Key Highlights

- A Common Effluent Treatment Plant (CETP) offers a collective treatment solution for industrial wastewater from multiple sources. CETPs emerged in India in the late 1980s as a response to increasing industrialization and growing environmental concerns over untreated effluent discharges. The development of CETPs was encouraged by government policies to assist small and medium-scale industries that cannot afford individual effluent treatment plants, ensuring environmentally sound and cost-effective wastewater management. They are crucial for small and medium-scale industries that cannot afford individual treatment plants.

- They are crucial for small and medium-scale industries that cannot afford individual treatment plants.

- The process involves primary, secondary, and tertiary treatment stages to meet strict discharge standards. CETPs provide higher control over pollution and make wastewater treatment more techno-economically viable. Key benefits include lower operating costs, organized sludge disposal, and reduced regulatory burdens for individual companies. In India, government bodies such as the Central Pollution Control Board (CPCB) and State Pollution Control Boards (SPCBs) are responsible for the regulation and oversight of CETPs. These authorities enforce compliance with discharge standards and monitor each stage of wastewater treatment and discharge.

- CETPs provide higher control over pollution and make wastewater treatment more techno-economically viable.

- Key benefits include lower operating costs, organized sludge disposal, and reduced regulatory burdens for individual companies.

- Proper sludge management, a byproduct of the process, is vital for the plant’s overall environmental performance.

Introduction

The rapid growth of industries has led to a significant increase in industrial wastewater, posing a major environmental challenge. Discharging this untreated effluent can contaminate water bodies and harm ecosystems. A Common Effluent Treatment Plant (CETP) has emerged as a vital solution. It provides a centralized facility for the collective treatment of wastewater from various industrial units. By combining effluents, CETPs use comprehensive processes, including tertiary treatment, to ensure the final discharge is safe and compliant with environmental norms.

Table of contents

- Key Highlights

- Introduction

- Understanding Common Effluent Treatment Plants (CETPs)

- Detailed Explanation of Primary and Secondary Treatment Stages in CETP

- Role and Importance of CETP in Pollution Control

- Key Processes and Components of a CETP Facility

- Future developments in CETP research

- How does a CETP work?

- Benefits of a CETP

- Design and operation of a CETP

- Challenges and solutions for implementing a CETP

- Types of Effluent Treatment Plants (ETPs) and CETP Processes

- Inlet Design Standards for CETPs

- Operational Parameters of CETPs

- Handling of Heavy Metals in CETPs

- Non-potable Reuse of Treated Effluent

- Reliability & Characteristics of CETPs

- Detailed CETP Process Flow

- Frequently Asked Questions

- Conclusion

Understanding Common Effluent Treatment Plants (CETPs)

A Common Effluent Treatment Plant, or CETP, is a facility designed to treat effluent from a cluster of industries. Instead of each factory managing its own wastewater, they can send it to a shared plant. This approach is especially beneficial for industrial estates where multiple small and medium-sized enterprises operate.

This collective model helps industries comply with environmental regulations and meet specific discharge standards. It centralizes the complex process of wastewater treatment, making it more efficient and manageable for all participating businesses. The following sections will explore what a CETP is and the types of waste it handles.

What is a CETP and Why Are They Essential for Industries?

A CETP is a shared wastewater treatment facility that serves multiple industrial units. Think of it as a community-based solution where industries pool their resources to treat their collective effluent. This is particularly essential for small and medium-scale businesses that may lack the financial resources or technical expertise to build and operate their own individual treatment plants.

The core purpose of a CETP is to make industrial wastewater treatment more accessible and affordable. By combining different effluent streams, the plant can effectively neutralize and equalize heterogeneous waste. According to a report by the Central Pollution Control Board of India, CETPs are a key strategy for managing pollution from industrial clusters [1]. This collective treatment approach makes the entire process more techno-economically viable.

Ultimately, these plants ensure a higher control over pollution. They help industries meet stringent discharge standards set by regulatory bodies, reducing the environmental footprint of an entire industrial area. This organized approach simplifies compliance monitoring and promotes sustainable industrial growth.

Types of Waste Treated in CETPs and Industry Applications

CETPs are designed to handle a wide variety of industrial wastewater, which can be highly complex and contain numerous pollutants. The nature of the waste depends on the industries contributing to the plant. This centralized waste management system allows for the effective treatment of otherwise difficult-to-manage effluents.

