Welcome to your ultimate guide on stp sludge and how to optimize operations within a sewage treatment plant. Many facility managers and environmental experts are asking the same question: how can we handle stp sludge in the most efficient, cost-effective, and compliant way?

This post will dive deep into every aspect of sludge handling, from understanding the fundamentals of sewage sludge treatment to designing a robust strategy that meets regulations while saving resources. By the end of this comprehensive article, you will discover proven techniques for treating, recycling, or disposing of sludge, so you can optimize your STP without guesswork.

Ever wondered why sludge processing can be such a challenge for wastewater professionals? The problem typically boils down to handling large volumes of semi-solid waste in a way that meets environmental regulations, stays within budget, and does not disrupt plant operations. In this guide, you will gain a clear, in-depth look at stp sludge—what it is, how it forms, and why efficient handling is crucial to the success of any sewage treatment plant.

Table of contents

- What Is STP Sludge?

- Why Proper STP Sludge Management Matters

- Understanding the Sewage Sludge Treatment Process

- Types of Sludge in Sewage Treatment

- Primary Sludge vs. Secondary Sludge

- Sludge Dewatering Techniques for Efficiency

- Sludge Thickening Methods

- Cost-Saving Strategies in Sludge Wastewater Treatment

- Environmental Considerations and Regulations

- Designing an Optimal Sludge Management Plan

- Maintenance and Operation Best Practices

- Real-World Case Studies

- Common FAQs on STP Sludge

- Conclusion

What Is STP Sludge?

STP sludge is the semi-solid material generated during the wastewater treatment process in Sewage Treatment Plants (STPs). When raw wastewater arrives at a treatment facility, it undergoes several stages:

- Preliminary screening and grit removal

- Primary clarification

- Biological or secondary treatment

- Secondary clarification

- Tertiary or advanced treatment (if needed)

During these processes, suspended solids, organic matter, and other contaminants settle or are biologically processed, eventually forming what we call “sludge.” The final form is a thick or semi-solid substance loaded with organic matter, pathogens, nutrients, and possibly metals or other pollutants.

Key Characteristics

- High Water Content: Typically 90–99% water.

- Nutrient Rich: Often high in nitrogen and phosphorus, beneficial for agricultural reuse if contaminants are within acceptable limits.

- Pathogens: Can contain harmful microorganisms that need to be controlled or destroyed.

- Heavy Metals: Depending on the industrial or municipal sources, may contain metals such as lead, zinc, or copper.

Understanding the nature of sludge is essential. It is not just “waste”; it can be a resource if handled correctly. Proper sludge management transforms a messy byproduct into something that can be used beneficially, often as fertilizer, or disposed of safely to protect public health and the environment.

Why Proper STP Sludge Management Matters

If you operate or manage a sewage treatment plant, you likely know that handling sludge is among your most significant operational challenges. Why does it matter so much?

- Operational Efficiency: Poor sludge management can bog down the entire STP process. If sludge accumulates faster than it is processed, it can cause equipment malfunctions, slow treatment rates, and even force facility shutdowns.

- Environmental Responsibility: Sludge containing pathogens or toxins can harm ecosystems and public health if not properly treated before disposal or reuse.

- Cost Savings: Sludge treatment can be expensive, often accounting for up to 50% of total wastewater treatment costs. Efficient methods reduce hauling fees, energy costs, and maintenance overhead.

- Regulatory Compliance: Governments and environmental agencies have strict regulations for sludge disposal and reuse. Non-compliance can lead to hefty fines and legal repercussions.

- Resource Recovery: Modern methods allow you to recover resources like biogas, fertilizers, or even water from sludge, turning an expense into a revenue source.

Given these factors, an integrated approach to stp sludge management becomes indispensable.

