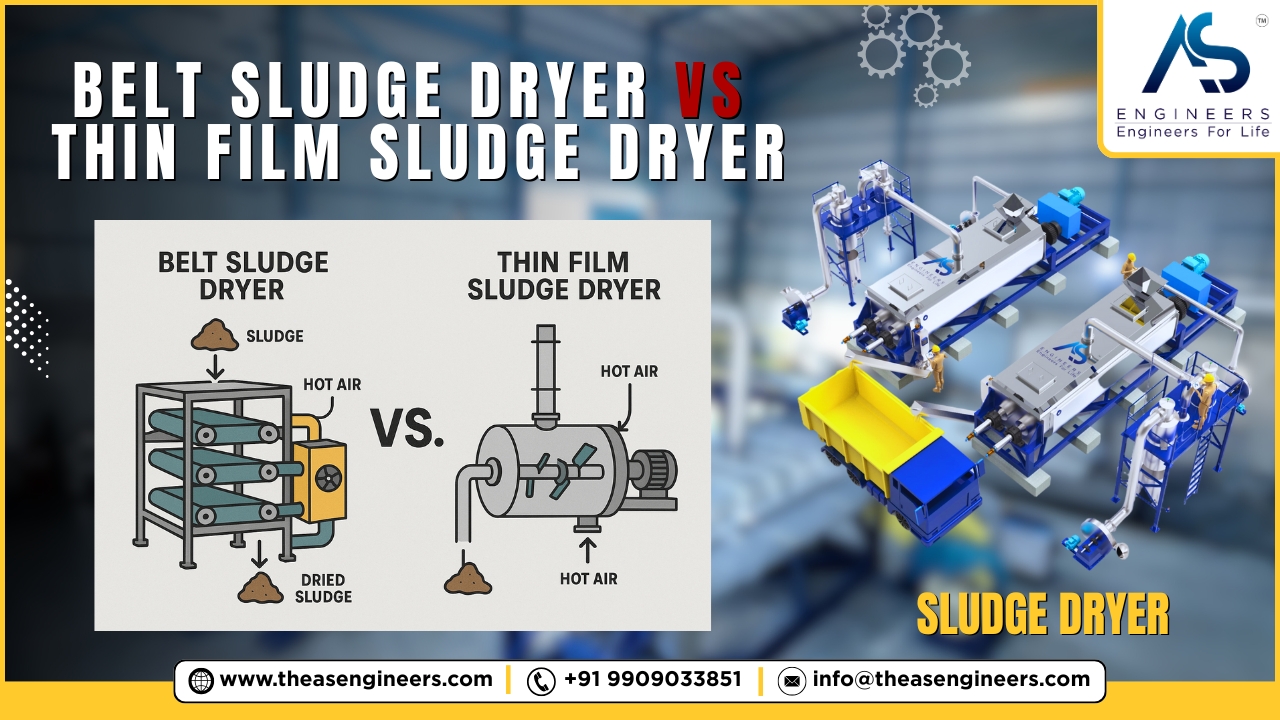

Sludge drying represents a critical step in waste management, transforming high-moisture content biosolids into stable, reduced-volume materials suitable for disposal or beneficial reuse. Both belt and thin film dryers utilize indirect heating methods, but their approaches to heat transfer and material handling differ significantly.

The primary objective remains consistent across both technologies: reduce moisture content from typical incoming levels of 75-85% down to final moisture levels of 5-10%. This dramatic reduction achieves volume reductions of up to 75%, substantially decreasing transportation costs and disposal fees while creating valuable end products like fertilizer pellets or soil amendments.

Modern thermal drying systems incorporate advanced process controls, energy recovery mechanisms, and emission control systems to meet stringent environmental regulations while maximizing operational efficiency.

Belt Sludge Dryer Technology Deep Dive

How Belt Sludge Dryers Operate

Belt sludge dryers employ a continuous conveyor belt system that transports dewatered sludge through heated drying chambers. The process begins when conditioned sludge, typically at 20-25% dry solids content, gets uniformly distributed across a perforated stainless steel belt.

The belt moves through multiple heating zones where hot air or steam circulates above and below the material. This dual-sided heating approach ensures uniform heat distribution throughout the sludge layer. Advanced systems incorporate multiple passes, allowing partially dried material to undergo additional drying cycles until achieving target moisture levels.

Temperature control systems maintain optimal drying conditions, typically operating between 200-400°F depending on sludge characteristics and desired final moisture content. The continuous belt operation enables steady-state processing with minimal temperature fluctuations.

Key Advantages of Belt Dryers

Uniform Heat Distribution: The perforated belt design allows heated air to pass through the sludge layer, ensuring consistent drying throughout the material thickness. This prevents the formation of hard, impermeable crusts that can impede moisture removal.