These plants can be categorized as either homogenous, serving similar industries, or heterogeneous, serving diverse industries. A heterogeneous CETP is often a better option as it can handle varied wastewater characteristics, which is common in most industrial estates. The final discharge is treated to remove pollutants before it is released.

CETPs are widely used across many sectors that produce significant wastewater. Key industry applications include:

- Pharmaceuticals

- Textiles and Dyes

- Chemical Manufacturing

- Tanneries

- Dye and intermediate

Detailed Explanation of Primary and Secondary Treatment Stages in CETP

The primary and secondary treatment stages in a Common Effluent Treatment Plant (CETP) are crucial processes designed to effectively reduce contaminants from industrial wastewater before it is discharged or further treated. The primary treatment stage primarily focuses on the physical and chemical removal of larger solids and suspended particles. Encompassing processes such as screening, sedimentation, and flocculation, this stage aims to separate heavier particles from the wastewater through gravity or chemical enhancement. This initial cleaning serves to protect the downstream biological treatment in the secondary stage, ensuring that the effluent introduced into this phase has lower solids content, allowing microorganisms to operate more efficiently.

During the secondary treatment stage, biological processes take center stage as microorganisms break down dissolved organic matter. This stage is often characterized by aeration tanks that promote oxygenation, enabling aerobic bacteria to flourish. These microorganisms consume organic pollutants, converting them into biomass, carbon dioxide, and other simpler compounds, which are later removed through sedimentation in clarifiers. The efficiency of this biological treatment varies based on the characteristics of the incoming effluent and the health of the microbial community, which must be monitored and managed continuously for optimal performance. Together, these treatment stages form an integrated approach to diminish pollutant loads before any final polishing steps, ensuring compliance with environmental discharge standards and fostering sustainable industrial practices.

Role and Importance of CETP in Pollution Control

The role of Common Effluent Treatment Plants (CETPs) in pollution control is multifaceted and pivotal for industrial sustainability. By serving as centralized facilities that aggregate and treat wastewater from multiple industries, CETPs play a crucial role in mitigating the environmental impact of industrial effluents. They help in maintaining compliance with strict discharge standards set by regulatory bodies, thereby preventing harmful substances from polluting local water bodies. Furthermore, CETPs facilitate the efficient treatment of heterogeneous waste streams, ensuring that varied pollutants are addressed through a systematic, multi-stage process.

This organized framework not only promotes a healthier ecosystem but also enhances the collective responsibility of industries towards pollution prevention. As environmental regulations become more stringent, the importance of CETPs in fostering sustainable industrial practices cannot be overstated; they represent a cost-effective, community-oriented approach to wastewater management that contributes significantly to environmental conservation. In essence, CETPs are not just treatment facilities; they are vital partners in the fight against industrial pollution.

Key Processes and Components of a CETP Facility

A Common Effluent Treatment Plant employs a multi-stage wastewater treatment process to effectively remove contaminants. The journey of wastewater through a CETP is systematic, moving from basic physical separation to advanced biological and chemical purification. Each stage is designed to target specific types of pollutants.

This comprehensive approach typically includes primary treatment, secondary treatment, and tertiary treatment. Together, these processes ensure that the final effluent is clean enough to be safely discharged into the environment. We will now look at the step-by-step process flow and the main components that make this possible.

Step-by-Step CETP Process Flow: How Wastewater Is Treated

The treatment of wastewater in a CETP follows a structured process flow designed to systematically remove pollutants. It begins with the collection of effluent from various industries into an equalization tank, which balances the varying characteristics of the wastewater to create a uniform mixture for consistent treatment.

From there, the water undergoes several distinct stages. Each step builds upon the last, gradually purifying the water until it meets regulatory standards. This methodical approach allows for higher control over the quality of the final discharge. The final stage often involves sludge management, a critical step that addresses the solid waste generated during treatment.