Understanding the Sewage Sludge Treatment Process

To create a robust strategy for sewage sludge treatment, you must first understand its typical stages. While processes can differ based on plant design and local regulations, here is a simplified sequence:

- Pre-Treatment (Thickening)

After separation from wastewater, sludge is often thickened to reduce its water content. This step can employ gravity thickeners, flotation thickeners, or mechanical devices such as belt thickeners. - Stabilization

Stabilization aims to reduce the sludge’s odor, pathogens, and biodegradable content. Common methods include anaerobic digestion, aerobic digestion, composting, and lime stabilization. - Conditioning

Before dewatering, operators may add chemicals (like polymers) to enhance water removal. This helps bind sludge particles together, making dewatering more efficient. - Dewatering

In this step, the sludge is further dried using filters, centrifuges, or belt presses. The goal is to achieve a higher solid content, lowering transportation and disposal costs. - Disposal or Reuse

Depending on its quality, dewatered sludge can be disposed of in landfills, incinerated, or reused in agriculture or land reclamation projects. Some plants recover energy from sludge via biogas capture.

Each step aims to reduce volume, neutralize harmful components, and, where possible, derive beneficial resources. The end game is always the same: manage sludge in a way that is safe, compliant, and economically viable.

Types of Sludge in Sewage Treatment

When you talk about sludge wastewater treatment, remember that not all sludge is the same. Categorizing sludge based on its source and characteristics helps you design targeted treatment strategies. Broadly, we can break it down into two main categories:

- Primary Sludge:

- Formed from the solids that settle out in the primary clarifier.

- Typically has a higher concentration of organic matter, debris, and grit.

- More dense and often easier to dewater than secondary sludge.

- Secondary Sludge (Waste Activated Sludge):

- Generated during the biological treatment stage (activated sludge or trickling filters).

- Contains microbial biomass and residual organic matter.

- Has higher water content and can be more challenging to dewater.

There can also be tertiary sludge if advanced treatments like filtration or chemical precipitation are used. The composition and treatability can vary significantly based on plant design, industrial discharges, and community wastewater characteristics.

Primary Sludge vs. Secondary Sludge

Distinguishing primary sludge from secondary sludge is crucial for tailoring your approach to sludge wastewater treatment. Let’s highlight some key differences:

| Aspect | Primary Sludge | Secondary Sludge |

|---|---|---|

| Source | Settling in the primary clarifier | Biological treatment (activated sludge systems, etc.) |

| Composition | Heavier solids, higher grit content, coarse organic matter | Predominantly bacterial flocs, dissolved organic matter |

| Water Content | Usually lower, making it somewhat easier to dewater | High water content, can be more difficult to dewater |

| Stabilization | Often stabilized using anaerobic digestion or lime treatment | Generally stabilized using digestion (anaerobic or aerobic) |

| Nutrient Levels | Moderate to high organic content | High microbial content, which may be valuable in composting |

The synergy of managing these two types effectively often leads to improved overall sludge handling efficiency. Some facilities mix primary and secondary sludge before further processing, while others treat them separately for optimal results.

Sludge Dewatering Techniques for Efficiency

One of the biggest operational costs in managing stp sludge is reducing its water content. The more water you remove, the easier (and cheaper) it is to transport or dispose of. Below are common dewatering techniques:

1. Belt Filter Press

- How It Works: Sludge is sandwiched between two belts that apply pressure to force out water.

- Pros: Continuous operation, relatively simple, cost-effective.

- Cons: Produces a sludge cake that may still contain a fair amount of moisture.

2. Centrifugation

- How It Works: High-speed centrifuges separate solids from liquids based on density differences.

- Pros: Capable of handling varying sludge types, produces a cake with relatively high solids.

- Cons: High-energy consumption, can require more skilled operators.

3. Plate and Frame Filter Press

- How It Works: Sludge is pumped into plates lined with filter cloth. Water passes through the cloth, leaving solids behind.

- Pros: Can achieve high-solid sludge cakes, low polymer usage.

- Cons: Batch operation, labor-intensive, and relatively slow.

4. Screw Press

- How It Works: A rotating screw inside a cylindrical screen gradually applies pressure, pushing water out of the sludge.

- Pros: Energy-efficient, low noise, minimal labor.

- Cons: Generally smaller capacity compared to belt presses or centrifuges.

The choice of dewatering method depends on your plant size, sludge characteristics, and budget. Conducting a pilot test or consulting with equipment manufacturers can yield insights into the best fit for your facility.

Sludge Thickening Methods

Thickening is often the step before dewatering, designed to increase the sludge’s solids concentration from a few percent to a more manageable range. Here are some widely adopted thickening methods:

Gravity Thickening

- Process: Sludge settles in large circular tanks; heavier solids accumulate at the bottom.