Gentle Material Handling: The continuous belt system minimizes mechanical stress on dried material, preserving particle integrity and preventing excessive dust generation. This characteristic proves particularly valuable when producing pelletized end products.

Flexible Processing Capacity: Belt dryers accommodate varying feed rates and moisture contents without significant process adjustments. This flexibility enables facilities to handle seasonal variations in sludge production effectively.

Easy Maintenance Access: The open belt design provides excellent access to all system components for routine maintenance and cleaning operations. Most maintenance tasks can be performed without complete system shutdown.

High Throughput Capability: Modern belt dryers process 5-50 tons of dry solids per day, making them suitable for medium to large municipal facilities and industrial applications.

Belt Dryer Limitations and Challenges

Higher Energy Consumption: The open belt design results in significant heat losses to the surrounding environment. Energy requirements typically range from 1,000-1,400 BTU per pound of water evaporated, higher than competing technologies.

Larger Footprint Requirements: Belt dryers require substantial floor space due to their linear configuration. A typical system processing 20 tons per day may require 3,000-5,000 square feet of building space.

Odor Management Complexity: The open belt system can release odorous compounds during the drying process, requiring sophisticated air handling and treatment systems to meet environmental regulations.

Limited Feedstock Flexibility: Belt dryers perform optimally with dewatered sludge containing 20-30% dry solids. Materials with higher or lower solids content may require additional pretreatment or process modifications.

Thin Film Sludge Dryer Technology Analysis

Thin Film Dryer Operating Principles

Thin film sludge dryers utilize an entirely different approach, employing heated surfaces to create thin layers of material that undergo rapid moisture removal. The system consists of heated cylinders or plates where sludge gets spread into thin films, typically 1-3mm thick.

Steam or hot oil heating systems maintain surface temperatures between 250-350°F. As the thin film contacts these heated surfaces, moisture rapidly evaporates and gets removed through vacuum systems or heated air circulation. The dried material continuously scrapes off the heated surface using mechanical scrapers or doctor blades.

This indirect heating method provides precise temperature control while minimizing direct contact between heating medium and sludge material. The result is efficient heat transfer with minimal thermal degradation of organic compounds.

Advantages of Thin Film Technology

Superior Energy Efficiency: Thin film dryers achieve heat transfer coefficients 3-5 times higher than belt systems. Energy requirements typically range from 800-1,000 BTU per pound of water evaporated, representing significant operational savings.

Compact System Design: The vertical or horizontal drum configuration requires 60-70% less floor space compared to equivalent-capacity belt dryers. This space efficiency proves crucial for facilities with limited building areas.

Excellent Heat Recovery Potential: The enclosed design enables effective vapor recovery and heat exchanger integration. Advanced systems recover 40-60% of input energy through vapor condensation and heat exchange.

Precise Process Control: The enclosed environment allows precise control of temperature, pressure, and residence time. This control capability enables consistent product quality regardless of feed variations.

Reduced Emissions: The closed system design minimizes fugitive emissions and simplifies air pollution control requirements. Vapor streams can be effectively captured and treated before release.

Thin Film Dryer Disadvantages

- Higher Capital Investment: Thin film dryers typically cost 20-30% more than equivalent belt systems due to complex heat transfer surfaces and precision manufacturing requirements.

- Maintenance Complexity: The enclosed design and rotating components require specialized maintenance procedures. Access to internal components often requires significant disassembly.

- Feed Preparation Requirements: Thin film systems require consistent feed characteristics. Variations in solids content or particle size can significantly impact performance and product quality.

- Potential for Fouling: Sticky or high-organic content sludges may adhere to heated surfaces, reducing heat transfer efficiency and requiring frequent cleaning cycles.

- Limited Capacity Range: Most thin film systems are designed for specific capacity ranges, making them less suitable for facilities with highly variable processing requirements.

Performance Comparison: Belt vs Thin Film Dryers

Energy Efficiency Analysis

Energy consumption represents the largest operational cost for sludge drying systems, typically accounting for 60-70% of total operating expenses. Thin film dryers demonstrate clear advantages in this critical area.

Belt Dryer Energy Performance:

- Energy consumption: 1,000-1,400 BTU/lb water evaporated

- Heat recovery potential: 20-30%

- Thermal efficiency: 60-70%

Thin Film Dryer Energy Performance:

- Energy consumption: 800-1,000 BTU/lb water evaporated

- Heat recovery potential: 40-60%

- Thermal efficiency: 75-85%

The energy savings from thin film technology can translate to $50,000-$150,000 annually for a 20-ton-per-day facility, depending on local energy costs and operating hours.