The typical process flow can be summarized in the following stages:

| Treatment Stage | Purpose |

|---|---|

| Preliminary Treatment | Removes large objects, grit, and coarse solids through screening to protect downstream equipment. |

| Primary Treatment | Uses physical and chemical processes like sedimentation and flocculation to remove suspended solids. |

| Secondary Treatment | Employs biological processes where microorganisms break down dissolved organic matter in the wastewater. |

| Tertiary Treatment | Acts as a final polishing stage to remove residual contaminants and disinfect the water before discharge. |

Main Components of CETPs and Their Functions

A CETP facility is comprised of several interconnected components, each performing a specific function in the wastewater treatment journey. These units work in harmony to ensure the effluent is purified to the required standards. The design integrates physical, chemical, and biological treatment mechanisms for comprehensive cleaning.

The process begins with collection and equalization units and moves through various reactors and clarifiers. A crucial part of the secondary treatment stage is the use of biological processes, which often rely on the continuous seeding of microorganisms to maintain a healthy and effective biomass for breaking down organic pollutants.

The main components and their roles include:

- Equalization Tanks: These tanks collect wastewater from different industries and mix it to create a homogenous effluent, which ensures a stable and efficient treatment process.

- Clarifiers: Used in primary and secondary treatment, these large tanks allow suspended solids to settle at the bottom as sludge, which is then removed.

- Aeration Tanks: A key part of secondary biological treatment, these tanks provide oxygen to microorganisms, helping them decompose organic contaminants in the wastewater.

- Sludge Handling Units: These components dewater and process the sludge removed from clarifiers, preparing it for safe disposal or reuse.

Future developments in CETP research

The field of wastewater treatment is constantly evolving, and future developments in CETP research are focused on enhancing efficiency, sustainability, and resource recovery. Researchers are exploring advanced future technologies to improve the efficacy of tertiary treatment stages. The goal is to produce higher-quality treated effluent that can be reused for non-potable purposes, such as industrial processes or irrigation, thus promoting a circular economy. This reduces the demand on fresh water sources and minimizes the environmental impact.

Another key area of development is the integration of smart monitoring and automation. These systems will allow for real-time tracking of operational parameters, enabling better process control and quicker responses to fluctuations in wastewater quality. As regulatory authorities demand more stringent compliance, these technologies will be crucial for assessing the performance of CETPs and ensuring they consistently meet environmental standards. The research also extends to more efficient sludge management techniques, aiming to reduce waste and recover valuable resources.

How does a CETP work?

A Common Effluent Treatment Plant works by collecting wastewater from various industrial units in a centralized location and subjecting it to a multi-stage purification process. Initially, the effluent enters an equalization tank, where different streams are mixed to create a uniform composition. This step is critical because it prevents shocks to the system from sudden changes in pollutant loads or pH levels.

After equalization, the wastewater moves through the primary treatment stage, where physical processes like screening and sedimentation remove large solids and suspended particles. Next is secondary treatment, a biological phase where microorganisms consume organic pollutants. Finally, the water may undergo tertiary treatment for final polishing and disinfection before its safe discharge. The entire CETP process is a systematic journey from highly contaminated industrial wastewater to treated water that meets environmental guidelines.

Benefits of a CETP

One of the most significant benefits of a Common Effluent Treatment Plant is the economic advantage it offers. For small and medium-scale industries, building and operating an individual effluent treatment plant can be prohibitively expensive. A CETP allows these industries to share the capital and operational costs, making compliance with environmental laws financially feasible. This collective treatment model lowers the financial barrier to effective industrial wastewater management.

Beyond cost savings, CETPs provide superior environmental oversight and higher control over pollution. With a single, professionally managed facility, it becomes easier for regulatory bodies to monitor and enforce discharge standards. The process also allows for the organized and safe disposal of treated wastewater and sludge. As the World Bank notes, such collective action is essential for managing industrial pollution in developing countries [2]. This centralized approach not only ensures better compliance but also simplifies the responsibilities of individual businesses.

Design and operation of a CETP

The design and operation of a CETP are complex processes that depend on several factors. The initial CETP design must consider the types of industries it will serve, the characteristics of their wastewater, and the expected flow rates. Engineers also account for the layout of the industrial estate and plan for future expansion. The treatment stages are selected based on the specific pollutants that need to be removed to meet discharge regulations.

Successful operation requires a skilled and educated workforce to manage the plant’s sophisticated processes. Key operational activities include monitoring water quality at various stages, managing chemical dosing, and ensuring the health of the biological treatment systems through practices like the continuous seeding of microorganisms. Proper maintenance of all equipment is essential to prevent breakdowns and ensure the plant runs reliably and efficiently.