- Applications: Works best for primary sludge or a mix of primary and secondary sludge.

- Advantages: Low operational cost, minimal energy requirement.

Dissolved Air Flotation (DAF)

- Process: Air bubbles attach to sludge particles, causing them to float to the surface.

- Applications: Useful for secondary sludge or any sludge with lighter particles.

- Advantages: High solids concentration in a relatively small footprint.

Mechanical Thickening

- Process: Relies on equipment like belt thickeners and rotary drum thickeners.

- Applications: Sludges with varying characteristics, especially waste activated sludge.

- Advantages: Automated, space-saving, and consistent results.

A well-implemented thickening process ensures that subsequent dewatering stages become less cumbersome and more cost-effective.

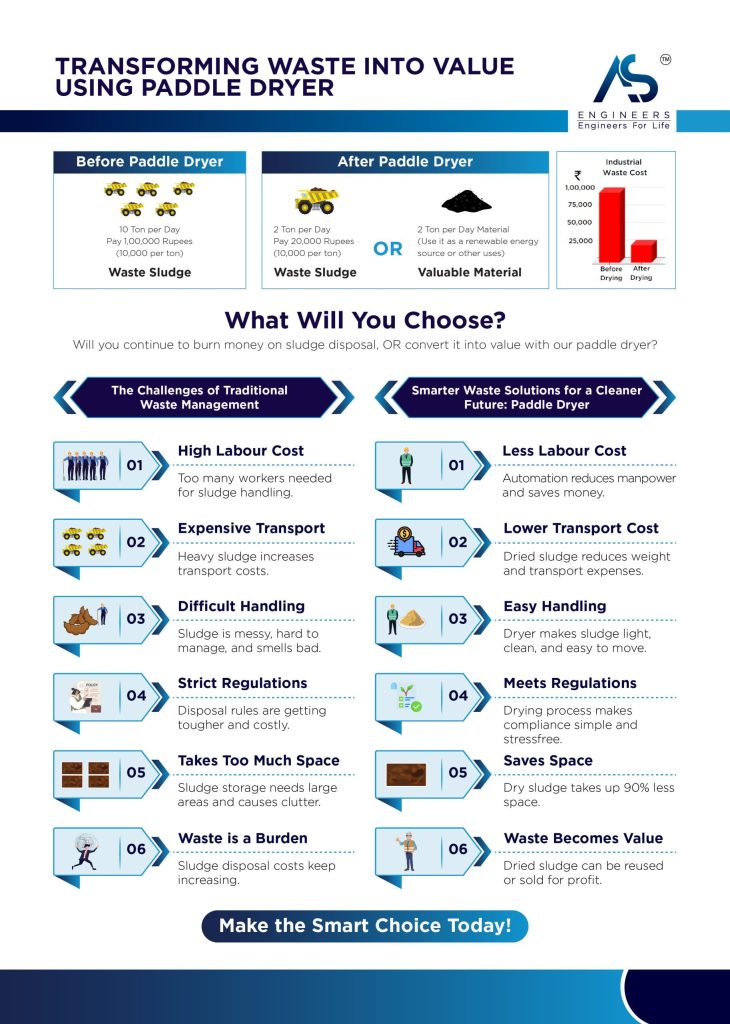

Cost-Saving Strategies in Sludge Wastewater Treatment

Sludge management can be a significant expense, but strategic choices lead to substantial savings. Let us examine key strategies:

- Energy Recovery:

- Anaerobic Digestion: Generates biogas that can fuel boilers or engines, thus reducing external energy demand.

- Combined Heat and Power (CHP): Uses generated biogas for electricity and heat within the plant.

- Volume Reduction:

- Thickening and Dewatering: The less water in your sludge, the lower your disposal and transportation costs.

- Thermal Drying: Further reduces sludge volume, though it requires careful cost-benefit analysis due to energy requirements.

- Chemical Optimization:

- Polymer Usage: Overdosing can inflate chemical costs without additional benefits. Periodic jar tests help fine-tune polymer dosage.