Processing Capacity and Flexibility

Belt dryers excel in high-capacity applications and provide superior flexibility for varying feed conditions. They can effectively process feeds ranging from 15-35% dry solids content without significant process modifications.

Thin film dryers offer consistent performance within their design parameters but require more precise feed preparation. They typically handle feeds with 25-40% dry solids content most effectively.

Capacity Ranges:

- Belt dryers: 5-50 tons dry solids/day

- Thin film dryers: 2-30 tons dry solids/day

Product Quality Considerations

Both technologies produce high-quality dried products suitable for various end uses, but product characteristics differ based on the drying mechanism.

Belt Dryer Products:

- Uniform particle size distribution

- Lower bulk density

- Good handling characteristics

- Suitable for pelletizing

Thin Film Dryer Products:

- Higher bulk density

- More uniform moisture content

- Potential for some particle size reduction

- Enhanced pathogen destruction due to higher temperatures

Economic Analysis: Capital and Operating Costs

Initial Capital Investment

Capital costs vary significantly based on system capacity, automation level, and site-specific requirements. However, general cost ranges provide useful comparison metrics:

Belt Dryer Capital Costs:

- Equipment: $800,000-$1,500,000 (20 TPD system)

- Installation: $300,000-$600,000

- Total project cost: $1,100,000-$2,100,000

Thin Film Dryer Capital Costs:

- Equipment: $1,000,000-$1,800,000 (20 TPD system)

- Installation: $400,000-$700,000

- Total project cost: $1,400,000-$2,500,000

Operating Cost Comparison

Annual operating costs include energy, maintenance, labor, and consumables. Based on a 20-ton-per-day facility operating 300 days annually:

Belt Dryer Annual Operating Costs:

- Energy: $180,000-$250,000

- Maintenance: $40,000-$60,000

- Labor: $80,000-$120,000

- Total: $300,000-$430,000

Thin Film Dryer Annual Operating Costs:

- Energy: $140,000-$180,000

- Maintenance: $60,000-$90,000

- Labor: $60,000-$80,000

- Total: $260,000-$350,000

Return on Investment Analysis

Despite higher initial capital costs, thin film dryers often provide superior long-term economics through reduced energy consumption and higher thermal efficiency. Payback periods typically range from 3-7 years depending on local energy costs and operating patterns.

| Feature | Belt Sludge Dryer | Thin Film Sludge Dryer |

|---|---|---|

| Working Principle | Sludge is evenly spread on a belt and dried by hot air flow | A thin film of sludge is continuously agitated on a heated surface |

| Drying Mechanism | Convective drying via hot air | Conductive drying via heated surface and rotor blades |

| Heat Transfer Mode | Indirect & Direct (air-contact) | Indirect (thermal conduction) |

| Sludge Handling Capacity | Suitable for large-scale, high-moisture sludge | Ideal for sticky, viscous, and heat-sensitive sludge |

| Temperature Range | 60°C to 150°C (low to medium) | 100°C to 180°C (medium to high, customizable) |

| Footprint | Large | Compact |

| Energy Consumption | Moderate to high (due to airflow system) | Low to moderate (efficient heat transfer) |

| Maintenance Needs | More mechanical parts like belts, rollers | Fewer moving parts, easier to clean |

| Automation & Control | Medium – batch or semi-continuous | High – fully automatic, continuous operation |

| Drying Efficiency | 60–80% moisture reduction | Up to 90–95% dry solids achievable |

| Use Cases | Municipal sludge, paper mill sludge, textile sludge | Pharmaceutical, chemical, oil sludge, hazardous sludge |

| Capital Cost | Lower initial cost | Higher initial investment |

| OPEX & ROI | Higher operational cost over time | Lower OPEX with faster ROI in long-term |

Environmental Impact and Regulatory Considerations

Emission Control Requirements

Both technologies must comply with air quality regulations governing particulate matter, volatile organic compounds, and odorous emissions. The design differences significantly impact emission control complexity and costs.

Belt Dryer Emissions:

- Open system requires comprehensive air handling

- Higher volume of exhaust air treatment

- Potential for fugitive emissions

- Odor control challenges

Thin Film Dryer Emissions:

- Enclosed system enables effective vapor capture

- Lower exhaust air volumes

- Minimal fugitive emissions

- Simplified odor control

Energy Consumption and Carbon Footprint

Thin film dryers’ superior energy efficiency translates directly to reduced carbon emissions. A 20-ton-per-day thin film system typically produces 200-400 fewer tons of CO2 annually compared to equivalent belt dryers.

This environmental advantage becomes increasingly important as facilities face carbon reduction mandates and sustainability reporting requirements.