Challenges and solutions for implementing a CETP

Implementing and running a CETP comes with a unique set of challenges. One of the biggest hurdles is the highly variable nature of the wastewater received from different industries. Fluctuations in flow, pH, and pollutant concentrations can create operational issues and affect treatment efficiency. Additionally, the presence of toxic compounds and heavy metals can inhibit the biological processes crucial for treatment, making it difficult to consistently meet discharge standards.

To overcome these challenges, CETPs implement robust solutions. A large equalization tank is essential to buffer and mix the incoming streams, creating a more uniform influent. Many CETPs also require participating industries to perform some level of pretreatment to remove specific, problematic contaminants before sending their effluent to the central plant. Effective waste management protocols for handling the generated sludge are also critical for sustainable operation.

Types of Effluent Treatment Plants (ETPs) and CETP Processes

The primary distinction in industrial wastewater treatment lies between individual Effluent Treatment Plants (ETPs) and Common Effluent Treatment Plants (CETPs). An ETP is a standalone facility dedicated to treating wastewater from a single industrial unit. In contrast, a CETP is a large-scale facility designed to treat the combined wastewater from multiple industries within an industrial estate. This collective approach is the defining feature of a CETP.

CETP processes are further categorized based on the type of industrial wastewater they handle. A “homogenous” CETP treats effluent from similar types of industries, resulting in relatively uniform wastewater characteristics. A “heterogeneous” CETP, which is more common, treats effluent from a diverse range of industries. This requires a more robust and flexible treatment design to handle the complex and variable mix of pollutants.

Inlet Design Standards for CETPs

The inlet design is a foundational element of a Common Effluent Treatment Plant, as it is the first point of contact with the raw industrial wastewater. Proper inlet design standards are crucial for ensuring the entire system operates efficiently. The design must accommodate the total effluent flow from all participating industries and be robust enough to handle fluctuations in volume and pollutant load.

Typically, the inlet section includes preliminary treatment units like screens and grit chambers. These components are responsible for removing large debris and heavy inorganic particles that could damage pumps and other downstream equipment. By effectively preparing the wastewater at the very beginning of the collective treatment process, a well-designed inlet helps protect the plant’s integrity and ensures a smoother, more reliable operation before the final discharge.

Operational Parameters of CETPs

Maintaining optimal operational parameters is key to the success of a CETP. Plant operators must continuously monitor several key indicators to ensure the treatment process is effective. These parameters include pH levels, Chemical Oxygen Demand (COD), Biological Oxygen Demand (BOD), and Total Suspended Solids (TSS). Keeping these metrics within a target range provides higher control over the entire treatment system.

Other important parameters include the dilution ratio of the effluent and the health of the biological treatment stage. Practices like the continuous seeding of microorganisms help maintain a stable and active biomass, which is essential for breaking down organic pollutants. Regular monitoring and adjustments of these operational parameters are necessary to ensure the plant consistently produces treated water that meets regulatory standards.

Handling of Heavy Metals in CETPs

The presence of heavy metals like aluminum, chromium, and manganese in industrial wastewater is a serious concern due to their toxicity and environmental impact. The handling of heavy metals is a critical function of the CETP process. Since many industries release effluents containing these elements, CETPs must be equipped with effective removal mechanisms to prevent their discharge into the environment.

The removal of heavy metals is typically achieved during the primary treatment stage through chemical precipitation. Chemicals are added to the wastewater that cause the dissolved metals to form solid particles, which can then be separated out as sludge. Some advanced CETPs may also use specialized bacterial consortiums that can metabolize or sequester certain metals. This targeted waste management ensures the final treated effluent is free from harmful heavy metal contamination.

Non-potable Reuse of Treated Effluent

A significant advantage of modern CETPs is the potential for non-potable reuse of the treated effluent. After undergoing extensive treatment, particularly advanced tertiary treatment, the final water is often of a quality high enough for various industrial and agricultural applications. This practice turns waste into a valuable resource, promoting water conservation and sustainability.