- pH Control: Ensuring optimal pH can improve dewatering and reduce polymer consumption.

- Reuse and Recycling:

- Land Application: If regulated limits allow, using sludge as fertilizer reduces disposal costs while replenishing soil nutrients.

- Composting: Often combined with yard waste, composted sludge can be sold or used for landscaping.

- Operational Efficiency:

- Automation: Supervisory Control and Data Acquisition (SCADA) systems can optimize process variables in real time.

- Regular Equipment Maintenance: Preventive maintenance reduces downtime and extends the life cycle of mechanical components.

By focusing on these strategies, facilities can reduce the overall cost of sludge wastewater treatment while improving their environmental footprint.

Environmental Considerations and Regulations

Operating a sewage treatment plant involves meeting regulations aimed at protecting water bodies, soil quality, and public health. Sludge often contains pathogens and contaminants, so governments impose strict guidelines on how it must be treated, stored, transported, and used or disposed of.

Key Regulatory Agencies

- Local Environmental Protection Agencies: Oversee compliance with national laws and local guidelines.

- Water Authorities: Set standards for effluent quality and sludge use.

- Occupational Safety and Health Bodies: Regulate worker safety around hazardous materials.

Typical Parameters

- Pathogen Reduction: Requirements may specify that sludge be treated to reduce harmful microorganisms below a certain threshold.

- Metal Limits: Sludge often has maximum permissible concentrations for metals like lead, cadmium, zinc, and mercury.

- Vector Attraction: Measures are required to prevent vectors like flies and rodents from being attracted to the sludge.

- Reporting and Record-Keeping: Facilities must track volumes, treatment methods, and disposal routes, often submitting periodic reports to regulators.

Adhering to these standards reduces the risk of environmental damage and public health hazards. It also protects your facility from lawsuits, fines, or revocation of operating licenses.

Designing an Optimal Sludge Management Plan

A structured approach is vital for handling stp sludge effectively. Consider these steps:

- Sludge Characterization

- Sampling: Test for moisture content, pH, pathogens, metals, and nutrient levels.

- Trend Analysis: Track seasonal or operational shifts to anticipate changes in sludge composition.

- Treatment Goals

- Volume Reduction: Aim for minimal water content to reduce hauling expenses.

- Stabilization: Eliminate odors, pathogens, and degrade volatile solids.

- Resource Recovery: Assess potential for biogas, fertilizers, or other byproducts.

- Technology Selection

- Thickening and Dewatering: Choose methods that fit your sludge characteristics.

- Stabilization: Evaluate aerobic or anaerobic digestion, composting, or chemical stabilization based on costs and site constraints.

- Pilot Testing

- Operational Feasibility: Try out proposed technologies on a small scale.

- Performance Metrics: Measure cake dryness, odor control, pathogen reduction, and chemical usage.

- Scalability and Redundancy

- Modular Design: Build capacity to handle future load increases or stricter regulations.

- Backup Systems: In case a primary system fails, you need alternatives to avoid unprocessed sludge buildup.

- Implementation and Training

- Staff Proficiency: Provide training on new equipment and standard operating procedures.

- Monitoring and Troubleshooting: Set up real-time monitoring systems to track performance, detect anomalies, and act quickly.

A well-thought-out plan is not a one-time exercise. Continual improvements, guided by performance data, ensure that your sludge management remains efficient and compliant for years to come.

Maintenance and Operation Best Practices

To ensure your plan works optimally over the long term, pay close attention to daily operations and maintenance. Here are essential practices:

- Regular Inspections

- Equipment Checks: Inspect centrifuges, presses, pumps, and digesters for wear and tear.

- Predictive Maintenance: Use vibration analysis, thermography, or oil analysis to spot early signs of failure.

- Instrumentation Calibration

- Sensors and Meters: Flow meters, pressure gauges, and pH sensors need routine calibration to provide accurate data.

- SCADA Systems: Ensure your automation and control systems are updated and reliable.

- Sludge Monitoring

- Moisture Content: Too high or too low can signal process inefficiencies.

- Chemical Dosing: Regular jar testing to adjust polymer dosages.

- Pathogen Testing: Especially important if sludge is used in agriculture.

- Housekeeping and Safety

- Cleanliness: Keep equipment clean to avoid clogging and microbial growth.