Maintenance and Operational Requirements

Belt Dryer Maintenance

Routine Maintenance Tasks:

- Belt inspection and tension adjustment

- Drive system lubrication

- Air handling system filter replacement

- Temperature sensor calibration

Major Maintenance Items:

- Belt replacement (every 3-5 years)

- Drive motor overhaul

- Heat exchanger cleaning

- Structural component inspection

Maintenance Accessibility: Excellent access to all components enables efficient maintenance operations with minimal downtime.

Thin Film Dryer Maintenance

Routine Maintenance Tasks:

- Scraper blade adjustment and replacement

- Seal inspection and replacement

- Heat transfer surface cleaning

- Rotating equipment lubrication

Major Maintenance Items:

- Heated surface refurbishment

- Mechanical drive overhaul

- Seal system replacement

- Internal component inspection

Maintenance Complexity: Higher complexity requires specialized technicians and more extensive downtime for major maintenance activities.

Application-Specific Selection Criteria

Municipal Wastewater Treatment Plants

Recommended for Belt Dryers:

- Facilities processing 15+ tons per day

- Sites with adequate building space

- Operations requiring maximum flexibility

- Facilities with limited specialized maintenance capabilities

Recommended for Thin Film Dryers:

- Facilities with space constraints

- Operations prioritizing energy efficiency

- Sites with stable sludge characteristics

- Facilities with skilled maintenance personnel

Industrial Applications

Food Processing Facilities: Thin film dryers excel in food processing applications due to precise temperature control and minimal product degradation.

Pharmaceutical Manufacturing: Both technologies can meet pharmaceutical requirements, but thin film systems offer superior process control for sensitive materials.

Chemical Processing: Belt dryers provide better handling of abrasive or corrosive materials due to easier maintenance access.

Future Technology Trends and Innovations

Advanced Process Control Systems

Modern sludge dryers incorporate sophisticated control systems utilizing artificial intelligence and machine learning algorithms to optimize energy consumption and product quality. These systems automatically adjust operating parameters based on feed characteristics and environmental conditions.

Heat Recovery Enhancements

New heat recovery technologies, including heat pumps and organic Rankine cycles, are being integrated with both belt and thin film dryers to further improve energy efficiency and reduce operating costs.

Hybrid Technologies

Emerging hybrid systems combine elements of both technologies, utilizing belt conveyors with thin film heating surfaces to capture advantages of both approaches while minimizing individual limitations.

Frequently Asked Questions

- What is the main difference between belt sludge dryer vs thin film sludge dryer systems? Belt dryers use perforated conveyor belts moving through heated chambers, while thin film dryers spread material into thin layers on heated surfaces. Thin film systems offer higher energy efficiency and smaller footprints, while belt dryers provide greater processing flexibility and easier maintenance access.

- Which technology offers better energy efficiency for sludge drying applications?

Thin film dryers typically consume 20-30% less energy than belt dryers, achieving 800-1,000 BTU per pound of water evaporated compared to belt dryers’ 1,000-1,400 BTU per pound. This translates to significant annual operating cost savings for most facilities. - How do capital costs compare between belt and thin film sludge dryers?

Thin film dryers typically require 15-25% higher initial capital investment due to complex heat transfer surfaces and precision manufacturing. However, lower operating costs often justify the higher upfront investment through 3-7 year payback periods. - What maintenance requirements should facilities expect with each technology?

Belt dryers offer easier maintenance access and lower complexity, while thin film dryers require specialized technicians and more extensive downtime for major maintenance. Belt systems need belt replacement every 3-5 years, while thin film systems require regular scraper blade replacement and seal maintenance. - Which sludge dryer technology works better for facilities with limited space?

Thin film dryers require 60-70% less floor space than equivalent belt systems due to their vertical or compact horizontal configurations. This makes them ideal for facilities with building space constraints or high real estate costs.

Conclusion

The choice between belt sludge dryer vs thin film sludge dryer technology ultimately depends on your facility’s specific requirements, constraints, and priorities. Belt dryers excel in high-capacity applications requiring maximum flexibility and straightforward maintenance, making them ideal for large municipal facilities with adequate space and variable processing demands.

Thin film dryers offer superior energy efficiency, compact design, and precise process control, making them perfect for facilities prioritizing operational cost reduction and environmental sustainability. While requiring higher initial investment and specialized maintenance capabilities, their long-term economic advantages often justify the additional complexity.

Consider your facility’s processing capacity, available space, maintenance capabilities, and long-term operational goals when making this critical technology selection. Both technologies represent proven, reliable solutions that can effectively meet your sludge drying requirements while delivering significant operational benefits over traditional disposal methods.

Ready to optimize your sludge drying operations? Evaluate your specific requirements against the detailed comparisons provided above, and consult with qualified equipment suppliers to develop customized solutions that maximize your facility’s performance and profitability.