This reuse of treated effluent is a practical solution to water scarcity in many industrial regions. Instead of being discharged into rivers or lakes, the purified water can be redirected for use in cooling towers, irrigation of non-food crops, or dust control on industrial sites. This approach reduces the demand on freshwater sources and showcases an effective waste management strategy that aligns with the principles of a circular economy.

Reliability & Characteristics of CETPs

The reliability of a CETP is measured by its consistent ability to treat wastewater to meet prescribed discharge standards. A reliable plant is one that performs predictably and effectively over time, ensuring continuous environmental compliance. This reliability provides higher control over regional water pollution and gives participating industries confidence in the system.

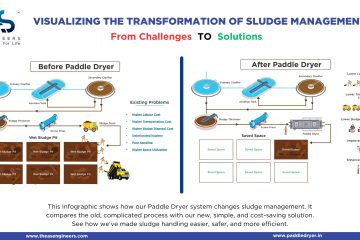

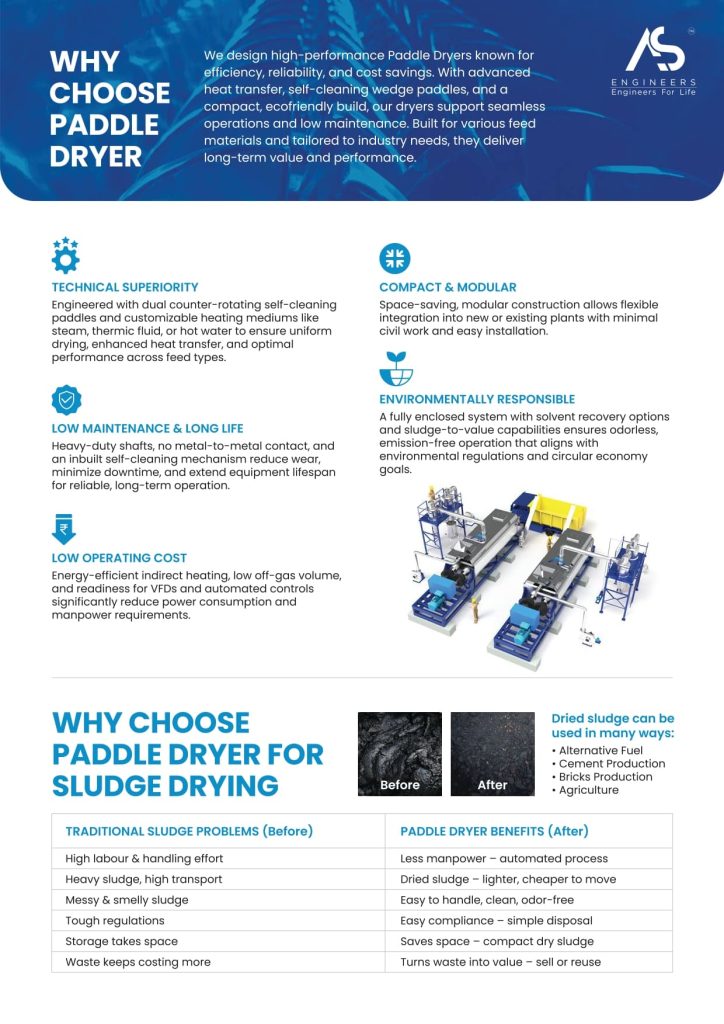

Several characteristics make CETPs a viable and attractive solution. They can handle complex commercial waste by neutralizing and diluting heterogeneous streams. They also allow for a professional and educated workforce to manage operations, which is often not feasible for individual plants. Most importantly, CETPs organize the disposal of both treated wastewater and sludge, a critical byproduct that requires careful management. Efficient sludge drying, often using technologies like paddle dryers from experts like AS Engineers, is crucial for minimizing final waste volume and disposal costs.

Detailed CETP Process Flow

A detailed CETP process flow showcases an integrated system where each stage seamlessly transitions to the next. The journey begins when raw effluent is collected and homogenized in equalization tanks. This step is crucial for providing a stable feed to the primary treatment units, where physical and chemical processes remove a significant portion of suspended solids. This initial cleaning prepares the water for the more delicate biological treatment phase.

Following primary treatment, the wastewater enters the secondary stage, where microorganisms do the heavy lifting of breaking down dissolved organic matter. This biological process is the heart of the CETP. Finally, the water flows to the tertiary treatment stage for polishing and disinfection, ensuring higher control over the final effluent quality before discharge. Throughout this detailed process, sludge is generated and sent to a separate handling unit, demonstrating how waste streams are managed at every step.