- Personal Protective Equipment (PPE): Protect workers from exposure to chemicals and pathogens.

- Containment: Use spill containment strategies around storage tanks to prevent environmental contamination.

- Periodic Review of Standard Operating Procedures (SOPs)

- Update as Needed: If equipment or regulations change, revise your SOPs.

- Training Refreshers: Conduct frequent in-house sessions so staff stay current.

Such best practices not only extend the life of your equipment but also ensure consistent treatment quality and regulatory compliance.

Real-World Case Studies

Understanding theory is one thing, but seeing real results in action drives home the lessons. Below are hypothetical case studies that illustrate various aspects of stp sludge management:

Case Study 1: Medium-Sized Municipal STP

Situation: A municipal wastewater plant treating about 5 million gallons per day faced rising transportation costs for hauling liquid sludge.

Solution: Operators installed a mechanical thickener followed by a belt press. They optimized polymer dosing through daily testing, cutting polymer consumption by 20%.

Outcome: Sludge volume decreased by 40%, lowering transportation and disposal costs significantly. Additionally, they diverted some of the dewatered sludge to a local composting facility, saving on landfill fees.

Case Study 2: Industrial STP with High Organic Load

Situation: An industrial park’s STP had sludge with high biodegradable organics, causing odor and pathogen issues.

Solution: Facility managers introduced anaerobic digestion. Biogas captured during digestion was used to power plant operations.

Outcome: Odor complaints dropped by 85%. The plant offset a portion of its energy bills using the generated biogas, and stabilized sludge was safely used in land reclamation projects.

Case Study 3: Coastal Resort Community

Situation: Seasonal fluctuations in wastewater flow led to inconsistent sludge characteristics. During peak tourist months, the plant struggled with high volumes of secondary sludge.

Solution: The STP integrated a centrifuge system capable of handling variable flows. Staff also introduced an advanced SCADA system to adjust chemical dosing and machine speeds automatically.

Outcome: Downtime decreased, and the community avoided penalties or negative press that could harm tourism revenue.

These examples underscore that tailored solutions, data-driven optimization, and constant vigilance pay dividends, no matter the plant’s size or load profile.

Common FAQs on STP Sludge

Below are quick answers to frequent questions. Each answer is concise (40–50 words) to be snippet-friendly for search engines:

1. How can I reduce the odor from stp sludge?

Use effective stabilization methods like anaerobic or aerobic digestion. Properly adjusting pH and ensuring adequate retention time also helps. Odor control chemicals and covering storage tanks minimize nuisances.

2. Is treated sludge safe for agriculture?

Yes, if it meets regulatory criteria for pathogen and contaminant limits. Many farmers value the nitrogen and phosphorus in treated sludge. Always verify local regulations before land application.

3. Which dewatering method offers the best cake dryness?

Centrifuges and plate-and-frame filter presses generally yield higher solids content, but the optimal choice depends on sludge characteristics and budget constraints.

4. How often should sludge handling equipment be serviced?

Perform routine checks weekly and thorough preventive maintenance at least quarterly. Follow manufacturer guidelines and track equipment performance data for early problem detection.

5. Can stp sludge generate energy?

Yes, anaerobic digestion produces biogas rich in methane. This can be used for heating or electricity generation, reducing operational costs and carbon footprint.

Conclusion

Effective handling of stp sludge forms the backbone of any well-operating sewage treatment plant. From understanding the sludge’s composition to selecting the right dewatering and thickening methods, each decision makes a tangible difference in operational efficiency, cost reduction, and environmental protection. By applying the strategies and best practices discussed here, you position your facility to meet or exceed regulatory requirements while leveraging untapped opportunities like resource recovery and energy production.

Remember that continuous improvement—guided by data, well-trained staff, and a willingness to adapt—will keep your sludge management program running smoothly. Whether you are a municipal authority, an industrial facility operator, or an environmental consultant, these insights aim to help you transform sludge from a problematic waste to a valuable resource.

Share your thoughts below or explore related guides to stay ahead in optimizing sewage sludge treatment. Your journey toward sustainable and efficient sludge management does not end here, so keep refining, innovating, and collaborating.