Frequently Asked Questions

How are CETPs different from individual effluent treatment plants (ETPs)?

A CETP provides collective treatment for wastewater from multiple industries in an industrial estate. In contrast, an ETP is a smaller plant that treats wastewater from only a single factory. CETPs offer a more cost-effective solution for small-to-medium enterprises and provide higher control over regional pollution by centralizing treatment.

What are the primary challenges faced by CETPs in India?

Primary challenges include managing the highly variable characteristics of incoming wastewater from diverse industries, which can cause operational issues. Other major concerns are the effective and sustainable management of large volumes of sludge, ensuring consistent compliance with strict discharge standards, and securing adequate funding for upgrades and maintenance.

What role does the paddle dryer play in managing CETP sludge?

A paddle dryer plays a crucial role in the efficient waste management of CETP sludge. It is the best way to significantly reduce the moisture content and volume of the sludge generated after treatment. This makes the sludge lighter, easier to handle, and less costly to transport for final discharge or disposal. As leading manufacturers, AS Engineers provides advanced paddle dryer solutions for sludge management.

What are the main components of the CETP (Centrally Enhanced Transfer Pricing) framework?

The main components of the CETP framework include guidelines for determining arm’s length pricing, documentation requirements to ensure transparency, and risk management strategies. These elements work together to create a consistent approach for valuing intercompany transactions effectively.

How does CETP differ from traditional transfer pricing methods?

This question seems to confuse two different acronyms. In this context, CETP stands for Common Effluent Treatment Plant, a physical facility for wastewater management. It is entirely unrelated to traditional transfer pricing, which is a financial accounting method used by multinational corporations for pricing transactions between their own divisions.

What industries or businesses can benefit most from implementing CETP practices?

Industries clustered in industrial estates, especially small and medium-scale enterprises, benefit most from CETPs. This includes sectors like textiles, pharmaceuticals, chemicals, tanneries, and food processing, which generate significant wastewater and can share the cost of collective treatment to meet discharge regulations.

Are there any compliance requirements associated with CETP that companies should be aware of?

Yes, companies using a CETP must adhere to specific compliance requirements. They are typically required to pre-treat their wastewater to meet the CETP’s inlet standards. They must also comply with all regulations set by environmental pollution control boards regarding their effluent discharge, ensuring they do not overload the collective system.

What is the CETP and why is it important in the context of trading?

In the context of industrial operations and not financial trading, a CETP (Common Effluent Treatment Plant) is vital. It enables industries to trade their products responsibly by providing a compliant and cost-effective way to manage their wastewater discharge. This ensures they can operate legally and sustainably without harming the environment.

How does the CETP impact market participants and their strategies?

A CETP positively impacts market participants (industries) by lowering their operational costs for environmental compliance. This allows them to allocate resources to other business strategies, like production or innovation. It also enhances their corporate image as environmentally responsible entities, which can be a competitive advantage.

What are some common misconceptions about the CETP?

A common misconception is that industries can send any type of raw effluent to a CETP. In reality, many plants require industries to pre-treat their waste to meet specific inlet standards. Another is that CETPs are a complete hands-off solution, but they require cooperation and financial contribution from all participating members.

Are there specific regulations associated with CETP that traders should be aware of?

Industrial “traders” or businesses must be aware of regulations from their local and national pollution control boards. These regulations dictate the permissible limits for pollutants in their effluent before it even reaches the CETP. Compliance with both these governmental discharge standards and the CETP’s own inlet criteria is mandatory.

Conclusion

In summary, Common Effluent Treatment Plants (CETPs) play a pivotal role in managing industrial wastewater, ensuring that it meets environmental standards before being released back into nature. Understanding the processes and components involved in CETP facilities is essential for industries aiming to comply with regulations while promoting sustainability. As the leading manufacturers of sludge management systems, AS Engineers provides innovative solutions like paddle dryers, which are crucial for effective CETP sludge management and drying. By adopting these technologies, industries can significantly enhance their effluent treatment capabilities. If you’re seeking expert advice or solutions tailored to your needs, don’t hesitate to book a free consultation with us today.